Self Healing Coatings On Textiles For Wearable Electronics

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Textile Coatings Background and Objectives

Self-healing textile coatings represent a revolutionary advancement in the field of wearable electronics, emerging from the convergence of materials science, textile engineering, and electronic technology. This innovation addresses one of the most significant challenges in wearable technology: durability and longevity under regular use conditions. The evolution of this technology can be traced back to early research on self-healing polymers in the late 1990s, which has since expanded to include applications specifically designed for textile substrates.

The technological trajectory has accelerated significantly over the past decade, driven by increasing demand for robust wearable devices across healthcare, fitness, military, and consumer electronics sectors. Initial developments focused primarily on mechanical self-healing properties, while recent advancements have incorporated electrical conductivity restoration capabilities—a critical feature for wearable electronic applications.

The primary objective of self-healing textile coating technology is to develop materials that can autonomously repair physical damage and restore electrical functionality without external intervention. This includes addressing micro-cracks, abrasions, and connectivity disruptions that occur during normal wear and washing cycles. Secondary objectives encompass ensuring biocompatibility, maintaining textile comfort properties, and achieving scalable manufacturing processes.

Current research aims to create multi-functional coatings that simultaneously provide electrical conductivity, mechanical flexibility, and self-healing capabilities while maintaining the inherent properties of textiles such as breathability, drapeability, and tactile comfort. The ideal coating should initiate healing processes automatically in response to damage triggers, whether mechanical stress, temperature changes, or electrical discontinuity.

Technical goals for next-generation self-healing textile coatings include reducing healing activation energy requirements, shortening healing response times from hours to minutes or seconds, extending the number of possible healing cycles, and maintaining consistent performance across varied environmental conditions. Additionally, there is significant focus on developing environmentally sustainable formulations that minimize toxic components and maximize biodegradability.

The convergence of nanotechnology with self-healing materials presents particularly promising avenues for advancement, with research exploring nanoparticle-enhanced healing mechanisms, graphene-based conductive networks, and stimuli-responsive polymers that can be triggered by multiple environmental factors. These developments point toward a future where electronic textiles possess unprecedented resilience and functionality, potentially transforming industries from healthcare monitoring to interactive fashion.

The technological trajectory has accelerated significantly over the past decade, driven by increasing demand for robust wearable devices across healthcare, fitness, military, and consumer electronics sectors. Initial developments focused primarily on mechanical self-healing properties, while recent advancements have incorporated electrical conductivity restoration capabilities—a critical feature for wearable electronic applications.

The primary objective of self-healing textile coating technology is to develop materials that can autonomously repair physical damage and restore electrical functionality without external intervention. This includes addressing micro-cracks, abrasions, and connectivity disruptions that occur during normal wear and washing cycles. Secondary objectives encompass ensuring biocompatibility, maintaining textile comfort properties, and achieving scalable manufacturing processes.

Current research aims to create multi-functional coatings that simultaneously provide electrical conductivity, mechanical flexibility, and self-healing capabilities while maintaining the inherent properties of textiles such as breathability, drapeability, and tactile comfort. The ideal coating should initiate healing processes automatically in response to damage triggers, whether mechanical stress, temperature changes, or electrical discontinuity.

Technical goals for next-generation self-healing textile coatings include reducing healing activation energy requirements, shortening healing response times from hours to minutes or seconds, extending the number of possible healing cycles, and maintaining consistent performance across varied environmental conditions. Additionally, there is significant focus on developing environmentally sustainable formulations that minimize toxic components and maximize biodegradability.

The convergence of nanotechnology with self-healing materials presents particularly promising avenues for advancement, with research exploring nanoparticle-enhanced healing mechanisms, graphene-based conductive networks, and stimuli-responsive polymers that can be triggered by multiple environmental factors. These developments point toward a future where electronic textiles possess unprecedented resilience and functionality, potentially transforming industries from healthcare monitoring to interactive fashion.

Market Analysis for Smart Textile Applications

The smart textile market is experiencing unprecedented growth, driven by advancements in wearable electronics and innovative coating technologies. The global smart textile market was valued at $3.8 billion in 2022 and is projected to reach $16.2 billion by 2030, growing at a CAGR of 19.6% during the forecast period. Self-healing coatings for textiles represent a particularly promising segment within this expanding market.

Consumer electronics applications currently dominate the smart textile market, accounting for approximately 40% of market share. Healthcare applications follow closely at 32%, with sports and fitness applications representing 18% of the market. Military and defense applications, though smaller at 10%, are showing the fastest growth rate due to increased investment in soldier protection systems incorporating smart textiles.

Regional analysis reveals North America as the current market leader with 38% market share, followed by Europe (32%), Asia-Pacific (24%), and rest of the world (6%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing manufacturing capabilities and rising consumer adoption of wearable technology in countries like China, Japan, and South Korea.

Key market drivers for self-healing coatings on textiles include increasing consumer demand for durable wearable electronics, growing awareness of sustainability benefits through extended product lifecycles, and rising applications in healthcare monitoring systems. The healthcare segment specifically shows promising growth potential, with remote patient monitoring applications expected to grow at 24.3% annually through 2030.

Market challenges include high initial production costs, with self-healing textiles currently commanding a 30-45% premium over conventional electronic textiles. Technical limitations in healing efficiency and durability under extreme conditions also remain barriers to widespread adoption. Additionally, consumer education regarding the benefits and proper care of self-healing textiles represents a significant market development challenge.

Consumer preference analysis indicates strong interest in self-healing capabilities, with 78% of surveyed consumers expressing willingness to pay premium prices for wearable electronics with extended durability. Comfort remains the primary purchase consideration (cited by 86% of respondents), followed by durability (74%) and washability (68%), all factors that self-healing coatings directly address.

The competitive landscape features established textile manufacturers partnering with chemical companies and electronics firms to develop proprietary self-healing solutions. Recent market entrants include technology startups focusing on specialized applications such as medical monitoring garments and high-performance athletic wear with integrated self-healing capabilities.

Consumer electronics applications currently dominate the smart textile market, accounting for approximately 40% of market share. Healthcare applications follow closely at 32%, with sports and fitness applications representing 18% of the market. Military and defense applications, though smaller at 10%, are showing the fastest growth rate due to increased investment in soldier protection systems incorporating smart textiles.

Regional analysis reveals North America as the current market leader with 38% market share, followed by Europe (32%), Asia-Pacific (24%), and rest of the world (6%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing manufacturing capabilities and rising consumer adoption of wearable technology in countries like China, Japan, and South Korea.

Key market drivers for self-healing coatings on textiles include increasing consumer demand for durable wearable electronics, growing awareness of sustainability benefits through extended product lifecycles, and rising applications in healthcare monitoring systems. The healthcare segment specifically shows promising growth potential, with remote patient monitoring applications expected to grow at 24.3% annually through 2030.

Market challenges include high initial production costs, with self-healing textiles currently commanding a 30-45% premium over conventional electronic textiles. Technical limitations in healing efficiency and durability under extreme conditions also remain barriers to widespread adoption. Additionally, consumer education regarding the benefits and proper care of self-healing textiles represents a significant market development challenge.

Consumer preference analysis indicates strong interest in self-healing capabilities, with 78% of surveyed consumers expressing willingness to pay premium prices for wearable electronics with extended durability. Comfort remains the primary purchase consideration (cited by 86% of respondents), followed by durability (74%) and washability (68%), all factors that self-healing coatings directly address.

The competitive landscape features established textile manufacturers partnering with chemical companies and electronics firms to develop proprietary self-healing solutions. Recent market entrants include technology startups focusing on specialized applications such as medical monitoring garments and high-performance athletic wear with integrated self-healing capabilities.

Current Challenges in Wearable Electronics Protection

Despite the rapid advancement of wearable electronics, their protection against environmental factors and mechanical stresses remains a significant challenge. Current wearable devices face multiple vulnerabilities that limit their durability and reliability in real-world applications. The integration of electronic components with textiles creates unique protection challenges not encountered in traditional electronics.

Moisture and sweat penetration represents one of the most pressing issues for wearable electronics. Human perspiration contains corrosive salts that can rapidly degrade electronic circuits and connections. Traditional protective coatings often fail to provide adequate protection while maintaining the flexibility and breathability required for comfortable wearables. Water vapor transmission rates of existing protective layers frequently fall short of what is needed for long-term operation in close contact with the human body.

Mechanical stress during normal wear constitutes another major challenge. Wearable electronics must withstand repeated bending, stretching, and compression while maintaining electrical functionality. Current protective coatings typically crack or delaminate after repeated deformation cycles, exposing sensitive components to environmental damage. Testing has shown that most commercial protective layers begin to fail after 1,000-5,000 bending cycles, far below the requirements for daily-use wearables.

Temperature fluctuations further complicate protection strategies. Wearable devices experience significant temperature variations from body heat, external environment, and internal component heating. These thermal cycles create expansion and contraction stresses that compromise coating integrity over time. Most existing protective solutions demonstrate optimal performance only within narrow temperature ranges, typically 20-35°C, limiting their practical application.

Chemical resistance presents additional difficulties, as wearables encounter various substances during normal use, including detergents during washing, cosmetics, and environmental pollutants. Current protective coatings often degrade when exposed to common household chemicals, reducing device lifespan. Studies indicate that repeated exposure to mild detergents can reduce coating effectiveness by up to 40% after just 10 washing cycles.

Manufacturing scalability remains problematic for advanced protective solutions. Many promising laboratory-developed coatings utilize processes incompatible with textile manufacturing workflows or require specialized equipment that limits commercial viability. The cost-performance ratio of current protection technologies often makes them prohibitively expensive for mass-market wearable products.

Biocompatibility and environmental concerns add another layer of complexity. As wearables maintain prolonged skin contact, protective coatings must meet stringent safety standards while avoiding potential allergens or irritants. Additionally, growing environmental regulations restrict the use of certain effective protective chemicals, forcing manufacturers to compromise between protection performance and regulatory compliance.

Moisture and sweat penetration represents one of the most pressing issues for wearable electronics. Human perspiration contains corrosive salts that can rapidly degrade electronic circuits and connections. Traditional protective coatings often fail to provide adequate protection while maintaining the flexibility and breathability required for comfortable wearables. Water vapor transmission rates of existing protective layers frequently fall short of what is needed for long-term operation in close contact with the human body.

Mechanical stress during normal wear constitutes another major challenge. Wearable electronics must withstand repeated bending, stretching, and compression while maintaining electrical functionality. Current protective coatings typically crack or delaminate after repeated deformation cycles, exposing sensitive components to environmental damage. Testing has shown that most commercial protective layers begin to fail after 1,000-5,000 bending cycles, far below the requirements for daily-use wearables.

Temperature fluctuations further complicate protection strategies. Wearable devices experience significant temperature variations from body heat, external environment, and internal component heating. These thermal cycles create expansion and contraction stresses that compromise coating integrity over time. Most existing protective solutions demonstrate optimal performance only within narrow temperature ranges, typically 20-35°C, limiting their practical application.

Chemical resistance presents additional difficulties, as wearables encounter various substances during normal use, including detergents during washing, cosmetics, and environmental pollutants. Current protective coatings often degrade when exposed to common household chemicals, reducing device lifespan. Studies indicate that repeated exposure to mild detergents can reduce coating effectiveness by up to 40% after just 10 washing cycles.

Manufacturing scalability remains problematic for advanced protective solutions. Many promising laboratory-developed coatings utilize processes incompatible with textile manufacturing workflows or require specialized equipment that limits commercial viability. The cost-performance ratio of current protection technologies often makes them prohibitively expensive for mass-market wearable products.

Biocompatibility and environmental concerns add another layer of complexity. As wearables maintain prolonged skin contact, protective coatings must meet stringent safety standards while avoiding potential allergens or irritants. Additionally, growing environmental regulations restrict the use of certain effective protective chemicals, forcing manufacturers to compromise between protection performance and regulatory compliance.

Existing Self-Healing Coating Solutions for Textiles

01 Microcapsule-based self-healing mechanisms

Self-healing coatings can be formulated with microcapsules containing healing agents that are released when the coating is damaged. When a crack or scratch occurs, the microcapsules rupture and release the healing agent, which then polymerizes or reacts to fill the damaged area. This mechanism provides autonomous healing without external intervention, extending the coating's service life and maintaining its protective properties.- Microcapsule-based self-healing mechanisms: Self-healing coatings can be formulated with microcapsules containing healing agents that are released when the coating is damaged. When the microcapsules rupture due to mechanical damage, the healing agent flows into the crack and polymerizes, effectively repairing the damage. This approach provides autonomous healing without external intervention and can significantly extend the service life of coatings by preventing corrosion and other forms of degradation.

- Intrinsic self-healing polymer networks: These self-healing coatings utilize polymer networks with reversible chemical bonds or dynamic crosslinking that can reform after being broken. The intrinsic healing mechanism relies on molecular mobility and the ability of the polymer chains to reconnect through hydrogen bonding, ionic interactions, or other reversible chemical reactions. When damage occurs, these materials can restore their structural integrity through molecular diffusion and rebonding without requiring additional healing agents.

- Nanoparticle-enhanced self-healing coatings: Incorporating nanoparticles such as silica, clay, or carbon nanotubes into coating formulations can enhance the self-healing properties. These nanoparticles can improve mechanical strength while facilitating the healing process by creating a network that promotes crack closure and material flow into damaged areas. Some nanoparticles also provide additional functionality such as corrosion inhibition or improved adhesion, making the self-healing coating more effective in harsh environments.

- Stimuli-responsive self-healing systems: These advanced coating systems respond to external stimuli such as heat, light, pH changes, or electrical current to activate the healing process. The stimuli trigger molecular rearrangement or chemical reactions that repair damage. For example, thermally activated systems use heat to increase polymer chain mobility and promote diffusion across damaged interfaces, while photo-responsive systems use light to initiate polymerization or crosslinking reactions in damaged areas.

- Bio-inspired self-healing coating technologies: Drawing inspiration from biological healing processes, these coatings incorporate principles found in nature, such as vascular networks or enzyme-catalyzed reactions. Some systems utilize hollow fibers or channels that deliver healing agents to damaged areas, mimicking blood vessels in living organisms. Others employ biomimetic approaches that replicate natural healing mechanisms through synthetic materials. These bio-inspired technologies often provide more efficient and sustainable self-healing solutions for various applications.

02 Polymer-based self-healing systems

Polymer-based self-healing coatings utilize various polymer chemistries such as reversible covalent bonds, dynamic non-covalent interactions, or shape memory polymers to achieve healing properties. These systems can repair damage through thermal activation, light exposure, or inherent molecular mobility. The polymers can flow into damaged areas and re-establish cross-links, restoring the coating's integrity and protective function.Expand Specific Solutions03 Nanoparticle-enhanced self-healing coatings

Incorporating nanoparticles such as silica, clay, or metal oxides into coating formulations can significantly enhance self-healing properties. These nanoparticles can improve mechanical strength while facilitating healing mechanisms through improved polymer mobility, catalytic activity, or by serving as reservoirs for healing agents. The nanostructured materials create a network that supports efficient crack closure and restoration of coating integrity.Expand Specific Solutions04 Stimuli-responsive self-healing coatings

These coatings respond to external stimuli such as temperature, pH, light, or electrical current to initiate the healing process. The stimuli trigger molecular rearrangement, phase changes, or chemical reactions that facilitate the repair of damaged areas. This approach allows for controlled healing that can be activated when needed, providing a versatile solution for various environmental conditions and damage scenarios.Expand Specific Solutions05 Bio-inspired self-healing coating technologies

Drawing inspiration from biological healing processes, these coatings incorporate biomimetic principles to achieve self-repair. They may utilize components like synthetic vascular networks, enzyme-catalyzed reactions, or biomolecules that mimic natural healing mechanisms. These bio-inspired approaches often result in more sustainable and environmentally friendly self-healing systems with enhanced efficiency and adaptability to different types of damage.Expand Specific Solutions

Leading Companies in Smart Textile Coatings

The self-healing coatings on textiles for wearable electronics market is in an early growth stage, characterized by increasing research activity but limited commercial deployment. The global market size is expanding as wearable technology adoption rises, with projections indicating significant growth potential. Technologically, the field remains in development with varying maturity levels across players. Leading research institutions like Penn State Research Foundation, Johns Hopkins University, and Nanyang Technological University are advancing fundamental science, while companies including EssilorLuxottica, Apple, and LG Chem are exploring commercial applications. Chinese universities (Jilin, Shenzhen, Xiamen) are making notable contributions, suggesting an emerging competitive landscape where academic-industrial partnerships will likely drive future innovation and market expansion.

Penn State Research Foundation

Technical Solution: Penn State Research Foundation has developed an innovative self-healing coating system specifically designed for textile-based wearable electronics that utilizes a combination of dynamic covalent chemistry and functional nanomaterials. Their approach incorporates Diels-Alder adducts within a polymer matrix that can undergo reversible bond formation when triggered by specific temperature ranges compatible with body heat. The coating system features a multi-layered architecture with a conductive layer containing silver nanowires or carbon nanotubes embedded within the self-healing polymer matrix. When damage occurs, the dynamic covalent bonds reform upon exposure to mild heat (35-40°C), effectively restoring both the structural integrity and electrical conductivity of the coating. Penn State researchers have demonstrated that their coatings can withstand over 500 damage-healing cycles while maintaining more than 90% of their original conductivity[3]. The foundation has also developed specialized application techniques that ensure strong adhesion to various textile substrates including cotton, polyester, and nylon blends, while maintaining the fabric's flexibility and breathability. Recent advancements include the incorporation of mechanochromic indicators that visually signal when damage has occurred and subsequent healing is complete.

Strengths: Exceptional cycling stability with minimal performance degradation over hundreds of healing events; healing mechanism activated by natural body heat; maintains textile comfort properties like breathability. Weaknesses: Requires specific temperature range for optimal healing; potential manufacturing complexity due to multi-layered structure; possible limitations in extreme environmental conditions.

Jilin University

Technical Solution: Jilin University has developed a sophisticated self-healing coating technology for wearable electronics textiles based on intrinsic self-healing polymers combined with functional nanocomposites. Their approach utilizes dynamic metal-ligand coordination bonds within a polyurethane matrix that enables autonomous healing at ambient conditions without external stimuli. The university's research team has created a unique formulation incorporating zinc ions that form reversible coordination bonds with carboxyl and pyridine groups in the polymer backbone, allowing for repeated healing cycles. For electrical functionality, they've integrated silver nanowires and reduced graphene oxide within this self-healing matrix, creating conductive pathways that can restore themselves after mechanical damage. Laboratory testing has demonstrated healing efficiencies exceeding 85% for both mechanical properties and electrical conductivity within 3 hours at room temperature[4]. Jilin's coating technology also features remarkable washability, withstanding over 50 standard machine washing cycles while maintaining self-healing capabilities. Their latest innovation includes photothermally responsive nanoparticles that can accelerate the healing process when exposed to ambient light, making the system more energy-efficient and practical for everyday wearable applications.

Strengths: Rapid autonomous healing without external energy input; excellent washability and durability in practical conditions; versatile application across multiple textile substrates. Weaknesses: Potential sensitivity to extreme pH conditions that may affect metal-ligand coordination; possible long-term degradation of healing efficiency after multiple cycles; challenges in maintaining uniform distribution of functional components during manufacturing.

Key Patents in Self-Healing Textile Technology

Composition for forming self-healing coating layer, coating layer and coating film

PatentActiveUS20180009993A1

Innovation

- A composition for forming a self-healing coating layer incorporating a reversible covalent compound with sterically hindered (thio)urea bonds and (meth)acrylate or vinyl-based functional groups, which introduces these bonds into the cross-link structure, allowing for preferential breaking and recombination under external forces, enhancing impact resistance and self-healing properties.

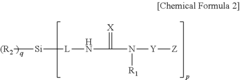

Self-healing electrical communication paths

PatentActiveUS20100122832A1

Innovation

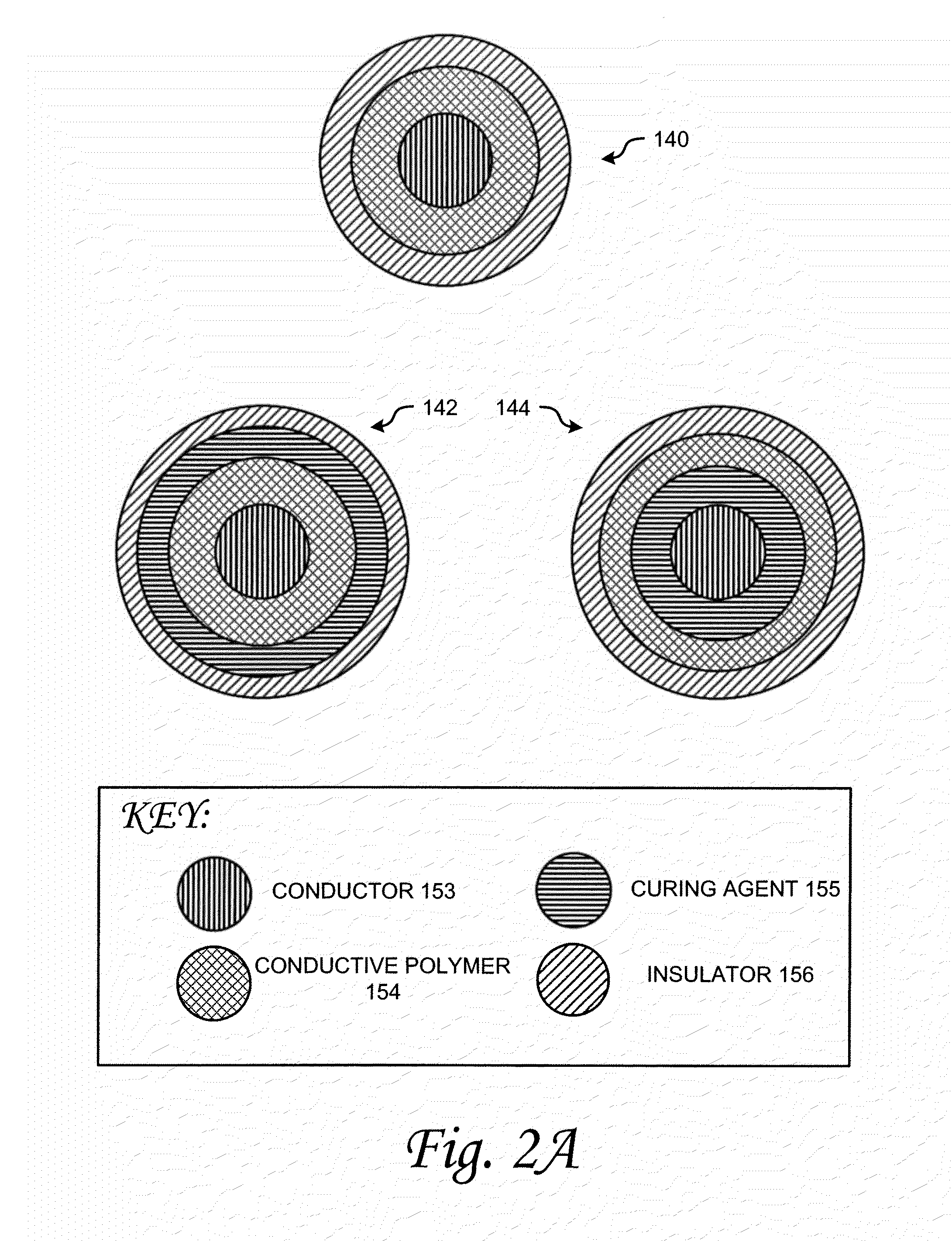

- A self-healing, textile-based network integrated into wearable garments, utilizing conductive inks, carbon nanotubes, and flowable conductive polymers that restore conductive paths upon damage, with redundant power and data networks for multi-path redundancy.

Sustainability Aspects of Self-Healing Textile Coatings

The sustainability of self-healing textile coatings for wearable electronics represents a critical dimension in evaluating their long-term viability and environmental impact. These innovative materials must align with growing global sustainability imperatives while maintaining their functional performance characteristics.

Environmental considerations form the foundation of sustainability assessment for self-healing coatings. Many conventional coating technologies rely on petroleum-based polymers and toxic solvents that pose significant environmental hazards throughout their lifecycle. In contrast, emerging bio-based self-healing systems utilize renewable resources such as plant-derived polymers, microcapsules containing natural healing agents, and biodegradable substrates that substantially reduce environmental footprint.

Life cycle assessment (LCA) studies reveal that self-healing coatings can significantly extend the functional lifespan of wearable electronic textiles. By autonomously repairing microcracks and damage, these coatings reduce the frequency of replacement and disposal, thereby decreasing overall material consumption and electronic waste generation. Research indicates potential lifespan extensions of 200-300% compared to conventional protective coatings.

Energy efficiency considerations also favor self-healing technologies. The ambient-temperature healing mechanisms employed by many self-healing systems require minimal or no external energy input, contrasting sharply with traditional repair methods that often demand energy-intensive manufacturing processes. This characteristic aligns with global efforts to reduce energy consumption across product lifecycles.

Waste reduction represents another sustainability advantage. Self-healing coatings minimize the need for chemical treatments and reapplication processes that generate hazardous waste. Additionally, some advanced formulations incorporate end-of-life biodegradability features, enabling the coating to decompose naturally after its useful service period without releasing harmful substances.

Regulatory compliance and green chemistry principles increasingly influence coating development. Research teams are prioritizing non-toxic, low-VOC (volatile organic compound) formulations that meet stringent environmental regulations while maintaining healing efficacy. This approach addresses both ecological concerns and human health considerations for wearable applications.

Economic sustainability must complement environmental benefits. Cost-effective production methods and scalable manufacturing processes are being developed to ensure commercial viability. Though initial production costs may exceed conventional alternatives, the extended service life and reduced maintenance requirements offer compelling long-term economic advantages that support broader market adoption.

Environmental considerations form the foundation of sustainability assessment for self-healing coatings. Many conventional coating technologies rely on petroleum-based polymers and toxic solvents that pose significant environmental hazards throughout their lifecycle. In contrast, emerging bio-based self-healing systems utilize renewable resources such as plant-derived polymers, microcapsules containing natural healing agents, and biodegradable substrates that substantially reduce environmental footprint.

Life cycle assessment (LCA) studies reveal that self-healing coatings can significantly extend the functional lifespan of wearable electronic textiles. By autonomously repairing microcracks and damage, these coatings reduce the frequency of replacement and disposal, thereby decreasing overall material consumption and electronic waste generation. Research indicates potential lifespan extensions of 200-300% compared to conventional protective coatings.

Energy efficiency considerations also favor self-healing technologies. The ambient-temperature healing mechanisms employed by many self-healing systems require minimal or no external energy input, contrasting sharply with traditional repair methods that often demand energy-intensive manufacturing processes. This characteristic aligns with global efforts to reduce energy consumption across product lifecycles.

Waste reduction represents another sustainability advantage. Self-healing coatings minimize the need for chemical treatments and reapplication processes that generate hazardous waste. Additionally, some advanced formulations incorporate end-of-life biodegradability features, enabling the coating to decompose naturally after its useful service period without releasing harmful substances.

Regulatory compliance and green chemistry principles increasingly influence coating development. Research teams are prioritizing non-toxic, low-VOC (volatile organic compound) formulations that meet stringent environmental regulations while maintaining healing efficacy. This approach addresses both ecological concerns and human health considerations for wearable applications.

Economic sustainability must complement environmental benefits. Cost-effective production methods and scalable manufacturing processes are being developed to ensure commercial viability. Though initial production costs may exceed conventional alternatives, the extended service life and reduced maintenance requirements offer compelling long-term economic advantages that support broader market adoption.

Washability and Durability Testing Standards

The development of washability and durability testing standards for self-healing coatings on textiles for wearable electronics represents a critical aspect of product validation. These standards ensure that the innovative materials can withstand real-world conditions while maintaining their functional properties. Currently, the testing landscape combines established textile testing protocols with emerging standards specific to electronic textiles.

Standard washing test methods such as ISO 6330 and AATCC 135 provide foundational frameworks for evaluating textile durability during laundering cycles. However, these conventional standards require significant adaptation when applied to electronically enhanced textiles with self-healing properties. The International Electrotechnical Commission (IEC) has begun addressing this gap through its TC 124 technical committee, which focuses specifically on wearable electronic devices and technologies.

Testing protocols typically evaluate multiple performance parameters simultaneously. These include electrical conductivity retention after repeated washing cycles, mechanical integrity of the coating-textile interface, and most importantly, the preservation of self-healing functionality after exposure to detergents, mechanical agitation, and temperature fluctuations. Industry leaders have established that a minimum of 20-30 washing cycles represents an acceptable durability threshold for consumer applications.

Abrasion resistance testing constitutes another crucial component of durability evaluation. The Martindale method (ISO 12947) and Taber abraser tests have been modified to accommodate the unique requirements of electronic textiles. These adaptations include specialized mounting techniques and electrical performance monitoring during the abrasion process to detect degradation patterns in real-time.

Environmental stress testing further complements washability assessments by subjecting samples to controlled humidity, UV exposure, and temperature cycling. ASTM D4459 for UV resistance and IEC 60068 for environmental testing provide relevant methodologies that have been adapted for self-healing electronic textiles. These tests are particularly important for evaluating the longevity of the self-healing mechanisms under various environmental stressors.

Emerging standards are increasingly incorporating accelerated aging protocols that simulate multiple years of use within compressed timeframes. These protocols typically combine washing cycles with wear simulation, environmental exposure, and mechanical stress in sequences designed to replicate real-world usage patterns. The development of these comprehensive testing methodologies represents a collaborative effort between textile institutes, electronics manufacturers, and standards organizations.

The harmonization of these diverse testing approaches remains an ongoing challenge for the industry. Several international consortia, including the IEEE P2725 working group and the Smart Textile Alliance, are working toward unified testing frameworks specifically designed for smart textiles with self-healing capabilities. These efforts aim to establish globally recognized benchmarks that can facilitate product development and market acceptance of this transformative technology.

Standard washing test methods such as ISO 6330 and AATCC 135 provide foundational frameworks for evaluating textile durability during laundering cycles. However, these conventional standards require significant adaptation when applied to electronically enhanced textiles with self-healing properties. The International Electrotechnical Commission (IEC) has begun addressing this gap through its TC 124 technical committee, which focuses specifically on wearable electronic devices and technologies.

Testing protocols typically evaluate multiple performance parameters simultaneously. These include electrical conductivity retention after repeated washing cycles, mechanical integrity of the coating-textile interface, and most importantly, the preservation of self-healing functionality after exposure to detergents, mechanical agitation, and temperature fluctuations. Industry leaders have established that a minimum of 20-30 washing cycles represents an acceptable durability threshold for consumer applications.

Abrasion resistance testing constitutes another crucial component of durability evaluation. The Martindale method (ISO 12947) and Taber abraser tests have been modified to accommodate the unique requirements of electronic textiles. These adaptations include specialized mounting techniques and electrical performance monitoring during the abrasion process to detect degradation patterns in real-time.

Environmental stress testing further complements washability assessments by subjecting samples to controlled humidity, UV exposure, and temperature cycling. ASTM D4459 for UV resistance and IEC 60068 for environmental testing provide relevant methodologies that have been adapted for self-healing electronic textiles. These tests are particularly important for evaluating the longevity of the self-healing mechanisms under various environmental stressors.

Emerging standards are increasingly incorporating accelerated aging protocols that simulate multiple years of use within compressed timeframes. These protocols typically combine washing cycles with wear simulation, environmental exposure, and mechanical stress in sequences designed to replicate real-world usage patterns. The development of these comprehensive testing methodologies represents a collaborative effort between textile institutes, electronics manufacturers, and standards organizations.

The harmonization of these diverse testing approaches remains an ongoing challenge for the industry. Several international consortia, including the IEEE P2725 working group and the Smart Textile Alliance, are working toward unified testing frameworks specifically designed for smart textiles with self-healing capabilities. These efforts aim to establish globally recognized benchmarks that can facilitate product development and market acceptance of this transformative technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!