Automated Damage Detection And Triggered Healing Systems Design

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Materials Background and Objectives

Self-healing materials represent a revolutionary class of smart materials capable of detecting and repairing damage autonomously, mimicking biological systems' natural healing capabilities. The concept emerged in the early 2000s, with pioneering work by researchers at the University of Illinois who developed microencapsulation techniques for polymer healing. Since then, the field has expanded dramatically, encompassing various material classes including polymers, metals, ceramics, and composites.

The evolution of self-healing materials has progressed through several distinct phases. Initially, research focused on passive healing mechanisms using embedded healing agents. This evolved toward more sophisticated intrinsic healing systems utilizing reversible chemical bonds. The current frontier involves the integration of damage detection systems with triggered healing responses—creating truly autonomous materials that can sense and respond to environmental stimuli without external intervention.

Market trends indicate growing demand for these materials across aerospace, automotive, construction, and electronics sectors, where component longevity and reliability are paramount. The global self-healing materials market is projected to reach $8.2 billion by 2027, growing at a CAGR of approximately 27% from 2020 to 2027, demonstrating significant commercial potential.

Automated damage detection represents the next critical advancement in this field. Current systems primarily rely on visual inspection or scheduled maintenance, which are inefficient and often detect damage only after significant progression. The integration of real-time monitoring capabilities with healing mechanisms would enable preemptive maintenance, substantially extending material lifespans and reducing catastrophic failures.

The primary technical objectives for automated damage detection and triggered healing systems include: developing sensitive and reliable damage detection mechanisms capable of identifying microscopic defects before they propagate; creating responsive triggering mechanisms that activate healing processes proportional to damage severity; designing multi-stage healing systems capable of addressing various damage types; and ensuring system longevity through multiple healing cycles without performance degradation.

Additional objectives include miniaturization of detection-healing systems for integration into complex structures, reducing energy requirements for healing processes, and developing standardized testing protocols to evaluate self-healing efficiency across different material platforms. The ultimate goal is creating truly autonomous materials systems that can maintain structural integrity throughout their service life with minimal external intervention, revolutionizing how we design and maintain critical infrastructure and components.

The evolution of self-healing materials has progressed through several distinct phases. Initially, research focused on passive healing mechanisms using embedded healing agents. This evolved toward more sophisticated intrinsic healing systems utilizing reversible chemical bonds. The current frontier involves the integration of damage detection systems with triggered healing responses—creating truly autonomous materials that can sense and respond to environmental stimuli without external intervention.

Market trends indicate growing demand for these materials across aerospace, automotive, construction, and electronics sectors, where component longevity and reliability are paramount. The global self-healing materials market is projected to reach $8.2 billion by 2027, growing at a CAGR of approximately 27% from 2020 to 2027, demonstrating significant commercial potential.

Automated damage detection represents the next critical advancement in this field. Current systems primarily rely on visual inspection or scheduled maintenance, which are inefficient and often detect damage only after significant progression. The integration of real-time monitoring capabilities with healing mechanisms would enable preemptive maintenance, substantially extending material lifespans and reducing catastrophic failures.

The primary technical objectives for automated damage detection and triggered healing systems include: developing sensitive and reliable damage detection mechanisms capable of identifying microscopic defects before they propagate; creating responsive triggering mechanisms that activate healing processes proportional to damage severity; designing multi-stage healing systems capable of addressing various damage types; and ensuring system longevity through multiple healing cycles without performance degradation.

Additional objectives include miniaturization of detection-healing systems for integration into complex structures, reducing energy requirements for healing processes, and developing standardized testing protocols to evaluate self-healing efficiency across different material platforms. The ultimate goal is creating truly autonomous materials systems that can maintain structural integrity throughout their service life with minimal external intervention, revolutionizing how we design and maintain critical infrastructure and components.

Market Demand Analysis for Automated Damage Detection

The global market for automated damage detection systems is experiencing significant growth, driven by increasing demands across multiple industries for solutions that can detect and address structural damage in real-time. According to recent market analyses, the automated damage detection market is projected to reach $8.3 billion by 2027, with a compound annual growth rate of 12.7% from 2022 to 2027.

The aerospace industry represents one of the largest market segments, where automated damage detection systems are critical for ensuring aircraft structural integrity and passenger safety. Commercial airlines and defense sectors are increasingly investing in these technologies to reduce maintenance costs and extend the service life of their fleets. The automotive industry follows closely, with manufacturers integrating damage detection systems in advanced vehicle designs to enhance safety features and support the development of autonomous vehicles.

Infrastructure monitoring presents another substantial market opportunity. Aging bridges, buildings, and pipelines worldwide require continuous monitoring to prevent catastrophic failures. Government initiatives focused on infrastructure modernization in developed countries are allocating significant budgets toward implementing automated damage detection technologies. For instance, the European Union's infrastructure renewal program has earmarked €15 billion specifically for smart monitoring systems over the next five years.

The energy sector, particularly renewable energy, demonstrates growing demand for these systems. Wind turbine operators are implementing automated damage detection to monitor blade integrity and optimize maintenance schedules, reducing downtime and increasing energy production efficiency. Similarly, solar farm operators are adopting these technologies to detect panel damage and performance degradation.

Consumer electronics manufacturers are also exploring applications for self-healing materials and damage detection systems in smartphones, tablets, and wearable devices. This represents an emerging market segment with substantial growth potential as consumers increasingly value product longevity and durability.

Market research indicates that end-users are primarily seeking systems that offer real-time monitoring capabilities, minimal false positives, integration with existing infrastructure, and cost-effective implementation. There is particularly strong demand for solutions that combine damage detection with automated or triggered healing mechanisms, creating comprehensive systems that not only identify problems but also initiate repair processes without human intervention.

Regional analysis shows North America currently leading the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate over the forecast period, driven by rapid industrialization, infrastructure development, and increasing technological adoption in countries like China, Japan, and South Korea.

The aerospace industry represents one of the largest market segments, where automated damage detection systems are critical for ensuring aircraft structural integrity and passenger safety. Commercial airlines and defense sectors are increasingly investing in these technologies to reduce maintenance costs and extend the service life of their fleets. The automotive industry follows closely, with manufacturers integrating damage detection systems in advanced vehicle designs to enhance safety features and support the development of autonomous vehicles.

Infrastructure monitoring presents another substantial market opportunity. Aging bridges, buildings, and pipelines worldwide require continuous monitoring to prevent catastrophic failures. Government initiatives focused on infrastructure modernization in developed countries are allocating significant budgets toward implementing automated damage detection technologies. For instance, the European Union's infrastructure renewal program has earmarked €15 billion specifically for smart monitoring systems over the next five years.

The energy sector, particularly renewable energy, demonstrates growing demand for these systems. Wind turbine operators are implementing automated damage detection to monitor blade integrity and optimize maintenance schedules, reducing downtime and increasing energy production efficiency. Similarly, solar farm operators are adopting these technologies to detect panel damage and performance degradation.

Consumer electronics manufacturers are also exploring applications for self-healing materials and damage detection systems in smartphones, tablets, and wearable devices. This represents an emerging market segment with substantial growth potential as consumers increasingly value product longevity and durability.

Market research indicates that end-users are primarily seeking systems that offer real-time monitoring capabilities, minimal false positives, integration with existing infrastructure, and cost-effective implementation. There is particularly strong demand for solutions that combine damage detection with automated or triggered healing mechanisms, creating comprehensive systems that not only identify problems but also initiate repair processes without human intervention.

Regional analysis shows North America currently leading the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate over the forecast period, driven by rapid industrialization, infrastructure development, and increasing technological adoption in countries like China, Japan, and South Korea.

Current State and Challenges in Self-Healing Technologies

Self-healing technologies have evolved significantly over the past decade, with current systems demonstrating varying degrees of effectiveness across different material platforms. Polymer-based self-healing materials have reached commercial maturity in certain applications, while ceramic and metal-based systems remain predominantly in research phases. The integration of automated damage detection with triggered healing mechanisms represents the cutting edge of this field, though significant challenges persist.

Current detection methodologies primarily rely on embedded sensor networks, acoustic emission monitoring, electrical resistance measurements, and optical fiber systems. While these approaches have proven effective in laboratory settings, their implementation in real-world environments faces substantial limitations regarding sensitivity, reliability, and durability under harsh operating conditions. Particularly challenging is the detection of microcracks before they propagate to critical failure points.

The healing triggering mechanisms present another set of technical hurdles. Contemporary systems employ various stimuli including thermal activation, electromagnetic fields, pH changes, and mechanical pressure. However, these mechanisms often require external intervention or significant energy input, limiting their autonomy and efficiency. The development of truly autonomous systems capable of both detecting damage and initiating healing without external intervention remains elusive.

Material compatibility issues further complicate advancement in this domain. The integration of sensing elements with healing agents frequently compromises the structural integrity of the host material. Additionally, many current healing agents have limited shelf life or become ineffective after a single healing cycle, restricting their practical application in long-term deployments.

Scale-up and manufacturing challenges represent significant barriers to widespread adoption. Laboratory-scale successes often fail to translate to industrial production due to complexities in maintaining uniform distribution of healing agents, ensuring consistent triggering mechanisms, and preserving functionality during conventional manufacturing processes.

Energy requirements for both detection and healing activation present sustainability concerns. Many current systems require substantial energy inputs for healing processes, contradicting the efficiency goals that self-healing technologies aim to achieve. The development of low-energy or energy-harvesting approaches remains an active but challenging research direction.

Regulatory frameworks and standardization for testing and validating automated healing systems are notably underdeveloped. The absence of industry-wide standards for performance metrics, reliability assessment, and safety certification impedes commercial adoption and cross-comparison of different technological approaches.

Current detection methodologies primarily rely on embedded sensor networks, acoustic emission monitoring, electrical resistance measurements, and optical fiber systems. While these approaches have proven effective in laboratory settings, their implementation in real-world environments faces substantial limitations regarding sensitivity, reliability, and durability under harsh operating conditions. Particularly challenging is the detection of microcracks before they propagate to critical failure points.

The healing triggering mechanisms present another set of technical hurdles. Contemporary systems employ various stimuli including thermal activation, electromagnetic fields, pH changes, and mechanical pressure. However, these mechanisms often require external intervention or significant energy input, limiting their autonomy and efficiency. The development of truly autonomous systems capable of both detecting damage and initiating healing without external intervention remains elusive.

Material compatibility issues further complicate advancement in this domain. The integration of sensing elements with healing agents frequently compromises the structural integrity of the host material. Additionally, many current healing agents have limited shelf life or become ineffective after a single healing cycle, restricting their practical application in long-term deployments.

Scale-up and manufacturing challenges represent significant barriers to widespread adoption. Laboratory-scale successes often fail to translate to industrial production due to complexities in maintaining uniform distribution of healing agents, ensuring consistent triggering mechanisms, and preserving functionality during conventional manufacturing processes.

Energy requirements for both detection and healing activation present sustainability concerns. Many current systems require substantial energy inputs for healing processes, contradicting the efficiency goals that self-healing technologies aim to achieve. The development of low-energy or energy-harvesting approaches remains an active but challenging research direction.

Regulatory frameworks and standardization for testing and validating automated healing systems are notably underdeveloped. The absence of industry-wide standards for performance metrics, reliability assessment, and safety certification impedes commercial adoption and cross-comparison of different technological approaches.

Current Technical Solutions for Triggered Healing Systems

01 Sensor-based damage detection systems

These systems utilize various sensors to detect damage in structures or materials. The sensors can monitor parameters such as strain, vibration, temperature, or acoustic emissions to identify potential damage. Once damage is detected, the system can trigger appropriate healing mechanisms or alert maintenance personnel. These automated systems provide real-time monitoring and can detect damage at early stages before it becomes critical.- Sensor-based damage detection systems: These systems utilize various sensors to detect damage in structures or materials. The sensors can monitor parameters such as strain, vibration, temperature, or acoustic emissions to identify potential damage. Once damage is detected, the system can trigger appropriate healing mechanisms or alert maintenance personnel. These automated systems provide continuous monitoring capabilities, allowing for early detection of damage before it becomes critical.

- Self-healing materials with embedded healing agents: These systems incorporate microencapsulated healing agents within materials that are automatically released when damage occurs. When cracks or other damage breaks the microcapsules, the healing agents flow into the damaged area and polymerize or solidify to repair the damage. This approach enables autonomous healing without external intervention, extending the lifespan of materials and structures while maintaining their structural integrity.

- Smart infrastructure monitoring systems: These systems are designed specifically for infrastructure applications such as bridges, buildings, and roads. They combine networks of sensors with data analytics to continuously monitor structural health and detect damage. When damage is detected, the systems can automatically trigger maintenance protocols or activate integrated healing mechanisms. These solutions help prevent catastrophic failures and optimize maintenance schedules based on actual condition rather than time-based intervals.

- AI and machine learning for damage prediction: These systems leverage artificial intelligence and machine learning algorithms to analyze sensor data and predict potential damage before it occurs. By recognizing patterns and anomalies in the data, these systems can identify early warning signs of damage and trigger preventive measures. The predictive capabilities allow for proactive maintenance and can significantly reduce downtime and repair costs by addressing issues before they develop into serious problems.

- Integrated damage detection and healing systems for vehicles: These systems are specifically designed for automotive and aerospace applications, providing real-time monitoring of critical components. They can detect impacts, fatigue, or wear in vehicle structures and automatically initiate healing processes or alert operators to potential issues. Some systems incorporate vascular networks that deliver healing agents to damaged areas, while others use shape-memory materials that can return to their original form after deformation.

02 Self-healing materials with embedded healing agents

These systems incorporate microencapsulated healing agents within materials that are automatically released when damage occurs. When cracks or other damage breaks the microcapsules, the healing agents flow into the damaged area and initiate a repair process. This approach enables autonomous healing without external intervention, extending the lifespan of materials and structures while maintaining their integrity and performance.Expand Specific Solutions03 AI and machine learning for damage prediction and detection

Advanced systems that employ artificial intelligence and machine learning algorithms to analyze data from monitoring systems and predict potential damage before it occurs. These systems can learn from historical data patterns to improve detection accuracy over time. The AI-based approach enables more sophisticated damage assessment, reduces false alarms, and can prioritize repairs based on severity and criticality of the detected damage.Expand Specific Solutions04 Networked monitoring systems for infrastructure

Comprehensive monitoring networks that integrate multiple sensors and communication technologies to detect damage across large-scale infrastructure such as bridges, buildings, or pipelines. These systems collect and transmit data to central monitoring stations for analysis and response coordination. The networked approach allows for coordinated monitoring of complex structures and can trigger automated maintenance protocols when damage is detected.Expand Specific Solutions05 Biomimetic self-healing systems

Innovative systems inspired by biological healing processes found in nature. These systems mimic how living organisms repair themselves by incorporating vascular networks, cellular regeneration mechanisms, or other biologically-inspired approaches. When damage is detected, these systems can autonomously initiate healing processes that restore structural integrity and functionality, similar to how wounds heal in living tissues.Expand Specific Solutions

Core Patents in Automated Damage Response Technologies

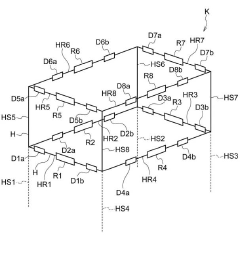

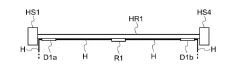

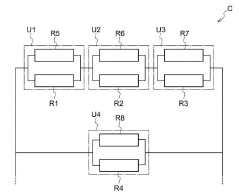

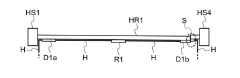

Damage detection system, damage detection method, and damage detection program

PatentInactiveJP2020201256A

Innovation

- A damage detection system utilizing a network of impedance elements and disconnection elements on building beams, measuring composite impedance values to identify damage based on changes in impedance, with cheaper resistive elements and alarm units for quick notification.

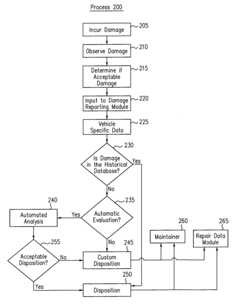

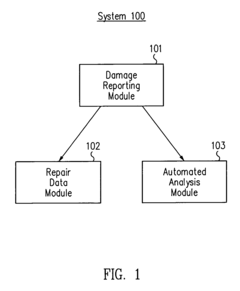

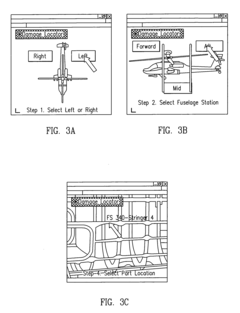

Automated damage assessment, report, and disposition

PatentActiveUS20070061109A1

Innovation

- A damage assessment system comprising a damage reporting module, an automated analysis module, and a repair data module that allows for user input, automated data object creation, and analysis using finite element analysis to determine corrective actions, reducing the need for manual communication and improving data retention and analysis efficiency.

Environmental Impact Assessment of Self-Healing Technologies

The environmental implications of self-healing technologies represent a critical dimension in evaluating their overall sustainability and long-term viability. When examining automated damage detection and triggered healing systems, several environmental considerations emerge across their lifecycle. The production phase of self-healing materials often involves specialized chemicals and compounds that may present toxicity concerns. For instance, microcapsule-based systems typically require synthetic polymers and chemical healing agents that could potentially release volatile organic compounds (VOCs) during manufacturing processes.

During the operational phase, self-healing technologies demonstrate significant environmental benefits through extended product lifespans. By autonomously repairing damage, these systems reduce the frequency of replacements and associated waste generation. Quantitative studies indicate that self-healing concrete structures can reduce lifetime carbon emissions by 35-50% compared to conventional concrete requiring regular replacement. Similarly, self-healing coatings for metal infrastructure have demonstrated potential to reduce maintenance-related emissions by up to 60% over a 25-year service period.

The energy consumption profile of automated damage detection systems presents a mixed environmental impact. While sensors and monitoring equipment require continuous power, advanced systems increasingly incorporate energy harvesting technologies such as piezoelectric elements that generate electricity from structural vibrations. This approach significantly reduces the carbon footprint associated with powering detection networks, particularly in remote infrastructure applications.

End-of-life considerations reveal both challenges and opportunities. Many current self-healing materials incorporate non-biodegradable components that may persist in the environment. However, research trends show promising developments in bio-based healing agents derived from renewable resources such as plant oils and bacterial cultures, which offer improved biodegradability profiles. These bio-inspired approaches could potentially transform the environmental footprint of self-healing technologies.

Water usage represents another important environmental factor, particularly for cementitious self-healing systems that may require moisture activation. While this increases water consumption during manufacturing, the reduction in replacement frequency creates a net positive water balance over the product lifecycle. Comprehensive lifecycle assessments indicate that advanced self-healing concrete formulations can reduce overall water consumption by approximately 28% compared to conventional concrete solutions requiring periodic replacement.

During the operational phase, self-healing technologies demonstrate significant environmental benefits through extended product lifespans. By autonomously repairing damage, these systems reduce the frequency of replacements and associated waste generation. Quantitative studies indicate that self-healing concrete structures can reduce lifetime carbon emissions by 35-50% compared to conventional concrete requiring regular replacement. Similarly, self-healing coatings for metal infrastructure have demonstrated potential to reduce maintenance-related emissions by up to 60% over a 25-year service period.

The energy consumption profile of automated damage detection systems presents a mixed environmental impact. While sensors and monitoring equipment require continuous power, advanced systems increasingly incorporate energy harvesting technologies such as piezoelectric elements that generate electricity from structural vibrations. This approach significantly reduces the carbon footprint associated with powering detection networks, particularly in remote infrastructure applications.

End-of-life considerations reveal both challenges and opportunities. Many current self-healing materials incorporate non-biodegradable components that may persist in the environment. However, research trends show promising developments in bio-based healing agents derived from renewable resources such as plant oils and bacterial cultures, which offer improved biodegradability profiles. These bio-inspired approaches could potentially transform the environmental footprint of self-healing technologies.

Water usage represents another important environmental factor, particularly for cementitious self-healing systems that may require moisture activation. While this increases water consumption during manufacturing, the reduction in replacement frequency creates a net positive water balance over the product lifecycle. Comprehensive lifecycle assessments indicate that advanced self-healing concrete formulations can reduce overall water consumption by approximately 28% compared to conventional concrete solutions requiring periodic replacement.

Integration Strategies with IoT and Smart Infrastructure

The integration of Automated Damage Detection and Triggered Healing Systems with IoT and Smart Infrastructure represents a transformative approach to infrastructure management. By leveraging the interconnected capabilities of IoT sensors and smart infrastructure frameworks, these systems can create comprehensive monitoring networks that continuously assess structural integrity across various environments.

IoT integration enables real-time data collection through strategically positioned sensor arrays that monitor critical parameters including strain, vibration, temperature, and chemical composition changes. These sensors form a distributed network that communicates through standardized protocols such as MQTT, CoAP, or LoRaWAN, allowing for efficient data transmission even in challenging environments with limited connectivity.

Edge computing architectures play a crucial role in this integration by processing sensor data locally before transmission to central systems. This approach reduces latency in damage detection and enables immediate healing responses in time-sensitive scenarios. The implementation of AI algorithms at the edge further enhances the system's capability to distinguish between normal operational variations and actual damage events requiring intervention.

Smart infrastructure frameworks provide the backbone for these integrated systems through digital twin technology, which creates virtual replicas of physical assets. These digital twins continuously update with real-time data, enabling predictive analytics and simulation of various damage scenarios. The synchronization between physical infrastructure and digital models facilitates more accurate healing responses and resource allocation.

Data management strategies represent another critical component of successful integration. Cloud-based platforms with specialized data lakes store historical performance data, creating valuable repositories for machine learning algorithms to identify patterns and predict potential failures before they occur. These platforms must implement robust security protocols to protect sensitive infrastructure data from unauthorized access.

Integration with existing Building Management Systems (BMS) and Infrastructure Asset Management platforms ensures that automated healing systems operate within established maintenance frameworks. API-based connectivity allows for seamless information exchange between legacy systems and new healing technologies, maximizing the value of existing investments while incorporating advanced capabilities.

Energy harvesting technologies further enhance system sustainability by powering distributed sensors through ambient energy sources such as vibration, temperature differentials, or solar radiation. This approach reduces maintenance requirements and extends the operational lifespan of remote monitoring components, particularly in difficult-to-access locations.

Human-in-the-loop interfaces remain essential despite automation advances, providing oversight capabilities and intervention options when systems encounter unprecedented scenarios. These interfaces must balance comprehensive information display with intuitive design to facilitate rapid decision-making during critical events.

IoT integration enables real-time data collection through strategically positioned sensor arrays that monitor critical parameters including strain, vibration, temperature, and chemical composition changes. These sensors form a distributed network that communicates through standardized protocols such as MQTT, CoAP, or LoRaWAN, allowing for efficient data transmission even in challenging environments with limited connectivity.

Edge computing architectures play a crucial role in this integration by processing sensor data locally before transmission to central systems. This approach reduces latency in damage detection and enables immediate healing responses in time-sensitive scenarios. The implementation of AI algorithms at the edge further enhances the system's capability to distinguish between normal operational variations and actual damage events requiring intervention.

Smart infrastructure frameworks provide the backbone for these integrated systems through digital twin technology, which creates virtual replicas of physical assets. These digital twins continuously update with real-time data, enabling predictive analytics and simulation of various damage scenarios. The synchronization between physical infrastructure and digital models facilitates more accurate healing responses and resource allocation.

Data management strategies represent another critical component of successful integration. Cloud-based platforms with specialized data lakes store historical performance data, creating valuable repositories for machine learning algorithms to identify patterns and predict potential failures before they occur. These platforms must implement robust security protocols to protect sensitive infrastructure data from unauthorized access.

Integration with existing Building Management Systems (BMS) and Infrastructure Asset Management platforms ensures that automated healing systems operate within established maintenance frameworks. API-based connectivity allows for seamless information exchange between legacy systems and new healing technologies, maximizing the value of existing investments while incorporating advanced capabilities.

Energy harvesting technologies further enhance system sustainability by powering distributed sensors through ambient energy sources such as vibration, temperature differentials, or solar radiation. This approach reduces maintenance requirements and extends the operational lifespan of remote monitoring components, particularly in difficult-to-access locations.

Human-in-the-loop interfaces remain essential despite automation advances, providing oversight capabilities and intervention options when systems encounter unprecedented scenarios. These interfaces must balance comprehensive information display with intuitive design to facilitate rapid decision-making during critical events.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!