CO2 Capture Membrane Material Choice Impact on Efficiency

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Technology Background and Objectives

Carbon dioxide capture technology has evolved significantly over the past decades, transitioning from conventional absorption methods to more advanced membrane-based separation techniques. Membrane technology for CO2 capture represents a promising approach that has gained substantial attention due to its potential energy efficiency, operational simplicity, and reduced environmental footprint compared to traditional capture methods. The historical development of this technology can be traced back to the 1980s, with significant acceleration in research and development occurring in the early 2000s as climate change concerns intensified globally.

The evolution of CO2 capture membrane technology has been characterized by continuous improvements in material science, manufacturing processes, and system integration. Early membranes suffered from low selectivity, poor durability, and high production costs, limiting their practical application. However, recent advancements in polymer chemistry, inorganic materials, and mixed matrix formulations have substantially enhanced membrane performance metrics, bringing this technology closer to commercial viability.

Current technological trends indicate a shift toward multi-functional membrane materials that can simultaneously achieve high CO2 permeability and selectivity while maintaining structural integrity under industrial operating conditions. The integration of facilitated transport mechanisms, incorporation of nanomaterials, and development of thermally rearranged polymers represent significant innovations that are reshaping the field. Additionally, there is growing interest in bio-inspired membrane designs that mimic natural CO2 transport systems found in biological organisms.

The primary technical objectives for CO2 capture membrane development include achieving permeability rates exceeding 1000 Barrer while maintaining CO2/N2 selectivity above 40 under realistic flue gas conditions. Additional goals involve developing membranes that can withstand temperatures above 100°C, resist plasticization in the presence of water vapor and contaminants, and maintain stable performance for at least 3-5 years of continuous operation. Cost reduction targets aim to bring membrane module production below $50/m² to ensure economic competitiveness with established capture technologies.

Beyond performance metrics, research objectives also encompass scalability considerations, focusing on developing manufacturing processes that can reliably produce high-quality membranes at industrial scale. Environmental sustainability goals include minimizing the embedded carbon footprint of membrane materials and ensuring end-of-life recyclability or biodegradability. The ultimate aim is to develop membrane systems capable of capturing CO2 at a cost below $30 per ton while achieving capture rates of at least 90% from various emission sources including power plants, cement factories, and direct air capture applications.

The evolution of CO2 capture membrane technology has been characterized by continuous improvements in material science, manufacturing processes, and system integration. Early membranes suffered from low selectivity, poor durability, and high production costs, limiting their practical application. However, recent advancements in polymer chemistry, inorganic materials, and mixed matrix formulations have substantially enhanced membrane performance metrics, bringing this technology closer to commercial viability.

Current technological trends indicate a shift toward multi-functional membrane materials that can simultaneously achieve high CO2 permeability and selectivity while maintaining structural integrity under industrial operating conditions. The integration of facilitated transport mechanisms, incorporation of nanomaterials, and development of thermally rearranged polymers represent significant innovations that are reshaping the field. Additionally, there is growing interest in bio-inspired membrane designs that mimic natural CO2 transport systems found in biological organisms.

The primary technical objectives for CO2 capture membrane development include achieving permeability rates exceeding 1000 Barrer while maintaining CO2/N2 selectivity above 40 under realistic flue gas conditions. Additional goals involve developing membranes that can withstand temperatures above 100°C, resist plasticization in the presence of water vapor and contaminants, and maintain stable performance for at least 3-5 years of continuous operation. Cost reduction targets aim to bring membrane module production below $50/m² to ensure economic competitiveness with established capture technologies.

Beyond performance metrics, research objectives also encompass scalability considerations, focusing on developing manufacturing processes that can reliably produce high-quality membranes at industrial scale. Environmental sustainability goals include minimizing the embedded carbon footprint of membrane materials and ensuring end-of-life recyclability or biodegradability. The ultimate aim is to develop membrane systems capable of capturing CO2 at a cost below $30 per ton while achieving capture rates of at least 90% from various emission sources including power plants, cement factories, and direct air capture applications.

Market Analysis for CO2 Capture Membrane Solutions

The global market for CO2 capture membrane solutions has experienced significant growth in recent years, driven primarily by increasing environmental regulations and corporate sustainability initiatives. Current market valuations indicate that the CO2 capture technology sector reached approximately 7.5 billion USD in 2022, with membrane-based solutions accounting for roughly 15% of this market. Industry analysts project a compound annual growth rate of 12-14% for membrane technologies through 2030, outpacing other carbon capture methodologies.

Demand patterns show notable regional variations, with Europe leading adoption due to stringent carbon pricing mechanisms and regulatory frameworks. The European Union's commitment to carbon neutrality by 2050 has created a robust market for advanced membrane solutions, particularly in industrial clusters in Germany, the Netherlands, and Scandinavia. North America follows as the second-largest market, with demand concentrated in the chemical, petrochemical, and power generation sectors.

The Asia-Pacific region represents the fastest-growing market segment, with China, Japan, and South Korea making substantial investments in membrane technology development. China's 14th Five-Year Plan explicitly prioritizes carbon capture technologies, creating significant market opportunities for both domestic and international membrane technology providers.

Industry-specific analysis reveals that power generation remains the largest application sector, accounting for approximately 40% of membrane solution deployments. Natural gas processing follows at 25%, while cement production and chemical manufacturing collectively represent another 20% of market applications. Emerging applications in steel production and hydrogen generation are showing promising growth trajectories.

Customer segmentation indicates three primary buyer categories: large industrial corporations implementing direct carbon reduction strategies, specialized carbon management service providers, and government-backed climate technology initiatives. The first segment demonstrates the highest willingness to pay premium prices for high-efficiency membrane solutions, particularly when these can be integrated into existing infrastructure with minimal modification.

Market barriers include high initial capital requirements, technical integration challenges with legacy systems, and competition from alternative carbon capture technologies. The membrane solution market faces particular pressure from amine-based absorption systems, which currently hold dominant market share despite higher operational costs and environmental concerns.

Pricing trends show gradual cost reductions as manufacturing scales increase, with current membrane solutions averaging 40-60 USD per ton of CO2 captured. This represents a significant improvement from 2015 levels but remains above the economic threshold for widespread adoption in price-sensitive sectors.

Demand patterns show notable regional variations, with Europe leading adoption due to stringent carbon pricing mechanisms and regulatory frameworks. The European Union's commitment to carbon neutrality by 2050 has created a robust market for advanced membrane solutions, particularly in industrial clusters in Germany, the Netherlands, and Scandinavia. North America follows as the second-largest market, with demand concentrated in the chemical, petrochemical, and power generation sectors.

The Asia-Pacific region represents the fastest-growing market segment, with China, Japan, and South Korea making substantial investments in membrane technology development. China's 14th Five-Year Plan explicitly prioritizes carbon capture technologies, creating significant market opportunities for both domestic and international membrane technology providers.

Industry-specific analysis reveals that power generation remains the largest application sector, accounting for approximately 40% of membrane solution deployments. Natural gas processing follows at 25%, while cement production and chemical manufacturing collectively represent another 20% of market applications. Emerging applications in steel production and hydrogen generation are showing promising growth trajectories.

Customer segmentation indicates three primary buyer categories: large industrial corporations implementing direct carbon reduction strategies, specialized carbon management service providers, and government-backed climate technology initiatives. The first segment demonstrates the highest willingness to pay premium prices for high-efficiency membrane solutions, particularly when these can be integrated into existing infrastructure with minimal modification.

Market barriers include high initial capital requirements, technical integration challenges with legacy systems, and competition from alternative carbon capture technologies. The membrane solution market faces particular pressure from amine-based absorption systems, which currently hold dominant market share despite higher operational costs and environmental concerns.

Pricing trends show gradual cost reductions as manufacturing scales increase, with current membrane solutions averaging 40-60 USD per ton of CO2 captured. This represents a significant improvement from 2015 levels but remains above the economic threshold for widespread adoption in price-sensitive sectors.

Current Status and Challenges in Membrane Material Development

Membrane-based CO2 capture technology has emerged as a promising approach for carbon emission reduction, with significant advancements in recent years. Currently, polymeric membranes dominate the commercial landscape due to their cost-effectiveness and processability. These include polyimides, polysulfones, and cellulose acetate membranes, which offer moderate selectivity and permeability. However, these conventional materials face inherent limitations in the permeability-selectivity trade-off, as described by Robeson's upper bound.

Inorganic membranes, particularly zeolites and metal-organic frameworks (MOFs), represent another category with superior thermal and chemical stability. These materials demonstrate exceptional CO2 separation performance but struggle with scalability and manufacturing complexity. The high production costs and brittleness of purely inorganic membranes have limited their industrial implementation despite their theoretical advantages.

Mixed matrix membranes (MMMs), combining polymeric matrices with inorganic fillers, have gained significant attention as they potentially overcome the limitations of both constituent materials. Recent research shows that incorporating MOFs, graphene oxide, or silica nanoparticles into polymer matrices can enhance CO2 permeability by 30-200% while maintaining or improving selectivity. However, challenges persist in achieving uniform dispersion of fillers and preventing interfacial defects.

Facilitated transport membranes represent another innovative approach, utilizing carriers that selectively and reversibly react with CO2. These membranes have demonstrated CO2/N2 selectivity exceeding 100, but suffer from carrier saturation at high pressures and degradation over time. Research efforts are focused on developing more stable carriers and optimizing membrane structures to mitigate these issues.

A significant challenge across all membrane types is the performance degradation under real operating conditions. Industrial flue gases contain contaminants like SOx, NOx, and water vapor that can plasticize polymers, block pores in inorganic membranes, or deactivate carriers in facilitated transport membranes. Long-term stability under these conditions remains a critical hurdle.

Manufacturing scalability presents another major challenge. While laboratory-scale membranes demonstrate impressive performance, translating these results to large-scale, defect-free membrane modules has proven difficult. Current industrial membrane modules typically achieve only 30-60% of the separation performance observed in laboratory tests.

Energy efficiency also remains a concern. The pressure differential required for membrane separation contributes significantly to the overall energy penalty of the capture process. Developing membranes that can operate effectively at lower pressure differentials would substantially improve the economic viability of membrane-based capture systems.

Globally, research efforts are concentrated in North America, Europe, and East Asia, with the United States, China, and Germany leading in patent filings and research publications. Recent collaborative international projects have accelerated development, though commercialization remains limited to niche applications rather than large-scale power plant implementations.

Inorganic membranes, particularly zeolites and metal-organic frameworks (MOFs), represent another category with superior thermal and chemical stability. These materials demonstrate exceptional CO2 separation performance but struggle with scalability and manufacturing complexity. The high production costs and brittleness of purely inorganic membranes have limited their industrial implementation despite their theoretical advantages.

Mixed matrix membranes (MMMs), combining polymeric matrices with inorganic fillers, have gained significant attention as they potentially overcome the limitations of both constituent materials. Recent research shows that incorporating MOFs, graphene oxide, or silica nanoparticles into polymer matrices can enhance CO2 permeability by 30-200% while maintaining or improving selectivity. However, challenges persist in achieving uniform dispersion of fillers and preventing interfacial defects.

Facilitated transport membranes represent another innovative approach, utilizing carriers that selectively and reversibly react with CO2. These membranes have demonstrated CO2/N2 selectivity exceeding 100, but suffer from carrier saturation at high pressures and degradation over time. Research efforts are focused on developing more stable carriers and optimizing membrane structures to mitigate these issues.

A significant challenge across all membrane types is the performance degradation under real operating conditions. Industrial flue gases contain contaminants like SOx, NOx, and water vapor that can plasticize polymers, block pores in inorganic membranes, or deactivate carriers in facilitated transport membranes. Long-term stability under these conditions remains a critical hurdle.

Manufacturing scalability presents another major challenge. While laboratory-scale membranes demonstrate impressive performance, translating these results to large-scale, defect-free membrane modules has proven difficult. Current industrial membrane modules typically achieve only 30-60% of the separation performance observed in laboratory tests.

Energy efficiency also remains a concern. The pressure differential required for membrane separation contributes significantly to the overall energy penalty of the capture process. Developing membranes that can operate effectively at lower pressure differentials would substantially improve the economic viability of membrane-based capture systems.

Globally, research efforts are concentrated in North America, Europe, and East Asia, with the United States, China, and Germany leading in patent filings and research publications. Recent collaborative international projects have accelerated development, though commercialization remains limited to niche applications rather than large-scale power plant implementations.

Existing Membrane Material Solutions and Performance Metrics

01 Advanced membrane materials for CO2 capture

Novel membrane materials have been developed to enhance CO2 capture efficiency. These include composite membranes, polymer-based membranes, and materials with specialized chemical structures that offer high selectivity for CO2 molecules. These advanced materials provide improved permeability and selectivity, which are crucial factors in determining membrane efficiency for carbon dioxide separation from gas mixtures.- Advanced membrane materials for CO2 capture: Novel membrane materials have been developed to enhance CO2 capture efficiency. These materials include polymer-based membranes, mixed matrix membranes, and composite membranes with specialized functional groups that have high CO2 selectivity. The advanced materials demonstrate improved permeability and selectivity for CO2 over other gases, leading to more efficient separation processes and reduced energy requirements for carbon capture.

- Membrane structure optimization for enhanced efficiency: Optimizing the physical structure of CO2 capture membranes significantly improves their efficiency. This includes developing thin-film composite structures, hollow fiber configurations, and multi-layered membrane designs that maximize surface area while minimizing mass transfer resistance. Structural innovations such as controlled porosity and channel formation help balance the trade-off between permeability and selectivity, resulting in higher CO2 capture rates with lower pressure drops across the membrane.

- Integration of facilitated transport mechanisms: Facilitated transport mechanisms incorporated into membranes enhance CO2 capture efficiency by utilizing carrier molecules that selectively bind with CO2. These carriers, such as amines or ionic liquids, are embedded within the membrane matrix to create reversible chemical interactions with CO2 molecules. This approach significantly increases CO2 permeance while maintaining high selectivity, allowing for more efficient separation even at low CO2 partial pressures typical in flue gas streams.

- Process optimization and operational parameters: Optimizing operational parameters and process conditions significantly impacts CO2 capture membrane efficiency. Factors such as temperature, pressure, feed gas composition, and flow rates can be carefully controlled to maximize membrane performance. Advanced process configurations, including multi-stage membrane systems, hybrid processes combining membranes with other capture technologies, and optimized flow patterns, have been developed to enhance overall system efficiency and reduce energy consumption.

- Surface modification and anti-fouling strategies: Surface modification techniques and anti-fouling strategies have been developed to maintain membrane efficiency over extended operation periods. These include hydrophilic or hydrophobic surface treatments, incorporation of nanoparticles, and development of self-cleaning membrane surfaces. Such modifications help prevent membrane fouling and degradation caused by contaminants in flue gas streams, thereby preserving separation performance and extending membrane lifespan, which contributes to improved long-term CO2 capture efficiency.

02 Membrane structure optimization techniques

Various techniques have been developed to optimize membrane structures for enhanced CO2 capture efficiency. These include creating multi-layer configurations, incorporating support structures, and developing hollow fiber membranes. The structural optimization focuses on increasing the surface area available for gas separation while maintaining mechanical stability, which significantly improves the overall efficiency of the CO2 capture process.Expand Specific Solutions03 Integration of catalysts and functional additives

The incorporation of catalysts and functional additives into membrane systems has shown significant improvements in CO2 capture efficiency. These additives can facilitate the transport of CO2 molecules across the membrane, enhance selectivity, or improve the membrane's resistance to harsh operating conditions. Examples include metal-organic frameworks, amine-functionalized materials, and specialized nanoparticles that create preferential pathways for CO2 transport.Expand Specific Solutions04 Process optimization and operating conditions

The efficiency of CO2 capture membranes is highly dependent on process parameters and operating conditions. Research has focused on optimizing factors such as temperature, pressure, gas flow rates, and humidity levels to maximize membrane performance. Advanced control systems and process integration strategies have been developed to maintain optimal conditions and handle variations in feed gas composition, significantly improving the overall efficiency of membrane-based carbon capture systems.Expand Specific Solutions05 Hybrid and integrated membrane systems

Hybrid systems that combine membrane technology with other CO2 capture methods have demonstrated enhanced efficiency. These integrated approaches may combine membranes with absorption, adsorption, or cryogenic separation techniques to overcome the limitations of individual methods. Such hybrid systems can achieve higher capture rates, reduced energy consumption, and improved economic viability compared to standalone membrane systems, particularly for challenging separation scenarios or varying gas compositions.Expand Specific Solutions

Key Industry Players and Research Institutions

The CO2 capture membrane material market is currently in a growth phase, with increasing global focus on carbon reduction technologies. The market size is expanding rapidly due to stringent environmental regulations and corporate sustainability commitments, projected to reach significant value by 2030. Technologically, the field shows varying maturity levels across different membrane types. Leading research institutions like King Abdullah University of Science & Technology and Colorado School of Mines are advancing fundamental materials science, while industrial players such as ExxonMobil Technology & Engineering, China Petroleum & Chemical Corp., and Compact Membrane Systems are focusing on scalable applications. Universities including Norwegian University of Science & Technology and Tianjin University are bridging the gap between theoretical research and practical implementation, creating a competitive landscape where academic-industrial partnerships are increasingly critical for commercialization success.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive membrane-based CO2 capture technology utilizing advanced mixed matrix membranes (MMMs). Their approach combines polymeric materials with inorganic fillers such as metal-organic frameworks (MOFs) and zeolites to create membranes with enhanced separation properties. Sinopec's membranes feature carefully engineered interfaces between the polymer matrix and inorganic particles to minimize defects while maximizing the benefits of both components[5]. Their research has demonstrated CO2 permeability improvements of up to 200% compared to pure polymer membranes while maintaining or improving selectivity. Sinopec has also developed specialized surface modification techniques for the inorganic fillers to improve their compatibility with the polymer matrix and prevent agglomeration[6]. The company has implemented these membranes in pilot-scale operations at several of their refineries, demonstrating stable performance under real industrial conditions with CO2 capture rates exceeding 85%. Their manufacturing process has been optimized for large-scale production, with membrane modules designed specifically for integration into existing industrial facilities with minimal modifications.

Strengths: Excellent balance between permeability and selectivity through the synergistic effects of polymeric and inorganic components. Robust performance in the presence of contaminants typical in industrial gas streams. Weaknesses: Achieving uniform dispersion of inorganic fillers remains challenging at industrial scale, and the complex structure of MMMs may lead to higher manufacturing costs compared to simple polymeric membranes.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced carbon capture membrane materials based on proprietary polymeric structures. Their approach focuses on carbonate-selective membranes that can efficiently separate CO2 from flue gas streams. The company has engineered composite membranes with specialized functional groups that enhance CO2 selectivity while maintaining high permeability. Their research demonstrates that these membranes can achieve separation factors exceeding 50 for CO2/N2 mixtures under typical flue gas conditions[1]. ExxonMobil's membrane technology incorporates a thin-film composite structure with a selective layer thickness of less than 100 nm, supported on a porous substrate that provides mechanical stability without compromising gas transport. The company has also developed manufacturing techniques that allow for large-scale production of these membranes with consistent quality and performance characteristics[2]. Field tests at their pilot facilities have shown sustained CO2 capture efficiencies of over 90% with significantly lower energy penalties compared to conventional amine scrubbing technologies.

Strengths: Superior CO2/N2 selectivity combined with high permeability, resulting in excellent separation performance. Engineered for durability in industrial environments with resistance to contaminants. Weaknesses: May require precise operating conditions to maintain optimal performance, and the manufacturing process for ultra-thin selective layers presents scaling challenges.

Critical Material Science Innovations for CO2 Capture

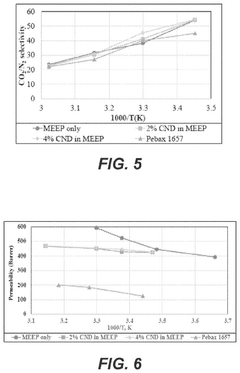

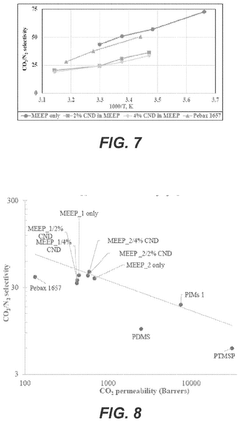

Carbon dioxide selective membranes, gas separation systems including the carbon dioxide selective membranes, and related methods

PatentPendingUS20250281872A1

Innovation

- A carbon dioxide selective membrane comprising a support and a selective structure of poly[bis((methoxyethoxy)ethoxy]phosphazene] (MEEP) is developed, which exhibits high CO2/N2 selectivity and self-guttering properties to repair defects, allowing efficient CO2 capture from low concentration streams.

Environmental Impact and Sustainability Assessment

The environmental impact of CO2 capture membrane technologies extends far beyond their immediate efficiency metrics. When evaluating membrane material choices, a comprehensive sustainability assessment must consider the entire life cycle of these materials, from raw material extraction to end-of-life disposal. Polymeric membranes, while often cost-effective, may involve petroleum-based precursors that contribute to fossil fuel dependency. Conversely, bio-based membrane materials offer reduced carbon footprints during production but may require more land and water resources.

Energy consumption during membrane manufacturing represents a significant environmental consideration. High-performance materials like graphene oxide or metal-organic frameworks (MOFs) typically demand energy-intensive synthesis processes, potentially offsetting some of their operational carbon capture benefits. This energy-efficiency paradox necessitates careful life cycle assessment (LCA) to determine the true environmental value proposition of advanced membrane materials.

Water usage patterns vary dramatically across different membrane material production processes. Certain ceramic and inorganic membranes require substantial water for synthesis and cleaning, while some polymeric options demonstrate more favorable water efficiency profiles. In water-stressed regions, this factor becomes particularly relevant when selecting appropriate membrane technologies for CO2 capture installations.

Chemical waste generation during membrane production and replacement cycles presents another critical environmental concern. Materials with longer operational lifespans generally offer superior sustainability profiles despite potentially higher initial environmental impacts. The degradation products of various membrane materials also differ significantly in their environmental persistence and toxicity, with some fluorinated polymers presenting particular concerns regarding long-term environmental accumulation.

Scalability considerations intersect directly with sustainability metrics. Materials that can be manufactured at industrial scale using existing infrastructure typically present lower environmental barriers to widespread adoption. Novel nanomaterials may offer exceptional CO2 capture performance but often face sustainability challenges in scaled production that must be addressed through green chemistry approaches and manufacturing innovations.

The circular economy potential of different membrane materials varies substantially. Some ceramic and metallic membranes offer excellent recyclability, while certain composite membranes present significant end-of-life challenges. Designing membranes with disassembly and material recovery in mind represents an emerging focus area that could substantially improve the overall sustainability profile of CO2 capture membrane technologies.

Energy consumption during membrane manufacturing represents a significant environmental consideration. High-performance materials like graphene oxide or metal-organic frameworks (MOFs) typically demand energy-intensive synthesis processes, potentially offsetting some of their operational carbon capture benefits. This energy-efficiency paradox necessitates careful life cycle assessment (LCA) to determine the true environmental value proposition of advanced membrane materials.

Water usage patterns vary dramatically across different membrane material production processes. Certain ceramic and inorganic membranes require substantial water for synthesis and cleaning, while some polymeric options demonstrate more favorable water efficiency profiles. In water-stressed regions, this factor becomes particularly relevant when selecting appropriate membrane technologies for CO2 capture installations.

Chemical waste generation during membrane production and replacement cycles presents another critical environmental concern. Materials with longer operational lifespans generally offer superior sustainability profiles despite potentially higher initial environmental impacts. The degradation products of various membrane materials also differ significantly in their environmental persistence and toxicity, with some fluorinated polymers presenting particular concerns regarding long-term environmental accumulation.

Scalability considerations intersect directly with sustainability metrics. Materials that can be manufactured at industrial scale using existing infrastructure typically present lower environmental barriers to widespread adoption. Novel nanomaterials may offer exceptional CO2 capture performance but often face sustainability challenges in scaled production that must be addressed through green chemistry approaches and manufacturing innovations.

The circular economy potential of different membrane materials varies substantially. Some ceramic and metallic membranes offer excellent recyclability, while certain composite membranes present significant end-of-life challenges. Designing membranes with disassembly and material recovery in mind represents an emerging focus area that could substantially improve the overall sustainability profile of CO2 capture membrane technologies.

Economic Feasibility and Scalability Analysis

The economic viability of CO2 capture membrane technologies hinges significantly on material selection, which directly impacts both capital expenditure and operational costs. Polymeric membranes generally offer lower manufacturing costs compared to inorganic alternatives, with materials like polysulfone and cellulose acetate providing economical options at $50-100/m². However, these cost advantages must be weighed against their typically lower CO2 separation efficiency and shorter operational lifespan.

Mixed matrix membranes (MMMs) represent a middle-ground solution, combining cost-effectiveness with improved performance. Initial economic analyses indicate that MMMs incorporating metal-organic frameworks can achieve capture costs of $40-60 per ton of CO2, approaching the U.S. Department of Energy's target of $30 per ton for economically viable carbon capture.

Scalability considerations reveal significant challenges in transitioning from laboratory-scale to industrial implementation. Current manufacturing processes for high-performance membranes like facilitated transport membranes face limitations in consistent quality control when scaled to industrial dimensions. The production of defect-free membrane surfaces exceeding 1000 m² remains technically challenging, particularly for composite and hybrid materials.

Infrastructure compatibility presents another critical economic factor. Retrofitting existing power plants with membrane-based capture systems requires substantial capital investment, estimated at $600-900 per kW of generating capacity. This investment varies significantly based on membrane material selection, with more durable materials like thermally rearranged polymers potentially offering lower lifetime costs despite higher initial expenses.

Market analysis indicates that membrane materials demonstrating operational stability beyond 3 years can achieve favorable levelized cost of capture metrics, even with moderately higher initial costs. For instance, zeolite-incorporated membranes with enhanced fouling resistance may command a 30-40% price premium but deliver up to 50% longer operational lifespans in industrial environments.

The economic equation is further complicated by energy requirements. Materials with higher intrinsic CO2 permeability generally reduce the energy penalty associated with capture operations. Recent techno-economic assessments suggest that advanced membrane materials could potentially reduce capture energy requirements to 0.8-1.2 GJ/ton CO2, representing a significant improvement over the 2.0-2.5 GJ/ton typical of first-generation materials.

For large-scale deployment, manufacturing capacity represents a potential bottleneck. Current global production capacity for specialized membrane materials remains limited, with estimates suggesting that scaling to meet global carbon capture needs would require 5-10 years of manufacturing infrastructure development, depending on material complexity.

Mixed matrix membranes (MMMs) represent a middle-ground solution, combining cost-effectiveness with improved performance. Initial economic analyses indicate that MMMs incorporating metal-organic frameworks can achieve capture costs of $40-60 per ton of CO2, approaching the U.S. Department of Energy's target of $30 per ton for economically viable carbon capture.

Scalability considerations reveal significant challenges in transitioning from laboratory-scale to industrial implementation. Current manufacturing processes for high-performance membranes like facilitated transport membranes face limitations in consistent quality control when scaled to industrial dimensions. The production of defect-free membrane surfaces exceeding 1000 m² remains technically challenging, particularly for composite and hybrid materials.

Infrastructure compatibility presents another critical economic factor. Retrofitting existing power plants with membrane-based capture systems requires substantial capital investment, estimated at $600-900 per kW of generating capacity. This investment varies significantly based on membrane material selection, with more durable materials like thermally rearranged polymers potentially offering lower lifetime costs despite higher initial expenses.

Market analysis indicates that membrane materials demonstrating operational stability beyond 3 years can achieve favorable levelized cost of capture metrics, even with moderately higher initial costs. For instance, zeolite-incorporated membranes with enhanced fouling resistance may command a 30-40% price premium but deliver up to 50% longer operational lifespans in industrial environments.

The economic equation is further complicated by energy requirements. Materials with higher intrinsic CO2 permeability generally reduce the energy penalty associated with capture operations. Recent techno-economic assessments suggest that advanced membrane materials could potentially reduce capture energy requirements to 0.8-1.2 GJ/ton CO2, representing a significant improvement over the 2.0-2.5 GJ/ton typical of first-generation materials.

For large-scale deployment, manufacturing capacity represents a potential bottleneck. Current global production capacity for specialized membrane materials remains limited, with estimates suggesting that scaling to meet global carbon capture needs would require 5-10 years of manufacturing infrastructure development, depending on material complexity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!