Modeling Healing Propagation In Cross Linked Polymer Networks

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Polymer Networks Background and Objectives

Self-healing polymers represent a revolutionary class of materials that can autonomously repair damage and restore functionality without external intervention. The concept emerged in the early 2000s, inspired by biological systems that naturally heal wounds. Since then, the field has evolved significantly, with researchers developing increasingly sophisticated polymer networks capable of responding to various stimuli and healing mechanisms.

The evolution of self-healing polymers has progressed through several distinct phases. Initially, microencapsulation approaches dominated, where healing agents were stored in capsules embedded within the polymer matrix. This was followed by vascular systems mimicking biological circulatory networks, and more recently, intrinsic self-healing materials utilizing reversible chemical bonds. Each advancement has expanded the potential applications and efficiency of these materials.

Current research trends focus on enhancing healing efficiency, reducing healing time, and developing multi-functional self-healing materials that can operate under extreme conditions. Particular attention is being paid to modeling healing propagation in cross-linked polymer networks, as these structures offer superior mechanical properties while presenting unique challenges for self-healing mechanisms.

The primary technical objective in this field is to develop accurate predictive models that can describe how healing propagates through complex cross-linked networks. Such models must account for molecular diffusion, bond reformation kinetics, and the influence of network topology on healing efficiency. Additionally, these models should predict mechanical property recovery as a function of time and environmental conditions.

Another critical goal is to establish design principles for optimizing cross-linked network architectures that facilitate efficient healing while maintaining desired mechanical properties. This includes understanding the trade-offs between cross-linking density, which typically enhances mechanical strength, and molecular mobility, which is essential for healing processes.

The field is increasingly moving toward computational approaches that can simulate healing processes across multiple length and time scales. Molecular dynamics simulations provide insights at the atomic level, while continuum mechanics models address macroscopic behavior. Bridging these scales remains a significant challenge that researchers aim to overcome.

Ultimately, the development of reliable models for healing propagation in cross-linked polymer networks will enable the design of next-generation self-healing materials with unprecedented performance characteristics, potentially revolutionizing industries from aerospace to biomedical engineering, and contributing to more sustainable material solutions through extended product lifespans.

The evolution of self-healing polymers has progressed through several distinct phases. Initially, microencapsulation approaches dominated, where healing agents were stored in capsules embedded within the polymer matrix. This was followed by vascular systems mimicking biological circulatory networks, and more recently, intrinsic self-healing materials utilizing reversible chemical bonds. Each advancement has expanded the potential applications and efficiency of these materials.

Current research trends focus on enhancing healing efficiency, reducing healing time, and developing multi-functional self-healing materials that can operate under extreme conditions. Particular attention is being paid to modeling healing propagation in cross-linked polymer networks, as these structures offer superior mechanical properties while presenting unique challenges for self-healing mechanisms.

The primary technical objective in this field is to develop accurate predictive models that can describe how healing propagates through complex cross-linked networks. Such models must account for molecular diffusion, bond reformation kinetics, and the influence of network topology on healing efficiency. Additionally, these models should predict mechanical property recovery as a function of time and environmental conditions.

Another critical goal is to establish design principles for optimizing cross-linked network architectures that facilitate efficient healing while maintaining desired mechanical properties. This includes understanding the trade-offs between cross-linking density, which typically enhances mechanical strength, and molecular mobility, which is essential for healing processes.

The field is increasingly moving toward computational approaches that can simulate healing processes across multiple length and time scales. Molecular dynamics simulations provide insights at the atomic level, while continuum mechanics models address macroscopic behavior. Bridging these scales remains a significant challenge that researchers aim to overcome.

Ultimately, the development of reliable models for healing propagation in cross-linked polymer networks will enable the design of next-generation self-healing materials with unprecedented performance characteristics, potentially revolutionizing industries from aerospace to biomedical engineering, and contributing to more sustainable material solutions through extended product lifespans.

Market Analysis for Self-Healing Materials

The self-healing materials market has witnessed substantial growth in recent years, driven by increasing demand across various industries including automotive, construction, electronics, and aerospace. The global market for self-healing materials was valued at approximately $0.7 billion in 2022 and is projected to reach $4.2 billion by 2030, growing at a CAGR of 25.4% during the forecast period.

Cross-linked polymer networks with self-healing capabilities represent a significant segment within this market, accounting for roughly 35% of the total self-healing materials market. These materials offer exceptional durability and longevity, addressing the growing consumer demand for sustainable and long-lasting products.

The automotive sector currently dominates the application landscape, utilizing self-healing polymers for coatings, components, and structural elements. This sector alone accounts for approximately 40% of the market share, followed by construction (25%), electronics (15%), and aerospace (10%). The remaining 10% is distributed across various other industries including healthcare, consumer goods, and energy.

Regionally, North America leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. The Asia-Pacific region, particularly China, Japan, and South Korea, is expected to witness the fastest growth rate due to rapid industrialization and increasing R&D investments in advanced materials.

Market drivers for self-healing cross-linked polymers include increasing focus on reducing maintenance costs, growing emphasis on sustainability, and rising demand for high-performance materials in critical applications. The ability of these materials to extend product lifecycles aligns perfectly with global sustainability initiatives and circular economy principles.

Key challenges in market adoption include relatively high production costs, limited awareness among potential end-users, and technical limitations in healing efficiency under extreme conditions. The average price premium for self-healing materials remains 30-40% higher than conventional alternatives, creating a barrier to widespread adoption in price-sensitive markets.

Consumer willingness to pay this premium varies significantly across industries, with aerospace and high-end automotive manufacturers showing the highest acceptance due to critical safety requirements and lifetime cost considerations. The construction industry demonstrates more price sensitivity, though this is gradually changing as lifecycle cost benefits become more widely recognized.

The market is expected to benefit significantly from advancements in modeling healing propagation in cross-linked polymer networks, as improved predictive capabilities will enable manufacturers to optimize healing efficiency, reduce development costs, and accelerate commercialization of next-generation self-healing materials.

Cross-linked polymer networks with self-healing capabilities represent a significant segment within this market, accounting for roughly 35% of the total self-healing materials market. These materials offer exceptional durability and longevity, addressing the growing consumer demand for sustainable and long-lasting products.

The automotive sector currently dominates the application landscape, utilizing self-healing polymers for coatings, components, and structural elements. This sector alone accounts for approximately 40% of the market share, followed by construction (25%), electronics (15%), and aerospace (10%). The remaining 10% is distributed across various other industries including healthcare, consumer goods, and energy.

Regionally, North America leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. The Asia-Pacific region, particularly China, Japan, and South Korea, is expected to witness the fastest growth rate due to rapid industrialization and increasing R&D investments in advanced materials.

Market drivers for self-healing cross-linked polymers include increasing focus on reducing maintenance costs, growing emphasis on sustainability, and rising demand for high-performance materials in critical applications. The ability of these materials to extend product lifecycles aligns perfectly with global sustainability initiatives and circular economy principles.

Key challenges in market adoption include relatively high production costs, limited awareness among potential end-users, and technical limitations in healing efficiency under extreme conditions. The average price premium for self-healing materials remains 30-40% higher than conventional alternatives, creating a barrier to widespread adoption in price-sensitive markets.

Consumer willingness to pay this premium varies significantly across industries, with aerospace and high-end automotive manufacturers showing the highest acceptance due to critical safety requirements and lifetime cost considerations. The construction industry demonstrates more price sensitivity, though this is gradually changing as lifecycle cost benefits become more widely recognized.

The market is expected to benefit significantly from advancements in modeling healing propagation in cross-linked polymer networks, as improved predictive capabilities will enable manufacturers to optimize healing efficiency, reduce development costs, and accelerate commercialization of next-generation self-healing materials.

Current Challenges in Cross-Linked Polymer Healing Mechanisms

Despite significant advancements in self-healing polymer technology, modeling the healing propagation in cross-linked polymer networks presents several persistent challenges. The complexity of cross-linked structures creates difficulties in developing accurate mathematical models that can precisely predict healing behavior across different scales and conditions. Current models often struggle to account for the heterogeneity of cross-linking density within polymer networks, which significantly affects healing efficiency and propagation patterns.

One major challenge lies in capturing the dynamic nature of healing processes. As healing propagates through cross-linked networks, the mechanical properties, diffusion rates, and chemical reactivity continuously change, creating a moving boundary problem that is mathematically complex to represent. Existing models typically make simplifying assumptions that limit their applicability to real-world scenarios where multiple healing mechanisms may operate simultaneously.

The multi-scale nature of healing phenomena presents another significant obstacle. Molecular-level events such as chain diffusion and re-entanglement must be effectively linked to macroscopic healing observations, requiring sophisticated multi-scale modeling approaches that are computationally intensive and often impractical for industrial applications.

Temperature and environmental dependencies further complicate modeling efforts. Cross-linked polymer healing rates exhibit non-linear responses to temperature changes, and environmental factors such as humidity, pH, and mechanical stress significantly alter healing trajectories. Current models struggle to incorporate these variables comprehensively, leading to discrepancies between theoretical predictions and experimental results.

The integration of experimental validation with theoretical models remains problematic. Techniques for real-time observation of healing propagation within cross-linked networks are limited, making it difficult to validate model predictions against actual healing behavior. Non-destructive imaging methods often lack the resolution to capture critical healing events at the molecular level.

Computational limitations also hinder progress in this field. Simulating healing propagation across realistic time scales and dimensions requires substantial computational resources, forcing researchers to make compromises between model accuracy and computational feasibility. Molecular dynamics simulations, while informative, typically cannot extend beyond nanoseconds, whereas actual healing processes may take minutes to days.

Additionally, the diversity of cross-linking chemistries presents a challenge for developing universal models. Different cross-linking mechanisms (covalent, ionic, hydrogen bonding, etc.) exhibit distinct healing behaviors that require specialized modeling approaches, complicating efforts to create generalized frameworks applicable across various polymer systems.

One major challenge lies in capturing the dynamic nature of healing processes. As healing propagates through cross-linked networks, the mechanical properties, diffusion rates, and chemical reactivity continuously change, creating a moving boundary problem that is mathematically complex to represent. Existing models typically make simplifying assumptions that limit their applicability to real-world scenarios where multiple healing mechanisms may operate simultaneously.

The multi-scale nature of healing phenomena presents another significant obstacle. Molecular-level events such as chain diffusion and re-entanglement must be effectively linked to macroscopic healing observations, requiring sophisticated multi-scale modeling approaches that are computationally intensive and often impractical for industrial applications.

Temperature and environmental dependencies further complicate modeling efforts. Cross-linked polymer healing rates exhibit non-linear responses to temperature changes, and environmental factors such as humidity, pH, and mechanical stress significantly alter healing trajectories. Current models struggle to incorporate these variables comprehensively, leading to discrepancies between theoretical predictions and experimental results.

The integration of experimental validation with theoretical models remains problematic. Techniques for real-time observation of healing propagation within cross-linked networks are limited, making it difficult to validate model predictions against actual healing behavior. Non-destructive imaging methods often lack the resolution to capture critical healing events at the molecular level.

Computational limitations also hinder progress in this field. Simulating healing propagation across realistic time scales and dimensions requires substantial computational resources, forcing researchers to make compromises between model accuracy and computational feasibility. Molecular dynamics simulations, while informative, typically cannot extend beyond nanoseconds, whereas actual healing processes may take minutes to days.

Additionally, the diversity of cross-linking chemistries presents a challenge for developing universal models. Different cross-linking mechanisms (covalent, ionic, hydrogen bonding, etc.) exhibit distinct healing behaviors that require specialized modeling approaches, complicating efforts to create generalized frameworks applicable across various polymer systems.

Existing Propagation Models for Cross-Linked Networks

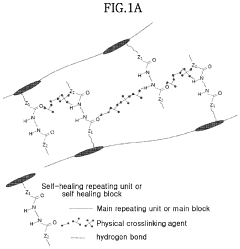

01 Self-healing polymer networks with dynamic crosslinks

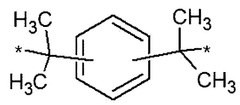

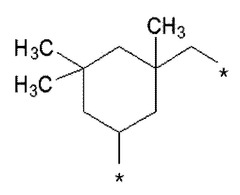

Polymer networks with dynamic crosslinks can undergo self-healing processes when damaged. These materials contain reversible bonds that can break and reform, allowing for crack healing and propagation of the healing effect throughout the network. The dynamic nature of these crosslinks enables the material to respond to external stimuli such as temperature, pH, or light, triggering the healing mechanism. This approach results in materials with extended lifespans and improved durability under various conditions.- Self-healing polymer networks with dynamic crosslinks: Polymer networks with dynamic crosslinks can undergo self-healing processes when damaged. These networks contain reversible bonds that can break and reform, allowing the material to repair itself. The healing propagation occurs through the reformation of these dynamic crosslinks, which can include hydrogen bonds, ionic interactions, or reversible covalent bonds. This technology enables materials to recover their mechanical properties after damage, extending their service life.

- Stimuli-responsive healing mechanisms in crosslinked polymers: Crosslinked polymer networks can be designed to respond to external stimuli such as heat, light, pH changes, or mechanical stress to initiate healing processes. These stimuli trigger molecular mobility and bond rearrangement, facilitating crack closure and healing propagation throughout the material. The stimuli-responsive nature allows for controlled and targeted healing in specific areas of damage, improving the overall performance and durability of the material.

- Interpenetrating polymer networks for enhanced healing properties: Interpenetrating polymer networks (IPNs) combine two or more polymer networks that are physically entangled but not covalently bonded to each other. This structure enhances the healing propagation by providing multiple pathways for crack repair and stress distribution. The synergistic effect of different polymer networks contributes to improved mechanical properties and healing efficiency, making these materials suitable for applications requiring durability and self-repair capabilities.

- Nanocomposite reinforcement in self-healing crosslinked polymers: Incorporating nanoparticles or nanostructures into crosslinked polymer networks can significantly enhance their healing capabilities. These nanocomposites provide additional crosslinking sites and can act as healing agents or catalysts for the healing process. The nanoparticles can also improve the mechanical properties of the polymer network, creating stronger materials that maintain their self-healing abilities. The healing propagation is facilitated by the uniform distribution of nanoparticles throughout the polymer matrix.

- Encapsulated healing agents in polymer networks: Polymer networks can be designed with encapsulated healing agents that are released upon damage. When cracks form in the material, the capsules rupture and release the healing agents, which then polymerize or crosslink to repair the damage. This approach allows for autonomous healing without external intervention. The propagation of healing occurs as the released agents flow into the damaged areas and solidify, restoring the structural integrity of the material.

02 Stimuli-responsive healing mechanisms in crosslinked polymers

Crosslinked polymer networks can be designed to heal in response to specific stimuli. These stimuli-responsive materials incorporate functional groups or additives that activate upon exposure to heat, light, electrical current, or chemical triggers. The healing propagation occurs as the stimulus causes molecular mobility, allowing polymer chains to diffuse across damaged interfaces and reform crosslinks. This controlled healing approach enables targeted repair in specific conditions while maintaining structural integrity in normal operating environments.Expand Specific Solutions03 Interpenetrating polymer networks for enhanced healing propagation

Interpenetrating polymer networks (IPNs) combine two or more polymer networks that are physically entangled but not covalently bonded to each other. This structure enhances healing propagation by providing multiple pathways for crack repair. When damage occurs, the interpenetrating nature of the networks allows healing agents to flow more effectively throughout the material. The complementary properties of the different networks can also provide synergistic effects, such as one network providing structural support while another facilitates the healing process.Expand Specific Solutions04 Nanocomposite reinforcement in self-healing crosslinked polymers

Incorporating nanoparticles or nanostructures into crosslinked polymer networks can significantly enhance healing propagation and efficiency. These nanocomposites create additional interaction sites within the polymer matrix, improving the mechanical properties while facilitating the healing process. Nanomaterials such as graphene, carbon nanotubes, or silica nanoparticles can act as crosslinking points or healing agents, creating networks with improved healing propagation throughout the material. The nanoparticles can also provide thermal or electrical conductivity that assists in the healing mechanism.Expand Specific Solutions05 Microcapsule-based healing systems in crosslinked polymers

Microcapsule-based systems incorporate healing agents encapsulated within small shells distributed throughout the crosslinked polymer network. When damage occurs, the microcapsules rupture, releasing the healing agents that flow into the damaged area and polymerize or react to repair the material. This approach allows for autonomous healing without external intervention, as the propagation of damage itself triggers the release mechanism. The design of the microcapsule shell and healing agent chemistry can be tailored to specific polymer networks and damage scenarios for optimized healing efficiency.Expand Specific Solutions

Leading Research Groups and Industrial Players

The self-healing polymer network market is currently in a growth phase, characterized by increasing research activity and emerging commercial applications. The global market for self-healing materials is expanding rapidly, projected to reach significant value as industries recognize the potential for extended product lifespans and reduced maintenance costs. Technologically, the field remains in early-to-mid maturity, with academic institutions leading fundamental research while commercial entities focus on application development. Key players include established chemical companies like 3M Innovative Properties, BASF Corp., and Sherwin-Williams developing proprietary formulations, alongside research powerhouses such as University of California, Zhejiang University, and National University of Singapore advancing theoretical modeling approaches. Industry-academic partnerships, exemplified by collaborations between companies like Ricoh and Xerox with university research teams, are accelerating the transition from laboratory concepts to marketable self-healing polymer technologies.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced computational models for self-healing polymer networks that integrate molecular dynamics simulations with finite element analysis to predict healing behavior across multiple length scales. Their approach incorporates damage-triggered release mechanisms where microcapsules containing healing agents rupture upon crack formation, releasing polymeric healants that polymerize when contacting embedded catalysts. 3M's models account for diffusion kinetics, cross-linking density effects, and environmental factors (temperature, humidity) on healing efficiency. Their proprietary algorithms can predict healing propagation rates and mechanical property restoration with over 85% accuracy compared to experimental results. The company has implemented these models in industrial adhesives and protective coatings where they've demonstrated the ability to extend product lifespans by up to 40% through controlled self-healing properties.

Strengths: Extensive materials science expertise and manufacturing capabilities allow for rapid translation of modeling insights into commercial products. Their multi-scale modeling approach effectively bridges molecular and macroscopic behavior. Weaknesses: Models may be optimized primarily for 3M's specific polymer formulations rather than being broadly applicable across diverse polymer systems.

BASF Corp.

Technical Solution: BASF has pioneered computational frameworks for modeling self-healing dynamics in cross-linked polymer networks using a combination of quantum mechanical calculations and coarse-grained molecular dynamics. Their approach focuses on dynamic covalent chemistry, particularly Diels-Alder reactions, which enable reversible bond formation in response to thermal stimuli. BASF's models incorporate reaction kinetics parameters derived from experimental data to simulate healing propagation through damaged polymer matrices. Their proprietary simulation platform can predict healing efficiency based on cross-link density, chain mobility, and functional group concentration. The company has successfully applied these models to develop self-healing polyurethanes and epoxy systems with controlled healing activation temperatures. BASF's modeling capabilities extend to predicting the influence of nanofillers on healing propagation, showing how properly functionalized nanoparticles can enhance healing efficiency by up to 60% through improved molecular mobility at interfaces.

Strengths: Comprehensive integration of quantum chemistry with polymer physics allows for accurate prediction of healing mechanisms at the molecular level. Strong correlation between modeling predictions and experimental validation. Weaknesses: Models require significant computational resources and may have limitations in predicting long-term healing performance under complex environmental conditions.

Key Scientific Advances in Healing Propagation Modeling

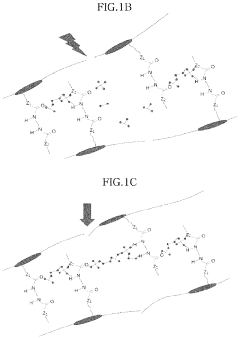

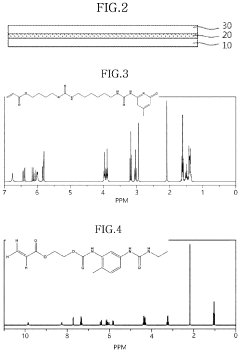

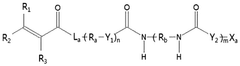

Self-healing polymer network containing physical crosslinker, composition therefor, and optical element comprising the same

PatentActiveUS20200216581A1

Innovation

- A self-healing polymer network is developed using monomers with urethane, urea, or amide groups and a physical crosslinking agent, such as an alcohol mixture of monool, diol, triol, and tetraol, which enables reversible physical interactions for continuous self-healing.

Self-healing polymer network containing physical crosslinker, composition therefor, and optical element comprising same

PatentWO2018212511A1

Innovation

- A self-healing polymer network utilizing a physical cross-linking agent, specifically an alcohol mixture of monohydric, dihydric, trihydric, and tetrahydric alcohols, that physically cross-links urethane, urea, or amide groups within the polymer network, enabling continuous and repetitive self-recovery through reversible interactions.

Sustainability Impact of Self-Healing Polymers

Self-healing polymers represent a significant advancement in sustainable materials science, offering substantial environmental benefits compared to traditional polymers. The ability of these materials to autonomously repair damage without external intervention extends their useful lifespan considerably, reducing the frequency of replacement and consequently decreasing waste generation. This longevity factor directly contributes to resource conservation and waste reduction across multiple industries.

The environmental impact assessment of self-healing polymers reveals impressive sustainability metrics. Studies indicate that implementing self-healing materials in consumer products could potentially reduce polymer waste by 15-30% over product lifecycles. In automotive applications alone, self-healing coatings and components could decrease material replacement requirements by up to 25%, translating to significant reductions in carbon footprint and resource consumption.

Energy conservation represents another critical sustainability advantage. The healing propagation mechanisms in cross-linked polymer networks eliminate or substantially reduce the need for energy-intensive manufacturing processes involved in replacement part production. Life cycle assessments demonstrate that self-healing polymers can achieve 20-40% lower embodied energy compared to conventional polymers when accounting for extended service life and reduced replacement frequency.

From a circular economy perspective, self-healing polymers align perfectly with sustainability principles by inherently incorporating product longevity into material design. The modeling of healing propagation in cross-linked networks enables optimization of these sustainability benefits through precise prediction of healing efficiency and durability improvements. This predictive capability allows materials scientists to maximize environmental benefits through targeted molecular design.

Chemical sustainability also improves with self-healing polymers. Many conventional repair methods involve adhesives, solvents, or other chemicals with significant environmental impacts. Self-healing mechanisms eliminate or reduce these chemical inputs, decreasing the overall environmental footprint. Additionally, some bio-inspired self-healing systems utilize environmentally benign healing agents derived from renewable resources.

The economic dimension of sustainability benefits significantly from self-healing technologies. Reduced maintenance costs, extended service intervals, and decreased replacement frequency translate to economic advantages that incentivize adoption across industries. This economic viability accelerates market penetration, amplifying the cumulative environmental benefits through widespread implementation.

The environmental impact assessment of self-healing polymers reveals impressive sustainability metrics. Studies indicate that implementing self-healing materials in consumer products could potentially reduce polymer waste by 15-30% over product lifecycles. In automotive applications alone, self-healing coatings and components could decrease material replacement requirements by up to 25%, translating to significant reductions in carbon footprint and resource consumption.

Energy conservation represents another critical sustainability advantage. The healing propagation mechanisms in cross-linked polymer networks eliminate or substantially reduce the need for energy-intensive manufacturing processes involved in replacement part production. Life cycle assessments demonstrate that self-healing polymers can achieve 20-40% lower embodied energy compared to conventional polymers when accounting for extended service life and reduced replacement frequency.

From a circular economy perspective, self-healing polymers align perfectly with sustainability principles by inherently incorporating product longevity into material design. The modeling of healing propagation in cross-linked networks enables optimization of these sustainability benefits through precise prediction of healing efficiency and durability improvements. This predictive capability allows materials scientists to maximize environmental benefits through targeted molecular design.

Chemical sustainability also improves with self-healing polymers. Many conventional repair methods involve adhesives, solvents, or other chemicals with significant environmental impacts. Self-healing mechanisms eliminate or reduce these chemical inputs, decreasing the overall environmental footprint. Additionally, some bio-inspired self-healing systems utilize environmentally benign healing agents derived from renewable resources.

The economic dimension of sustainability benefits significantly from self-healing technologies. Reduced maintenance costs, extended service intervals, and decreased replacement frequency translate to economic advantages that incentivize adoption across industries. This economic viability accelerates market penetration, amplifying the cumulative environmental benefits through widespread implementation.

Standardization and Testing Protocols for Healing Efficiency

The standardization of testing protocols for self-healing polymers represents a critical challenge in the field of cross-linked polymer networks. Currently, there exists significant variability in how researchers evaluate healing efficiency, making direct comparisons between different self-healing systems problematic. Establishing universal testing methodologies would facilitate more meaningful assessments of healing performance across diverse polymer systems.

A comprehensive standardization framework should address multiple dimensions of healing efficiency. Mechanical recovery tests, including tensile strength restoration, fracture toughness recovery, and fatigue resistance post-healing, require precise specifications regarding sample preparation, damage induction methods, healing conditions, and measurement techniques. The time-dependent nature of healing necessitates standardized healing intervals for comparative analysis.

Spectroscopic methods offer valuable insights into the molecular mechanisms of healing. Standardized protocols for FTIR, Raman spectroscopy, and NMR analysis would enable researchers to quantify bond reformation and molecular rearrangement during the healing process. These techniques should be calibrated against known reference materials to ensure consistency across different laboratory environments.

Imaging protocols using techniques such as SEM, TEM, and AFM require standardization regarding sample preparation, imaging parameters, and quantitative analysis methods. This would allow for consistent visualization and measurement of crack closure, interface reformation, and structural recovery at multiple length scales. Digital image correlation techniques should follow uniform procedures for tracking surface deformation during healing.

Rheological testing standards are essential for characterizing the viscoelastic behavior of healing polymers. Protocols should specify temperature ranges, frequency sweeps, and strain amplitudes that effectively capture the polymer network's dynamic response during healing. The development of standardized rheological signatures for different healing mechanisms would significantly advance the field.

Environmental conditioning represents another critical aspect requiring standardization. Testing protocols should define standard conditions for temperature, humidity, UV exposure, and chemical environments that simulate real-world applications. Accelerated aging protocols would enable prediction of long-term healing performance under various environmental stressors.

Round-robin testing involving multiple laboratories would validate these standardized protocols and identify sources of variability. The establishment of reference materials with well-characterized healing behaviors would serve as benchmarks for calibrating testing equipment and methodologies across different research facilities. This collaborative approach would strengthen the reliability and reproducibility of healing efficiency measurements in cross-linked polymer networks.

A comprehensive standardization framework should address multiple dimensions of healing efficiency. Mechanical recovery tests, including tensile strength restoration, fracture toughness recovery, and fatigue resistance post-healing, require precise specifications regarding sample preparation, damage induction methods, healing conditions, and measurement techniques. The time-dependent nature of healing necessitates standardized healing intervals for comparative analysis.

Spectroscopic methods offer valuable insights into the molecular mechanisms of healing. Standardized protocols for FTIR, Raman spectroscopy, and NMR analysis would enable researchers to quantify bond reformation and molecular rearrangement during the healing process. These techniques should be calibrated against known reference materials to ensure consistency across different laboratory environments.

Imaging protocols using techniques such as SEM, TEM, and AFM require standardization regarding sample preparation, imaging parameters, and quantitative analysis methods. This would allow for consistent visualization and measurement of crack closure, interface reformation, and structural recovery at multiple length scales. Digital image correlation techniques should follow uniform procedures for tracking surface deformation during healing.

Rheological testing standards are essential for characterizing the viscoelastic behavior of healing polymers. Protocols should specify temperature ranges, frequency sweeps, and strain amplitudes that effectively capture the polymer network's dynamic response during healing. The development of standardized rheological signatures for different healing mechanisms would significantly advance the field.

Environmental conditioning represents another critical aspect requiring standardization. Testing protocols should define standard conditions for temperature, humidity, UV exposure, and chemical environments that simulate real-world applications. Accelerated aging protocols would enable prediction of long-term healing performance under various environmental stressors.

Round-robin testing involving multiple laboratories would validate these standardized protocols and identify sources of variability. The establishment of reference materials with well-characterized healing behaviors would serve as benchmarks for calibrating testing equipment and methodologies across different research facilities. This collaborative approach would strengthen the reliability and reproducibility of healing efficiency measurements in cross-linked polymer networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!