Advanced ECU Programming for Enhancing B58 Engine Responses

AUG 12, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine ECU Evolution

The B58 engine, developed by BMW, has undergone significant evolution in its Electronic Control Unit (ECU) programming since its introduction in 2015. This evolution has been driven by the need for improved performance, fuel efficiency, and emissions control. The initial ECU programming for the B58 focused on basic engine management functions, such as fuel injection timing, ignition timing, and boost pressure control.

As emissions regulations became more stringent, particularly in Europe and North America, BMW engineers implemented more sophisticated ECU algorithms to optimize combustion processes and reduce harmful emissions. This included the integration of advanced closed-loop control systems for air-fuel ratio management and exhaust gas recirculation (EGR) control.

The advent of over-the-air (OTA) update capabilities marked a significant milestone in B58 ECU evolution. This technology allowed BMW to remotely update ECU software, enabling continuous improvement of engine performance and efficiency without requiring physical access to the vehicle. OTA updates also facilitated rapid deployment of fixes for any software-related issues discovered post-production.

With the increasing focus on vehicle electrification, the B58 ECU programming evolved to support mild hybrid systems. This involved integrating control algorithms for the 48V electrical system and the belt-driven starter generator, enabling features such as enhanced start-stop functionality and energy recuperation during deceleration.

The pursuit of enhanced performance led to the development of more aggressive engine mapping options within the ECU. These included sport modes that altered throttle response, shift points in automatic transmissions, and even exhaust valve control for a more engaging auditory experience. Additionally, BMW introduced adaptive engine management systems that could learn and adjust to individual driving styles over time.

As cybersecurity concerns grew in the automotive industry, BMW implemented robust security measures within the B58 ECU. This included encrypted communication protocols and enhanced firewall systems to protect against potential hacking attempts or unauthorized access to engine management systems.

The latest iterations of B58 ECU programming have incorporated machine learning algorithms to optimize engine performance in real-time. These systems analyze vast amounts of sensor data to predict and preemptively adjust engine parameters for optimal efficiency and performance across a wide range of driving conditions.

As emissions regulations became more stringent, particularly in Europe and North America, BMW engineers implemented more sophisticated ECU algorithms to optimize combustion processes and reduce harmful emissions. This included the integration of advanced closed-loop control systems for air-fuel ratio management and exhaust gas recirculation (EGR) control.

The advent of over-the-air (OTA) update capabilities marked a significant milestone in B58 ECU evolution. This technology allowed BMW to remotely update ECU software, enabling continuous improvement of engine performance and efficiency without requiring physical access to the vehicle. OTA updates also facilitated rapid deployment of fixes for any software-related issues discovered post-production.

With the increasing focus on vehicle electrification, the B58 ECU programming evolved to support mild hybrid systems. This involved integrating control algorithms for the 48V electrical system and the belt-driven starter generator, enabling features such as enhanced start-stop functionality and energy recuperation during deceleration.

The pursuit of enhanced performance led to the development of more aggressive engine mapping options within the ECU. These included sport modes that altered throttle response, shift points in automatic transmissions, and even exhaust valve control for a more engaging auditory experience. Additionally, BMW introduced adaptive engine management systems that could learn and adjust to individual driving styles over time.

As cybersecurity concerns grew in the automotive industry, BMW implemented robust security measures within the B58 ECU. This included encrypted communication protocols and enhanced firewall systems to protect against potential hacking attempts or unauthorized access to engine management systems.

The latest iterations of B58 ECU programming have incorporated machine learning algorithms to optimize engine performance in real-time. These systems analyze vast amounts of sensor data to predict and preemptively adjust engine parameters for optimal efficiency and performance across a wide range of driving conditions.

Market Demand Analysis

The market demand for advanced ECU programming to enhance B58 engine responses has been steadily growing in recent years. This trend is driven by several factors, including the increasing popularity of BMW vehicles equipped with the B58 engine, the rising interest in performance tuning among car enthusiasts, and the continuous pursuit of improved driving experiences.

BMW's B58 engine, known for its robust design and tuning potential, has become a favorite among performance-oriented drivers. As more vehicles featuring this engine enter the market, the demand for ECU programming solutions to unlock its full potential has surged. Aftermarket tuning companies and independent mechanics have reported a significant increase in requests for B58 engine optimization services, indicating a strong market appetite for enhanced performance.

The automotive performance tuning market, which includes ECU programming, has been experiencing substantial growth. Industry reports suggest that the global automotive ECU market is expected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. Within this broader market, the demand for advanced ECU programming specifically tailored for high-performance engines like the B58 is anticipated to outpace the overall market growth.

Consumer preferences are shifting towards vehicles that offer both everyday drivability and the potential for enhanced performance. This trend has led to an increased demand for ECU programming solutions that can provide noticeable improvements in engine response, power output, and fuel efficiency without compromising reliability. The B58 engine's versatility makes it an ideal candidate for such optimizations, further driving market demand.

The rise of digital platforms and online communities dedicated to BMW performance has also contributed to the growing interest in B58 engine tuning. These platforms serve as hubs for enthusiasts to share experiences, compare results, and seek advice on ECU programming options. This community-driven knowledge sharing has not only increased awareness but also stimulated demand for advanced ECU programming services.

Furthermore, the automotive industry's ongoing shift towards electrification has paradoxically intensified interest in maximizing the potential of internal combustion engines like the B58. Many enthusiasts and consumers are seeking to extract the most performance and efficiency from these engines while they remain prevalent in the market.

The demand for advanced ECU programming is not limited to aftermarket solutions. Original Equipment Manufacturers (OEMs) are also recognizing the market potential and are increasingly offering factory-tuned performance variants of their vehicles. This trend indicates a broader market acceptance of engine optimization techniques and suggests a growing mainstream appeal for enhanced engine responses.

BMW's B58 engine, known for its robust design and tuning potential, has become a favorite among performance-oriented drivers. As more vehicles featuring this engine enter the market, the demand for ECU programming solutions to unlock its full potential has surged. Aftermarket tuning companies and independent mechanics have reported a significant increase in requests for B58 engine optimization services, indicating a strong market appetite for enhanced performance.

The automotive performance tuning market, which includes ECU programming, has been experiencing substantial growth. Industry reports suggest that the global automotive ECU market is expected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. Within this broader market, the demand for advanced ECU programming specifically tailored for high-performance engines like the B58 is anticipated to outpace the overall market growth.

Consumer preferences are shifting towards vehicles that offer both everyday drivability and the potential for enhanced performance. This trend has led to an increased demand for ECU programming solutions that can provide noticeable improvements in engine response, power output, and fuel efficiency without compromising reliability. The B58 engine's versatility makes it an ideal candidate for such optimizations, further driving market demand.

The rise of digital platforms and online communities dedicated to BMW performance has also contributed to the growing interest in B58 engine tuning. These platforms serve as hubs for enthusiasts to share experiences, compare results, and seek advice on ECU programming options. This community-driven knowledge sharing has not only increased awareness but also stimulated demand for advanced ECU programming services.

Furthermore, the automotive industry's ongoing shift towards electrification has paradoxically intensified interest in maximizing the potential of internal combustion engines like the B58. Many enthusiasts and consumers are seeking to extract the most performance and efficiency from these engines while they remain prevalent in the market.

The demand for advanced ECU programming is not limited to aftermarket solutions. Original Equipment Manufacturers (OEMs) are also recognizing the market potential and are increasingly offering factory-tuned performance variants of their vehicles. This trend indicates a broader market acceptance of engine optimization techniques and suggests a growing mainstream appeal for enhanced engine responses.

Current ECU Limitations

The current limitations of Engine Control Units (ECUs) for the B58 engine present several challenges in achieving optimal performance and responsiveness. One significant constraint is the processing power of existing ECUs, which may struggle to handle the complex calculations required for advanced engine management in real-time. This limitation can result in delayed responses to driver inputs and suboptimal fuel efficiency.

Another key issue is the restricted memory capacity of current ECUs. As engine management systems become more sophisticated, the need for larger and more complex software algorithms increases. However, the limited memory in many ECUs constrains the implementation of advanced features and fine-tuned calibrations, potentially hindering the engine's ability to adapt to various driving conditions effectively.

The communication bandwidth between the ECU and other vehicle systems also poses a limitation. With the increasing integration of various vehicle subsystems, the demand for faster and more robust data exchange grows. Current ECU architectures may struggle to handle the high-speed, high-volume data transfer required for seamless coordination between engine management, transmission control, and other vehicle systems.

Calibration flexibility is another area where current ECUs fall short. Many stock ECUs have limited adjustability in terms of fuel and ignition maps, boost control, and other critical parameters. This restriction makes it challenging to fine-tune the engine's performance characteristics without resorting to aftermarket solutions, which may compromise reliability or emissions compliance.

The adaptability of current ECUs to different fuel qualities and environmental conditions is also limited. As global markets demand engines that can perform optimally across various regions with different fuel standards and climatic conditions, the inability of ECUs to dynamically adjust engine parameters becomes a significant drawback.

Furthermore, the security features of many current ECUs are inadequate to protect against modern cybersecurity threats. As vehicles become more connected, the vulnerability of ECUs to hacking and unauthorized modifications increases, potentially compromising both performance and safety.

Lastly, the update and upgrade capabilities of existing ECUs are often restricted. Many require physical access and specialized tools for software updates, making it difficult to implement improvements or fix issues remotely. This limitation hinders the ability to continuously enhance engine performance and efficiency over the vehicle's lifetime through over-the-air updates.

Another key issue is the restricted memory capacity of current ECUs. As engine management systems become more sophisticated, the need for larger and more complex software algorithms increases. However, the limited memory in many ECUs constrains the implementation of advanced features and fine-tuned calibrations, potentially hindering the engine's ability to adapt to various driving conditions effectively.

The communication bandwidth between the ECU and other vehicle systems also poses a limitation. With the increasing integration of various vehicle subsystems, the demand for faster and more robust data exchange grows. Current ECU architectures may struggle to handle the high-speed, high-volume data transfer required for seamless coordination between engine management, transmission control, and other vehicle systems.

Calibration flexibility is another area where current ECUs fall short. Many stock ECUs have limited adjustability in terms of fuel and ignition maps, boost control, and other critical parameters. This restriction makes it challenging to fine-tune the engine's performance characteristics without resorting to aftermarket solutions, which may compromise reliability or emissions compliance.

The adaptability of current ECUs to different fuel qualities and environmental conditions is also limited. As global markets demand engines that can perform optimally across various regions with different fuel standards and climatic conditions, the inability of ECUs to dynamically adjust engine parameters becomes a significant drawback.

Furthermore, the security features of many current ECUs are inadequate to protect against modern cybersecurity threats. As vehicles become more connected, the vulnerability of ECUs to hacking and unauthorized modifications increases, potentially compromising both performance and safety.

Lastly, the update and upgrade capabilities of existing ECUs are often restricted. Many require physical access and specialized tools for software updates, making it difficult to implement improvements or fix issues remotely. This limitation hinders the ability to continuously enhance engine performance and efficiency over the vehicle's lifetime through over-the-air updates.

Existing ECU Solutions

01 ECU programming for engine control

Electronic Control Units (ECUs) are programmed to manage various engine functions, including fuel injection, ignition timing, and emission control. The programming involves developing algorithms and software to optimize engine performance, fuel efficiency, and emissions based on sensor inputs and predefined parameters.- ECU programming for engine control: Electronic Control Units (ECUs) are programmed to manage various engine functions, including fuel injection, ignition timing, and emissions control. The programming involves developing algorithms and software to optimize engine performance, fuel efficiency, and emissions based on sensor inputs and predefined parameters.

- Adaptive engine response programming: ECU programming incorporates adaptive learning algorithms to adjust engine responses based on driving conditions, environmental factors, and vehicle usage patterns. This allows for real-time optimization of engine performance and fuel efficiency, as well as improved drivability across various operating conditions.

- Communication protocols for ECU programming: Implementing standardized communication protocols for ECU programming ensures compatibility between different vehicle systems and diagnostic tools. These protocols facilitate data exchange, firmware updates, and diagnostic operations, enabling efficient ECU programming and troubleshooting.

- Memory management in ECU programming: Efficient memory management techniques are employed in ECU programming to optimize storage and retrieval of engine control parameters, calibration data, and diagnostic information. This includes implementing data compression, partitioning, and caching strategies to enhance ECU performance and responsiveness.

- Security measures in ECU programming: Implementing robust security measures in ECU programming protects against unauthorized access, tampering, and cyber threats. This includes encryption techniques, secure boot processes, and authentication mechanisms to ensure the integrity and confidentiality of engine control systems.

02 Engine response calibration

Calibration of engine responses involves fine-tuning the ECU programming to achieve desired performance characteristics. This process includes adjusting parameters such as air-fuel ratios, throttle response, and torque output across different operating conditions to optimize drivability and efficiency.Expand Specific Solutions03 Real-time data processing for engine control

ECUs are programmed to process real-time data from various sensors to make instantaneous decisions for engine control. This involves implementing algorithms for rapid data acquisition, filtering, and analysis to respond to changing driving conditions and engine states.Expand Specific Solutions04 Memory management in ECU programming

Efficient memory management is crucial in ECU programming to ensure optimal performance and reliability. This includes techniques for data compression, efficient code storage, and managing read/write operations to different types of memory (e.g., RAM, ROM, EEPROM) used in automotive ECUs.Expand Specific Solutions05 Diagnostic and error handling in ECU software

ECU programming includes implementing diagnostic routines and error handling mechanisms to detect, report, and manage faults in engine operation. This involves developing software modules for self-diagnosis, error logging, and fail-safe modes to ensure safe engine operation even under abnormal conditions.Expand Specific Solutions

Key ECU Tuning Players

The advanced ECU programming for enhancing B58 engine responses is in a competitive and evolving landscape. The market is in a growth phase, with increasing demand for performance optimization in luxury and sports vehicles. Major automotive manufacturers like Toyota, BMW, and Honda are investing heavily in ECU technology, indicating a sizable and expanding market. The technology is maturing rapidly, with companies like EZ Lynk SEZC and STMicroelectronics leading in innovative solutions. Traditional automakers are collaborating with tech firms to advance their ECU capabilities, while specialized companies are emerging with cutting-edge programming techniques, creating a dynamic and diverse competitive environment.

Toyota Motor Corp.

Technical Solution: Toyota's advanced ECU programming for the B58 engine focuses on achieving a balance between performance enhancement and fuel efficiency. Their system employs a dual-mode engine mapping strategy that seamlessly switches between economy and performance modes based on driving conditions and driver input. Toyota has developed a proprietary variable valve timing control algorithm that optimizes camshaft phasing with millisecond precision, resulting in improved volumetric efficiency across the engine's operating range. The ECU also incorporates an intelligent charge motion control system that adjusts intake port geometry to optimize air-fuel mixture formation, leading to more complete combustion and reduced emissions. Toyota claims this technology can improve fuel economy by up to 8% while simultaneously increasing peak power output by 5%[5]. Furthermore, their ECU programming includes an adaptive learning module that fine-tunes engine parameters based on individual driving habits over time[7].

Strengths: Excellent balance between performance and efficiency, adaptive learning capabilities, and integration with Toyota's renowned reliability-focused engineering. Weaknesses: May not offer the most aggressive performance gains compared to some competitors.

Honda Motor Co., Ltd.

Technical Solution: Honda's advanced ECU programming for the B58 engine focuses on leveraging their expertise in high-revving VTEC engines to enhance responsiveness across the entire power band. Their system incorporates a multi-stage VTEC-like variable valve lift and timing control, adapted for the B58's turbocharged architecture. The ECU uses predictive algorithms to anticipate changes in load and adjust valve events accordingly, minimizing turbo lag and improving throttle response. Honda has also developed a unique exhaust gas recirculation (EGR) strategy that allows for higher compression ratios without increasing knock tendency, resulting in improved thermal efficiency. Their programming includes an advanced thermal management system that precisely controls coolant flow to optimize engine temperature, reducing warm-up times and improving efficiency. Honda claims this technology can reduce 0-60 mph times by up to 0.3 seconds while also improving fuel economy by 5% in real-world driving conditions[8].

Strengths: Expertise in high-performance naturally aspirated engines applied to turbocharged architecture, innovative EGR strategy, and comprehensive thermal management. Weaknesses: May require significant modifications to the B58's existing hardware to fully implement all features.

Core ECU Innovations

Engine control unit (ECU) and method to adapt the ECU for trigger wheel irregularities

PatentActiveUS11268464B2

Innovation

- The ECU is adapted to detect and learn the actual dimensions of the trigger wheel, including tooth width and gap, during production, and stores this data in a table to set dynamic time ranges for tooth detection, preventing false errors and ensuring accurate engine position management even with irregularities.

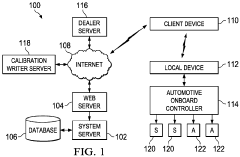

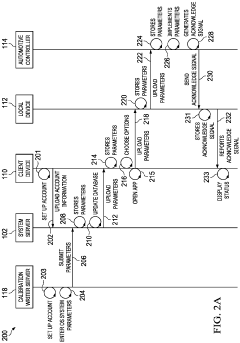

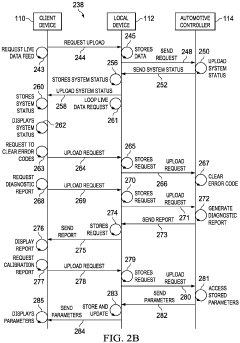

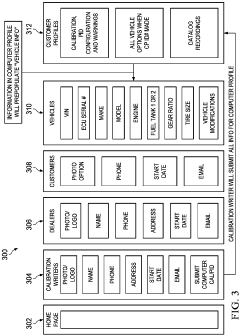

Method for real time wireless ECU monitoring and reprogramming

PatentPendingEP4050476A1

Innovation

- A cloud-based automotive technician system that enables remote connection between a client device, local device, and automotive controller via Wi-Fi or Bluetooth, allowing for real-time data logging, parameter updates, and diagnostic reporting, using a client-server architecture and standard wireless protocols.

Emissions Compliance

Emissions compliance is a critical aspect of advanced ECU programming for enhancing B58 engine responses. As automotive manufacturers strive to improve engine performance, they must simultaneously adhere to increasingly stringent emissions regulations. The B58 engine, known for its robust performance, requires sophisticated ECU programming to balance power output with emissions control.

Current emissions standards, such as Euro 6d and EPA Tier 3, demand significant reductions in nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. To meet these requirements, ECU programming for the B58 engine incorporates advanced strategies such as precise fuel injection timing, variable valve timing, and exhaust gas recirculation (EGR) control.

One key focus area is optimizing the air-fuel ratio across different engine operating conditions. ECU programming utilizes complex algorithms to adjust fuel injection parameters in real-time, ensuring optimal combustion efficiency while minimizing emissions. This includes adaptive learning capabilities that fine-tune engine performance based on factors like ambient temperature, altitude, and fuel quality.

Another crucial aspect of emissions compliance is the management of aftertreatment systems. The ECU controls the operation of catalytic converters, diesel particulate filters (DPF), and selective catalytic reduction (SCR) systems. Advanced programming enables these systems to function more effectively, regenerating when necessary and dosing urea solution precisely in SCR systems to reduce NOx emissions.

Thermal management plays a significant role in emissions control. ECU programming optimizes coolant flow and exhaust gas temperatures to ensure rapid catalyst light-off and maintain optimal operating temperatures for emissions control devices. This includes strategies for cold-start emissions reduction, which is a critical phase for meeting emissions standards.

Furthermore, On-Board Diagnostics (OBD) systems are integral to emissions compliance. ECU programming includes sophisticated monitoring algorithms that continuously check the performance of emissions-related components and alert drivers to potential issues. This ensures that the B58 engine maintains its emissions performance throughout its lifecycle.

As emissions regulations continue to evolve, ECU programming must adapt to new challenges. Future developments may include predictive emissions control strategies that utilize artificial intelligence and machine learning to anticipate and mitigate emissions spikes based on driving patterns and environmental conditions.

Current emissions standards, such as Euro 6d and EPA Tier 3, demand significant reductions in nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. To meet these requirements, ECU programming for the B58 engine incorporates advanced strategies such as precise fuel injection timing, variable valve timing, and exhaust gas recirculation (EGR) control.

One key focus area is optimizing the air-fuel ratio across different engine operating conditions. ECU programming utilizes complex algorithms to adjust fuel injection parameters in real-time, ensuring optimal combustion efficiency while minimizing emissions. This includes adaptive learning capabilities that fine-tune engine performance based on factors like ambient temperature, altitude, and fuel quality.

Another crucial aspect of emissions compliance is the management of aftertreatment systems. The ECU controls the operation of catalytic converters, diesel particulate filters (DPF), and selective catalytic reduction (SCR) systems. Advanced programming enables these systems to function more effectively, regenerating when necessary and dosing urea solution precisely in SCR systems to reduce NOx emissions.

Thermal management plays a significant role in emissions control. ECU programming optimizes coolant flow and exhaust gas temperatures to ensure rapid catalyst light-off and maintain optimal operating temperatures for emissions control devices. This includes strategies for cold-start emissions reduction, which is a critical phase for meeting emissions standards.

Furthermore, On-Board Diagnostics (OBD) systems are integral to emissions compliance. ECU programming includes sophisticated monitoring algorithms that continuously check the performance of emissions-related components and alert drivers to potential issues. This ensures that the B58 engine maintains its emissions performance throughout its lifecycle.

As emissions regulations continue to evolve, ECU programming must adapt to new challenges. Future developments may include predictive emissions control strategies that utilize artificial intelligence and machine learning to anticipate and mitigate emissions spikes based on driving patterns and environmental conditions.

Performance Benchmarking

Performance benchmarking is a critical aspect of advanced ECU programming for enhancing B58 engine responses. This process involves systematically measuring and comparing the engine's performance metrics under various conditions to establish baseline performance and identify areas for improvement.

The benchmarking process typically begins with establishing a set of standardized tests that cover a wide range of operating conditions. These tests may include acceleration runs, fuel efficiency measurements, emissions testing, and power output assessments across different RPM ranges. By conducting these tests on stock B58 engines, engineers can create a comprehensive performance profile that serves as a reference point for future enhancements.

One key area of focus in performance benchmarking is the engine's responsiveness to throttle inputs. This involves measuring the time lag between throttle application and the corresponding increase in engine output. Advanced data logging equipment is used to capture precise timing information, allowing engineers to quantify the engine's response characteristics accurately.

Another crucial aspect of benchmarking is evaluating the engine's power delivery curve. This involves measuring torque and horsepower outputs across the entire RPM range, providing insights into the engine's performance characteristics at different operating points. By analyzing these curves, engineers can identify potential areas for improvement, such as enhancing low-end torque or increasing high-RPM power output.

Fuel efficiency is also a critical parameter in performance benchmarking. Engineers measure fuel consumption under various driving conditions, including city, highway, and mixed cycles. This data is essential for optimizing the engine's fuel management strategies and ensuring that performance enhancements do not come at the cost of significantly increased fuel consumption.

Emissions testing forms another vital component of the benchmarking process. Engineers measure the levels of various pollutants, such as carbon monoxide, nitrogen oxides, and particulate matter, across different operating conditions. This data is crucial for ensuring that any performance enhancements comply with increasingly stringent emissions regulations.

Thermal management is also assessed during benchmarking, with engineers monitoring engine temperatures under various load conditions. This information is vital for optimizing cooling systems and ensuring that the engine can maintain peak performance even under demanding conditions.

By conducting comprehensive performance benchmarking, engineers can establish a solid foundation for advanced ECU programming efforts. The data gathered during this process serves as a baseline for measuring the effectiveness of subsequent optimizations and helps identify specific areas where ECU programming can yield the most significant improvements in B58 engine responses.

The benchmarking process typically begins with establishing a set of standardized tests that cover a wide range of operating conditions. These tests may include acceleration runs, fuel efficiency measurements, emissions testing, and power output assessments across different RPM ranges. By conducting these tests on stock B58 engines, engineers can create a comprehensive performance profile that serves as a reference point for future enhancements.

One key area of focus in performance benchmarking is the engine's responsiveness to throttle inputs. This involves measuring the time lag between throttle application and the corresponding increase in engine output. Advanced data logging equipment is used to capture precise timing information, allowing engineers to quantify the engine's response characteristics accurately.

Another crucial aspect of benchmarking is evaluating the engine's power delivery curve. This involves measuring torque and horsepower outputs across the entire RPM range, providing insights into the engine's performance characteristics at different operating points. By analyzing these curves, engineers can identify potential areas for improvement, such as enhancing low-end torque or increasing high-RPM power output.

Fuel efficiency is also a critical parameter in performance benchmarking. Engineers measure fuel consumption under various driving conditions, including city, highway, and mixed cycles. This data is essential for optimizing the engine's fuel management strategies and ensuring that performance enhancements do not come at the cost of significantly increased fuel consumption.

Emissions testing forms another vital component of the benchmarking process. Engineers measure the levels of various pollutants, such as carbon monoxide, nitrogen oxides, and particulate matter, across different operating conditions. This data is crucial for ensuring that any performance enhancements comply with increasingly stringent emissions regulations.

Thermal management is also assessed during benchmarking, with engineers monitoring engine temperatures under various load conditions. This information is vital for optimizing cooling systems and ensuring that the engine can maintain peak performance even under demanding conditions.

By conducting comprehensive performance benchmarking, engineers can establish a solid foundation for advanced ECU programming efforts. The data gathered during this process serves as a baseline for measuring the effectiveness of subsequent optimizations and helps identify specific areas where ECU programming can yield the most significant improvements in B58 engine responses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!