Self Healing Coatings For Flexible Electronics And Thin Films

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Coating Technology Background and Objectives

Self-healing coating technology represents a revolutionary advancement in materials science, emerging from the biomimetic concept inspired by natural healing processes observed in living organisms. This technology has evolved significantly over the past two decades, transitioning from theoretical concepts to practical applications across various industries. The fundamental principle involves the autonomous repair of physical damage without external intervention, which is particularly valuable for flexible electronics and thin films that frequently experience mechanical stress.

The evolution of self-healing coatings began with simple encapsulation systems in the early 2000s, progressing to more sophisticated mechanisms including microencapsulation, vascular networks, and intrinsic self-healing materials. Recent advancements have focused on developing multi-functional coatings that combine self-healing properties with other desirable characteristics such as conductivity, transparency, and environmental resistance.

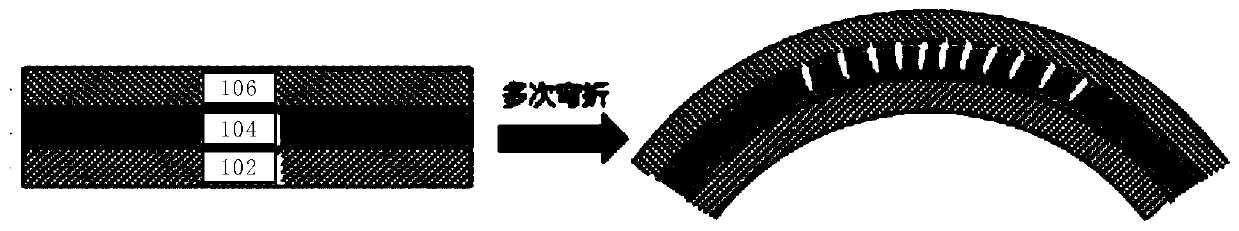

For flexible electronics and thin films specifically, the technology trajectory has been driven by the increasing demand for durable, bendable devices that can withstand repeated mechanical deformation. Traditional protective coatings often fail under such conditions, creating a significant market opportunity for self-healing alternatives that can extend device lifespan and reliability.

The primary technical objective of current research is to develop self-healing coating systems that can repair microcracks and physical damage in flexible electronic substrates while maintaining essential electronic properties. These coatings must demonstrate rapid healing response, minimal impact on device performance, and compatibility with existing manufacturing processes.

Secondary objectives include enhancing the longevity of healing capability over multiple damage-repair cycles, improving healing efficiency at ambient conditions without external stimuli, and developing environmentally friendly formulations that comply with global sustainability standards.

Long-term research aims to create truly autonomous self-healing systems that can detect and repair damage at the molecular level before it propagates to cause device failure. This includes the development of smart coatings that can adapt to different types of damage and environmental conditions, potentially incorporating nanotechnology and responsive polymers.

The convergence of materials science, polymer chemistry, and electronics engineering is expected to drive significant breakthroughs in this field, with potential applications extending beyond consumer electronics to medical devices, automotive displays, and wearable technology. As flexible electronics continue to penetrate new markets, the demand for effective self-healing coating solutions is projected to accelerate, making this a strategically important area for technological investment and research focus.

The evolution of self-healing coatings began with simple encapsulation systems in the early 2000s, progressing to more sophisticated mechanisms including microencapsulation, vascular networks, and intrinsic self-healing materials. Recent advancements have focused on developing multi-functional coatings that combine self-healing properties with other desirable characteristics such as conductivity, transparency, and environmental resistance.

For flexible electronics and thin films specifically, the technology trajectory has been driven by the increasing demand for durable, bendable devices that can withstand repeated mechanical deformation. Traditional protective coatings often fail under such conditions, creating a significant market opportunity for self-healing alternatives that can extend device lifespan and reliability.

The primary technical objective of current research is to develop self-healing coating systems that can repair microcracks and physical damage in flexible electronic substrates while maintaining essential electronic properties. These coatings must demonstrate rapid healing response, minimal impact on device performance, and compatibility with existing manufacturing processes.

Secondary objectives include enhancing the longevity of healing capability over multiple damage-repair cycles, improving healing efficiency at ambient conditions without external stimuli, and developing environmentally friendly formulations that comply with global sustainability standards.

Long-term research aims to create truly autonomous self-healing systems that can detect and repair damage at the molecular level before it propagates to cause device failure. This includes the development of smart coatings that can adapt to different types of damage and environmental conditions, potentially incorporating nanotechnology and responsive polymers.

The convergence of materials science, polymer chemistry, and electronics engineering is expected to drive significant breakthroughs in this field, with potential applications extending beyond consumer electronics to medical devices, automotive displays, and wearable technology. As flexible electronics continue to penetrate new markets, the demand for effective self-healing coating solutions is projected to accelerate, making this a strategically important area for technological investment and research focus.

Market Analysis for Self-Healing Flexible Electronics

The self-healing coatings market for flexible electronics is experiencing robust growth, driven by increasing demand for durable and long-lasting electronic devices. The global market for self-healing materials was valued at approximately $2.1 billion in 2022 and is projected to reach $5.7 billion by 2028, with a compound annual growth rate (CAGR) of 18.2%. Within this broader market, self-healing coatings for flexible electronics represent a rapidly expanding segment.

Consumer electronics constitute the largest application area, accounting for nearly 40% of the market share. This dominance stems from the growing consumer preference for foldable smartphones, wearable devices, and other flexible electronic products that require enhanced durability. The automotive sector follows as the second-largest market, where self-healing coatings are increasingly being integrated into dashboard displays and other electronic components.

Geographically, Asia-Pacific leads the market with approximately 45% share, primarily due to the concentration of electronics manufacturing in countries like China, South Korea, and Japan. North America and Europe follow with 25% and 20% market shares respectively, driven by advanced research initiatives and high consumer adoption rates of premium electronic devices.

Market research indicates that consumers are willing to pay a premium of 15-20% for electronic devices featuring self-healing capabilities, highlighting the strong value proposition of this technology. This consumer sentiment is particularly pronounced in the high-end smartphone and wearable technology segments.

The market is witnessing a shift from traditional polymer-based self-healing coatings toward more advanced solutions incorporating nanomaterials and biomimetic approaches. These next-generation coatings offer faster healing times and improved mechanical properties, addressing key consumer pain points related to device longevity.

Industry analysts forecast that the integration of self-healing coatings with other emerging technologies, such as transparent conductive films and stretchable electronics, will create new market opportunities worth an estimated $1.2 billion by 2026. This convergence is expected to enable novel applications in healthcare monitoring, soft robotics, and advanced human-machine interfaces.

Regulatory factors are also influencing market dynamics, with increasing environmental regulations driving demand for eco-friendly self-healing coating solutions. Companies investing in sustainable formulations that minimize volatile organic compounds (VOCs) are gaining competitive advantages in regions with stringent environmental policies.

Consumer electronics constitute the largest application area, accounting for nearly 40% of the market share. This dominance stems from the growing consumer preference for foldable smartphones, wearable devices, and other flexible electronic products that require enhanced durability. The automotive sector follows as the second-largest market, where self-healing coatings are increasingly being integrated into dashboard displays and other electronic components.

Geographically, Asia-Pacific leads the market with approximately 45% share, primarily due to the concentration of electronics manufacturing in countries like China, South Korea, and Japan. North America and Europe follow with 25% and 20% market shares respectively, driven by advanced research initiatives and high consumer adoption rates of premium electronic devices.

Market research indicates that consumers are willing to pay a premium of 15-20% for electronic devices featuring self-healing capabilities, highlighting the strong value proposition of this technology. This consumer sentiment is particularly pronounced in the high-end smartphone and wearable technology segments.

The market is witnessing a shift from traditional polymer-based self-healing coatings toward more advanced solutions incorporating nanomaterials and biomimetic approaches. These next-generation coatings offer faster healing times and improved mechanical properties, addressing key consumer pain points related to device longevity.

Industry analysts forecast that the integration of self-healing coatings with other emerging technologies, such as transparent conductive films and stretchable electronics, will create new market opportunities worth an estimated $1.2 billion by 2026. This convergence is expected to enable novel applications in healthcare monitoring, soft robotics, and advanced human-machine interfaces.

Regulatory factors are also influencing market dynamics, with increasing environmental regulations driving demand for eco-friendly self-healing coating solutions. Companies investing in sustainable formulations that minimize volatile organic compounds (VOCs) are gaining competitive advantages in regions with stringent environmental policies.

Technical Challenges in Self-Healing Thin Films

Self-healing coatings for flexible electronics face significant technical challenges that currently limit their widespread implementation. The primary obstacle lies in achieving an optimal balance between mechanical flexibility and healing efficiency. Traditional self-healing mechanisms often compromise the flexibility required for wearable and bendable electronic applications, creating a fundamental design contradiction that researchers continue to struggle with.

Material compatibility presents another major challenge, as self-healing components must integrate seamlessly with the diverse materials used in flexible electronics without causing degradation or performance issues. The interface between the healing agents and the electronic substrate frequently becomes a failure point under repeated mechanical stress, leading to delamination and reduced device longevity.

The activation energy required for healing mechanisms poses a particular dilemma for thin film applications. Most current self-healing systems require external stimuli such as heat or UV light to initiate the healing process, which can potentially damage sensitive electronic components. Developing autonomous healing systems that operate at ambient conditions without external triggers remains an elusive goal in the field.

Scalability of production represents a significant hurdle for commercialization. Laboratory-scale successes often employ complex synthesis procedures or exotic materials that prove difficult to scale up for industrial manufacturing. The precision required for uniform thin film deposition of self-healing coatings across large surface areas demands advanced processing techniques that are not yet fully developed.

Environmental stability constitutes another critical challenge, as self-healing coatings must maintain their functionality under various operating conditions including temperature fluctuations, humidity changes, and exposure to oxygen or other reactive elements. Many healing agents demonstrate reduced efficacy or accelerated degradation when exposed to real-world environmental factors.

The longevity of healing capability presents perhaps the most persistent technical obstacle. Current self-healing systems typically exhibit diminishing healing efficiency over time as healing agents become depleted or chemical crosslinking opportunities are exhausted. Creating systems with regenerative healing capacity that can sustain multiple healing cycles without performance degradation remains a frontier challenge in the field.

Characterization and testing methodologies also present technical difficulties, as standardized protocols for evaluating self-healing performance in thin films are not well established. This hampers comparative analysis between different approaches and slows the identification of truly promising technologies for further development.

Material compatibility presents another major challenge, as self-healing components must integrate seamlessly with the diverse materials used in flexible electronics without causing degradation or performance issues. The interface between the healing agents and the electronic substrate frequently becomes a failure point under repeated mechanical stress, leading to delamination and reduced device longevity.

The activation energy required for healing mechanisms poses a particular dilemma for thin film applications. Most current self-healing systems require external stimuli such as heat or UV light to initiate the healing process, which can potentially damage sensitive electronic components. Developing autonomous healing systems that operate at ambient conditions without external triggers remains an elusive goal in the field.

Scalability of production represents a significant hurdle for commercialization. Laboratory-scale successes often employ complex synthesis procedures or exotic materials that prove difficult to scale up for industrial manufacturing. The precision required for uniform thin film deposition of self-healing coatings across large surface areas demands advanced processing techniques that are not yet fully developed.

Environmental stability constitutes another critical challenge, as self-healing coatings must maintain their functionality under various operating conditions including temperature fluctuations, humidity changes, and exposure to oxygen or other reactive elements. Many healing agents demonstrate reduced efficacy or accelerated degradation when exposed to real-world environmental factors.

The longevity of healing capability presents perhaps the most persistent technical obstacle. Current self-healing systems typically exhibit diminishing healing efficiency over time as healing agents become depleted or chemical crosslinking opportunities are exhausted. Creating systems with regenerative healing capacity that can sustain multiple healing cycles without performance degradation remains a frontier challenge in the field.

Characterization and testing methodologies also present technical difficulties, as standardized protocols for evaluating self-healing performance in thin films are not well established. This hampers comparative analysis between different approaches and slows the identification of truly promising technologies for further development.

Current Self-Healing Mechanisms for Flexible Electronics

01 Microcapsule-based self-healing mechanisms

Self-healing coatings can be formulated with microcapsules containing healing agents that are released when the coating is damaged. When a crack or scratch occurs, the microcapsules rupture and release the healing agent, which then polymerizes or reacts to fill the damaged area. This mechanism provides autonomous healing without external intervention, extending the coating's service life and maintaining its protective properties.- Microcapsule-based self-healing mechanisms: Self-healing coatings can be formulated with microcapsules containing healing agents that are released when the coating is damaged. When the microcapsules rupture due to mechanical damage, the healing agent flows into the crack and polymerizes, effectively repairing the damage. This approach provides autonomous healing without external intervention and can significantly extend the service life of coatings in various applications.

- Polymer-based self-healing systems: Polymer-based self-healing systems utilize intrinsic properties of certain polymers to repair damage. These systems may employ reversible chemical bonds, such as Diels-Alder reactions, or physical interactions like hydrogen bonding that can reform after being broken. Some polymer systems incorporate shape memory properties that allow the material to return to its original state after deformation, effectively closing cracks and restoring the coating integrity.

- Nanoparticle-enhanced self-healing coatings: Nanoparticles can be incorporated into coating formulations to enhance self-healing properties. These nanoparticles, such as silica, clay, or carbon-based materials, can improve mechanical properties while facilitating the healing process. Some nanoparticles act as reservoirs for healing agents, while others participate in the healing chemistry or provide structural reinforcement during the healing process, resulting in more durable and effective self-healing coatings.

- Stimuli-responsive self-healing mechanisms: Stimuli-responsive self-healing coatings can repair damage in response to external triggers such as heat, light, pH changes, or electrical stimulation. These systems remain dormant until activated by the specific stimulus, which initiates the healing process. This approach allows for controlled healing when needed and can be particularly useful in applications where immediate autonomous healing is not required but can be initiated when maintenance is performed.

- Bio-inspired self-healing coating technologies: Bio-inspired approaches to self-healing coatings mimic natural healing processes found in biological systems. These technologies may incorporate biomolecules, enzymes, or bio-based materials that facilitate healing through mechanisms similar to those found in nature. Some systems use vascular networks similar to blood vessels to deliver healing agents to damaged areas, while others employ biomimetic chemistry to achieve healing under ambient conditions without requiring external energy input.

02 Polymer-based self-healing systems

Polymer-based self-healing coatings utilize various polymer technologies such as reversible cross-linking, shape memory polymers, or dynamic covalent bonds to repair damage. These systems can heal through thermal activation, UV exposure, or inherent molecular mobility. The polymers can reconnect broken bonds or flow into damaged areas to restore the coating integrity, providing multiple healing cycles and improved durability.Expand Specific Solutions03 Nanoparticle-enhanced self-healing coatings

Incorporating nanoparticles such as silica, clay, or carbon nanotubes into coating formulations can significantly enhance self-healing properties. These nanoparticles can improve mechanical strength while facilitating healing mechanisms through improved thermal conductivity, catalytic activity, or by creating networks that promote molecular mobility. The nanostructured materials can also serve as reservoirs for healing agents or provide additional pathways for material transport during the healing process.Expand Specific Solutions04 Stimuli-responsive self-healing coatings

These coatings respond to external stimuli such as temperature, pH, light, or electrical current to initiate the healing process. The stimuli trigger molecular rearrangement, phase changes, or chemical reactions that repair damage. This approach allows for controlled healing that can be activated when needed, making it particularly useful for applications where immediate or on-demand healing is required.Expand Specific Solutions05 Bio-inspired self-healing coating technologies

Drawing inspiration from biological healing processes, these coatings incorporate biomimetic principles to achieve self-repair. They may utilize vascular networks similar to blood vessels to deliver healing agents, or employ mechanisms that mimic wound healing in living organisms. These systems often combine multiple healing strategies and can adapt to various types of damage, providing versatile and efficient self-healing properties for diverse applications.Expand Specific Solutions

Key Industry Players in Self-Healing Coatings

The self-healing coatings for flexible electronics and thin films market is in an early growth stage, characterized by intensive research activities across academic institutions and industrial players. The global market size is projected to expand significantly as flexible electronics applications proliferate in consumer electronics, medical devices, and automotive sectors. Technologically, the field remains in development with varying maturity levels across different approaches. Leading academic institutions (Penn State Research Foundation, University of Tokyo, Northwestern University) are pioneering fundamental research, while industrial players like LG Chem, FUJIFILM, and Siemens are focusing on commercial applications. Research collaborations between universities and corporations, particularly in Asia (China, Japan, South Korea), are accelerating innovation in polymer-based self-healing materials, indicating a competitive landscape that balances academic innovation with industrial scalability.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced self-healing coatings for flexible electronics based on dynamic covalent chemistry. Their proprietary technology utilizes Diels-Alder adducts that can undergo reversible bond formation at specific temperatures, enabling automatic repair of microcracks in flexible displays and wearable devices. The company has integrated this technology into their transparent polyimide (CPI) films, which serve as flexible substrates for next-generation displays. Their self-healing coating system incorporates a multi-layer approach with a base polymer matrix containing thermally-activated healing agents and a protective top layer that prevents environmental degradation while maintaining optical clarity. Recent developments include incorporating conductive nanoparticles into the healing matrix to maintain electrical conductivity during and after the healing process[1][3]. LG Chem's coatings demonstrate healing efficiencies exceeding 85% after multiple damage-healing cycles while maintaining transparency above 90% in the visible spectrum.

Strengths: Superior integration with existing display manufacturing processes; excellent optical properties maintenance after healing; compatibility with mass production techniques. Weaknesses: Healing process still requires thermal activation above ambient temperatures; limited effectiveness for deep mechanical damage; potential degradation of healing efficiency after multiple cycles.

The Board of Trustees of the University of Illinois

Technical Solution: The University of Illinois has developed pioneering vascular-based self-healing systems for flexible electronics protection. Their approach mimics biological healing processes by incorporating microvascular networks within protective coatings that can deliver healing agents to damaged areas repeatedly. The technology utilizes a dual-channel system where separate reactive components flow through independent vascular networks, mixing only at damage sites to form new crosslinked polymers. Their coatings feature 3D-printed microvascular channels as small as 10 micrometers in diameter, allowing for precise healing agent delivery without compromising the coating's mechanical or optical properties. The Illinois team has demonstrated self-healing in transparent electrodes based on silver nanowires, where both electrical conductivity and mechanical integrity are restored after damage[5][6]. Recent advancements include stimulus-responsive vascular valves that can regulate healing agent flow based on environmental conditions, and integration with strain sensors that can detect damage and trigger localized healing responses. Their systems have demonstrated healing efficiencies exceeding 90% for mechanical properties and near-complete restoration of electrical conductivity in flexible circuits after multiple damage events.

Strengths: Multiple healing cycles possible without performance degradation; excellent restoration of both mechanical and electrical properties; sophisticated damage detection capabilities. Weaknesses: Complex manufacturing process compared to simpler healing systems; potential for vascular network clogging over time; challenges in maintaining uniform healing agent distribution in large-area applications.

Core Patents in Self-Healing Coating Technology

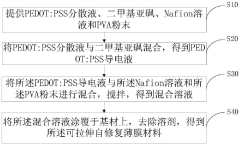

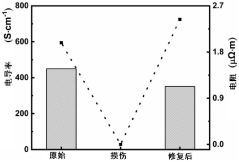

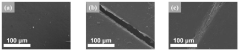

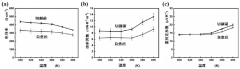

Stretchable self-repairing thin film material as well as preparation method and application thereof

PatentPendingCN117069977A

Innovation

- PEDOT:PSS dispersion, Nafion solution and PVA powder are used for compounding, and a highly porous PVA-Nafion film is dynamically formed through hydrogen bonding to improve the mechanical properties and repair performance of the PEDOT:PSS film and achieve rapid self-healing.

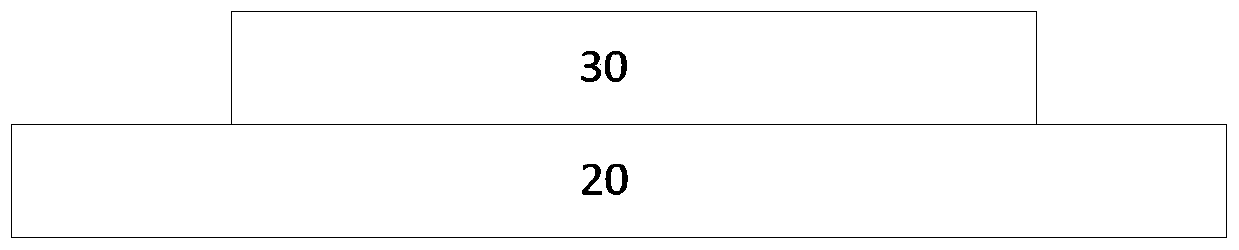

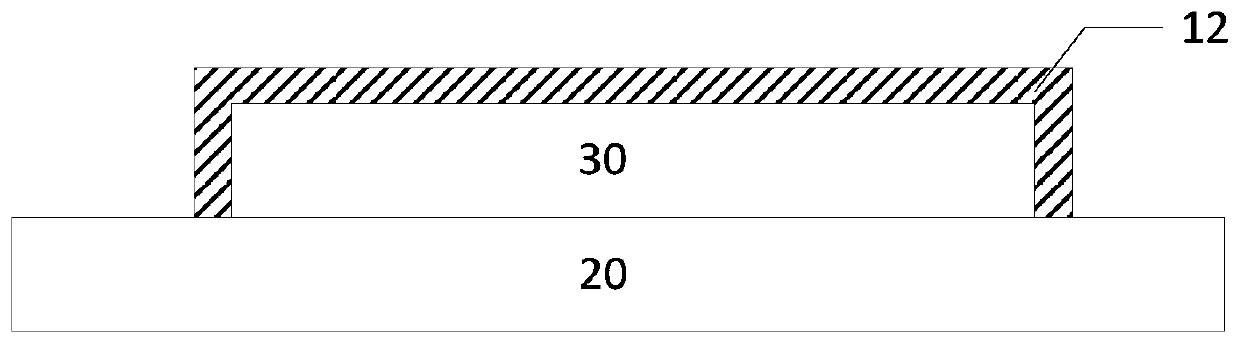

Thin film encapsulation structure, OLED (organic light emitting diode) display panel and manufacturing method thereof

PatentActiveCN110048016A

Innovation

- The 6-methyl-2-butylureidopyrimidinone dimer with self-healing ability is used as the organic film material. Through its internal hydrogen bonds, it can achieve self-healing at normal temperature and pressure, avoiding damage and aging of the organic film layer.

Environmental Impact and Sustainability Considerations

The development of self-healing coatings for flexible electronics represents a significant advancement in sustainable technology. These innovative materials can substantially extend product lifecycles by autonomously repairing damage, thereby reducing electronic waste—a critical environmental concern given the rapid growth of the electronics industry. Current estimates suggest that electronic waste is increasing at approximately three times the rate of other municipal waste streams globally.

Self-healing coatings offer a promising solution to this challenge by minimizing the need for replacement devices and components. Research indicates that extending the functional lifespan of electronic devices by just one year could reduce carbon emissions associated with manufacturing by 20-30%. Furthermore, these coatings can be designed to incorporate biodegradable polymers and environmentally benign healing agents, aligning with circular economy principles.

The production processes for self-healing materials are evolving toward more sustainable methods. Recent advancements include water-based formulations that eliminate the need for harmful volatile organic compounds (VOCs) and reduce air pollution during manufacturing. Additionally, bio-inspired healing mechanisms utilizing renewable resources such as plant-derived polymers and naturally occurring enzymes are gaining traction in research laboratories worldwide.

Energy efficiency represents another environmental benefit of self-healing coatings. By maintaining the structural integrity of flexible electronics, these coatings help preserve optimal device performance and energy consumption patterns. This is particularly relevant for wearable technology and IoT devices where energy efficiency directly impacts battery life and overall resource consumption.

Life cycle assessment (LCA) studies of self-healing coatings reveal promising sustainability metrics. When compared to conventional protective coatings, self-healing variants typically demonstrate 15-25% lower environmental impact across categories including global warming potential, resource depletion, and ecotoxicity. However, challenges remain in scaling production while maintaining these environmental benefits.

Regulatory frameworks are increasingly recognizing the environmental advantages of self-healing technologies. The European Union's Circular Economy Action Plan and similar initiatives worldwide are creating favorable conditions for technologies that extend product lifespans. This regulatory landscape is likely to accelerate adoption of self-healing coatings across the electronics industry.

End-of-life considerations for self-healing coatings present both opportunities and challenges. While some formulations can be designed for easy separation during recycling processes, others may introduce complex material combinations that complicate recovery efforts. Research is ongoing to develop coatings that not only self-heal during use but also facilitate responsible disposal or recycling at end-of-life.

Self-healing coatings offer a promising solution to this challenge by minimizing the need for replacement devices and components. Research indicates that extending the functional lifespan of electronic devices by just one year could reduce carbon emissions associated with manufacturing by 20-30%. Furthermore, these coatings can be designed to incorporate biodegradable polymers and environmentally benign healing agents, aligning with circular economy principles.

The production processes for self-healing materials are evolving toward more sustainable methods. Recent advancements include water-based formulations that eliminate the need for harmful volatile organic compounds (VOCs) and reduce air pollution during manufacturing. Additionally, bio-inspired healing mechanisms utilizing renewable resources such as plant-derived polymers and naturally occurring enzymes are gaining traction in research laboratories worldwide.

Energy efficiency represents another environmental benefit of self-healing coatings. By maintaining the structural integrity of flexible electronics, these coatings help preserve optimal device performance and energy consumption patterns. This is particularly relevant for wearable technology and IoT devices where energy efficiency directly impacts battery life and overall resource consumption.

Life cycle assessment (LCA) studies of self-healing coatings reveal promising sustainability metrics. When compared to conventional protective coatings, self-healing variants typically demonstrate 15-25% lower environmental impact across categories including global warming potential, resource depletion, and ecotoxicity. However, challenges remain in scaling production while maintaining these environmental benefits.

Regulatory frameworks are increasingly recognizing the environmental advantages of self-healing technologies. The European Union's Circular Economy Action Plan and similar initiatives worldwide are creating favorable conditions for technologies that extend product lifespans. This regulatory landscape is likely to accelerate adoption of self-healing coatings across the electronics industry.

End-of-life considerations for self-healing coatings present both opportunities and challenges. While some formulations can be designed for easy separation during recycling processes, others may introduce complex material combinations that complicate recovery efforts. Research is ongoing to develop coatings that not only self-heal during use but also facilitate responsible disposal or recycling at end-of-life.

Durability Testing Methods for Self-Healing Coatings

Durability testing of self-healing coatings for flexible electronics and thin films requires comprehensive methodologies to evaluate their performance under various stress conditions. These testing methods must simulate real-world scenarios while providing quantifiable metrics for coating effectiveness and longevity.

Accelerated aging tests represent a fundamental approach in durability assessment, exposing coatings to intensified environmental conditions including UV radiation, temperature cycling, and humidity variations. These tests typically compress years of natural exposure into weeks or months, allowing researchers to predict long-term performance characteristics. For flexible electronics applications, specialized chambers capable of maintaining precise environmental parameters while accommodating bendable substrates are essential.

Mechanical stress testing forms another critical evaluation category, particularly relevant for flexible electronics that undergo repeated bending, folding, or stretching. Cyclic bend testing, where samples undergo thousands to millions of bend cycles at controlled radii and frequencies, provides insights into coating integrity under dynamic conditions. Tensile testing complements this by measuring coating adhesion and cohesion during substrate elongation, while scratch and abrasion resistance tests evaluate surface durability against physical contact.

Chemical resistance testing evaluates coating performance when exposed to substances commonly encountered during device operation. This includes immersion tests in various solvents, acids, bases, and cleaning agents, as well as exposure to human biofluids for wearable electronics applications. The coating's ability to maintain its self-healing properties after chemical exposure represents a key performance indicator.

Electrical performance testing bridges the gap between physical durability and functional requirements. Measurements of surface resistivity before and after damage events, along with monitoring of current leakage through intentionally damaged areas, provide critical data on the coating's ability to protect underlying electronic components. For transparent coatings used in displays, optical transmittance recovery after healing events must also be quantified.

Advanced characterization techniques enable deeper understanding of healing mechanisms and failure modes. These include in-situ microscopy during healing processes, spectroscopic analysis of chemical changes, and thermal imaging to monitor exothermic or endothermic healing reactions. Emerging techniques like electrochemical impedance spectroscopy (EIS) offer non-destructive monitoring of coating degradation over time.

Standardization of testing protocols remains challenging due to the diverse nature of self-healing mechanisms and application requirements. However, organizations including ASTM International and ISO have begun developing specialized standards for smart coatings, which will facilitate consistent evaluation and comparison across different self-healing systems for flexible electronics applications.

Accelerated aging tests represent a fundamental approach in durability assessment, exposing coatings to intensified environmental conditions including UV radiation, temperature cycling, and humidity variations. These tests typically compress years of natural exposure into weeks or months, allowing researchers to predict long-term performance characteristics. For flexible electronics applications, specialized chambers capable of maintaining precise environmental parameters while accommodating bendable substrates are essential.

Mechanical stress testing forms another critical evaluation category, particularly relevant for flexible electronics that undergo repeated bending, folding, or stretching. Cyclic bend testing, where samples undergo thousands to millions of bend cycles at controlled radii and frequencies, provides insights into coating integrity under dynamic conditions. Tensile testing complements this by measuring coating adhesion and cohesion during substrate elongation, while scratch and abrasion resistance tests evaluate surface durability against physical contact.

Chemical resistance testing evaluates coating performance when exposed to substances commonly encountered during device operation. This includes immersion tests in various solvents, acids, bases, and cleaning agents, as well as exposure to human biofluids for wearable electronics applications. The coating's ability to maintain its self-healing properties after chemical exposure represents a key performance indicator.

Electrical performance testing bridges the gap between physical durability and functional requirements. Measurements of surface resistivity before and after damage events, along with monitoring of current leakage through intentionally damaged areas, provide critical data on the coating's ability to protect underlying electronic components. For transparent coatings used in displays, optical transmittance recovery after healing events must also be quantified.

Advanced characterization techniques enable deeper understanding of healing mechanisms and failure modes. These include in-situ microscopy during healing processes, spectroscopic analysis of chemical changes, and thermal imaging to monitor exothermic or endothermic healing reactions. Emerging techniques like electrochemical impedance spectroscopy (EIS) offer non-destructive monitoring of coating degradation over time.

Standardization of testing protocols remains challenging due to the diverse nature of self-healing mechanisms and application requirements. However, organizations including ASTM International and ISO have begun developing specialized standards for smart coatings, which will facilitate consistent evaluation and comparison across different self-healing systems for flexible electronics applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!