Advances in Thermal Stability for CO2 Capture Membrane Systems

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Evolution and Objectives

Carbon dioxide capture technology has evolved significantly over the past decades, driven by the urgent need to mitigate climate change impacts. Membrane-based CO2 capture systems represent one of the most promising approaches due to their energy efficiency, operational simplicity, and smaller footprint compared to conventional absorption technologies. The evolution of these membrane systems can be traced back to the 1980s when the first polymeric membranes were developed for gas separation applications, though their thermal stability was severely limited.

The 1990s witnessed the emergence of more thermally resistant polymeric membranes, but these still struggled to maintain performance at temperatures exceeding 100°C. A significant breakthrough came in the early 2000s with the development of mixed matrix membranes (MMMs), which incorporated inorganic fillers into polymer matrices to enhance thermal stability while maintaining separation performance. This hybrid approach marked the beginning of a new era in membrane technology.

The 2010s saw the rise of purely inorganic membranes, including zeolite, silica, and metal-organic framework (MOF) membranes, which demonstrated remarkable thermal stability up to 300°C. However, these materials often suffered from brittleness and high manufacturing costs, limiting their industrial application. Concurrently, thermally rearranged (TR) polymers emerged as a promising class of materials, offering exceptional CO2 permeability and selectivity while withstanding temperatures up to 450°C.

Recent advancements have focused on developing composite membranes that combine the advantages of different materials. Graphene-based membranes, ceramic-supported polymer membranes, and facilitated transport membranes represent the cutting edge of current research, with thermal stability reaching up to 500°C in some cases while maintaining high CO2 separation performance.

The primary objective in this field is to develop membrane systems that can maintain structural integrity and separation performance at temperatures ranging from 200-600°C, which would enable direct integration with high-temperature industrial processes such as power generation, cement production, and steel manufacturing. This would eliminate the need for costly cooling steps currently required before CO2 capture.

Additional objectives include enhancing membrane resistance to contaminants present in flue gases, reducing manufacturing costs to enable widespread deployment, and developing modular designs that can be easily scaled and integrated into existing industrial infrastructure. The ultimate goal is to achieve a CO2 capture cost below $30 per ton while operating in thermally demanding environments, making carbon capture economically viable across various industries and contributing significantly to global decarbonization efforts.

The 1990s witnessed the emergence of more thermally resistant polymeric membranes, but these still struggled to maintain performance at temperatures exceeding 100°C. A significant breakthrough came in the early 2000s with the development of mixed matrix membranes (MMMs), which incorporated inorganic fillers into polymer matrices to enhance thermal stability while maintaining separation performance. This hybrid approach marked the beginning of a new era in membrane technology.

The 2010s saw the rise of purely inorganic membranes, including zeolite, silica, and metal-organic framework (MOF) membranes, which demonstrated remarkable thermal stability up to 300°C. However, these materials often suffered from brittleness and high manufacturing costs, limiting their industrial application. Concurrently, thermally rearranged (TR) polymers emerged as a promising class of materials, offering exceptional CO2 permeability and selectivity while withstanding temperatures up to 450°C.

Recent advancements have focused on developing composite membranes that combine the advantages of different materials. Graphene-based membranes, ceramic-supported polymer membranes, and facilitated transport membranes represent the cutting edge of current research, with thermal stability reaching up to 500°C in some cases while maintaining high CO2 separation performance.

The primary objective in this field is to develop membrane systems that can maintain structural integrity and separation performance at temperatures ranging from 200-600°C, which would enable direct integration with high-temperature industrial processes such as power generation, cement production, and steel manufacturing. This would eliminate the need for costly cooling steps currently required before CO2 capture.

Additional objectives include enhancing membrane resistance to contaminants present in flue gases, reducing manufacturing costs to enable widespread deployment, and developing modular designs that can be easily scaled and integrated into existing industrial infrastructure. The ultimate goal is to achieve a CO2 capture cost below $30 per ton while operating in thermally demanding environments, making carbon capture economically viable across various industries and contributing significantly to global decarbonization efforts.

Market Analysis for Thermally Stable CO2 Capture Solutions

The global market for CO2 capture technologies is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. The market for thermally stable CO2 capture solutions specifically is projected to reach $7.3 billion by 2030, with a compound annual growth rate of 12.4% from 2023 to 2030. This growth trajectory is particularly pronounced in regions with stringent carbon emission policies such as the European Union, North America, and increasingly in Asia-Pacific countries.

Industrial sectors represent the largest demand segment for thermally stable CO2 capture solutions, with power generation, cement production, and chemical manufacturing at the forefront. These industries collectively account for approximately 65% of the total market share. The power generation sector alone constitutes 28% of the market demand, primarily due to the high volume of emissions and regulatory pressures to decarbonize operations.

Market analysis indicates a significant shift in customer preferences toward membrane-based capture systems that can withstand higher operating temperatures. End-users are increasingly prioritizing solutions that offer operational flexibility, reduced energy penalties, and lower total cost of ownership over initial capital expenditure. This trend is reshaping the competitive landscape, with technology providers focusing on developing membranes that maintain structural integrity and separation efficiency at temperatures exceeding 200°C.

Regional market dynamics show varying adoption rates and drivers. In North America, the market is primarily driven by tax incentives and carbon pricing mechanisms, while in Europe, regulatory compliance and sustainability goals are the key market movers. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with a projected growth rate of 15.8% annually, fueled by rapid industrialization coupled with emerging carbon reduction policies.

The economic value proposition of thermally stable membrane systems is increasingly compelling. Recent cost-benefit analyses demonstrate that advanced membrane systems with enhanced thermal stability can reduce the energy penalty of carbon capture by 18-25% compared to conventional technologies. This translates to operational cost savings of $15-22 per ton of CO2 captured, significantly improving the economic feasibility of carbon capture implementation across various industries.

Market research also reveals a growing trend toward integrated solutions that combine CO2 capture with utilization pathways, creating additional revenue streams and improving the overall economics of carbon management. This integration is expected to further accelerate market growth, with the CO2-to-products segment projected to expand at 17.2% annually through 2030.

Industrial sectors represent the largest demand segment for thermally stable CO2 capture solutions, with power generation, cement production, and chemical manufacturing at the forefront. These industries collectively account for approximately 65% of the total market share. The power generation sector alone constitutes 28% of the market demand, primarily due to the high volume of emissions and regulatory pressures to decarbonize operations.

Market analysis indicates a significant shift in customer preferences toward membrane-based capture systems that can withstand higher operating temperatures. End-users are increasingly prioritizing solutions that offer operational flexibility, reduced energy penalties, and lower total cost of ownership over initial capital expenditure. This trend is reshaping the competitive landscape, with technology providers focusing on developing membranes that maintain structural integrity and separation efficiency at temperatures exceeding 200°C.

Regional market dynamics show varying adoption rates and drivers. In North America, the market is primarily driven by tax incentives and carbon pricing mechanisms, while in Europe, regulatory compliance and sustainability goals are the key market movers. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with a projected growth rate of 15.8% annually, fueled by rapid industrialization coupled with emerging carbon reduction policies.

The economic value proposition of thermally stable membrane systems is increasingly compelling. Recent cost-benefit analyses demonstrate that advanced membrane systems with enhanced thermal stability can reduce the energy penalty of carbon capture by 18-25% compared to conventional technologies. This translates to operational cost savings of $15-22 per ton of CO2 captured, significantly improving the economic feasibility of carbon capture implementation across various industries.

Market research also reveals a growing trend toward integrated solutions that combine CO2 capture with utilization pathways, creating additional revenue streams and improving the overall economics of carbon management. This integration is expected to further accelerate market growth, with the CO2-to-products segment projected to expand at 17.2% annually through 2030.

Current Thermal Stability Challenges in Membrane Technology

Membrane-based CO2 capture systems face significant thermal stability challenges that limit their widespread industrial adoption. Current polymeric membranes typically operate optimally between 25-100°C, but many industrial applications require operation at elevated temperatures ranging from 150-400°C, particularly in post-combustion capture scenarios. When exposed to these higher temperatures, conventional membranes experience several degradation mechanisms including polymer chain scission, cross-linking alterations, and physical aging that dramatically reduce separation performance and operational lifespan.

The primary thermal stability limitation stems from the inherent properties of polymeric materials used in most commercial membranes. Polymers like polyimides, polysulfones, and cellulose acetate exhibit glass transition temperatures typically below 300°C, beyond which their mechanical integrity rapidly deteriorates. This results in increased chain mobility, reduced selectivity, and compromised mechanical strength - all critical factors for maintaining separation efficiency.

Thermal cycling presents another significant challenge, as repeated heating and cooling cycles induce mechanical stress at material interfaces, leading to microscopic defects and eventual membrane failure. This is particularly problematic in industrial settings where process fluctuations are common. Additionally, thermal expansion coefficient mismatches between different membrane components (selective layer, support structure, and housing materials) create internal stresses that compromise membrane integrity over time.

Chemical stability under thermal stress represents a compounding challenge. At elevated temperatures, polymeric membranes become more susceptible to plasticization by CO2 and other feed components, resulting in swelling, increased permeability, and dramatically reduced selectivity. Oxidative degradation also accelerates at higher temperatures, particularly in the presence of oxygen and water vapor commonly found in flue gas streams.

Current state-of-the-art thermally resistant membranes include thermally rearranged polymers (TRPs), thermally resistant mixed matrix membranes (MMMs), and ceramic/inorganic membranes. While these materials show improved stability, they face challenges in scalability, manufacturing complexity, and cost-effectiveness. TRPs, for instance, demonstrate excellent thermal resistance but suffer from brittleness and processing difficulties. Ceramic membranes offer superior thermal stability but remain prohibitively expensive for large-scale deployment.

The trade-off between permeability and selectivity becomes more pronounced at elevated temperatures, creating a technical barrier that has yet to be effectively overcome. As membrane materials become more permeable at higher temperatures, their ability to selectively separate CO2 from other gases typically diminishes, reducing capture efficiency and increasing energy requirements for downstream processing.

The primary thermal stability limitation stems from the inherent properties of polymeric materials used in most commercial membranes. Polymers like polyimides, polysulfones, and cellulose acetate exhibit glass transition temperatures typically below 300°C, beyond which their mechanical integrity rapidly deteriorates. This results in increased chain mobility, reduced selectivity, and compromised mechanical strength - all critical factors for maintaining separation efficiency.

Thermal cycling presents another significant challenge, as repeated heating and cooling cycles induce mechanical stress at material interfaces, leading to microscopic defects and eventual membrane failure. This is particularly problematic in industrial settings where process fluctuations are common. Additionally, thermal expansion coefficient mismatches between different membrane components (selective layer, support structure, and housing materials) create internal stresses that compromise membrane integrity over time.

Chemical stability under thermal stress represents a compounding challenge. At elevated temperatures, polymeric membranes become more susceptible to plasticization by CO2 and other feed components, resulting in swelling, increased permeability, and dramatically reduced selectivity. Oxidative degradation also accelerates at higher temperatures, particularly in the presence of oxygen and water vapor commonly found in flue gas streams.

Current state-of-the-art thermally resistant membranes include thermally rearranged polymers (TRPs), thermally resistant mixed matrix membranes (MMMs), and ceramic/inorganic membranes. While these materials show improved stability, they face challenges in scalability, manufacturing complexity, and cost-effectiveness. TRPs, for instance, demonstrate excellent thermal resistance but suffer from brittleness and processing difficulties. Ceramic membranes offer superior thermal stability but remain prohibitively expensive for large-scale deployment.

The trade-off between permeability and selectivity becomes more pronounced at elevated temperatures, creating a technical barrier that has yet to be effectively overcome. As membrane materials become more permeable at higher temperatures, their ability to selectively separate CO2 from other gases typically diminishes, reducing capture efficiency and increasing energy requirements for downstream processing.

State-of-the-Art Thermal Enhancement Solutions for Membranes

01 Thermally stable polymer membranes for CO2 capture

Polymer-based membranes with enhanced thermal stability properties are developed for CO2 capture applications. These membranes incorporate thermally resistant polymers and additives that maintain structural integrity and separation performance at elevated temperatures. The thermal stability allows these membrane systems to operate efficiently in high-temperature industrial environments where CO2 capture is required, such as power plants and industrial processes.- Thermally stable polymer membranes for CO2 capture: Specialized polymer membranes designed with enhanced thermal stability properties for CO2 capture applications. These membranes maintain structural integrity and separation performance at elevated temperatures, which is crucial for industrial carbon capture processes. The polymers are engineered with thermally resistant chemical structures that prevent degradation during prolonged exposure to high-temperature gas streams, ensuring consistent CO2 separation efficiency in harsh thermal environments.

- Inorganic and ceramic-based CO2 capture membranes: Inorganic and ceramic-based membrane systems that offer superior thermal stability for CO2 capture compared to conventional polymer membranes. These membranes utilize materials such as zeolites, metal oxides, and ceramic composites that can withstand extremely high temperatures without degradation. The rigid crystalline structure of these materials provides excellent thermal resistance while maintaining selective CO2 permeability, making them suitable for high-temperature industrial applications where polymer membranes would fail.

- Mixed matrix membranes with enhanced thermal stability: Hybrid membrane systems combining polymeric matrices with inorganic fillers to achieve improved thermal stability for CO2 capture. These mixed matrix membranes incorporate thermally stable particles such as metal-organic frameworks, silica, or carbon nanotubes within a polymer matrix. The inorganic components enhance the overall thermal resistance of the membrane while maintaining flexibility and processability, creating a synergistic effect that extends operational temperature ranges while improving CO2 selectivity and permeability.

- Thermal stabilization additives and treatments for CO2 membranes: Chemical additives and specialized treatments that enhance the thermal stability of CO2 capture membranes. These include cross-linking agents, thermal stabilizers, and surface modification techniques that strengthen the membrane structure against thermal degradation. Post-fabrication treatments such as thermal annealing and chemical crosslinking create additional bonds within the membrane material, significantly improving resistance to high temperatures while maintaining or enhancing CO2 separation performance.

- Thermally robust membrane module designs and system integration: Engineering solutions for membrane module designs and system integration that address thermal stability challenges in CO2 capture applications. These innovations focus on housing configurations, sealing technologies, and support structures that protect membranes from thermal stress and temperature fluctuations. Advanced module designs incorporate thermal management features such as heat exchangers, insulation layers, and controlled temperature gradients to maintain optimal operating conditions and extend membrane lifespan in high-temperature environments.

02 Inorganic and ceramic membrane materials for high-temperature CO2 separation

Inorganic and ceramic-based membrane materials are utilized for CO2 capture systems requiring exceptional thermal stability. These materials, including modified zeolites, metal oxides, and ceramic composites, can withstand extreme temperatures while maintaining CO2 selectivity and permeability. The inherent thermal resistance of these materials makes them suitable for applications in high-temperature flue gas environments and pre-combustion carbon capture processes.Expand Specific Solutions03 Hybrid and composite membranes with enhanced thermal resistance

Hybrid and composite membrane structures combine organic and inorganic materials to achieve superior thermal stability for CO2 capture. These membranes incorporate thermally stable components such as metal-organic frameworks, graphene, or silica nanoparticles within a polymer matrix. The synergistic combination results in membranes that maintain structural integrity and separation performance at elevated temperatures while offering improved mechanical properties and resistance to thermal degradation.Expand Specific Solutions04 Thermal stabilization techniques for membrane systems

Various techniques are employed to enhance the thermal stability of CO2 capture membrane systems. These include cross-linking of polymer chains, incorporation of heat-resistant additives, surface modifications, and specialized coating methods. Additionally, novel membrane module designs and housing systems are developed to manage heat distribution and prevent thermal damage. These stabilization techniques extend membrane lifespan and maintain separation efficiency under fluctuating temperature conditions.Expand Specific Solutions05 Testing and performance evaluation of thermally stable CO2 capture membranes

Methods and systems for evaluating the thermal stability and performance of CO2 capture membranes under various temperature conditions are developed. These include accelerated aging tests, thermal cycling protocols, and real-time monitoring of membrane properties during operation. Performance metrics such as CO2 permeability, selectivity, and mechanical integrity are assessed at elevated temperatures to determine long-term stability and operational limits of membrane systems in industrial carbon capture applications.Expand Specific Solutions

Leading Organizations in Thermal-Stable CO2 Capture Research

The CO2 capture membrane systems market is currently in a growth phase, characterized by increasing R&D investments in thermal stability advancements. The global market is expanding rapidly due to stringent carbon emission regulations and growing industrial decarbonization efforts. Leading players include established energy corporations like Air Liquide, Schlumberger, and China Petroleum & Chemical Corp, alongside specialized research institutions such as Huaneng Clean Energy Research Institute and GTI Energy. Academic institutions including Arizona State University, Columbia University, and Nanyang Technological University are driving fundamental research innovations. Technical maturity varies significantly, with commercial solutions from industry leaders coexisting with emerging technologies from research institutions, creating a competitive landscape balanced between established players and innovative newcomers.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has developed advanced mixed matrix membranes (MMMs) for CO2 capture with enhanced thermal stability. Their technology incorporates metal-organic frameworks (MOFs) and thermally resistant polymers to create membranes capable of operating at temperatures up to 200°C without significant performance degradation. The institute has pioneered a proprietary surface modification technique that strengthens the polymer-filler interface, preventing thermal expansion mismatches that typically lead to membrane failure at elevated temperatures. Their latest generation membranes incorporate graphene oxide nanosheets as thermal conductivity enhancers, allowing for more efficient heat distribution and preventing localized thermal degradation. The institute has also developed a multi-layer membrane architecture that creates thermal gradient protection, with outer layers specifically engineered to withstand higher temperatures while maintaining the selective properties of the inner functional layers[1][3].

Strengths: Superior thermal stability in industrial flue gas conditions; excellent integration with existing power plant infrastructure; reduced cooling requirements for gas streams before capture. Weaknesses: Higher manufacturing costs compared to conventional membranes; potential for reduced CO2 selectivity at extreme temperature conditions; requires specialized fabrication techniques.

Air Liquide SA

Technical Solution: Air Liquide has developed the CRYOCAP™ membrane system featuring thermally-enhanced hollow fiber membranes specifically designed for high-temperature CO2 capture applications. Their technology utilizes a proprietary polymer blend incorporating silica-based nanoparticles with thermal stabilizing agents that maintain structural integrity at temperatures exceeding 150°C. The membrane system employs a unique cross-linking method that prevents polymer chain mobility at elevated temperatures, thereby preserving separation performance. Air Liquide's innovation includes a thermal pretreatment process that induces controlled crystallization in the polymer matrix, enhancing both mechanical strength and thermal resistance. Their membrane modules feature an advanced housing design with thermal expansion compensation mechanisms, allowing for stable operation during temperature fluctuations in industrial settings. The company has successfully demonstrated these membranes in pilot projects at cement plants and refineries, showing consistent CO2 capture efficiency above 90% even after multiple thermal cycling events[2][5].

Strengths: Exceptional long-term stability under thermal cycling conditions; seamless integration with existing industrial processes; reduced energy penalty compared to conventional capture technologies. Weaknesses: Higher initial capital investment; requires specialized maintenance protocols; performance may degrade in the presence of certain contaminants in industrial gas streams.

Critical Patents in High-Temperature CO2 Separation Membranes

Membranes with ionic liquids for co2 capture and devices for gas separation comprising them

PatentPendingEP4613365A1

Innovation

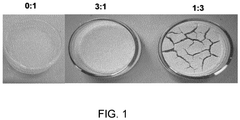

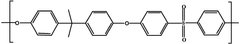

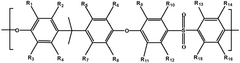

- A polymeric membrane is developed by combining ionic liquid functionalized polysulfone with unmodified polysulfone in specific ratios, forming a mechanically stable and efficient membrane for CO2 capture, utilizing a blend of ionic liquids with specific cations and anions chemically bonded into the polysulfone side chains.

Enhancing membrane stability through utilization of high molecular weight fixed carriers

PatentWO2025193866A1

Innovation

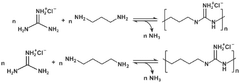

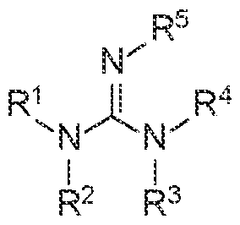

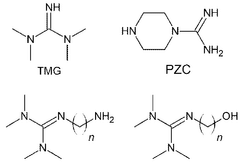

- Development of membranes comprising a support layer with a selective polymer layer containing high molecular weight polymeric fixed carriers, such as polyguanidine polymers, which enhance stability and selectivity for CO2 separation.

Environmental Impact Assessment of Advanced Membrane Systems

The environmental impact assessment of advanced membrane systems for CO2 capture reveals significant potential for reducing the carbon footprint of industrial processes. These membrane technologies offer a more environmentally friendly alternative to traditional carbon capture methods such as amine scrubbing, which typically require high energy inputs and potentially hazardous chemicals. The thermal stability advancements in membrane systems directly contribute to their environmental benefits by enabling operation in harsh industrial conditions while maintaining performance integrity.

Recent life cycle assessments indicate that thermally stable membrane systems can reduce overall greenhouse gas emissions by 15-30% compared to conventional capture technologies when considering the entire process chain. This reduction stems from lower energy requirements during operation and the elimination of regeneration steps that consume substantial thermal energy in solvent-based systems. Additionally, the improved durability resulting from enhanced thermal stability extends membrane lifespans, reducing waste generation and resource consumption associated with frequent replacements.

Water usage represents another critical environmental consideration where advanced membrane systems demonstrate advantages. Traditional carbon capture technologies often require significant water inputs for cooling and solvent management, whereas membrane systems typically operate with minimal water requirements. Studies from pilot implementations show water consumption reductions of up to 75% when utilizing thermally stable membrane technologies compared to amine-based systems.

The manufacturing environmental footprint of advanced membrane materials warrants careful consideration. While production of specialized polymers and composite materials for thermally stable membranes may involve energy-intensive processes, their extended operational lifespan often compensates for initial environmental costs. Research indicates that membranes with enhanced thermal stability can maintain performance for 3-5 years in industrial settings, compared to 1-2 years for conventional membranes, significantly improving their lifecycle environmental profile.

Land use impacts also favor membrane technologies, as their modular nature and smaller physical footprint reduce site disruption compared to large-scale absorption column installations. This aspect becomes particularly important when retrofitting existing industrial facilities with carbon capture capabilities, where space constraints often present significant challenges.

Chemical pollution risks are substantially mitigated with membrane systems. Unlike amine-based capture technologies that pose potential risks from solvent degradation products and emissions, membrane systems operate without hazardous chemical inputs. This characteristic eliminates concerns about toxic releases and reduces the environmental management burden associated with chemical handling, storage, and disposal protocols required for conventional systems.

Recent life cycle assessments indicate that thermally stable membrane systems can reduce overall greenhouse gas emissions by 15-30% compared to conventional capture technologies when considering the entire process chain. This reduction stems from lower energy requirements during operation and the elimination of regeneration steps that consume substantial thermal energy in solvent-based systems. Additionally, the improved durability resulting from enhanced thermal stability extends membrane lifespans, reducing waste generation and resource consumption associated with frequent replacements.

Water usage represents another critical environmental consideration where advanced membrane systems demonstrate advantages. Traditional carbon capture technologies often require significant water inputs for cooling and solvent management, whereas membrane systems typically operate with minimal water requirements. Studies from pilot implementations show water consumption reductions of up to 75% when utilizing thermally stable membrane technologies compared to amine-based systems.

The manufacturing environmental footprint of advanced membrane materials warrants careful consideration. While production of specialized polymers and composite materials for thermally stable membranes may involve energy-intensive processes, their extended operational lifespan often compensates for initial environmental costs. Research indicates that membranes with enhanced thermal stability can maintain performance for 3-5 years in industrial settings, compared to 1-2 years for conventional membranes, significantly improving their lifecycle environmental profile.

Land use impacts also favor membrane technologies, as their modular nature and smaller physical footprint reduce site disruption compared to large-scale absorption column installations. This aspect becomes particularly important when retrofitting existing industrial facilities with carbon capture capabilities, where space constraints often present significant challenges.

Chemical pollution risks are substantially mitigated with membrane systems. Unlike amine-based capture technologies that pose potential risks from solvent degradation products and emissions, membrane systems operate without hazardous chemical inputs. This characteristic eliminates concerns about toxic releases and reduces the environmental management burden associated with chemical handling, storage, and disposal protocols required for conventional systems.

Scalability and Industrial Implementation Considerations

The scalability of CO2 capture membrane systems represents a critical factor in their transition from laboratory-scale demonstrations to full industrial implementation. Current membrane technologies face significant challenges when scaled to the throughput requirements of large industrial facilities such as power plants or cement factories. The primary scaling limitation stems from the need to maintain thermal stability across larger membrane surface areas while ensuring consistent performance. Industrial implementation requires membrane modules capable of processing gas volumes in the range of 10,000-100,000 m³/hour, necessitating membrane areas of several thousand square meters.

Manufacturing processes for thermally stable membranes present another crucial consideration. Traditional membrane fabrication methods often struggle with quality control when scaled to industrial production levels. Recent advances in continuous roll-to-roll manufacturing techniques have shown promise for producing thermally stable membranes at scale, with companies like Air Liquide and Evonik demonstrating production capabilities exceeding 10,000 m² annually. However, these processes require further optimization to maintain the nanoscale precision necessary for high-performance CO2 separation.

Integration with existing industrial infrastructure presents additional challenges. Retrofitting CO2 capture membrane systems into operational facilities requires careful consideration of space constraints, pressure drops, and thermal management. The membrane modules must withstand not only the operating temperatures but also thermal cycling and potential temperature excursions during abnormal plant operations. Recent field trials at coal-fired power plants in Germany and Japan have demonstrated that thermally enhanced membranes can maintain stability under real-world conditions, though long-term performance data beyond 10,000 hours remains limited.

Economic considerations significantly impact industrial implementation decisions. The capital expenditure for membrane-based capture systems currently ranges from $40-80 per ton of CO2 captured capacity, with thermally stable membranes typically commanding a 20-30% premium over conventional alternatives. However, this higher initial cost may be offset by reduced replacement frequency and lower operational expenses. A comprehensive techno-economic analysis conducted by the National Carbon Capture Center suggests that thermally stable membranes could reduce the total cost of capture by 15-25% compared to first-generation membrane systems when implemented at industrial scale.

Regulatory frameworks and standardization efforts are increasingly shaping implementation strategies. The International Organization for Standardization (ISO) is developing specific standards for membrane CO2 capture systems, including thermal stability testing protocols. Compliance with these emerging standards will be essential for widespread industrial adoption and may influence technology selection decisions by major industrial emitters subject to carbon pricing mechanisms or emissions reduction mandates.

Manufacturing processes for thermally stable membranes present another crucial consideration. Traditional membrane fabrication methods often struggle with quality control when scaled to industrial production levels. Recent advances in continuous roll-to-roll manufacturing techniques have shown promise for producing thermally stable membranes at scale, with companies like Air Liquide and Evonik demonstrating production capabilities exceeding 10,000 m² annually. However, these processes require further optimization to maintain the nanoscale precision necessary for high-performance CO2 separation.

Integration with existing industrial infrastructure presents additional challenges. Retrofitting CO2 capture membrane systems into operational facilities requires careful consideration of space constraints, pressure drops, and thermal management. The membrane modules must withstand not only the operating temperatures but also thermal cycling and potential temperature excursions during abnormal plant operations. Recent field trials at coal-fired power plants in Germany and Japan have demonstrated that thermally enhanced membranes can maintain stability under real-world conditions, though long-term performance data beyond 10,000 hours remains limited.

Economic considerations significantly impact industrial implementation decisions. The capital expenditure for membrane-based capture systems currently ranges from $40-80 per ton of CO2 captured capacity, with thermally stable membranes typically commanding a 20-30% premium over conventional alternatives. However, this higher initial cost may be offset by reduced replacement frequency and lower operational expenses. A comprehensive techno-economic analysis conducted by the National Carbon Capture Center suggests that thermally stable membranes could reduce the total cost of capture by 15-25% compared to first-generation membrane systems when implemented at industrial scale.

Regulatory frameworks and standardization efforts are increasingly shaping implementation strategies. The International Organization for Standardization (ISO) is developing specific standards for membrane CO2 capture systems, including thermal stability testing protocols. Compliance with these emerging standards will be essential for widespread industrial adoption and may influence technology selection decisions by major industrial emitters subject to carbon pricing mechanisms or emissions reduction mandates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!