Repairable Coatings For Aerospace Composite Structures Technical Notes

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Composite Coating Evolution and Objectives

The evolution of aerospace composite coatings has undergone significant transformation over the past decades, driven by the increasing demand for lightweight, durable, and high-performance materials in aircraft construction. Initially, aerospace coatings were primarily designed for metallic structures, focusing on corrosion protection and aesthetic appearance. However, with the introduction of composite materials in aerospace applications during the 1970s, coating technologies had to adapt to new substrate characteristics and performance requirements.

The 1980s marked a pivotal shift as composite usage expanded from secondary structures to primary load-bearing components. This transition necessitated the development of specialized coating systems capable of addressing the unique challenges posed by composite materials, including moisture ingress, UV degradation, and thermal cycling effects. By the 1990s, environmental regulations began to significantly influence coating formulations, driving the industry away from chromate-based systems toward more environmentally friendly alternatives.

The early 2000s witnessed the emergence of multifunctional coating systems that not only provided protection but also offered additional capabilities such as ice resistance, static dissipation, and radar absorption. This period also saw increased research into self-healing mechanisms, laying the groundwork for today's repairable coating technologies. The integration of nanotechnology into aerospace coatings began around 2010, enabling unprecedented improvements in durability, adhesion, and damage resistance at reduced weight penalties.

Current technological objectives for repairable coatings in aerospace composite structures focus on several key areas. Primary among these is the development of in-situ repair capabilities that allow damage mitigation without extensive disassembly or ground time. Engineers are working toward coatings that can autonomously detect and respond to environmental stressors or physical damage, thereby extending maintenance intervals and reducing operational costs.

Another critical objective is the enhancement of coating-composite interface compatibility to ensure long-term adhesion under extreme operational conditions. This includes addressing the challenges of thermal expansion mismatch and chemical compatibility across diverse composite substrates. Additionally, there is significant interest in developing coatings that can provide real-time structural health monitoring through embedded sensors or smart materials that change properties in response to stress or damage.

The industry is also pursuing sustainability goals, aiming to develop bio-based coating formulations with reduced environmental impact throughout their lifecycle while maintaining or exceeding current performance standards. These objectives collectively drive research toward creating next-generation coating systems that will enable safer, more efficient, and more sustainable aerospace operations.

The 1980s marked a pivotal shift as composite usage expanded from secondary structures to primary load-bearing components. This transition necessitated the development of specialized coating systems capable of addressing the unique challenges posed by composite materials, including moisture ingress, UV degradation, and thermal cycling effects. By the 1990s, environmental regulations began to significantly influence coating formulations, driving the industry away from chromate-based systems toward more environmentally friendly alternatives.

The early 2000s witnessed the emergence of multifunctional coating systems that not only provided protection but also offered additional capabilities such as ice resistance, static dissipation, and radar absorption. This period also saw increased research into self-healing mechanisms, laying the groundwork for today's repairable coating technologies. The integration of nanotechnology into aerospace coatings began around 2010, enabling unprecedented improvements in durability, adhesion, and damage resistance at reduced weight penalties.

Current technological objectives for repairable coatings in aerospace composite structures focus on several key areas. Primary among these is the development of in-situ repair capabilities that allow damage mitigation without extensive disassembly or ground time. Engineers are working toward coatings that can autonomously detect and respond to environmental stressors or physical damage, thereby extending maintenance intervals and reducing operational costs.

Another critical objective is the enhancement of coating-composite interface compatibility to ensure long-term adhesion under extreme operational conditions. This includes addressing the challenges of thermal expansion mismatch and chemical compatibility across diverse composite substrates. Additionally, there is significant interest in developing coatings that can provide real-time structural health monitoring through embedded sensors or smart materials that change properties in response to stress or damage.

The industry is also pursuing sustainability goals, aiming to develop bio-based coating formulations with reduced environmental impact throughout their lifecycle while maintaining or exceeding current performance standards. These objectives collectively drive research toward creating next-generation coating systems that will enable safer, more efficient, and more sustainable aerospace operations.

Market Demand Analysis for Self-Healing Aerospace Coatings

The aerospace industry is witnessing a significant shift towards advanced composite materials, creating a substantial market demand for specialized self-healing coatings. Current market analysis indicates that the global aerospace coatings market is projected to reach $3.5 billion by 2027, with self-healing variants expected to capture an increasing share due to their superior performance characteristics and long-term cost benefits.

The primary market drivers for self-healing aerospace coatings stem from the industry's persistent challenges: reducing maintenance costs, extending aircraft service life, and minimizing downtime. Commercial airlines typically lose between $10,000 and $150,000 per hour when aircraft are grounded for maintenance, creating strong economic incentives for technologies that can reduce inspection and repair frequencies.

Military aerospace applications represent another substantial market segment, with defense departments worldwide investing heavily in technologies that enhance aircraft durability and combat readiness. The U.S. Department of Defense alone allocates approximately $5 billion annually for aircraft maintenance and repair operations, a portion of which could be significantly reduced through effective self-healing coating implementations.

Regional market analysis reveals that North America currently dominates demand, accounting for 42% of the global aerospace coatings market, followed by Europe at 28% and Asia-Pacific at 22%. However, the fastest growth is occurring in emerging markets, particularly in China and India, where commercial aviation sectors are expanding at annual rates exceeding 15%.

Customer segmentation within this market reveals three primary buyer categories: Original Equipment Manufacturers (OEMs), Maintenance, Repair, and Overhaul (MRO) service providers, and military/defense organizations. Each segment has distinct requirements and adoption timelines, with OEMs increasingly incorporating self-healing technologies into new aircraft designs to offer competitive advantages in lifecycle cost management.

Market research indicates that customers are willing to pay premium prices for coatings that demonstrate verifiable reductions in maintenance requirements. Survey data shows that aerospace maintenance directors would accept a 30-40% price premium for coatings that could extend maintenance intervals by at least 25%.

The regulatory landscape is also driving market demand, with environmental regulations increasingly restricting traditional coating components. Self-healing technologies that reduce the frequency of reapplication and minimize volatile organic compound (VOC) emissions align well with these regulatory trends, creating additional market pull for these innovations.

Competitive analysis reveals that while several major coating manufacturers have research programs in this area, few have brought comprehensive self-healing solutions to market, indicating significant first-mover advantage potential for companies that can successfully commercialize effective technologies in this space.

The primary market drivers for self-healing aerospace coatings stem from the industry's persistent challenges: reducing maintenance costs, extending aircraft service life, and minimizing downtime. Commercial airlines typically lose between $10,000 and $150,000 per hour when aircraft are grounded for maintenance, creating strong economic incentives for technologies that can reduce inspection and repair frequencies.

Military aerospace applications represent another substantial market segment, with defense departments worldwide investing heavily in technologies that enhance aircraft durability and combat readiness. The U.S. Department of Defense alone allocates approximately $5 billion annually for aircraft maintenance and repair operations, a portion of which could be significantly reduced through effective self-healing coating implementations.

Regional market analysis reveals that North America currently dominates demand, accounting for 42% of the global aerospace coatings market, followed by Europe at 28% and Asia-Pacific at 22%. However, the fastest growth is occurring in emerging markets, particularly in China and India, where commercial aviation sectors are expanding at annual rates exceeding 15%.

Customer segmentation within this market reveals three primary buyer categories: Original Equipment Manufacturers (OEMs), Maintenance, Repair, and Overhaul (MRO) service providers, and military/defense organizations. Each segment has distinct requirements and adoption timelines, with OEMs increasingly incorporating self-healing technologies into new aircraft designs to offer competitive advantages in lifecycle cost management.

Market research indicates that customers are willing to pay premium prices for coatings that demonstrate verifiable reductions in maintenance requirements. Survey data shows that aerospace maintenance directors would accept a 30-40% price premium for coatings that could extend maintenance intervals by at least 25%.

The regulatory landscape is also driving market demand, with environmental regulations increasingly restricting traditional coating components. Self-healing technologies that reduce the frequency of reapplication and minimize volatile organic compound (VOC) emissions align well with these regulatory trends, creating additional market pull for these innovations.

Competitive analysis reveals that while several major coating manufacturers have research programs in this area, few have brought comprehensive self-healing solutions to market, indicating significant first-mover advantage potential for companies that can successfully commercialize effective technologies in this space.

Current Challenges in Aerospace Composite Protection

The aerospace industry faces significant challenges in protecting composite structures, which have become increasingly prevalent in modern aircraft design due to their superior strength-to-weight ratio compared to traditional metals. Despite these advantages, composites remain vulnerable to environmental degradation, impact damage, and erosion, necessitating advanced protective coating systems.

One of the primary challenges is developing coatings that can withstand extreme temperature fluctuations. Aircraft operate in environments ranging from -60°C at cruising altitude to over 80°C on sun-exposed surfaces during ground operations. These thermal cycles create expansion and contraction stresses that can lead to coating delamination and cracking, particularly at the interface between the coating and composite substrate.

UV radiation presents another significant challenge, as prolonged exposure can degrade both the protective coating and the underlying composite matrix. Current UV-resistant additives often compromise other coating properties such as flexibility or repairability, creating a complex engineering trade-off.

Moisture ingress remains a persistent issue for aerospace composites. Water absorption can lead to hydrolysis of the polymer matrix and degradation of fiber-matrix interfaces, resulting in reduced mechanical properties. Effective moisture barrier coatings must maintain their integrity throughout the aircraft's service life while accommodating the inherent flexibility of composite structures.

Impact resistance represents a critical challenge, as composites are particularly susceptible to barely visible impact damage (BVID) that can significantly reduce structural integrity. Protective coatings must absorb and distribute impact energy without compromising their protective functions or adhesion to the substrate.

Erosion protection is increasingly important as composites are used in high-velocity areas such as leading edges. Particulate matter, rain, and ice can cause progressive material loss, affecting aerodynamic performance and structural integrity. Current erosion-resistant coatings often lack the repairability needed for practical field maintenance.

Chemical resistance poses another challenge, as aircraft are exposed to various fluids including hydraulic fluids, de-icing agents, and jet fuel. These substances can degrade conventional coatings, compromising their protective capabilities and potentially affecting the underlying composite structure.

Perhaps most critically, the aerospace industry struggles with developing truly repairable coating systems. Unlike metal structures where damaged coatings can be stripped and reapplied without significant substrate concerns, composite repair processes must avoid thermal or chemical damage to the underlying structure. Current repair methods often result in performance compromises or require complex equipment unsuitable for field operations.

One of the primary challenges is developing coatings that can withstand extreme temperature fluctuations. Aircraft operate in environments ranging from -60°C at cruising altitude to over 80°C on sun-exposed surfaces during ground operations. These thermal cycles create expansion and contraction stresses that can lead to coating delamination and cracking, particularly at the interface between the coating and composite substrate.

UV radiation presents another significant challenge, as prolonged exposure can degrade both the protective coating and the underlying composite matrix. Current UV-resistant additives often compromise other coating properties such as flexibility or repairability, creating a complex engineering trade-off.

Moisture ingress remains a persistent issue for aerospace composites. Water absorption can lead to hydrolysis of the polymer matrix and degradation of fiber-matrix interfaces, resulting in reduced mechanical properties. Effective moisture barrier coatings must maintain their integrity throughout the aircraft's service life while accommodating the inherent flexibility of composite structures.

Impact resistance represents a critical challenge, as composites are particularly susceptible to barely visible impact damage (BVID) that can significantly reduce structural integrity. Protective coatings must absorb and distribute impact energy without compromising their protective functions or adhesion to the substrate.

Erosion protection is increasingly important as composites are used in high-velocity areas such as leading edges. Particulate matter, rain, and ice can cause progressive material loss, affecting aerodynamic performance and structural integrity. Current erosion-resistant coatings often lack the repairability needed for practical field maintenance.

Chemical resistance poses another challenge, as aircraft are exposed to various fluids including hydraulic fluids, de-icing agents, and jet fuel. These substances can degrade conventional coatings, compromising their protective capabilities and potentially affecting the underlying composite structure.

Perhaps most critically, the aerospace industry struggles with developing truly repairable coating systems. Unlike metal structures where damaged coatings can be stripped and reapplied without significant substrate concerns, composite repair processes must avoid thermal or chemical damage to the underlying structure. Current repair methods often result in performance compromises or require complex equipment unsuitable for field operations.

Current Self-Healing Coating Technologies for Aerospace Applications

01 Self-healing coating technologies

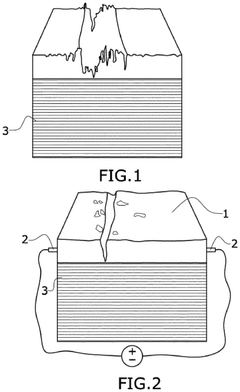

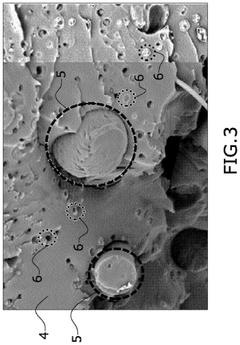

Self-healing coatings incorporate materials that can automatically repair damage without external intervention. These coatings typically contain microcapsules filled with healing agents that are released when the coating is damaged, or they may utilize reversible chemical bonds that can reform after being broken. This technology enables coatings to recover from scratches, cracks, and other forms of physical damage, extending the coating's service life and maintaining its protective properties.- Self-healing coating technologies: Self-healing coatings incorporate materials that can automatically repair damage without external intervention. These coatings typically contain microcapsules filled with healing agents that are released when the coating is damaged, or they may utilize reversible chemical bonds that can reform after being broken. This technology enables coatings to maintain their protective and aesthetic properties over time, extending their service life and reducing maintenance costs.

- Repair methods for electronic device coatings: Specialized techniques for repairing coatings on electronic devices and displays focus on maintaining functionality while restoring appearance. These methods often involve precision application of repair materials compatible with sensitive electronic components, careful curing processes, and techniques that ensure repaired areas match the original coating in terms of transparency, conductivity, or other functional properties. Such approaches are particularly important for touchscreens, display panels, and protective casings.

- Environmentally responsive repair systems: Advanced coating systems that respond to environmental triggers to initiate repair processes. These coatings may react to temperature changes, pH shifts, light exposure, or mechanical stress to activate healing mechanisms. Some systems incorporate phase-changing materials or stimuli-responsive polymers that can flow into damaged areas when activated by the appropriate environmental condition, then solidify to restore the coating integrity without requiring manual intervention.

- Diagnostic and assessment methods for coating repair: Systems and methods for evaluating coating damage and determining appropriate repair strategies. These approaches include non-destructive testing techniques, imaging systems, and analytical tools that can assess the extent and nature of coating damage. Some methods incorporate artificial intelligence or machine learning algorithms to recommend optimal repair procedures based on damage patterns, coating composition, and environmental factors, ensuring efficient and effective restoration of protective coatings.

- Multi-layer repairable coating systems: Coating architectures featuring multiple functional layers designed to enhance repairability. These systems may include sacrificial top layers that can be easily removed and replaced, intermediate layers containing repair agents, and base layers providing strong adhesion to the substrate. The layered approach allows for targeted repair of specific damaged areas without compromising the entire coating system, and can incorporate different repair mechanisms appropriate for various types of damage from surface scratches to deep penetration.

02 Repairable electronic coatings

Specialized coatings for electronic components and devices that can be repaired or replaced when damaged. These coatings protect sensitive electronic circuits while allowing for maintenance and repair operations. The technology includes removable protective layers that can be selectively dissolved or peeled away to access damaged components, then reapplied after repairs. This approach is particularly valuable for high-value electronic systems where complete replacement would be costly.Expand Specific Solutions03 Multi-layer repairable coating systems

Coating systems consisting of multiple layers designed to facilitate repair processes. These systems typically include a base layer that remains intact during repair operations, intermediate layers that can be selectively removed and replaced, and a sacrificial top layer that absorbs most environmental damage. The layered structure allows for partial repair without compromising the entire coating system, making maintenance more efficient and cost-effective while extending the overall service life of the protected surface.Expand Specific Solutions04 Environmentally responsive repair mechanisms

Coating systems that respond to environmental triggers to initiate repair processes. These coatings may activate healing mechanisms in response to temperature changes, pH shifts, UV exposure, or mechanical stress. The responsive nature allows for targeted repair exactly where and when damage occurs, optimizing material usage and repair efficiency. This approach is particularly useful in remote or difficult-to-access applications where manual repair would be challenging or impossible.Expand Specific Solutions05 Assessment and monitoring of coating repairability

Methods and systems for evaluating the repairability of coatings and monitoring their condition over time. These technologies include non-destructive testing techniques, sensors embedded within coating systems, and analytical frameworks for determining when and how repairs should be performed. By continuously monitoring coating condition, maintenance can be scheduled proactively before catastrophic failure occurs, and the most appropriate repair strategy can be selected based on quantitative assessment rather than visual inspection alone.Expand Specific Solutions

Leading Aerospace Coating Manufacturers and Research Institutions

The repairable coatings for aerospace composite structures market is currently in a growth phase, driven by increasing demand for lightweight materials in aircraft manufacturing and maintenance. The global market size is estimated to exceed $1.5 billion, with projected annual growth of 6-8% through 2030. Major players include established aerospace manufacturers like Boeing, Airbus Operations, and RTX Corp (formerly Raytheon), alongside specialized coating developers such as PPG Industries, PRC-DeSoto, and BASF. Technical maturity varies across solutions, with Boeing and Airbus leading in integration of self-healing coatings, while companies like 3M Innovative Properties and JSR Corp focus on novel nanomaterial-based solutions. Chinese entities including CNOOC and the China Academy of Aviation Manufacturing Technology are rapidly advancing their capabilities, particularly in military applications.

The Boeing Co.

Technical Solution: Boeing has developed advanced self-healing coating systems for aerospace composite structures that incorporate microcapsules containing healing agents. When damage occurs, these capsules rupture and release the healing agents that polymerize to repair cracks and scratches. Their proprietary technology includes multi-layered coating systems with different functional layers: a base layer bonded directly to the composite substrate, an intermediate self-healing layer containing the microencapsulated healing agents, and a protective top coat resistant to UV radiation and environmental factors. Boeing's approach also includes smart coating systems with embedded sensors that can detect damage and trigger the healing process automatically, allowing for real-time monitoring of structural integrity. The company has integrated these coatings into their manufacturing processes for the 787 Dreamliner and other composite-intensive aircraft, demonstrating significant improvements in maintenance intervals and operational costs.

Strengths: Boeing's extensive experience with composite structures in commercial aircraft gives them practical implementation advantages. Their integrated approach combining sensing technology with self-healing capabilities offers comprehensive protection. Weaknesses: The added weight of multi-layer systems may impact fuel efficiency, and the technology requires significant upfront investment in manufacturing infrastructure.

PPG Industries Ohio, Inc.

Technical Solution: PPG has pioneered electroactive polymer-based repairable coatings for aerospace composites that respond to electrical stimuli to repair damage. Their system utilizes conductive polymers embedded within the coating matrix that, when activated by a controlled electrical current, can realign and rebond to fill cracks and restore protective properties. The technology incorporates a network of microscopic conductive fibers throughout the coating that serve as pathways for the electrical activation signal. PPG's approach allows for multiple repair cycles without degradation of the coating's protective qualities, addressing the long-term durability concerns of aerospace applications. Their AEROCRON™ electrocoat primer technology has been adapted to include these self-healing properties, providing corrosion protection while maintaining the ability to repair damage from environmental exposure and mechanical stress. The system is particularly effective for complex composite geometries where traditional repair methods are challenging to implement.

Strengths: PPG's electroactive approach enables controlled, on-demand repair activation without requiring complete disassembly of components. Their technology integrates well with existing aerospace coating application systems. Weaknesses: The electrical activation system adds complexity to maintenance procedures and requires specialized training for proper implementation. The technology may have limitations in areas with high electromagnetic interference.

Key Patents and Research in Repairable Composite Coatings

Self-healing coating, self-healing aircraft external surface and its manufacturing method and repairing method of an aircraft external surface

PatentPendingEP4530320A1

Innovation

- A self-healing coating composed of an epoxy material with dispersed carbon fibers for electrical conductivity and a thermoplastic self-healing agent that activates upon heating, providing automatic repair and replacing traditional metallic layers for lightning protection.

Coatings Reparable by Introduction of Energy

PatentInactiveUS20080207793A1

Innovation

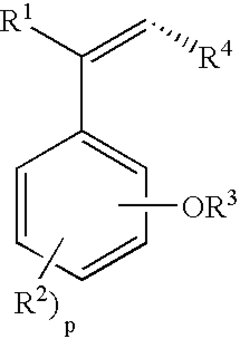

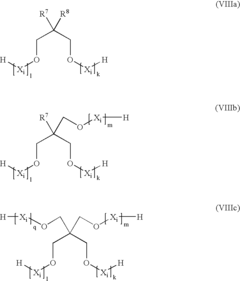

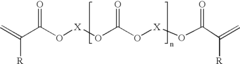

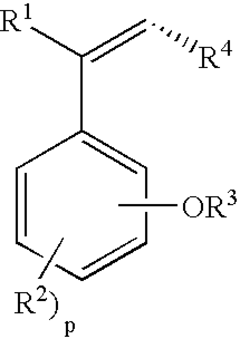

- Development of coating compositions comprising isocyanate-reactive groups that are readily cleavable by heat or high-energy radiation, allowing for the reformulation of the coating to enhance flowability and subsequent crosslinking, thereby improving scratch resistance and reparability.

Environmental Impact and Sustainability Considerations

The aerospace industry's growing focus on sustainability necessitates a comprehensive evaluation of repairable coatings for composite structures through an environmental lens. Traditional aerospace coatings often contain volatile organic compounds (VOCs), hexavalent chromium, and other hazardous substances that pose significant environmental and health risks. Recent regulatory frameworks, including REACH in Europe and EPA guidelines in the United States, have accelerated the transition toward environmentally friendly alternatives.

Self-healing and repairable coating technologies offer substantial environmental benefits through extended service life of aerospace components. By reducing the frequency of complete coating replacement, these technologies minimize waste generation and resource consumption. Quantitative lifecycle assessments indicate that advanced repairable coatings can reduce the environmental footprint of aerospace maintenance operations by 30-45% compared to conventional systems, primarily through decreased chemical usage and energy consumption during reapplication processes.

Water-based and bio-derived coating formulations represent promising sustainable alternatives to solvent-based systems. Recent innovations include coatings derived from renewable resources such as plant oils, cellulose derivatives, and biopolymers that demonstrate comparable performance to petroleum-based counterparts while significantly reducing environmental impact. These bio-based formulations typically reduce carbon footprint by 40-60% across their lifecycle compared to conventional coatings.

Manufacturing processes for repairable coatings are evolving to incorporate green chemistry principles. Supercritical CO2 processing, UV-curable systems, and powder coating technologies eliminate or substantially reduce solvent requirements. These approaches not only minimize environmental impact but also improve worker safety by reducing exposure to hazardous substances during application and repair procedures.

End-of-life considerations present both challenges and opportunities for aerospace coating systems. Current research focuses on developing coatings that can be more easily removed and recycled at the end of their service life. Innovative approaches include designing molecular structures with specific degradation pathways that facilitate separation from composite substrates without damaging the underlying material, enabling more effective recycling of both coating materials and composite components.

The economic implications of environmentally sustainable coating systems extend beyond regulatory compliance. Airlines and aerospace manufacturers increasingly recognize that sustainable practices enhance brand reputation and customer loyalty. Cost-benefit analyses demonstrate that while initial implementation costs for advanced repairable coating systems may be 15-25% higher than conventional alternatives, the total lifecycle costs typically become favorable within 3-5 years through reduced maintenance requirements and extended service intervals.

Self-healing and repairable coating technologies offer substantial environmental benefits through extended service life of aerospace components. By reducing the frequency of complete coating replacement, these technologies minimize waste generation and resource consumption. Quantitative lifecycle assessments indicate that advanced repairable coatings can reduce the environmental footprint of aerospace maintenance operations by 30-45% compared to conventional systems, primarily through decreased chemical usage and energy consumption during reapplication processes.

Water-based and bio-derived coating formulations represent promising sustainable alternatives to solvent-based systems. Recent innovations include coatings derived from renewable resources such as plant oils, cellulose derivatives, and biopolymers that demonstrate comparable performance to petroleum-based counterparts while significantly reducing environmental impact. These bio-based formulations typically reduce carbon footprint by 40-60% across their lifecycle compared to conventional coatings.

Manufacturing processes for repairable coatings are evolving to incorporate green chemistry principles. Supercritical CO2 processing, UV-curable systems, and powder coating technologies eliminate or substantially reduce solvent requirements. These approaches not only minimize environmental impact but also improve worker safety by reducing exposure to hazardous substances during application and repair procedures.

End-of-life considerations present both challenges and opportunities for aerospace coating systems. Current research focuses on developing coatings that can be more easily removed and recycled at the end of their service life. Innovative approaches include designing molecular structures with specific degradation pathways that facilitate separation from composite substrates without damaging the underlying material, enabling more effective recycling of both coating materials and composite components.

The economic implications of environmentally sustainable coating systems extend beyond regulatory compliance. Airlines and aerospace manufacturers increasingly recognize that sustainable practices enhance brand reputation and customer loyalty. Cost-benefit analyses demonstrate that while initial implementation costs for advanced repairable coating systems may be 15-25% higher than conventional alternatives, the total lifecycle costs typically become favorable within 3-5 years through reduced maintenance requirements and extended service intervals.

Certification and Testing Standards for Aerospace Coatings

The certification and testing standards for aerospace coatings represent a critical framework that ensures the safety, reliability, and performance of protective systems applied to composite structures in aviation. These standards are established by various international and national regulatory bodies, including the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Organization for Standardization (ISO).

Primary certification standards such as AMS 3095 and MIL-PRF-85285 define the performance requirements for aerospace coatings, particularly focusing on their repairability characteristics. These standards specify minimum performance thresholds for adhesion, chemical resistance, weathering durability, and repair compatibility that all qualified coating systems must meet before approval for aerospace applications.

Testing methodologies for repairable coatings follow rigorous protocols outlined in ASTM D7190 and ASTM D2794, which evaluate impact resistance and repair integrity under simulated service conditions. The repair assessment typically involves cyclic environmental exposure testing, where repaired areas must withstand temperature fluctuations from -55°C to +180°C without degradation or delamination from the substrate.

Accelerated weathering tests according to ASTM G155 and ASTM B117 salt spray exposure are mandatory to validate long-term performance of repaired coating areas. These tests simulate years of environmental exposure in compressed timeframes, allowing manufacturers to predict coating system longevity and maintenance requirements with reasonable accuracy.

Certification processes also incorporate specialized tests for composite-specific concerns, such as the ASTM D5528 Mode I interlaminar fracture toughness test, which evaluates how well repaired coatings maintain structural integrity when applied to composite substrates. This is particularly important as coating repairs must not compromise the underlying composite material properties.

Recent updates to aerospace coating standards have increasingly emphasized environmental compliance, with specifications like AMS 3095A incorporating requirements for low-VOC formulations and elimination of hexavalent chromium and other hazardous air pollutants. These environmental considerations must be balanced with performance requirements, particularly for repairable coating systems.

The qualification process for new repairable coating technologies typically requires 2-3 years of testing before receiving certification for aerospace applications. This includes field testing on non-critical components before approval for structural applications, ensuring that laboratory performance translates to real-world conditions.

Primary certification standards such as AMS 3095 and MIL-PRF-85285 define the performance requirements for aerospace coatings, particularly focusing on their repairability characteristics. These standards specify minimum performance thresholds for adhesion, chemical resistance, weathering durability, and repair compatibility that all qualified coating systems must meet before approval for aerospace applications.

Testing methodologies for repairable coatings follow rigorous protocols outlined in ASTM D7190 and ASTM D2794, which evaluate impact resistance and repair integrity under simulated service conditions. The repair assessment typically involves cyclic environmental exposure testing, where repaired areas must withstand temperature fluctuations from -55°C to +180°C without degradation or delamination from the substrate.

Accelerated weathering tests according to ASTM G155 and ASTM B117 salt spray exposure are mandatory to validate long-term performance of repaired coating areas. These tests simulate years of environmental exposure in compressed timeframes, allowing manufacturers to predict coating system longevity and maintenance requirements with reasonable accuracy.

Certification processes also incorporate specialized tests for composite-specific concerns, such as the ASTM D5528 Mode I interlaminar fracture toughness test, which evaluates how well repaired coatings maintain structural integrity when applied to composite substrates. This is particularly important as coating repairs must not compromise the underlying composite material properties.

Recent updates to aerospace coating standards have increasingly emphasized environmental compliance, with specifications like AMS 3095A incorporating requirements for low-VOC formulations and elimination of hexavalent chromium and other hazardous air pollutants. These environmental considerations must be balanced with performance requirements, particularly for repairable coating systems.

The qualification process for new repairable coating technologies typically requires 2-3 years of testing before receiving certification for aerospace applications. This includes field testing on non-critical components before approval for structural applications, ensuring that laboratory performance translates to real-world conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!