Self Healing Coatings For Marine And Offshore Corrosion Control

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Corrosion Control Background and Objectives

Marine corrosion represents one of the most significant challenges in maritime and offshore industries, causing billions of dollars in damage annually. The harsh saline environment, combined with constant exposure to moisture, creates ideal conditions for accelerated corrosion of metal structures. Traditional protective measures have primarily relied on barrier coatings, sacrificial anodes, and corrosion inhibitors, which require regular maintenance and replacement, leading to operational downtime and increased costs.

The evolution of corrosion control technologies has progressed from simple oil-based paints to sophisticated multi-layer coating systems. However, even advanced conventional coatings eventually fail due to mechanical damage, environmental degradation, or inherent coating defects. This technological limitation has driven the search for more sustainable and autonomous protection systems, culminating in the emerging field of self-healing coatings.

Self-healing coatings represent a paradigm shift in corrosion protection strategy, moving from passive defense to active response mechanisms. These innovative materials can detect damage and initiate repair processes without external intervention, potentially extending service life and reducing maintenance requirements significantly. The concept draws inspiration from biological systems that naturally repair damage through various healing mechanisms.

The primary objective of self-healing coating technology for marine applications is to develop robust, long-lasting protective systems that can autonomously respond to coating damage and prevent corrosion initiation. Specific goals include extending maintenance intervals by at least 50%, reducing lifecycle costs by 30-40%, and minimizing environmental impact through reduced material consumption and fewer toxic compounds.

Current research focuses on several self-healing mechanisms, including microencapsulation of healing agents, reversible polymer networks, shape memory materials, and stimuli-responsive systems. Each approach offers unique advantages and faces distinct challenges in the marine environment, where factors such as hydrostatic pressure, biofouling, and UV degradation complicate implementation.

The development trajectory aims to progress from laboratory demonstrations to field-tested commercial products within the next decade. This transition requires addressing key technical challenges such as healing efficiency in submerged conditions, long-term stability of healing mechanisms, compatibility with existing coating systems, and cost-effective manufacturing processes.

Success in this field would revolutionize marine asset protection, particularly for critical infrastructure like offshore platforms, ships, pipelines, and port facilities. Beyond economic benefits, advanced self-healing coatings could enhance safety by reducing structural failures and contribute to sustainability goals by extending asset lifespans and reducing material consumption.

The evolution of corrosion control technologies has progressed from simple oil-based paints to sophisticated multi-layer coating systems. However, even advanced conventional coatings eventually fail due to mechanical damage, environmental degradation, or inherent coating defects. This technological limitation has driven the search for more sustainable and autonomous protection systems, culminating in the emerging field of self-healing coatings.

Self-healing coatings represent a paradigm shift in corrosion protection strategy, moving from passive defense to active response mechanisms. These innovative materials can detect damage and initiate repair processes without external intervention, potentially extending service life and reducing maintenance requirements significantly. The concept draws inspiration from biological systems that naturally repair damage through various healing mechanisms.

The primary objective of self-healing coating technology for marine applications is to develop robust, long-lasting protective systems that can autonomously respond to coating damage and prevent corrosion initiation. Specific goals include extending maintenance intervals by at least 50%, reducing lifecycle costs by 30-40%, and minimizing environmental impact through reduced material consumption and fewer toxic compounds.

Current research focuses on several self-healing mechanisms, including microencapsulation of healing agents, reversible polymer networks, shape memory materials, and stimuli-responsive systems. Each approach offers unique advantages and faces distinct challenges in the marine environment, where factors such as hydrostatic pressure, biofouling, and UV degradation complicate implementation.

The development trajectory aims to progress from laboratory demonstrations to field-tested commercial products within the next decade. This transition requires addressing key technical challenges such as healing efficiency in submerged conditions, long-term stability of healing mechanisms, compatibility with existing coating systems, and cost-effective manufacturing processes.

Success in this field would revolutionize marine asset protection, particularly for critical infrastructure like offshore platforms, ships, pipelines, and port facilities. Beyond economic benefits, advanced self-healing coatings could enhance safety by reducing structural failures and contribute to sustainability goals by extending asset lifespans and reducing material consumption.

Market Analysis for Self-Healing Coating Solutions

The global market for self-healing coatings in marine and offshore applications is experiencing significant growth, driven by increasing awareness of corrosion-related costs and the need for sustainable maintenance solutions. The marine industry alone faces annual corrosion costs exceeding $50 billion globally, with offshore structures particularly vulnerable due to constant exposure to harsh saline environments.

Current market analysis indicates that the self-healing coatings segment for marine applications is growing at a compound annual growth rate of approximately 18%, outpacing the broader protective coatings market which grows at 5-7% annually. This accelerated growth reflects the substantial value proposition these advanced coatings offer in extending asset lifespans and reducing maintenance requirements.

Regional market distribution shows North America and Europe currently dominating with approximately 60% market share collectively, primarily due to stringent environmental regulations and higher adoption rates of advanced technologies. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by expanding shipbuilding activities in China, South Korea, and Japan, alongside increasing offshore exploration in Southeast Asian waters.

End-user segmentation reveals that commercial shipping represents the largest application sector (42%), followed by offshore oil and gas installations (28%), naval vessels (18%), and recreational marine craft (12%). The offshore segment specifically shows the highest growth potential due to the extreme corrosion challenges faced in these environments and the prohibitive costs of maintenance operations.

Price sensitivity analysis indicates that despite premium pricing (typically 2.5-3 times higher than conventional coatings), self-healing solutions demonstrate compelling return on investment through extended maintenance intervals and reduced downtime. Market research shows customers are increasingly evaluating total lifecycle costs rather than initial application expenses.

Competitive landscape assessment reveals a market currently dominated by specialty chemical companies and coating manufacturers with strong R&D capabilities. Market concentration remains moderate with the top five players controlling approximately 45% of the market share, while numerous smaller specialized firms focus on niche applications or regional markets.

Customer adoption patterns show a transition from initial skepticism to growing acceptance, particularly among fleet operators and offshore platform managers who have documented maintenance cost reductions of 30-40% over asset lifespans. Case studies from early adopters have become powerful market drivers, accelerating adoption across the industry.

Current market analysis indicates that the self-healing coatings segment for marine applications is growing at a compound annual growth rate of approximately 18%, outpacing the broader protective coatings market which grows at 5-7% annually. This accelerated growth reflects the substantial value proposition these advanced coatings offer in extending asset lifespans and reducing maintenance requirements.

Regional market distribution shows North America and Europe currently dominating with approximately 60% market share collectively, primarily due to stringent environmental regulations and higher adoption rates of advanced technologies. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by expanding shipbuilding activities in China, South Korea, and Japan, alongside increasing offshore exploration in Southeast Asian waters.

End-user segmentation reveals that commercial shipping represents the largest application sector (42%), followed by offshore oil and gas installations (28%), naval vessels (18%), and recreational marine craft (12%). The offshore segment specifically shows the highest growth potential due to the extreme corrosion challenges faced in these environments and the prohibitive costs of maintenance operations.

Price sensitivity analysis indicates that despite premium pricing (typically 2.5-3 times higher than conventional coatings), self-healing solutions demonstrate compelling return on investment through extended maintenance intervals and reduced downtime. Market research shows customers are increasingly evaluating total lifecycle costs rather than initial application expenses.

Competitive landscape assessment reveals a market currently dominated by specialty chemical companies and coating manufacturers with strong R&D capabilities. Market concentration remains moderate with the top five players controlling approximately 45% of the market share, while numerous smaller specialized firms focus on niche applications or regional markets.

Customer adoption patterns show a transition from initial skepticism to growing acceptance, particularly among fleet operators and offshore platform managers who have documented maintenance cost reductions of 30-40% over asset lifespans. Case studies from early adopters have become powerful market drivers, accelerating adoption across the industry.

Self-Healing Technology Status and Challenges

Self-healing coatings represent a significant advancement in corrosion protection technology for marine and offshore applications. Currently, these innovative coatings are being developed and implemented across various stages of technological maturity, from laboratory research to commercial deployment. The global research landscape shows concentrated efforts in North America, Europe, and East Asia, with emerging contributions from other regions.

The fundamental challenge in marine environments stems from the aggressive combination of saltwater, UV radiation, mechanical stress, and biological fouling that accelerates coating degradation. Traditional protective coatings typically fail after exposure to these harsh conditions, requiring costly maintenance and replacement cycles that impact operational efficiency of marine vessels and offshore structures.

Self-healing coating technologies can be categorized into several approaches based on their healing mechanisms. Microencapsulation systems, where healing agents are stored in microscopic capsules that rupture upon damage, have shown promising results in laboratory settings but face stability challenges in long-term marine exposure. Vascular network systems, mimicking biological circulatory systems, offer continuous healing agent delivery but present significant manufacturing complexity for large-scale marine applications.

Intrinsic self-healing materials, which can repair damage through inherent chemical or physical processes without external intervention, show particular promise for marine environments. However, these materials often demonstrate limited healing efficiency under submerged conditions or at lower temperatures typical of deep-sea applications.

Technical limitations currently hindering widespread adoption include healing efficiency in submerged environments, long-term durability under cyclic loading, compatibility with existing coating systems, and cost-effective manufacturing at industrial scale. The healing response time remains problematic for rapid corrosion scenarios, with most current technologies requiring hours or days to effectively seal breaches.

Regulatory challenges further complicate advancement, as novel chemical components in self-healing formulations must meet increasingly stringent environmental regulations for marine applications. The leaching of healing agents into marine ecosystems presents both technical and regulatory hurdles that researchers must address.

Despite these challenges, recent breakthroughs in stimuli-responsive polymers and bio-inspired healing mechanisms have demonstrated significant potential for overcoming current limitations. Multi-functional coatings that combine self-healing with anti-fouling or ice-phobic properties represent the cutting edge of research, potentially offering comprehensive protection systems for marine environments.

The fundamental challenge in marine environments stems from the aggressive combination of saltwater, UV radiation, mechanical stress, and biological fouling that accelerates coating degradation. Traditional protective coatings typically fail after exposure to these harsh conditions, requiring costly maintenance and replacement cycles that impact operational efficiency of marine vessels and offshore structures.

Self-healing coating technologies can be categorized into several approaches based on their healing mechanisms. Microencapsulation systems, where healing agents are stored in microscopic capsules that rupture upon damage, have shown promising results in laboratory settings but face stability challenges in long-term marine exposure. Vascular network systems, mimicking biological circulatory systems, offer continuous healing agent delivery but present significant manufacturing complexity for large-scale marine applications.

Intrinsic self-healing materials, which can repair damage through inherent chemical or physical processes without external intervention, show particular promise for marine environments. However, these materials often demonstrate limited healing efficiency under submerged conditions or at lower temperatures typical of deep-sea applications.

Technical limitations currently hindering widespread adoption include healing efficiency in submerged environments, long-term durability under cyclic loading, compatibility with existing coating systems, and cost-effective manufacturing at industrial scale. The healing response time remains problematic for rapid corrosion scenarios, with most current technologies requiring hours or days to effectively seal breaches.

Regulatory challenges further complicate advancement, as novel chemical components in self-healing formulations must meet increasingly stringent environmental regulations for marine applications. The leaching of healing agents into marine ecosystems presents both technical and regulatory hurdles that researchers must address.

Despite these challenges, recent breakthroughs in stimuli-responsive polymers and bio-inspired healing mechanisms have demonstrated significant potential for overcoming current limitations. Multi-functional coatings that combine self-healing with anti-fouling or ice-phobic properties represent the cutting edge of research, potentially offering comprehensive protection systems for marine environments.

Current Self-Healing Coating Mechanisms

01 Microcapsule-based self-healing coatings

These coatings incorporate microcapsules containing healing agents that are released when the coating is damaged. When a crack forms, the microcapsules rupture and release the healing agent, which polymerizes or reacts to seal the crack and prevent corrosion. This technology provides autonomous healing without external intervention, extending the service life of coated surfaces exposed to corrosive environments.- Microcapsule-based self-healing coatings: Self-healing coatings containing microcapsules filled with healing agents provide effective corrosion control. When the coating is damaged, the microcapsules rupture and release healing agents that polymerize or react to form a protective barrier, automatically repairing the damaged area and preventing corrosion from spreading. These systems can incorporate various healing agents including epoxy resins, polyurethanes, and siloxanes that form protective films when released.

- Polymer-based self-healing mechanisms: Advanced polymer systems with intrinsic self-healing capabilities offer effective corrosion protection. These coatings utilize reversible chemical bonds, such as Diels-Alder reactions, hydrogen bonding, or ionic interactions that can reform after damage occurs. Some formulations incorporate shape memory polymers that return to their original configuration when triggered by environmental stimuli like temperature or pH changes, effectively sealing cracks and preventing corrosion initiation.

- Nanocontainer and nanoparticle technologies: Nanocontainers and nanoparticles enhance self-healing corrosion protection by providing controlled release of corrosion inhibitors. These systems can be triggered by environmental changes such as pH shifts that occur during corrosion processes. Nanoparticles including silica, layered double hydroxides, and halloysite nanotubes can be loaded with corrosion inhibitors and incorporated into coating matrices, creating responsive systems that release protective agents precisely when and where corrosion begins.

- Bio-inspired self-healing coatings: Bio-inspired approaches to self-healing coatings mimic natural healing processes found in biological systems. These coatings incorporate components like chitosan, plant extracts, or bacterial systems that respond to environmental triggers. Some formulations contain microorganisms that produce protective compounds when exposed to corrosive conditions, while others utilize plant-derived compounds with inherent corrosion inhibition properties that can migrate to damaged areas and form protective films.

- Smart coating systems with multiple healing mechanisms: Advanced multi-functional coating systems combine several self-healing mechanisms to provide comprehensive corrosion protection. These systems may integrate microcapsules, nanocontainers, and intrinsic self-healing polymers in a layered architecture. Some formulations incorporate stimuli-responsive components that can be activated by external triggers such as light, electrical current, or magnetic fields, allowing for on-demand healing and corrosion control even in challenging environments.

02 Polymer-based self-healing systems

Polymer-based self-healing coatings utilize specialized polymers that can reconnect or reform bonds when damaged. These systems may incorporate dynamic covalent bonds, supramolecular interactions, or shape memory polymers that respond to environmental stimuli such as temperature or pH changes. The polymers can flow into damaged areas and re-establish protective barriers, providing effective corrosion control through continuous repair of the coating matrix.Expand Specific Solutions03 Nanocontainer and nanocomposite technologies

These advanced coatings incorporate nanoscale containers or nanoparticles that store and release corrosion inhibitors in response to environmental triggers. The nanocontainers may be loaded with corrosion inhibitors, pH buffers, or other active agents that are released only when corrosion begins. Nanocomposite structures enhance the mechanical properties of the coating while providing controlled release of protective agents, offering superior long-term corrosion protection.Expand Specific Solutions04 Bio-inspired self-healing mechanisms

These coatings mimic biological healing processes found in nature. They may incorporate biomimetic materials, enzymes, or biological compounds that facilitate healing responses similar to those in living organisms. Some systems use vascular networks similar to blood vessels to deliver healing agents to damaged areas. These bio-inspired approaches provide sustainable and environmentally friendly solutions for corrosion control with minimal toxic components.Expand Specific Solutions05 Smart coating systems with multiple healing mechanisms

These advanced coating systems combine multiple self-healing strategies to provide comprehensive corrosion protection under various conditions. They may integrate microcapsules, shape-memory polymers, and stimuli-responsive materials in a layered structure. Some incorporate sensors that detect corrosion at early stages and trigger appropriate healing responses. These multi-functional coatings offer redundant protection mechanisms and can adapt to different types of damage and environmental conditions.Expand Specific Solutions

Key Industry Players in Marine Protective Coatings

The marine self-healing coating market is in a growth phase, with increasing demand driven by rising awareness of corrosion costs in maritime industries. The global market is projected to expand significantly as offshore structures and vessels require more durable protection solutions. Leading research institutions like Jilin University, Northwestern University, and Max Planck Society are advancing fundamental technologies, while commercial players such as Autonomic Materials, Inc. have begun commercializing self-healing solutions. Major industrial corporations including Siemens, Boeing, and Petróleo Brasileiro are investing in application-specific developments. The technology shows varying maturity levels, with microencapsulation approaches being more established than newer biomimetic systems. Academic-industry partnerships between entities like University of Science & Technology Beijing and China Shipbuilding Industry are accelerating practical implementations for harsh marine environments.

Jilin University

Technical Solution: Jilin University has developed an innovative self-healing coating system based on supramolecular chemistry principles for marine applications. Their approach utilizes dynamic covalent bonds and non-covalent interactions that can reform after being broken, enabling autonomous healing of coating damage. The university's research team has created a multi-functional coating incorporating polyurethane networks modified with disulfide bonds and hydrogen bonding sites that facilitate self-healing at ambient temperatures in marine environments[1]. The coating system also integrates controlled-release corrosion inhibitors within mesoporous silica nanocontainers that respond to pH changes occurring at corrosion sites. Laboratory testing has demonstrated that these coatings can heal scratches up to 200 μm wide within 24 hours in simulated seawater conditions, with electrochemical impedance spectroscopy showing restoration of barrier properties to 85-95% of the original coating integrity[3]. The university has further enhanced this technology by incorporating graphene oxide nanosheets functionalized with self-healing polymers, which significantly improve the mechanical properties while maintaining healing capabilities.

Strengths: Excellent healing efficiency at ambient temperatures without external stimuli; environmentally responsive release of corrosion inhibitors; strong fundamental research backing with comprehensive characterization. Weaknesses: Currently limited to laboratory scale demonstrations; potential challenges in scaling up production; relatively slow healing response time compared to some competing technologies.

Autonomic Materials, Inc.

Technical Solution: Autonomic Materials has developed a pioneering microencapsulation-based self-healing coating system specifically designed for marine and offshore applications. Their technology incorporates microcapsules containing reactive healing agents that are dispersed throughout the coating matrix. When mechanical damage occurs, these capsules rupture and release the healing agents which polymerize upon contact with environmental catalysts or secondary components, effectively sealing cracks and preventing corrosion initiation[1]. The company's proprietary formulations include specialized isocyanate and polyamine chemistries encapsulated in urea-formaldehyde shells that remain stable in harsh marine environments but activate quickly when needed. Their coatings have demonstrated the ability to autonomously heal multiple damage events and provide extended protection even after significant mechanical impacts, with field tests showing up to 5x longer protection compared to conventional marine coatings[3].

Strengths: Proven commercial viability with multiple successful deployments in marine environments; ability to respond to multiple damage events without external intervention; compatibility with existing coating application systems. Weaknesses: Higher initial cost compared to traditional coatings; limited shelf life of reactive components; potential environmental concerns regarding some encapsulated chemicals.

Critical Patents in Marine Self-Healing Technologies

Method for forming a self-healing corrosion preventative film

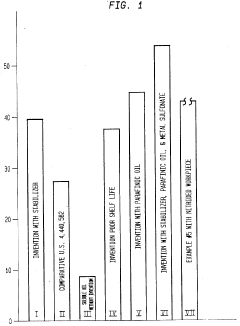

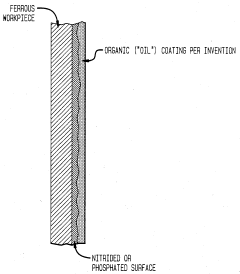

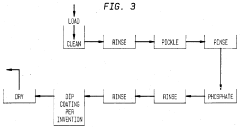

PatentInactiveUS4748055A

Innovation

- The use of emulsions produced from oil-based concentrates comprising petroleum oils, siloxanes, organic salts derived from polyfunctional long chain organic compounds, and sorbitan derivatives, which are applied over prepared ferrous metal surfaces like nitrided or phosphated workpieces, forming self-healing polymer coatings.

Environmental Impact and Sustainability Considerations

The environmental impact of marine coatings has become a critical consideration in the development and application of self-healing coatings for corrosion control. Traditional anti-corrosion solutions often contain heavy metals and biocides that pose significant threats to marine ecosystems. Self-healing coatings represent a promising alternative with potentially reduced environmental footprints, as they can extend service life and minimize the need for frequent reapplication and maintenance.

The leaching of toxic compounds from conventional marine coatings has been linked to bioaccumulation in marine organisms and disruption of aquatic food chains. Self-healing coatings, particularly those utilizing bio-based healing agents and environmentally benign catalysts, can substantially reduce these harmful effects. Recent studies indicate that microcapsule-based self-healing systems using renewable materials like tung oil or linseed oil demonstrate comparable performance to synthetic alternatives while offering enhanced biodegradability.

Life Cycle Assessment (LCA) studies comparing conventional and self-healing coating systems reveal significant sustainability advantages for the latter. The extended service life of self-healing coatings—potentially 1.5 to 3 times longer than conventional systems—translates to reduced raw material consumption, lower energy requirements for manufacturing replacement coatings, and decreased waste generation. These benefits compound when considering the carbon footprint associated with maintenance operations for offshore structures.

Regulatory frameworks worldwide are increasingly restricting the use of environmentally harmful substances in marine coatings. The International Maritime Organization (IMO) and regional bodies like the European Chemicals Agency have implemented stringent controls on biocides and heavy metals. Self-healing coating technologies align well with these evolving regulations, positioning them favorably in the market as environmentally preferable alternatives.

The development of fully biodegradable self-healing coating systems remains a significant challenge. Current research focuses on incorporating green chemistry principles into the design of healing agents and triggers. Promising approaches include the use of microorganisms that can precipitate protective minerals, plant-derived polymers with intrinsic healing capabilities, and bio-inspired designs that mimic natural self-healing processes found in organisms like mussels and barnacles.

Energy efficiency considerations also favor self-healing coatings, as smoother, continuously repaired surfaces reduce drag on marine vessels, potentially decreasing fuel consumption by 3-5% compared to vessels with deteriorated conventional coatings. This translates to substantial reductions in greenhouse gas emissions over the operational lifetime of ships and offshore structures.

The leaching of toxic compounds from conventional marine coatings has been linked to bioaccumulation in marine organisms and disruption of aquatic food chains. Self-healing coatings, particularly those utilizing bio-based healing agents and environmentally benign catalysts, can substantially reduce these harmful effects. Recent studies indicate that microcapsule-based self-healing systems using renewable materials like tung oil or linseed oil demonstrate comparable performance to synthetic alternatives while offering enhanced biodegradability.

Life Cycle Assessment (LCA) studies comparing conventional and self-healing coating systems reveal significant sustainability advantages for the latter. The extended service life of self-healing coatings—potentially 1.5 to 3 times longer than conventional systems—translates to reduced raw material consumption, lower energy requirements for manufacturing replacement coatings, and decreased waste generation. These benefits compound when considering the carbon footprint associated with maintenance operations for offshore structures.

Regulatory frameworks worldwide are increasingly restricting the use of environmentally harmful substances in marine coatings. The International Maritime Organization (IMO) and regional bodies like the European Chemicals Agency have implemented stringent controls on biocides and heavy metals. Self-healing coating technologies align well with these evolving regulations, positioning them favorably in the market as environmentally preferable alternatives.

The development of fully biodegradable self-healing coating systems remains a significant challenge. Current research focuses on incorporating green chemistry principles into the design of healing agents and triggers. Promising approaches include the use of microorganisms that can precipitate protective minerals, plant-derived polymers with intrinsic healing capabilities, and bio-inspired designs that mimic natural self-healing processes found in organisms like mussels and barnacles.

Energy efficiency considerations also favor self-healing coatings, as smoother, continuously repaired surfaces reduce drag on marine vessels, potentially decreasing fuel consumption by 3-5% compared to vessels with deteriorated conventional coatings. This translates to substantial reductions in greenhouse gas emissions over the operational lifetime of ships and offshore structures.

Durability Testing and Performance Standards

Durability testing and performance standards for self-healing coatings in marine and offshore environments represent critical aspects of their development and implementation. These coatings must withstand extreme conditions including constant saltwater exposure, UV radiation, temperature fluctuations, and mechanical stresses while maintaining their self-healing capabilities over extended periods.

Industry standards such as ASTM D6083, ISO 20340, and NORSOK M-501 provide baseline requirements for marine coatings, though specific standards for self-healing properties remain under development. Testing protocols typically involve accelerated aging tests including salt spray exposure (ASTM B117), cyclic corrosion testing (ISO 16701), and immersion testing (ASTM D870) to simulate years of environmental exposure in compressed timeframes.

Performance evaluation metrics focus on several key parameters. Self-healing efficiency is measured through artificial damage recovery assessment, where coatings are deliberately scratched and their healing response is monitored using techniques such as electrochemical impedance spectroscopy (EIS) and scanning electron microscopy (SEM). Healing time requirements vary by application, with critical infrastructure demanding faster recovery rates than less critical components.

Long-term protection capabilities are evaluated through multi-year field testing at marine test sites, where coated panels are exposed to actual ocean conditions and periodically examined. These real-world tests provide validation for laboratory results and reveal performance characteristics impossible to predict in accelerated testing environments.

Mechanical durability testing includes adhesion testing (ASTM D3359), impact resistance (ASTM D2794), and abrasion resistance (ASTM D4060) to ensure coatings maintain integrity under physical stresses common in marine operations. Self-healing coatings must demonstrate that their healing mechanisms remain functional after repeated mechanical challenges.

Emerging performance standards are beginning to incorporate sustainability metrics, including leaching tests to measure environmental impact of healing agents and lifecycle assessments to quantify the overall environmental footprint compared to conventional coating systems. The reduced maintenance requirements of self-healing coatings often translate to significant sustainability advantages.

Industry acceptance requires standardized testing protocols that can reliably predict service life, with many classification societies and regulatory bodies working to establish minimum performance thresholds for self-healing marine coatings. Current efforts focus on developing accelerated test methods that correlate more accurately with real-world performance, particularly for newer healing mechanisms like microcapsule-based and vascular network systems.

Industry standards such as ASTM D6083, ISO 20340, and NORSOK M-501 provide baseline requirements for marine coatings, though specific standards for self-healing properties remain under development. Testing protocols typically involve accelerated aging tests including salt spray exposure (ASTM B117), cyclic corrosion testing (ISO 16701), and immersion testing (ASTM D870) to simulate years of environmental exposure in compressed timeframes.

Performance evaluation metrics focus on several key parameters. Self-healing efficiency is measured through artificial damage recovery assessment, where coatings are deliberately scratched and their healing response is monitored using techniques such as electrochemical impedance spectroscopy (EIS) and scanning electron microscopy (SEM). Healing time requirements vary by application, with critical infrastructure demanding faster recovery rates than less critical components.

Long-term protection capabilities are evaluated through multi-year field testing at marine test sites, where coated panels are exposed to actual ocean conditions and periodically examined. These real-world tests provide validation for laboratory results and reveal performance characteristics impossible to predict in accelerated testing environments.

Mechanical durability testing includes adhesion testing (ASTM D3359), impact resistance (ASTM D2794), and abrasion resistance (ASTM D4060) to ensure coatings maintain integrity under physical stresses common in marine operations. Self-healing coatings must demonstrate that their healing mechanisms remain functional after repeated mechanical challenges.

Emerging performance standards are beginning to incorporate sustainability metrics, including leaching tests to measure environmental impact of healing agents and lifecycle assessments to quantify the overall environmental footprint compared to conventional coating systems. The reduced maintenance requirements of self-healing coatings often translate to significant sustainability advantages.

Industry acceptance requires standardized testing protocols that can reliably predict service life, with many classification societies and regulatory bodies working to establish minimum performance thresholds for self-healing marine coatings. Current efforts focus on developing accelerated test methods that correlate more accurately with real-world performance, particularly for newer healing mechanisms like microcapsule-based and vascular network systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!