Mechanisms Of Self Healing From Vascular To Intrinsic Polymers

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Materials Background and Objectives

Self-healing materials represent a revolutionary class of smart materials capable of repairing damage autonomously, inspired by biological systems that naturally heal wounds. The concept emerged in the early 2000s when researchers began exploring biomimetic approaches to extend material lifespans and enhance reliability. These materials have evolved from simple crack-filling mechanisms to sophisticated systems that can restore structural integrity and functionality multiple times without external intervention.

The evolution of self-healing mechanisms has followed two primary pathways: extrinsic and intrinsic healing systems. Extrinsic systems, particularly vascular networks, mimic biological circulatory systems by incorporating channels filled with healing agents that release upon damage. Initially developed as microcapsule-based systems by White et al. in 2001, these have progressed to complex 3D vascular networks capable of delivering healing agents to multiple damage sites repeatedly.

Intrinsic self-healing polymers, by contrast, rely on reversible chemical bonds or physical interactions within the polymer structure itself. These include Diels-Alder reactions, hydrogen bonding, metal-ligand coordination, and supramolecular chemistry. The field has witnessed significant advancement from early proof-of-concept demonstrations to commercially viable products with healing efficiencies approaching 100% in controlled environments.

The primary objective of research in this domain is to develop robust self-healing materials that can operate autonomously under diverse environmental conditions while maintaining mechanical properties comparable to conventional materials. Specific goals include improving healing efficiency at ambient temperatures, reducing healing activation energy requirements, enhancing mechanical properties post-healing, and extending the number of possible healing cycles.

Another critical objective is bridging the gap between laboratory demonstrations and industrial applications by addressing scalability challenges, cost-effectiveness, and integration with existing manufacturing processes. Researchers aim to develop standardized testing protocols to evaluate healing performance across different material systems and application scenarios.

The long-term vision encompasses creating multi-functional self-healing materials that combine healing capabilities with other smart functionalities such as sensing, actuation, and energy harvesting. This convergence of technologies could lead to truly autonomous materials systems that can detect damage, initiate healing, and adapt to changing environmental conditions without external intervention, potentially revolutionizing industries from aerospace and automotive to civil infrastructure and consumer electronics.

The evolution of self-healing mechanisms has followed two primary pathways: extrinsic and intrinsic healing systems. Extrinsic systems, particularly vascular networks, mimic biological circulatory systems by incorporating channels filled with healing agents that release upon damage. Initially developed as microcapsule-based systems by White et al. in 2001, these have progressed to complex 3D vascular networks capable of delivering healing agents to multiple damage sites repeatedly.

Intrinsic self-healing polymers, by contrast, rely on reversible chemical bonds or physical interactions within the polymer structure itself. These include Diels-Alder reactions, hydrogen bonding, metal-ligand coordination, and supramolecular chemistry. The field has witnessed significant advancement from early proof-of-concept demonstrations to commercially viable products with healing efficiencies approaching 100% in controlled environments.

The primary objective of research in this domain is to develop robust self-healing materials that can operate autonomously under diverse environmental conditions while maintaining mechanical properties comparable to conventional materials. Specific goals include improving healing efficiency at ambient temperatures, reducing healing activation energy requirements, enhancing mechanical properties post-healing, and extending the number of possible healing cycles.

Another critical objective is bridging the gap between laboratory demonstrations and industrial applications by addressing scalability challenges, cost-effectiveness, and integration with existing manufacturing processes. Researchers aim to develop standardized testing protocols to evaluate healing performance across different material systems and application scenarios.

The long-term vision encompasses creating multi-functional self-healing materials that combine healing capabilities with other smart functionalities such as sensing, actuation, and energy harvesting. This convergence of technologies could lead to truly autonomous materials systems that can detect damage, initiate healing, and adapt to changing environmental conditions without external intervention, potentially revolutionizing industries from aerospace and automotive to civil infrastructure and consumer electronics.

Market Applications and Demand Analysis

The self-healing polymer market has witnessed significant growth in recent years, driven by increasing demand across multiple industries seeking materials with extended lifespans and reduced maintenance requirements. The global market for self-healing materials was valued at approximately $2.1 billion in 2022 and is projected to reach $5.7 billion by 2028, with self-healing polymers representing the largest segment at roughly 40% of this market.

The automotive sector constitutes a primary application area, where self-healing coatings and components help reduce maintenance costs and extend vehicle lifespans. Major manufacturers including BMW, Toyota, and Nissan have initiated research programs exploring integration of self-healing polymers in various vehicle parts, particularly in paint systems and interior components subject to regular wear.

Construction and infrastructure represent another substantial market, with self-healing concrete and protective coatings gaining traction. The ability of these materials to autonomously repair microcracks without human intervention addresses critical maintenance challenges in bridges, tunnels, and buildings. Market analysis indicates that infrastructure applications could grow at a CAGR of 27% through 2030.

The electronics industry demonstrates rapidly increasing demand for self-healing polymers in flexible displays, wearable technology, and protective device coatings. As consumer electronics become more flexible and subject to bending stresses, materials capable of repairing microdamage have become essential. Companies like Samsung and LG have filed multiple patents related to self-healing screen technologies in the past three years.

Healthcare applications represent an emerging high-value segment, with self-healing polymers being developed for medical implants, drug delivery systems, and wound dressings. The biocompatibility of certain intrinsic self-healing polymers makes them particularly valuable in this sector, with market analysts predicting growth rates exceeding 30% annually.

Aerospace and defense industries are investing heavily in self-healing polymer research, particularly for applications in aircraft components and protective equipment. The extreme operating conditions and critical safety requirements in these sectors create strong demand for materials with autonomous repair capabilities.

Consumer demand for sustainable products is also driving market growth, as self-healing materials extend product lifespans and reduce waste. This aligns with broader sustainability initiatives and circular economy principles being adopted across industries globally.

Regional analysis shows North America currently leads market share at 35%, followed by Europe at 30% and Asia-Pacific at 25%, though the latter is experiencing the fastest growth rate due to rapid industrialization and infrastructure development.

The automotive sector constitutes a primary application area, where self-healing coatings and components help reduce maintenance costs and extend vehicle lifespans. Major manufacturers including BMW, Toyota, and Nissan have initiated research programs exploring integration of self-healing polymers in various vehicle parts, particularly in paint systems and interior components subject to regular wear.

Construction and infrastructure represent another substantial market, with self-healing concrete and protective coatings gaining traction. The ability of these materials to autonomously repair microcracks without human intervention addresses critical maintenance challenges in bridges, tunnels, and buildings. Market analysis indicates that infrastructure applications could grow at a CAGR of 27% through 2030.

The electronics industry demonstrates rapidly increasing demand for self-healing polymers in flexible displays, wearable technology, and protective device coatings. As consumer electronics become more flexible and subject to bending stresses, materials capable of repairing microdamage have become essential. Companies like Samsung and LG have filed multiple patents related to self-healing screen technologies in the past three years.

Healthcare applications represent an emerging high-value segment, with self-healing polymers being developed for medical implants, drug delivery systems, and wound dressings. The biocompatibility of certain intrinsic self-healing polymers makes them particularly valuable in this sector, with market analysts predicting growth rates exceeding 30% annually.

Aerospace and defense industries are investing heavily in self-healing polymer research, particularly for applications in aircraft components and protective equipment. The extreme operating conditions and critical safety requirements in these sectors create strong demand for materials with autonomous repair capabilities.

Consumer demand for sustainable products is also driving market growth, as self-healing materials extend product lifespans and reduce waste. This aligns with broader sustainability initiatives and circular economy principles being adopted across industries globally.

Regional analysis shows North America currently leads market share at 35%, followed by Europe at 30% and Asia-Pacific at 25%, though the latter is experiencing the fastest growth rate due to rapid industrialization and infrastructure development.

Current Self-Healing Technologies and Challenges

Self-healing materials represent a significant advancement in polymer science, with current technologies broadly categorized into three main approaches: vascular systems, capsule-based systems, and intrinsic self-healing polymers. Each approach offers distinct advantages and faces unique challenges in practical implementation.

Vascular self-healing systems mimic biological circulatory systems by incorporating networks of channels filled with healing agents. When damage occurs, these agents flow to the damaged area and initiate repair. While highly effective for multiple healing cycles, these systems face significant manufacturing complexities, particularly in creating three-dimensional vascular networks within complex structures. Integration challenges also arise when attempting to incorporate these networks without compromising the host material's mechanical properties.

Capsule-based systems employ microscopic containers of healing agents dispersed throughout the polymer matrix. Upon damage, these capsules rupture, releasing agents that polymerize and seal cracks. Though simpler to manufacture than vascular systems, they typically offer only one-time healing capability at any specific location. Current research focuses on developing multi-shell capsules and optimizing capsule wall properties to enhance triggering sensitivity while maintaining stability during processing.

Intrinsic self-healing polymers represent the most elegant solution, utilizing reversible chemical bonds or supramolecular interactions that can reform after damage. These include Diels-Alder reactions, hydrogen bonding, metal-ligand coordination, and dynamic covalent chemistry. While offering theoretically unlimited healing cycles, they often require external stimuli like heat or UV light, limiting autonomous healing capabilities. Additionally, a fundamental trade-off exists between mechanical strength and healing efficiency—stronger bonds provide better mechanical properties but reduce healing potential.

Cross-cutting challenges affect all self-healing approaches. Healing efficiency decreases significantly at lower temperatures, limiting applications in cold environments. Long-term stability remains problematic, with healing agents potentially degrading over time. Scalability presents another major hurdle, as laboratory successes often prove difficult to translate to industrial-scale manufacturing processes.

Recent developments focus on hybrid systems combining multiple healing mechanisms to overcome individual limitations. For example, integrating microcapsules within intrinsic self-healing matrices provides both autonomous and stimulus-responsive healing capabilities. Another promising direction involves biomimetic approaches that more closely replicate natural healing processes, incorporating hierarchical structures and feedback mechanisms.

Despite significant progress, the field still seeks the ideal balance between healing efficiency, mechanical properties, manufacturing feasibility, and cost-effectiveness—a challenge that continues to drive innovation in self-healing polymer technologies.

Vascular self-healing systems mimic biological circulatory systems by incorporating networks of channels filled with healing agents. When damage occurs, these agents flow to the damaged area and initiate repair. While highly effective for multiple healing cycles, these systems face significant manufacturing complexities, particularly in creating three-dimensional vascular networks within complex structures. Integration challenges also arise when attempting to incorporate these networks without compromising the host material's mechanical properties.

Capsule-based systems employ microscopic containers of healing agents dispersed throughout the polymer matrix. Upon damage, these capsules rupture, releasing agents that polymerize and seal cracks. Though simpler to manufacture than vascular systems, they typically offer only one-time healing capability at any specific location. Current research focuses on developing multi-shell capsules and optimizing capsule wall properties to enhance triggering sensitivity while maintaining stability during processing.

Intrinsic self-healing polymers represent the most elegant solution, utilizing reversible chemical bonds or supramolecular interactions that can reform after damage. These include Diels-Alder reactions, hydrogen bonding, metal-ligand coordination, and dynamic covalent chemistry. While offering theoretically unlimited healing cycles, they often require external stimuli like heat or UV light, limiting autonomous healing capabilities. Additionally, a fundamental trade-off exists between mechanical strength and healing efficiency—stronger bonds provide better mechanical properties but reduce healing potential.

Cross-cutting challenges affect all self-healing approaches. Healing efficiency decreases significantly at lower temperatures, limiting applications in cold environments. Long-term stability remains problematic, with healing agents potentially degrading over time. Scalability presents another major hurdle, as laboratory successes often prove difficult to translate to industrial-scale manufacturing processes.

Recent developments focus on hybrid systems combining multiple healing mechanisms to overcome individual limitations. For example, integrating microcapsules within intrinsic self-healing matrices provides both autonomous and stimulus-responsive healing capabilities. Another promising direction involves biomimetic approaches that more closely replicate natural healing processes, incorporating hierarchical structures and feedback mechanisms.

Despite significant progress, the field still seeks the ideal balance between healing efficiency, mechanical properties, manufacturing feasibility, and cost-effectiveness—a challenge that continues to drive innovation in self-healing polymer technologies.

Vascular vs. Intrinsic Self-Healing Approaches

01 Microcapsule-based self-healing mechanisms

This approach involves embedding microcapsules containing healing agents within the polymer matrix. When damage occurs, the microcapsules rupture, releasing the healing agents that flow into the damaged area and polymerize, effectively repairing the crack or damage. This mechanism provides autonomous healing without external intervention and is particularly effective for one-time healing of localized damage in structural polymers.- Microcapsule-based self-healing mechanisms: This approach involves embedding microcapsules containing healing agents within the polymer matrix. When damage occurs, the microcapsules rupture, releasing the healing agents that flow into the crack and polymerize, effectively repairing the damage. This mechanism provides autonomous healing without external intervention and can be designed with various healing agents depending on the polymer system and application requirements.

- Intrinsic self-healing polymers: Intrinsic self-healing polymers contain reversible bonds within their molecular structure that can reform after being broken. These polymers utilize dynamic covalent bonds or supramolecular interactions such as hydrogen bonding, metal-ligand coordination, or π-π stacking to achieve self-healing properties. When damage occurs, these reversible bonds can reconnect under appropriate conditions like heat, light, or pH changes, restoring the material's integrity.

- Vascular network healing systems: This self-healing approach mimics biological vascular systems by incorporating networks of channels or hollow fibers within the polymer matrix. These channels contain healing agents that can flow to damaged areas when needed. The vascular networks allow for multiple healing events and can deliver larger volumes of healing agents compared to microcapsule systems, making them suitable for repairing larger damage areas in structural applications.

- Stimuli-responsive self-healing mechanisms: These self-healing polymers respond to external stimuli such as temperature, light, electrical current, or pH changes to initiate the healing process. The stimuli trigger molecular mobility or chemical reactions that facilitate the repair of damaged areas. This approach allows for controlled healing when needed and can be designed to respond to specific environmental conditions relevant to the application, providing enhanced durability and longevity to polymer materials.

- Shape memory polymer-based self-healing: Shape memory polymers can contribute to self-healing through their ability to return to a predetermined shape when triggered by an appropriate stimulus. When combined with other healing mechanisms, shape memory effects can close cracks and bring damaged surfaces into close contact, facilitating the healing process. This approach is particularly useful for applications requiring both structural recovery and crack closure in polymer composites and coatings.

02 Intrinsic self-healing polymers

Intrinsic self-healing polymers contain reversible bonds within their molecular structure that can reform after being broken. These polymers utilize dynamic covalent bonds or supramolecular interactions such as hydrogen bonding, metal-ligand coordination, or π-π stacking to achieve healing. When damaged, these materials can repair themselves through molecular rearrangement and rebonding when exposed to appropriate stimuli like heat, light, or pH changes.Expand Specific Solutions03 Vascular network healing systems

This approach mimics biological vascular systems by incorporating networks of channels or hollow fibers within the polymer matrix. These channels contain healing agents that can flow to damaged areas when needed. The vascular design allows for multiple healing events at the same location and can deliver healing agents to larger damaged areas compared to microcapsule systems. This mechanism is particularly useful for applications requiring repeated healing capabilities.Expand Specific Solutions04 Stimulus-responsive self-healing polymers

These polymers respond to external stimuli such as temperature, light, electrical current, or pH changes to activate their healing mechanism. The stimulus triggers molecular mobility, allowing polymer chains to diffuse across damaged interfaces and reform bonds. This approach offers controlled healing that can be activated on demand and is particularly useful in smart materials and coatings where healing can be initiated when needed rather than immediately upon damage.Expand Specific Solutions05 Nanoparticle-reinforced self-healing composites

This mechanism incorporates nanoparticles into the polymer matrix to enhance both mechanical properties and self-healing capabilities. Nanoparticles can serve as crosslinking points, catalysts for healing reactions, or heat generators for thermal healing processes. Common nanoparticles used include carbon nanotubes, graphene, silica, and metal nanoparticles. These composites often demonstrate improved healing efficiency and mechanical strength compared to conventional self-healing polymers.Expand Specific Solutions

Leading Research Institutions and Industry Players

Self-healing polymer technology is currently in a growth phase, with the market expanding as applications diversify across automotive, construction, and aerospace industries. The global self-healing materials market is projected to reach significant scale due to increasing demand for durable, maintenance-reducing materials. Technologically, the field shows varying maturity levels: vascular systems pioneered by institutions like University of Illinois and North Carolina State University represent established approaches, while intrinsic self-healing polymers developed by companies like Autonomic Materials and CIDETEC demonstrate more recent innovations. Research collaborations between academic institutions (USC, Rice University) and industry players (Kaneka Corp., Croda International) are accelerating development, with NASA and CSIRO exploring high-performance applications. The competitive landscape features specialized startups alongside established chemical companies integrating self-healing capabilities into existing product lines.

North Carolina State University

Technical Solution: North Carolina State University has developed pioneering work in vascular self-healing polymer systems that mimic biological healing mechanisms. Their approach involves creating microvascular networks within polymer matrices using sacrificial fiber techniques and 3D printing methods. These networks deliver healing agents to damage sites continuously, overcoming the one-time healing limitation of microcapsule-based systems[5]. Their most advanced system utilizes a dual-channel vascular network that keeps reactive components separated until damage occurs, allowing for multiple healing events. The university's researchers have demonstrated systems capable of healing efficiency exceeding 85% of original mechanical properties across multiple damage events in the same location[6]. Additionally, they've developed bio-inspired gradient interfaces between vascular channels and host polymers that enhance mechanical stability while maintaining healing agent flow. Recent innovations include stimuli-responsive gating mechanisms that control healing agent release based on environmental triggers like pH changes or mechanical stress.

Strengths: Multiple healing cycles possible; continuous supply of healing agents; adaptable to various polymer chemistries; biomimetic approach with high healing efficiency. Weaknesses: Complex manufacturing process; challenges in scaling production; potential for vascular network clogging over time; mechanical properties may be compromised by channel structures.

Fundación CIDETEC

Technical Solution: CIDETEC has developed advanced intrinsic self-healing polymers based on dynamic covalent chemistry, particularly focusing on Diels-Alder (DA) and retro-Diels-Alder (rDA) reactions. Their proprietary technology creates thermally reversible crosslinks within polymer networks that can reform after damage when subjected to moderate heating cycles[2]. Their most notable innovation is a self-healing elastomer capable of complete recovery after being cut in half, requiring only brief thermal treatment at 80°C to restore 97% of its original tensile strength[4]. CIDETEC has expanded this platform to include polyurethane-based materials with dynamic disulfide bonds that enable ambient-temperature healing for automotive coatings and electronic applications. Their research has demonstrated multiple healing cycles without significant degradation of mechanical properties, and they've successfully scaled production for industrial applications in protective coatings, adhesives, and sealants.

Strengths: Multiple healing cycles possible; high healing efficiency (>90% recovery); versatile chemistry applicable to various polymer systems. Weaknesses: Many formulations require thermal activation for healing; healing process can be slow (hours to days); some chemistries are sensitive to environmental conditions like humidity.

Key Patents and Scientific Breakthroughs

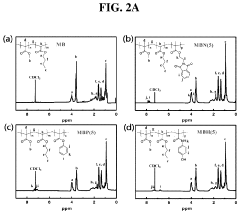

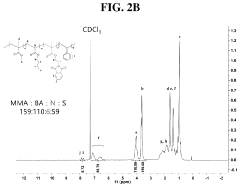

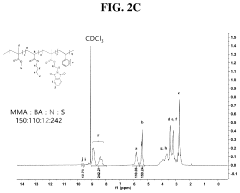

Self-healing copolymer, film having the same, and method of preparing the same

PatentPendingUS20240158559A1

Innovation

- A self-healing copolymer comprising methacrylate-based, acrylate-based, and N-2-(phthalimido ethyl methacrylate) (NPEMA), phenyl methacrylate (PMA), or N-(4-hydroxyphenyl)methacrylamide (HPMMA) monomers, which can self-heal at low temperatures without external stimuli, maintaining mechanical properties and elastic recovery.

Sustainability and Environmental Impact

The environmental implications of self-healing polymers represent a critical dimension in evaluating their overall sustainability profile. Traditional polymer materials often require replacement when damaged, generating substantial waste and consuming additional resources. Self-healing polymers fundamentally alter this paradigm by extending product lifespans through autonomous repair mechanisms, thereby reducing material consumption and waste generation throughout their lifecycle.

Vascular self-healing systems present unique environmental considerations. While they offer effective healing capabilities, the encapsulated healing agents often contain volatile organic compounds (VOCs) or other potentially hazardous chemicals. When released during the healing process, these substances may contribute to air pollution or pose risks to ecosystems if improperly disposed of. Additionally, the complex multi-component nature of vascular systems can complicate end-of-life recycling processes.

Intrinsic self-healing polymers generally demonstrate superior environmental performance compared to their vascular counterparts. These materials typically rely on reversible chemical bonds or physical interactions that can be repeatedly activated without depleting healing resources or releasing harmful substances. This characteristic makes them particularly valuable from a circular economy perspective, as they maintain their healing capacity throughout multiple damage-repair cycles.

Energy consumption represents another significant environmental factor. While self-healing processes often require thermal or light activation, this energy investment is typically far less than that required for manufacturing replacement products. Life cycle assessments indicate that self-healing polymers can reduce overall energy consumption by 30-50% compared to conventional materials when considering full product lifecycles.

Recent innovations have focused on developing bio-based and biodegradable self-healing polymers, further enhancing their sustainability credentials. These materials incorporate renewable resources such as cellulose, chitosan, or plant-derived monomers, reducing dependence on petroleum-based feedstocks. Some advanced formulations can even biodegrade into environmentally benign compounds at end-of-life, addressing concerns about persistent polymer pollution.

The carbon footprint reduction potential of self-healing polymers is substantial. By extending product lifespans and reducing manufacturing frequency, these materials can significantly decrease greenhouse gas emissions associated with polymer production, which typically ranges from 1.7 to 3.5 kg CO2e per kilogram of conventional polymer. This reduction aligns with global climate mitigation strategies and corporate sustainability goals across multiple industries.

Vascular self-healing systems present unique environmental considerations. While they offer effective healing capabilities, the encapsulated healing agents often contain volatile organic compounds (VOCs) or other potentially hazardous chemicals. When released during the healing process, these substances may contribute to air pollution or pose risks to ecosystems if improperly disposed of. Additionally, the complex multi-component nature of vascular systems can complicate end-of-life recycling processes.

Intrinsic self-healing polymers generally demonstrate superior environmental performance compared to their vascular counterparts. These materials typically rely on reversible chemical bonds or physical interactions that can be repeatedly activated without depleting healing resources or releasing harmful substances. This characteristic makes them particularly valuable from a circular economy perspective, as they maintain their healing capacity throughout multiple damage-repair cycles.

Energy consumption represents another significant environmental factor. While self-healing processes often require thermal or light activation, this energy investment is typically far less than that required for manufacturing replacement products. Life cycle assessments indicate that self-healing polymers can reduce overall energy consumption by 30-50% compared to conventional materials when considering full product lifecycles.

Recent innovations have focused on developing bio-based and biodegradable self-healing polymers, further enhancing their sustainability credentials. These materials incorporate renewable resources such as cellulose, chitosan, or plant-derived monomers, reducing dependence on petroleum-based feedstocks. Some advanced formulations can even biodegrade into environmentally benign compounds at end-of-life, addressing concerns about persistent polymer pollution.

The carbon footprint reduction potential of self-healing polymers is substantial. By extending product lifespans and reducing manufacturing frequency, these materials can significantly decrease greenhouse gas emissions associated with polymer production, which typically ranges from 1.7 to 3.5 kg CO2e per kilogram of conventional polymer. This reduction aligns with global climate mitigation strategies and corporate sustainability goals across multiple industries.

Standardization and Testing Protocols

The standardization of testing protocols for self-healing polymers represents a critical challenge in advancing this technology from laboratory curiosities to commercial applications. Currently, the field suffers from significant inconsistencies in how healing efficiency is measured and reported, making direct comparisons between different self-healing systems nearly impossible. Researchers employ various testing methodologies, healing conditions, and evaluation metrics that often yield incomparable results.

A fundamental issue lies in the diversity of mechanical testing procedures. While some researchers utilize tensile testing to evaluate healing performance, others rely on compression, flexural, or impact tests. Even within the same testing category, parameters such as strain rate, sample dimensions, and environmental conditions vary widely across studies, further complicating meaningful comparisons.

For vascular self-healing systems, standardization must address the quantification of healing agent delivery efficiency, channel architecture optimization, and long-term stability of the vascular network. Protocols should specify channel diameter ranges, network density parameters, and healing agent viscosity requirements to ensure reproducible results.

Intrinsic self-healing polymers present additional standardization challenges due to their temperature and time-dependent healing behaviors. Testing protocols must clearly define healing conditions including temperature profiles, humidity levels, and healing duration. The field requires consensus on whether healing should be evaluated under ambient conditions or optimized environments that may not reflect real-world applications.

Quantification metrics also require standardization. While healing efficiency is commonly expressed as the ratio of recovered property to original property, there is no consensus on which specific property (strength, toughness, elongation) should serve as the primary evaluation criterion. Additionally, cyclic healing performance—the ability to heal multiple times at the same location—lacks standardized assessment methods.

Non-destructive evaluation techniques represent another area requiring protocol development. Methods such as ultrasonic testing, infrared thermography, and computed tomography show promise for monitoring healing processes in real-time, but standardized procedures for their application to self-healing materials remain underdeveloped.

International standards organizations, including ASTM International and ISO, have begun preliminary work on developing standardized testing protocols for self-healing materials, but comprehensive standards remain years away. Industry-academic collaborations will be essential to establish testing frameworks that balance scientific rigor with practical relevance for commercial applications.

A fundamental issue lies in the diversity of mechanical testing procedures. While some researchers utilize tensile testing to evaluate healing performance, others rely on compression, flexural, or impact tests. Even within the same testing category, parameters such as strain rate, sample dimensions, and environmental conditions vary widely across studies, further complicating meaningful comparisons.

For vascular self-healing systems, standardization must address the quantification of healing agent delivery efficiency, channel architecture optimization, and long-term stability of the vascular network. Protocols should specify channel diameter ranges, network density parameters, and healing agent viscosity requirements to ensure reproducible results.

Intrinsic self-healing polymers present additional standardization challenges due to their temperature and time-dependent healing behaviors. Testing protocols must clearly define healing conditions including temperature profiles, humidity levels, and healing duration. The field requires consensus on whether healing should be evaluated under ambient conditions or optimized environments that may not reflect real-world applications.

Quantification metrics also require standardization. While healing efficiency is commonly expressed as the ratio of recovered property to original property, there is no consensus on which specific property (strength, toughness, elongation) should serve as the primary evaluation criterion. Additionally, cyclic healing performance—the ability to heal multiple times at the same location—lacks standardized assessment methods.

Non-destructive evaluation techniques represent another area requiring protocol development. Methods such as ultrasonic testing, infrared thermography, and computed tomography show promise for monitoring healing processes in real-time, but standardized procedures for their application to self-healing materials remain underdeveloped.

International standards organizations, including ASTM International and ISO, have begun preliminary work on developing standardized testing protocols for self-healing materials, but comprehensive standards remain years away. Industry-academic collaborations will be essential to establish testing frameworks that balance scientific rigor with practical relevance for commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!