Self Healing Coatings For Battery Pack Thermal Management Systems

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Coating Background and Objectives

Battery thermal management systems (BTMS) have emerged as a critical component in the evolution of electric vehicle (EV) technology, directly influencing battery performance, safety, and longevity. The development of these systems has progressed significantly over the past decade, transitioning from simple air cooling mechanisms to sophisticated liquid cooling systems and advanced thermal interface materials. Self-healing coatings represent the next frontier in this technological progression, offering potential solutions to persistent challenges in thermal management efficiency and durability.

The historical development of battery thermal management coatings began with basic insulative materials designed primarily to prevent thermal runaway. As EV adoption accelerated, these coatings evolved to incorporate more complex functionalities, including enhanced thermal conductivity, electrical insulation properties, and resistance to environmental factors. Recent advancements have focused on developing materials that can maintain optimal performance over extended periods despite the harsh operating conditions typical in battery environments.

Current technical trends in this field are moving toward multi-functional coatings that simultaneously address multiple aspects of battery thermal management. These include nano-enhanced composite materials that offer superior thermal conductivity, phase-change materials that provide temperature stabilization, and increasingly, self-healing capabilities that can repair microcracks and damage autonomously. This evolution reflects the industry's recognition that thermal management is not merely about heat dissipation but encompasses a complex interplay of factors affecting battery health and performance.

The primary objective of research into self-healing coatings for BTMS is to develop materials that can maintain optimal thermal conductivity pathways throughout the battery pack's operational lifetime. This involves creating coatings capable of detecting and repairing damage without external intervention, thereby preserving the integrity of thermal interfaces even under cyclic thermal stress, vibration, and chemical exposure. Secondary objectives include enhancing the coatings' compatibility with various battery chemistries, improving their environmental sustainability, and ensuring cost-effectiveness for mass production.

Technical goals for these advanced coatings include achieving healing response times under 24 hours, maintaining thermal conductivity above 5 W/m·K after multiple damage-healing cycles, ensuring electrical insulation properties above 10^9 Ω·cm, and demonstrating durability for at least 1000 charge-discharge cycles under typical EV operating conditions. Additionally, these materials must maintain their self-healing capabilities across a wide temperature range (-20°C to 60°C) to accommodate various operating environments.

The historical development of battery thermal management coatings began with basic insulative materials designed primarily to prevent thermal runaway. As EV adoption accelerated, these coatings evolved to incorporate more complex functionalities, including enhanced thermal conductivity, electrical insulation properties, and resistance to environmental factors. Recent advancements have focused on developing materials that can maintain optimal performance over extended periods despite the harsh operating conditions typical in battery environments.

Current technical trends in this field are moving toward multi-functional coatings that simultaneously address multiple aspects of battery thermal management. These include nano-enhanced composite materials that offer superior thermal conductivity, phase-change materials that provide temperature stabilization, and increasingly, self-healing capabilities that can repair microcracks and damage autonomously. This evolution reflects the industry's recognition that thermal management is not merely about heat dissipation but encompasses a complex interplay of factors affecting battery health and performance.

The primary objective of research into self-healing coatings for BTMS is to develop materials that can maintain optimal thermal conductivity pathways throughout the battery pack's operational lifetime. This involves creating coatings capable of detecting and repairing damage without external intervention, thereby preserving the integrity of thermal interfaces even under cyclic thermal stress, vibration, and chemical exposure. Secondary objectives include enhancing the coatings' compatibility with various battery chemistries, improving their environmental sustainability, and ensuring cost-effectiveness for mass production.

Technical goals for these advanced coatings include achieving healing response times under 24 hours, maintaining thermal conductivity above 5 W/m·K after multiple damage-healing cycles, ensuring electrical insulation properties above 10^9 Ω·cm, and demonstrating durability for at least 1000 charge-discharge cycles under typical EV operating conditions. Additionally, these materials must maintain their self-healing capabilities across a wide temperature range (-20°C to 60°C) to accommodate various operating environments.

Market Analysis for Self-Healing Thermal Management Solutions

The self-healing coatings market for battery thermal management systems is experiencing significant growth, driven by the rapid expansion of electric vehicle (EV) adoption worldwide. Current market valuations indicate that the global thermal management solutions for batteries reached approximately 2.5 billion USD in 2022, with self-healing technologies representing an emerging segment estimated at 380 million USD. Industry analysts project this specialized market to grow at a compound annual growth rate (CAGR) of 18-22% through 2030, substantially outpacing the broader thermal management market's growth rate of 8-10%.

The demand for these advanced coatings is primarily fueled by the automotive sector, which currently accounts for nearly 65% of the total market share. Major automotive manufacturers including Tesla, BYD, Volkswagen Group, and General Motors have initiated research partnerships with coating technology developers to integrate self-healing solutions into their next-generation EV battery systems.

Consumer electronics represents the second-largest application segment at 18% market share, with increasing interest from smartphone and laptop manufacturers seeking to address thermal management challenges in increasingly powerful portable devices. The aerospace and defense sectors, though smaller at 8% market share, demonstrate higher willingness to pay premium prices for high-performance self-healing thermal solutions.

Geographically, Asia-Pacific dominates the market with 42% share, led by China's massive EV manufacturing ecosystem and Japan's advanced materials innovation. North America follows at 28%, with significant research activities concentrated in California's technology corridor and Michigan's automotive research centers. Europe accounts for 24% of the market, with particularly strong growth in Germany and Scandinavian countries due to their aggressive EV adoption policies.

Market penetration analysis reveals that self-healing thermal coatings have achieved only 12-15% penetration within the broader thermal management solutions market, indicating substantial room for growth. The primary market restraints include high initial implementation costs, with self-healing solutions commanding a 30-40% price premium over conventional coatings, and technical challenges related to long-term durability under extreme temperature cycling conditions.

Customer surveys indicate that battery manufacturers prioritize three key performance metrics when evaluating self-healing thermal solutions: healing response time (with preferences for sub-minute activation), temperature regulation precision (±1°C tolerance), and lifecycle durability (minimum 8-year performance guarantee). These requirements are shaping product development roadmaps across the industry.

The competitive landscape remains fragmented, with specialized materials science companies holding technological advantages but facing challenges in scaling production to meet growing demand from tier-one automotive suppliers and battery manufacturers. This has created opportunities for strategic partnerships and acquisition activities, with five major deals valued over 50 million USD completed in the past 18 months.

The demand for these advanced coatings is primarily fueled by the automotive sector, which currently accounts for nearly 65% of the total market share. Major automotive manufacturers including Tesla, BYD, Volkswagen Group, and General Motors have initiated research partnerships with coating technology developers to integrate self-healing solutions into their next-generation EV battery systems.

Consumer electronics represents the second-largest application segment at 18% market share, with increasing interest from smartphone and laptop manufacturers seeking to address thermal management challenges in increasingly powerful portable devices. The aerospace and defense sectors, though smaller at 8% market share, demonstrate higher willingness to pay premium prices for high-performance self-healing thermal solutions.

Geographically, Asia-Pacific dominates the market with 42% share, led by China's massive EV manufacturing ecosystem and Japan's advanced materials innovation. North America follows at 28%, with significant research activities concentrated in California's technology corridor and Michigan's automotive research centers. Europe accounts for 24% of the market, with particularly strong growth in Germany and Scandinavian countries due to their aggressive EV adoption policies.

Market penetration analysis reveals that self-healing thermal coatings have achieved only 12-15% penetration within the broader thermal management solutions market, indicating substantial room for growth. The primary market restraints include high initial implementation costs, with self-healing solutions commanding a 30-40% price premium over conventional coatings, and technical challenges related to long-term durability under extreme temperature cycling conditions.

Customer surveys indicate that battery manufacturers prioritize three key performance metrics when evaluating self-healing thermal solutions: healing response time (with preferences for sub-minute activation), temperature regulation precision (±1°C tolerance), and lifecycle durability (minimum 8-year performance guarantee). These requirements are shaping product development roadmaps across the industry.

The competitive landscape remains fragmented, with specialized materials science companies holding technological advantages but facing challenges in scaling production to meet growing demand from tier-one automotive suppliers and battery manufacturers. This has created opportunities for strategic partnerships and acquisition activities, with five major deals valued over 50 million USD completed in the past 18 months.

Self-Healing Coating Technology Status and Challenges

Self-healing coating technology for battery pack thermal management systems has witnessed significant advancements globally, yet faces several critical challenges. Current research indicates that while the fundamental principles of self-healing mechanisms have been established, their application in battery thermal management contexts remains in early developmental stages. Leading research institutions in the United States, Germany, China, and South Korea have demonstrated promising results in laboratory settings, but commercial-scale implementation continues to be limited.

The primary technical challenge lies in developing coatings that can withstand the extreme temperature fluctuations typical in battery pack environments, which range from -40°C to over 80°C during operation. Conventional self-healing materials often lose their restorative capabilities at temperature extremes, creating a significant barrier to practical application in battery systems.

Another substantial obstacle is the integration of self-healing properties with thermal conductivity requirements. Current self-healing polymers and composites generally exhibit poor thermal conductivity, which contradicts the primary function of thermal management coatings. Research efforts to incorporate thermally conductive fillers often compromise the self-healing mechanisms, creating a complex engineering trade-off.

Durability under repeated healing cycles presents another significant challenge. Most existing self-healing coatings demonstrate diminishing efficacy after multiple healing events, with performance degradation occurring after 3-5 healing cycles. For battery applications requiring 8-10 years of operational life, this represents a substantial gap in technology readiness.

The chemical compatibility between self-healing coatings and battery components introduces additional complications. Many healing agents and catalysts can potentially react with battery materials or electrolytes if leakage occurs, raising safety concerns that must be addressed before widespread adoption.

From a manufacturing perspective, scalable production techniques for complex self-healing coating systems remain underdeveloped. Current laboratory-scale synthesis methods often involve multi-step processes that are difficult to translate to industrial production environments, increasing costs and limiting commercial viability.

Geographically, research leadership in this field shows distinct patterns. North American and European institutions lead in fundamental research and patent filings for novel self-healing mechanisms, while Asian manufacturers, particularly in Japan and South Korea, demonstrate advantages in integration technologies and production scaling. This distribution creates opportunities for international collaboration but also presents challenges in technology transfer and intellectual property protection.

The primary technical challenge lies in developing coatings that can withstand the extreme temperature fluctuations typical in battery pack environments, which range from -40°C to over 80°C during operation. Conventional self-healing materials often lose their restorative capabilities at temperature extremes, creating a significant barrier to practical application in battery systems.

Another substantial obstacle is the integration of self-healing properties with thermal conductivity requirements. Current self-healing polymers and composites generally exhibit poor thermal conductivity, which contradicts the primary function of thermal management coatings. Research efforts to incorporate thermally conductive fillers often compromise the self-healing mechanisms, creating a complex engineering trade-off.

Durability under repeated healing cycles presents another significant challenge. Most existing self-healing coatings demonstrate diminishing efficacy after multiple healing events, with performance degradation occurring after 3-5 healing cycles. For battery applications requiring 8-10 years of operational life, this represents a substantial gap in technology readiness.

The chemical compatibility between self-healing coatings and battery components introduces additional complications. Many healing agents and catalysts can potentially react with battery materials or electrolytes if leakage occurs, raising safety concerns that must be addressed before widespread adoption.

From a manufacturing perspective, scalable production techniques for complex self-healing coating systems remain underdeveloped. Current laboratory-scale synthesis methods often involve multi-step processes that are difficult to translate to industrial production environments, increasing costs and limiting commercial viability.

Geographically, research leadership in this field shows distinct patterns. North American and European institutions lead in fundamental research and patent filings for novel self-healing mechanisms, while Asian manufacturers, particularly in Japan and South Korea, demonstrate advantages in integration technologies and production scaling. This distribution creates opportunities for international collaboration but also presents challenges in technology transfer and intellectual property protection.

Current Self-Healing Coating Technical Solutions

01 Microcapsule-based self-healing mechanisms

Self-healing coatings can be formulated with microcapsules containing healing agents that are released when the coating is damaged. When the microcapsules rupture due to mechanical damage, the healing agent flows into the crack and polymerizes, effectively repairing the damage. This approach provides autonomous healing without external intervention and can significantly extend the service life of coatings by preventing corrosion and other forms of degradation.- Microcapsule-based self-healing mechanisms: Self-healing coatings can be formulated with microcapsules containing healing agents that are released when the coating is damaged. When cracks form in the coating, the microcapsules rupture and release the healing agents, which then polymerize or react to repair the damage. This mechanism provides autonomous healing without external intervention, extending the coating's service life and maintaining its protective properties.

- Polymer-based self-healing systems: Polymer-based self-healing systems utilize various polymer chemistries to achieve healing capabilities. These include thermoplastic polymers that can flow and rebond when heated, thermosetting polymers with reversible crosslinks, and supramolecular polymers with dynamic bonds. The polymers can reform broken bonds through mechanisms such as hydrogen bonding, ionic interactions, or Diels-Alder reactions, allowing the coating to recover its original properties after damage.

- Stimuli-responsive self-healing coatings: These coatings respond to external stimuli such as heat, light, pH changes, or electrical current to initiate the healing process. When exposed to the appropriate stimulus, the coating undergoes molecular rearrangement or chemical reactions that repair damage. For example, some coatings contain thermally reversible bonds that reform when heat is applied, while others use photochemical reactions triggered by UV light to restore damaged areas.

- Bio-inspired self-healing mechanisms: Bio-inspired self-healing coatings mimic natural healing processes found in biological systems. These include vascular networks that deliver healing agents to damaged areas, similar to blood vessels in living organisms, and gradient-based healing systems inspired by plant structures. Some formulations incorporate biomolecules or enzymes that catalyze healing reactions, while others use biomimetic materials that can reorganize their structure in response to damage.

- Nanocomposite self-healing coatings: Nanocomposite self-healing coatings incorporate nanomaterials such as nanoparticles, nanotubes, or nanosheets to enhance the healing capabilities. These nanomaterials can serve as reinforcing agents, catalysts for healing reactions, or carriers for healing agents. Some nanocomposites use magnetic nanoparticles that respond to magnetic fields to facilitate healing, while others employ carbon nanotubes or graphene to improve mechanical properties and create conductive pathways for electrical healing mechanisms.

02 Intrinsic self-healing polymer networks

Intrinsic self-healing coatings utilize reversible chemical bonds or dynamic crosslinking within the polymer network to enable healing. These systems can repair damage through mechanisms such as hydrogen bonding, ionic interactions, or Diels-Alder reactions when triggered by stimuli like heat or light. The advantage of intrinsic systems is that they can undergo multiple healing cycles without depleting healing agents, providing long-term protection and durability to the coated surface.Expand Specific Solutions03 Nanoparticle-enhanced self-healing coatings

Incorporating nanoparticles such as silica, clay, or carbon nanotubes into coating formulations can enhance self-healing properties. These nanoparticles can improve mechanical strength while facilitating the healing process by creating networks that promote molecular mobility and rebonding. Some nanoparticles also provide additional functionality such as corrosion inhibition or improved adhesion, resulting in multi-functional self-healing coating systems with superior performance characteristics.Expand Specific Solutions04 Environmentally-responsive self-healing mechanisms

Self-healing coatings can be designed to respond to environmental stimuli such as temperature, pH, humidity, or UV light. These smart coatings activate their healing mechanisms when specific environmental conditions are detected, providing targeted protection when needed. For example, some coatings release corrosion inhibitors in response to pH changes caused by corrosion initiation, while others utilize shape memory polymers that recover their original configuration when heated above a transition temperature.Expand Specific Solutions05 Bio-inspired self-healing coating technologies

Drawing inspiration from biological healing processes, these coatings incorporate biomimetic approaches such as vascular networks or enzyme-mediated healing mechanisms. Vascular systems mimic blood vessels by creating interconnected channels that can continuously supply healing agents to damaged areas. Enzyme-catalyzed healing utilizes biological catalysts to accelerate repair reactions under mild conditions. These bio-inspired approaches offer sustainable alternatives with efficient healing capabilities and reduced environmental impact.Expand Specific Solutions

Key Industry Players in Self-Healing Coating Development

The self-healing coatings market for battery pack thermal management systems is in an early growth stage, characterized by increasing research activity but limited commercial deployment. The global market is projected to expand significantly as electric vehicle adoption accelerates, with estimates suggesting a compound annual growth rate exceeding 15% through 2030. Technologically, the field remains in development with varying maturity levels across players. Leading research institutions like South China University of Technology, Penn State Research Foundation, and Ocean University of China are advancing fundamental science, while commercial entities including CNOOC Changzhou Paint & Coatings Industry Research Institute, BASF Corp., and Siemens AG are developing practical applications. Automotive manufacturers like GM Global Technology Operations are integrating these technologies into battery thermal management systems, indicating growing industry acceptance despite remaining technical challenges in durability and scalability.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced self-healing coatings for battery thermal management systems that utilize microcapsule technology. Their approach embeds microscopic capsules containing healing agents within the coating matrix applied to battery pack components. When damage occurs, these capsules rupture, releasing the healing agents that polymerize upon contact with catalysts also embedded in the coating or when exposed to the ambient environment. This system is particularly designed to address thermal cycling stresses in electric vehicle battery packs, where temperature fluctuations can cause coating cracks and subsequent thermal management inefficiencies. GM's solution incorporates thermally conductive fillers within the self-healing matrix to maintain optimal heat transfer properties even after healing events. The technology also features multi-stage healing mechanisms that can address both microcracks and larger structural damages through different healing pathways, ensuring long-term protection of the battery thermal management system.

Strengths: Specialized for automotive battery applications with proven performance in extreme temperature cycling conditions; integrated with existing manufacturing processes for scalability. Weaknesses: Healing agents may have limited shelf life; performance might degrade after multiple healing cycles; potential for increased coating thickness affecting thermal conductivity.

Korea Research Institute of Chemical Technology

Technical Solution: The Korea Research Institute of Chemical Technology (KRICT) has developed an innovative self-healing coating system for battery thermal management applications utilizing intrinsic self-healing polymers combined with thermally conductive ceramic nanoparticles. Their approach features a supramolecular polymer network with hydrogen bonding and π-π interactions that can autonomously repair damage without external stimuli. The coating incorporates boron nitride nanosheets and aluminum oxide particles to enhance thermal conductivity while maintaining the self-healing properties. KRICT's research has demonstrated that their coating can recover up to 95% of its original thermal conductivity after damage, with healing occurring within 6-12 hours at room temperature and accelerating at elevated temperatures typical in battery operation. The institute has also developed a specialized application method that ensures uniform distribution of the nanoparticles throughout the polymer matrix, preventing agglomeration that could compromise healing efficiency. Their system includes corrosion inhibitors that protect the underlying battery components even if the coating is temporarily compromised, providing an additional safety layer for the thermal management system.

Strengths: Exceptional room-temperature healing capabilities without requiring external stimuli; maintains high thermal conductivity even after multiple healing cycles; relatively simple manufacturing process compared to microcapsule-based systems. Weaknesses: Higher cost due to specialized polymer chemistry and nanoparticle components; potential environmental concerns with some of the nanomaterials used; limited data on very long-term performance (>5 years).

Critical Patents and Research in Self-Healing Materials

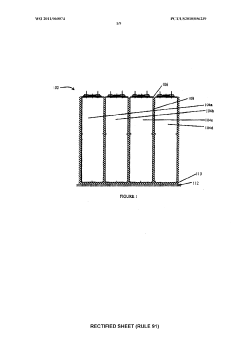

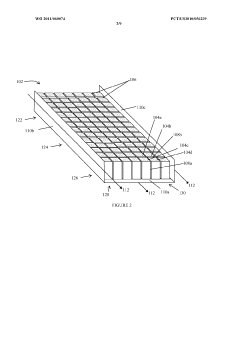

Thermal barrier coating system having self-healing ability

PatentWO2017018571A1

Innovation

- A heat shield coating system comprising a base material layer, a bonding layer, and a heat-shielding coating layer with a second material that transforms into a fluid to fill cracks and prevent their progression, enhancing interfacial stability and durability. The system includes a ZrO2-based ceramic as the primary material and a secondary material with low melting point or high fluidity, supported in a heat-resistant capsule, to maintain the heat shield function under thermal and mechanical stress.

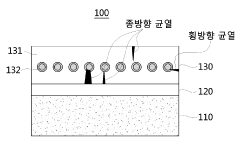

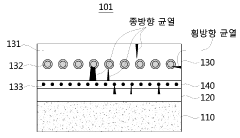

Battery thermal management systems and methods

PatentWO2011060074A9

Innovation

- A thermal management system comprising a battery pack with an interstitial member and thermally conductive plates, where a flowing fluid can reversibly change direction to optimize heat transfer between the battery cells, using thermally conductive materials like aluminum to maintain thermal homogeneity across the pack.

Environmental Impact and Sustainability Considerations

The development of self-healing coatings for battery pack thermal management systems necessitates careful consideration of environmental impacts and sustainability factors throughout their lifecycle. These innovative coatings, while offering significant performance benefits, must align with increasingly stringent environmental regulations and corporate sustainability goals.

Raw material sourcing represents a critical environmental consideration. Traditional coating materials often contain volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances. Self-healing coating technologies are increasingly incorporating bio-based polymers, renewable resources, and non-toxic alternatives that reduce environmental footprint while maintaining performance characteristics.

Manufacturing processes for self-healing coatings present both challenges and opportunities for sustainability. Energy consumption during production remains a concern, though advancements in low-temperature curing technologies and more efficient manufacturing methods are reducing the carbon footprint associated with coating production. Water-based formulations are gradually replacing solvent-based systems, significantly reducing VOC emissions during manufacturing and application.

The operational phase of self-healing coatings delivers substantial environmental benefits through extended service life of battery thermal management systems. By reducing the frequency of component replacement and maintenance, these coatings minimize waste generation and resource consumption over the battery pack lifecycle. This longevity factor represents a significant contribution to circular economy principles.

End-of-life considerations for self-healing coatings are increasingly important as electric vehicle adoption accelerates. Research is advancing in developing coatings that can be more easily separated from substrates during recycling processes, enhancing the recoverability of valuable battery materials. Biodegradable self-healing components are emerging as promising solutions that minimize environmental persistence after disposal.

Carbon footprint analysis reveals that while initial production of advanced self-healing coatings may require more energy than conventional alternatives, lifecycle assessments demonstrate net environmental benefits through extended service life and reduced maintenance requirements. Studies indicate potential carbon emission reductions of 15-30% over the full lifecycle when implementing these technologies in battery thermal management systems.

Regulatory compliance is evolving rapidly in this sector, with frameworks like the EU's REACH regulation and various global initiatives restricting hazardous substances influencing coating formulation. Forward-thinking manufacturers are proactively developing self-healing coating technologies that not only meet current standards but anticipate future regulatory requirements, positioning these solutions for long-term market viability while supporting broader sustainability objectives.

Raw material sourcing represents a critical environmental consideration. Traditional coating materials often contain volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances. Self-healing coating technologies are increasingly incorporating bio-based polymers, renewable resources, and non-toxic alternatives that reduce environmental footprint while maintaining performance characteristics.

Manufacturing processes for self-healing coatings present both challenges and opportunities for sustainability. Energy consumption during production remains a concern, though advancements in low-temperature curing technologies and more efficient manufacturing methods are reducing the carbon footprint associated with coating production. Water-based formulations are gradually replacing solvent-based systems, significantly reducing VOC emissions during manufacturing and application.

The operational phase of self-healing coatings delivers substantial environmental benefits through extended service life of battery thermal management systems. By reducing the frequency of component replacement and maintenance, these coatings minimize waste generation and resource consumption over the battery pack lifecycle. This longevity factor represents a significant contribution to circular economy principles.

End-of-life considerations for self-healing coatings are increasingly important as electric vehicle adoption accelerates. Research is advancing in developing coatings that can be more easily separated from substrates during recycling processes, enhancing the recoverability of valuable battery materials. Biodegradable self-healing components are emerging as promising solutions that minimize environmental persistence after disposal.

Carbon footprint analysis reveals that while initial production of advanced self-healing coatings may require more energy than conventional alternatives, lifecycle assessments demonstrate net environmental benefits through extended service life and reduced maintenance requirements. Studies indicate potential carbon emission reductions of 15-30% over the full lifecycle when implementing these technologies in battery thermal management systems.

Regulatory compliance is evolving rapidly in this sector, with frameworks like the EU's REACH regulation and various global initiatives restricting hazardous substances influencing coating formulation. Forward-thinking manufacturers are proactively developing self-healing coating technologies that not only meet current standards but anticipate future regulatory requirements, positioning these solutions for long-term market viability while supporting broader sustainability objectives.

Safety Standards and Certification Requirements

Safety standards and certification requirements for self-healing coatings in battery pack thermal management systems are governed by multiple regulatory frameworks that ensure both performance and safety. These standards vary across regions but generally focus on thermal stability, chemical compatibility, and long-term reliability under extreme conditions.

The International Electrotechnical Commission (IEC) has established IEC 62133 and IEC 61960 standards that address safety requirements for batteries, including thermal management systems. Self-healing coatings must comply with these standards by demonstrating resistance to thermal runaway and maintaining structural integrity during thermal cycling tests. Additionally, UL 2580 specifically addresses batteries for use in electric vehicles and includes requirements for materials used in thermal management systems.

ASTM International provides testing methodologies such as ASTM D7027 for scratch resistance and ASTM D2794 for impact resistance that are applicable to self-healing coatings. These tests evaluate the coating's ability to recover from mechanical damage, which is crucial for maintaining thermal management efficiency over time.

In the automotive sector, ISO 6469-1 outlines safety specifications for electrically propelled road vehicles, including requirements for battery thermal management systems. Self-healing coatings must meet these specifications to be certified for use in electric vehicle applications. The SAE J2464 standard specifically addresses electric and hybrid vehicle battery systems and includes thermal abuse tests that coatings must withstand.

Environmental regulations also impact certification requirements. The European Union's REACH regulation and RoHS directive restrict the use of certain hazardous substances in materials, affecting the chemical composition of self-healing coatings. Similarly, California's Proposition 65 requires warnings for products containing chemicals known to cause cancer or reproductive harm.

Certification processes typically involve third-party testing by organizations such as UL, TÜV, or SGS. These entities evaluate self-healing coatings against established standards and issue certifications that manufacturers can use to demonstrate compliance. The certification process includes accelerated aging tests, thermal shock tests, and chemical compatibility assessments to ensure long-term performance.

Emerging standards are being developed specifically for advanced materials in energy storage applications. The National Fire Protection Association (NFPA) is working on standards for fire protection in battery systems that will likely include requirements for thermal management coatings. Similarly, the International Organization for Standardization (ISO) is developing standards for battery safety that will address thermal management materials.

The International Electrotechnical Commission (IEC) has established IEC 62133 and IEC 61960 standards that address safety requirements for batteries, including thermal management systems. Self-healing coatings must comply with these standards by demonstrating resistance to thermal runaway and maintaining structural integrity during thermal cycling tests. Additionally, UL 2580 specifically addresses batteries for use in electric vehicles and includes requirements for materials used in thermal management systems.

ASTM International provides testing methodologies such as ASTM D7027 for scratch resistance and ASTM D2794 for impact resistance that are applicable to self-healing coatings. These tests evaluate the coating's ability to recover from mechanical damage, which is crucial for maintaining thermal management efficiency over time.

In the automotive sector, ISO 6469-1 outlines safety specifications for electrically propelled road vehicles, including requirements for battery thermal management systems. Self-healing coatings must meet these specifications to be certified for use in electric vehicle applications. The SAE J2464 standard specifically addresses electric and hybrid vehicle battery systems and includes thermal abuse tests that coatings must withstand.

Environmental regulations also impact certification requirements. The European Union's REACH regulation and RoHS directive restrict the use of certain hazardous substances in materials, affecting the chemical composition of self-healing coatings. Similarly, California's Proposition 65 requires warnings for products containing chemicals known to cause cancer or reproductive harm.

Certification processes typically involve third-party testing by organizations such as UL, TÜV, or SGS. These entities evaluate self-healing coatings against established standards and issue certifications that manufacturers can use to demonstrate compliance. The certification process includes accelerated aging tests, thermal shock tests, and chemical compatibility assessments to ensure long-term performance.

Emerging standards are being developed specifically for advanced materials in energy storage applications. The National Fire Protection Association (NFPA) is working on standards for fire protection in battery systems that will likely include requirements for thermal management coatings. Similarly, the International Organization for Standardization (ISO) is developing standards for battery safety that will address thermal management materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!