Advanced Alkylation Techniques for Petrochemicals

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkylation Evolution

Alkylation, a fundamental process in petrochemical production, has undergone significant evolution since its inception in the 1930s. Initially developed for the production of high-octane aviation fuel during World War II, alkylation has become an integral part of modern refinery operations, particularly in the production of gasoline blending components.

The early stages of alkylation primarily utilized sulfuric acid as a catalyst. This method, while effective, posed significant environmental and safety challenges. The 1950s and 1960s saw the introduction of hydrofluoric acid (HF) alkylation, which offered improved efficiency and product quality. However, concerns over the toxicity and potential hazards of HF led to ongoing research into safer alternatives.

The 1970s and 1980s marked a period of technological refinement, with improvements in reactor design, catalyst recovery, and process control. These advancements enhanced the overall efficiency and safety of alkylation units. During this time, solid acid catalysts began to emerge as a potential alternative to liquid acid catalysts, promising reduced environmental impact and improved handling safety.

The 1990s and early 2000s witnessed a surge in research and development efforts focused on solid acid catalysts. Various materials, including zeolites, supported metal oxides, and ionic liquids, were explored for their potential in alkylation processes. While these solid catalysts showed promise in laboratory settings, scaling up to commercial operations proved challenging due to issues with catalyst deactivation and product selectivity.

In recent years, the alkylation landscape has been shaped by two primary drivers: environmental regulations and the pursuit of operational efficiency. This has led to the development of advanced alkylation technologies that aim to address the limitations of traditional processes. Notable among these is the AlkyClean process, which utilizes a proprietary solid acid catalyst, eliminating the need for liquid acids entirely.

Concurrently, efforts to improve existing HF and sulfuric acid alkylation processes have continued. Innovations in acid regeneration, improved safety systems, and enhanced process control have extended the viability of these traditional methods. The introduction of additives to mitigate the volatility of HF has also been a significant development in improving the safety profile of HF alkylation units.

Looking forward, the evolution of alkylation technology is likely to focus on further improvements in catalyst performance, process intensification, and the integration of digital technologies for optimized operations. The ongoing pursuit of more environmentally friendly and safer alkylation processes remains a key driver in the field, with research continuing into novel catalyst materials and reactor designs.

The early stages of alkylation primarily utilized sulfuric acid as a catalyst. This method, while effective, posed significant environmental and safety challenges. The 1950s and 1960s saw the introduction of hydrofluoric acid (HF) alkylation, which offered improved efficiency and product quality. However, concerns over the toxicity and potential hazards of HF led to ongoing research into safer alternatives.

The 1970s and 1980s marked a period of technological refinement, with improvements in reactor design, catalyst recovery, and process control. These advancements enhanced the overall efficiency and safety of alkylation units. During this time, solid acid catalysts began to emerge as a potential alternative to liquid acid catalysts, promising reduced environmental impact and improved handling safety.

The 1990s and early 2000s witnessed a surge in research and development efforts focused on solid acid catalysts. Various materials, including zeolites, supported metal oxides, and ionic liquids, were explored for their potential in alkylation processes. While these solid catalysts showed promise in laboratory settings, scaling up to commercial operations proved challenging due to issues with catalyst deactivation and product selectivity.

In recent years, the alkylation landscape has been shaped by two primary drivers: environmental regulations and the pursuit of operational efficiency. This has led to the development of advanced alkylation technologies that aim to address the limitations of traditional processes. Notable among these is the AlkyClean process, which utilizes a proprietary solid acid catalyst, eliminating the need for liquid acids entirely.

Concurrently, efforts to improve existing HF and sulfuric acid alkylation processes have continued. Innovations in acid regeneration, improved safety systems, and enhanced process control have extended the viability of these traditional methods. The introduction of additives to mitigate the volatility of HF has also been a significant development in improving the safety profile of HF alkylation units.

Looking forward, the evolution of alkylation technology is likely to focus on further improvements in catalyst performance, process intensification, and the integration of digital technologies for optimized operations. The ongoing pursuit of more environmentally friendly and safer alkylation processes remains a key driver in the field, with research continuing into novel catalyst materials and reactor designs.

Petrochemical Demand

The petrochemical industry has witnessed a significant surge in demand for advanced alkylation techniques, driven by the growing need for high-quality fuels and specialty chemicals. This demand is primarily fueled by the automotive and aerospace sectors, which require cleaner-burning and higher-performance fuels. The global market for alkylation products is experiencing steady growth, with a particular emphasis on isooctane and other high-octane components used in gasoline blending.

In recent years, there has been a notable shift towards more environmentally friendly alkylation processes, responding to stringent regulations on emissions and fuel quality. This has led to increased interest in solid acid catalysts and ionic liquid-based alkylation technologies, which offer reduced environmental impact compared to traditional sulfuric or hydrofluoric acid-based processes.

The petrochemical industry is also seeing a rising demand for alkylated aromatics, which are crucial intermediates in the production of detergents, lubricants, and various specialty chemicals. This trend is particularly strong in emerging economies, where rapid industrialization and urbanization are driving the need for a wide range of petrochemical products.

Another factor influencing the demand for advanced alkylation techniques is the changing feedstock landscape. With the increasing availability of light olefins from shale gas processing, there is a growing interest in alkylation processes that can efficiently utilize these feedstocks to produce high-value products.

The automotive industry's transition towards electric vehicles is expected to impact the long-term demand for traditional alkylation products used in gasoline. However, this shift is also creating new opportunities for specialty alkylates used in lubricants and other high-performance materials required for electric vehicle components.

In the Asia-Pacific region, particularly in China and India, there is a robust demand for alkylation technologies due to the rapid expansion of refining capacities and the increasing focus on producing cleaner fuels. This regional growth is expected to be a significant driver for innovations in alkylation techniques in the coming years.

The demand for advanced alkylation techniques is also being shaped by the broader trend towards circular economy principles in the petrochemical industry. There is growing interest in developing alkylation processes that can utilize recycled or bio-based feedstocks, aligning with sustainability goals and potentially opening new market segments.

In recent years, there has been a notable shift towards more environmentally friendly alkylation processes, responding to stringent regulations on emissions and fuel quality. This has led to increased interest in solid acid catalysts and ionic liquid-based alkylation technologies, which offer reduced environmental impact compared to traditional sulfuric or hydrofluoric acid-based processes.

The petrochemical industry is also seeing a rising demand for alkylated aromatics, which are crucial intermediates in the production of detergents, lubricants, and various specialty chemicals. This trend is particularly strong in emerging economies, where rapid industrialization and urbanization are driving the need for a wide range of petrochemical products.

Another factor influencing the demand for advanced alkylation techniques is the changing feedstock landscape. With the increasing availability of light olefins from shale gas processing, there is a growing interest in alkylation processes that can efficiently utilize these feedstocks to produce high-value products.

The automotive industry's transition towards electric vehicles is expected to impact the long-term demand for traditional alkylation products used in gasoline. However, this shift is also creating new opportunities for specialty alkylates used in lubricants and other high-performance materials required for electric vehicle components.

In the Asia-Pacific region, particularly in China and India, there is a robust demand for alkylation technologies due to the rapid expansion of refining capacities and the increasing focus on producing cleaner fuels. This regional growth is expected to be a significant driver for innovations in alkylation techniques in the coming years.

The demand for advanced alkylation techniques is also being shaped by the broader trend towards circular economy principles in the petrochemical industry. There is growing interest in developing alkylation processes that can utilize recycled or bio-based feedstocks, aligning with sustainability goals and potentially opening new market segments.

Technical Hurdles

Advanced alkylation techniques for petrochemicals face several significant technical hurdles that impede their widespread adoption and efficiency. One of the primary challenges is the development of more selective catalysts. Current catalysts often produce a mixture of products, including unwanted side reactions, which reduces overall yield and increases separation costs. Researchers are striving to design catalysts with improved selectivity to target specific alkylation products while minimizing byproduct formation.

Another major obstacle is the management of catalyst deactivation. Alkylation catalysts, particularly in liquid acid systems, tend to lose their activity over time due to coke formation and other fouling mechanisms. This necessitates frequent catalyst regeneration or replacement, leading to increased operational costs and downtime. Developing catalysts with enhanced stability and resistance to deactivation remains a key focus area for researchers and industry professionals.

The environmental impact of traditional alkylation processes presents another significant challenge. Many conventional techniques rely on strong acids like hydrofluoric or sulfuric acid, which pose serious safety and environmental risks. There is a pressing need to develop greener alkylation methods that utilize less hazardous materials and produce fewer waste products. This includes exploring solid acid catalysts and ionic liquid systems as potential alternatives to conventional liquid acid catalysts.

Energy efficiency is another critical hurdle in advanced alkylation techniques. Current processes often require high temperatures and pressures, resulting in substantial energy consumption. Improving the energy efficiency of alkylation reactions through process intensification, novel reactor designs, and more active catalysts is crucial for enhancing the sustainability and economic viability of these techniques.

The scalability of new alkylation technologies from laboratory to industrial scale poses additional challenges. Many promising techniques demonstrated at the bench scale face difficulties in maintaining their performance when scaled up to commercial production levels. Issues such as heat and mass transfer limitations, catalyst lifetime, and process control become more pronounced at larger scales, requiring innovative engineering solutions.

Lastly, the integration of advanced alkylation techniques with existing petrochemical infrastructure presents both technical and economic challenges. Retrofitting existing plants or designing new facilities to accommodate novel alkylation processes requires significant capital investment and careful consideration of process compatibility. Overcoming these integration hurdles is essential for the widespread adoption of advanced alkylation technologies in the petrochemical industry.

Another major obstacle is the management of catalyst deactivation. Alkylation catalysts, particularly in liquid acid systems, tend to lose their activity over time due to coke formation and other fouling mechanisms. This necessitates frequent catalyst regeneration or replacement, leading to increased operational costs and downtime. Developing catalysts with enhanced stability and resistance to deactivation remains a key focus area for researchers and industry professionals.

The environmental impact of traditional alkylation processes presents another significant challenge. Many conventional techniques rely on strong acids like hydrofluoric or sulfuric acid, which pose serious safety and environmental risks. There is a pressing need to develop greener alkylation methods that utilize less hazardous materials and produce fewer waste products. This includes exploring solid acid catalysts and ionic liquid systems as potential alternatives to conventional liquid acid catalysts.

Energy efficiency is another critical hurdle in advanced alkylation techniques. Current processes often require high temperatures and pressures, resulting in substantial energy consumption. Improving the energy efficiency of alkylation reactions through process intensification, novel reactor designs, and more active catalysts is crucial for enhancing the sustainability and economic viability of these techniques.

The scalability of new alkylation technologies from laboratory to industrial scale poses additional challenges. Many promising techniques demonstrated at the bench scale face difficulties in maintaining their performance when scaled up to commercial production levels. Issues such as heat and mass transfer limitations, catalyst lifetime, and process control become more pronounced at larger scales, requiring innovative engineering solutions.

Lastly, the integration of advanced alkylation techniques with existing petrochemical infrastructure presents both technical and economic challenges. Retrofitting existing plants or designing new facilities to accommodate novel alkylation processes requires significant capital investment and careful consideration of process compatibility. Overcoming these integration hurdles is essential for the widespread adoption of advanced alkylation technologies in the petrochemical industry.

Current Techniques

01 Catalytic alkylation processes

Various catalytic processes are employed for alkylation reactions. These include the use of solid acid catalysts, zeolites, and metal-based catalysts. The choice of catalyst can significantly influence the reaction selectivity, yield, and product distribution. Catalytic alkylation is widely used in the production of high-octane gasoline components and other valuable chemicals.- Catalytic alkylation processes: Various catalytic processes are employed for alkylation reactions. These include the use of solid acid catalysts, zeolites, and other heterogeneous catalysts to promote the alkylation of hydrocarbons. The catalysts can enhance reaction rates, improve selectivity, and allow for milder reaction conditions.

- Alkylation of aromatic compounds: Techniques for alkylating aromatic compounds, such as benzene and its derivatives, are widely used in the chemical industry. These methods often involve the use of specific catalysts and reaction conditions to achieve desired product distributions and minimize side reactions.

- Alkylation in petroleum refining: Alkylation processes play a crucial role in petroleum refining, particularly in the production of high-octane gasoline components. These techniques often involve the reaction of light olefins with isobutane using strong acid catalysts under controlled conditions to produce branched alkanes.

- Continuous flow alkylation systems: Continuous flow systems for alkylation reactions have been developed to improve efficiency and product quality. These systems often incorporate specialized reactor designs, catalyst regeneration methods, and process control strategies to maintain optimal reaction conditions over extended periods.

- Green alkylation techniques: Environmentally friendly alkylation methods have gained attention in recent years. These techniques focus on using less hazardous reagents, reducing waste generation, and improving energy efficiency. Examples include the use of ionic liquids as catalysts, solvent-free reactions, and the development of bio-based alkylating agents.

02 Alkylation of aromatics

Techniques for alkylating aromatic compounds are crucial in the production of various industrial chemicals. These methods often involve the reaction of an aromatic substrate with an alkylating agent in the presence of a catalyst. The process can be optimized for selectivity towards specific isomers or products, depending on the desired application.Expand Specific Solutions03 Olefin alkylation

Olefin alkylation is a key process in the petrochemical industry, particularly for the production of high-octane gasoline components. This technique involves the reaction of olefins with isoparaffins to form branched alkanes. Various catalysts and process conditions are employed to optimize the reaction efficiency and product quality.Expand Specific Solutions04 Alkylation reactor design and process optimization

The design of alkylation reactors and optimization of process conditions are critical for improving efficiency and product quality. This includes considerations such as reactor configuration, temperature control, catalyst management, and separation techniques. Advanced reactor designs and process control strategies can enhance yield, selectivity, and overall process economics.Expand Specific Solutions05 Novel alkylation techniques and applications

Emerging alkylation techniques and novel applications are continually being developed. These may include new catalytic systems, alternative feedstocks, or innovative reaction conditions. Such advancements aim to improve efficiency, reduce environmental impact, or enable the production of new valuable chemicals through alkylation processes.Expand Specific Solutions

Industry Leaders

The advanced alkylation techniques for petrochemicals market is in a growth phase, driven by increasing demand for high-octane fuels and petrochemical products. The global market size is estimated to be in the billions, with steady expansion projected. Technologically, the field is evolving rapidly, with major players like China Petroleum & Chemical Corp., ExxonMobil, and SABIC investing heavily in R&D. These companies, along with others such as Total Petrochemicals, UOP LLC, and Sinopec Research Institute, are at the forefront of developing innovative alkylation processes, focusing on efficiency improvements, catalyst optimization, and environmental sustainability. The competitive landscape is characterized by strategic partnerships, licensing agreements, and continuous technological advancements to maintain market position.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced alkylation techniques for petrochemicals, focusing on solid acid catalysts and ionic liquid catalysts. Their solid acid catalyst technology uses a novel zeolite-based catalyst that enhances alkylation efficiency and reduces corrosion issues associated with traditional sulfuric acid catalysts [1]. The company has also made significant progress in ionic liquid-based alkylation, which operates at lower temperatures and pressures, improving energy efficiency and product quality [3]. Sinopec's research has led to the implementation of these technologies in several of their refineries, demonstrating scalability and industrial applicability [5].

Strengths: Improved catalyst efficiency, reduced corrosion, and enhanced energy efficiency. Weaknesses: High initial investment costs for technology implementation and potential challenges in catalyst regeneration.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has pioneered the AlkyClean® solid acid alkylation technology, which eliminates the need for liquid acids in the alkylation process. This innovative approach uses a proprietary solid acid catalyst that can be regenerated in situ, significantly reducing environmental and safety risks associated with traditional liquid acid catalysts [2]. The technology operates at higher temperatures than conventional alkylation processes, allowing for better integration with refinery heat recovery systems and improved energy efficiency [4]. ExxonMobil has successfully demonstrated this technology at commercial scale, processing up to 10,000 barrels per day of alkylate production [6].

Strengths: Elimination of liquid acid handling, improved safety, and better energy integration. Weaknesses: Higher operating temperatures may require specialized equipment and materials.

Innovative Patents

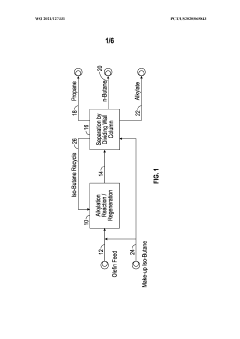

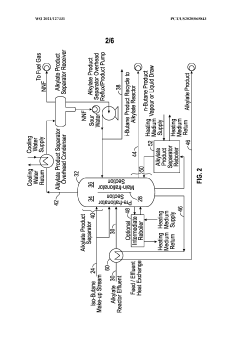

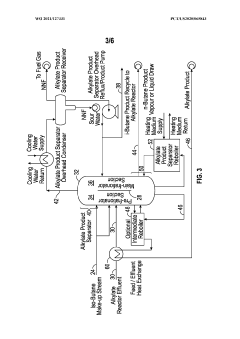

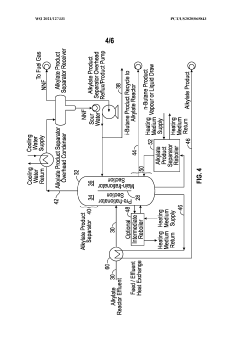

Diving wall column in alkylation process for reactor recycle and product separation

PatentWO2021127331A1

Innovation

- The implementation of a dividing wall column (DWC) in the alkylation process to separate alkylate reactor effluent into iso-butane, n-butane, and alkylate product streams, allowing for efficient recycling of iso-butane and optimizing energy usage through heat integration and reboiler configuration.

Alkylation process using an alkyl halide promoted pyridinium ionic liquid catalyst

PatentActiveEP2597078A1

Innovation

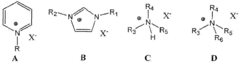

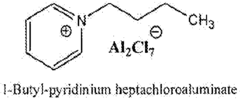

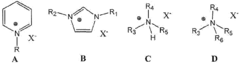

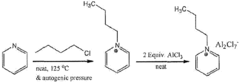

- An alkylation process using a catalyst comprising a mixture of acidic ionic liquids, such as chloroaluminate ionic liquids prepared by mixing aluminum trichloride with hydrocarbyl substituted pyridinium or imidazolium halides, and an alkyl halide, which promotes the reaction while reducing the need for hazardous substances.

Environmental Impact

Advanced alkylation techniques in petrochemicals have significant environmental implications that warrant careful consideration. These processes, while essential for producing high-quality fuels and chemicals, can potentially impact air quality, water resources, and soil conditions. The primary environmental concerns associated with alkylation include emissions of volatile organic compounds (VOCs), greenhouse gases, and the generation of hazardous waste materials.

Air pollution is a major environmental issue linked to alkylation processes. The release of VOCs, particularly during catalyst regeneration and product separation stages, can contribute to the formation of ground-level ozone and smog. Additionally, the energy-intensive nature of alkylation operations often results in increased carbon dioxide emissions, exacerbating climate change concerns. To mitigate these impacts, many petrochemical facilities have implemented advanced emission control technologies, such as thermal oxidizers and scrubber systems, to reduce the release of harmful pollutants.

Water pollution is another critical environmental aspect of alkylation techniques. The process typically requires substantial amounts of water for cooling and washing operations, potentially leading to thermal pollution and contamination of local water bodies. Wastewater from alkylation units may contain traces of hydrocarbons, acids, and other chemicals that can harm aquatic ecosystems if not properly treated. Advanced water treatment technologies, including membrane filtration and biological treatment systems, are increasingly being employed to minimize the environmental footprint of alkylation processes on water resources.

Soil contamination is a less immediate but equally important environmental concern. Spills or leaks of alkylation catalysts, particularly those containing sulfuric or hydrofluoric acid, can have severe consequences for soil quality and groundwater. The highly corrosive nature of these substances necessitates stringent containment measures and robust emergency response protocols to prevent and mitigate potential soil contamination incidents.

The petrochemical industry has been proactively addressing these environmental challenges through various initiatives. The development of solid acid catalysts for alkylation processes represents a significant advancement in reducing the environmental risks associated with liquid acid catalysts. These solid catalysts not only minimize the potential for acid-related accidents but also reduce waste generation and simplify handling procedures.

Furthermore, the integration of alkylation units with other refinery processes through heat integration and material recycling has led to improved energy efficiency and reduced overall emissions. Some facilities have also explored the use of renewable energy sources to power alkylation operations, further reducing their carbon footprint.

As environmental regulations become increasingly stringent, the petrochemical industry continues to invest in research and development of cleaner alkylation technologies. This includes exploring novel catalyst formulations, process intensification techniques, and advanced monitoring systems to enhance environmental performance while maintaining product quality and economic viability.

Air pollution is a major environmental issue linked to alkylation processes. The release of VOCs, particularly during catalyst regeneration and product separation stages, can contribute to the formation of ground-level ozone and smog. Additionally, the energy-intensive nature of alkylation operations often results in increased carbon dioxide emissions, exacerbating climate change concerns. To mitigate these impacts, many petrochemical facilities have implemented advanced emission control technologies, such as thermal oxidizers and scrubber systems, to reduce the release of harmful pollutants.

Water pollution is another critical environmental aspect of alkylation techniques. The process typically requires substantial amounts of water for cooling and washing operations, potentially leading to thermal pollution and contamination of local water bodies. Wastewater from alkylation units may contain traces of hydrocarbons, acids, and other chemicals that can harm aquatic ecosystems if not properly treated. Advanced water treatment technologies, including membrane filtration and biological treatment systems, are increasingly being employed to minimize the environmental footprint of alkylation processes on water resources.

Soil contamination is a less immediate but equally important environmental concern. Spills or leaks of alkylation catalysts, particularly those containing sulfuric or hydrofluoric acid, can have severe consequences for soil quality and groundwater. The highly corrosive nature of these substances necessitates stringent containment measures and robust emergency response protocols to prevent and mitigate potential soil contamination incidents.

The petrochemical industry has been proactively addressing these environmental challenges through various initiatives. The development of solid acid catalysts for alkylation processes represents a significant advancement in reducing the environmental risks associated with liquid acid catalysts. These solid catalysts not only minimize the potential for acid-related accidents but also reduce waste generation and simplify handling procedures.

Furthermore, the integration of alkylation units with other refinery processes through heat integration and material recycling has led to improved energy efficiency and reduced overall emissions. Some facilities have also explored the use of renewable energy sources to power alkylation operations, further reducing their carbon footprint.

As environmental regulations become increasingly stringent, the petrochemical industry continues to invest in research and development of cleaner alkylation technologies. This includes exploring novel catalyst formulations, process intensification techniques, and advanced monitoring systems to enhance environmental performance while maintaining product quality and economic viability.

Regulatory Framework

The regulatory framework surrounding advanced alkylation techniques in the petrochemical industry is complex and multifaceted, reflecting the need to balance technological innovation with environmental and safety concerns. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Maritime Organization (IMO) have established guidelines and conventions that impact the development and implementation of alkylation processes. These include regulations on emissions control, waste management, and the transportation of hazardous materials.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating alkylation processes through various acts and programs. The Clean Air Act and the Clean Water Act set stringent standards for emissions and effluents from petrochemical facilities. The Resource Conservation and Recovery Act (RCRA) governs the handling and disposal of hazardous wastes generated during alkylation processes. Additionally, the Occupational Safety and Health Administration (OSHA) enforces safety standards to protect workers in petrochemical plants.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which require petrochemical companies to register and evaluate the safety of chemicals used in alkylation processes. The EU's Industrial Emissions Directive (IED) also sets emission limits and mandates the use of Best Available Techniques (BAT) in petrochemical operations, including advanced alkylation.

In emerging markets, such as China and India, regulatory frameworks are evolving rapidly to address environmental concerns while supporting industrial growth. China's Environmental Protection Law and India's Environment Protection Act provide the foundation for regulating petrochemical operations, with an increasing focus on emissions reduction and sustainable practices.

Regulatory bodies are increasingly emphasizing the importance of lifecycle assessments for petrochemical processes. This approach considers the environmental impact of alkylation techniques from raw material extraction to end-product disposal, encouraging the development of more sustainable and efficient technologies.

As advanced alkylation techniques continue to evolve, regulatory frameworks are adapting to address new challenges. There is a growing trend towards performance-based regulations, which focus on achieving specific environmental and safety outcomes rather than prescribing specific technologies. This approach allows for greater flexibility in implementing innovative alkylation techniques while maintaining high standards of environmental protection and safety.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating alkylation processes through various acts and programs. The Clean Air Act and the Clean Water Act set stringent standards for emissions and effluents from petrochemical facilities. The Resource Conservation and Recovery Act (RCRA) governs the handling and disposal of hazardous wastes generated during alkylation processes. Additionally, the Occupational Safety and Health Administration (OSHA) enforces safety standards to protect workers in petrochemical plants.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which require petrochemical companies to register and evaluate the safety of chemicals used in alkylation processes. The EU's Industrial Emissions Directive (IED) also sets emission limits and mandates the use of Best Available Techniques (BAT) in petrochemical operations, including advanced alkylation.

In emerging markets, such as China and India, regulatory frameworks are evolving rapidly to address environmental concerns while supporting industrial growth. China's Environmental Protection Law and India's Environment Protection Act provide the foundation for regulating petrochemical operations, with an increasing focus on emissions reduction and sustainable practices.

Regulatory bodies are increasingly emphasizing the importance of lifecycle assessments for petrochemical processes. This approach considers the environmental impact of alkylation techniques from raw material extraction to end-product disposal, encouraging the development of more sustainable and efficient technologies.

As advanced alkylation techniques continue to evolve, regulatory frameworks are adapting to address new challenges. There is a growing trend towards performance-based regulations, which focus on achieving specific environmental and safety outcomes rather than prescribing specific technologies. This approach allows for greater flexibility in implementing innovative alkylation techniques while maintaining high standards of environmental protection and safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!