Research on Key Parameters for CO2 Capture Membrane Optimization

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Technology Background and Objectives

Carbon dioxide capture and separation technologies have evolved significantly over the past several decades, driven by increasing global concerns about climate change and greenhouse gas emissions. Membrane-based CO2 capture represents one of the most promising approaches due to its energy efficiency, operational simplicity, and reduced environmental footprint compared to conventional absorption or adsorption methods. The development trajectory of membrane technology for CO2 capture has progressed from early polymer-based membranes with limited selectivity to advanced mixed matrix membranes (MMMs) and facilitated transport membranes that demonstrate remarkable performance characteristics.

The evolution of CO2 capture membrane technology has been marked by several significant milestones. In the 1980s, cellulose acetate membranes were first commercialized for natural gas sweetening. The 1990s saw the emergence of polyimide membranes with improved thermal and chemical stability. The early 2000s witnessed the development of thermally rearranged polymers and polymers of intrinsic microporosity (PIMs) that offered unprecedented combinations of permeability and selectivity. Most recently, the integration of nanomaterials such as metal-organic frameworks (MOFs), graphene derivatives, and zeolites into polymer matrices has pushed performance boundaries even further.

Current technological trends indicate a shift toward multifunctional membrane designs that simultaneously address multiple performance parameters. These include not only CO2 permeability and CO2/N2 selectivity but also mechanical durability, resistance to plasticization, tolerance to contaminants, and long-term stability under realistic operating conditions. The convergence of materials science, nanotechnology, and process engineering has accelerated innovation in this field, enabling more sophisticated membrane architectures and compositions.

The primary technical objectives for CO2 capture membrane optimization include surpassing the Robeson upper bound that describes the traditional trade-off between permeability and selectivity, achieving economically viable CO2 capture costs below $30/ton, developing membranes with operational lifespans exceeding five years under industrial conditions, and designing scalable manufacturing processes that maintain nanoscale precision at commercial production volumes.

Additionally, there is growing recognition of the need to optimize membranes for specific deployment scenarios, including post-combustion capture from power plants, pre-combustion capture from syngas, direct air capture, and industrial point sources such as cement and steel production. Each application presents unique challenges regarding feed composition, pressure, temperature, and contaminant profiles that significantly influence membrane performance requirements and optimal material selection.

The ultimate goal of research on key parameters for CO2 capture membrane optimization is to develop next-generation membrane materials and modules that can achieve CO2 capture costs competitive with or superior to alternative technologies while offering the additional benefits of smaller footprint, operational flexibility, and reduced environmental impact.

The evolution of CO2 capture membrane technology has been marked by several significant milestones. In the 1980s, cellulose acetate membranes were first commercialized for natural gas sweetening. The 1990s saw the emergence of polyimide membranes with improved thermal and chemical stability. The early 2000s witnessed the development of thermally rearranged polymers and polymers of intrinsic microporosity (PIMs) that offered unprecedented combinations of permeability and selectivity. Most recently, the integration of nanomaterials such as metal-organic frameworks (MOFs), graphene derivatives, and zeolites into polymer matrices has pushed performance boundaries even further.

Current technological trends indicate a shift toward multifunctional membrane designs that simultaneously address multiple performance parameters. These include not only CO2 permeability and CO2/N2 selectivity but also mechanical durability, resistance to plasticization, tolerance to contaminants, and long-term stability under realistic operating conditions. The convergence of materials science, nanotechnology, and process engineering has accelerated innovation in this field, enabling more sophisticated membrane architectures and compositions.

The primary technical objectives for CO2 capture membrane optimization include surpassing the Robeson upper bound that describes the traditional trade-off between permeability and selectivity, achieving economically viable CO2 capture costs below $30/ton, developing membranes with operational lifespans exceeding five years under industrial conditions, and designing scalable manufacturing processes that maintain nanoscale precision at commercial production volumes.

Additionally, there is growing recognition of the need to optimize membranes for specific deployment scenarios, including post-combustion capture from power plants, pre-combustion capture from syngas, direct air capture, and industrial point sources such as cement and steel production. Each application presents unique challenges regarding feed composition, pressure, temperature, and contaminant profiles that significantly influence membrane performance requirements and optimal material selection.

The ultimate goal of research on key parameters for CO2 capture membrane optimization is to develop next-generation membrane materials and modules that can achieve CO2 capture costs competitive with or superior to alternative technologies while offering the additional benefits of smaller footprint, operational flexibility, and reduced environmental impact.

Market Demand Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations place the carbon capture industry at approximately 2 billion USD in 2023, with projections indicating a compound annual growth rate of 19-21% through 2030, potentially reaching 7-9 billion USD. This growth trajectory is supported by substantial government investments, with the US Inflation Reduction Act allocating 369 billion USD toward climate initiatives, including carbon capture technologies.

Membrane-based CO2 capture solutions specifically are gaining traction due to their energy efficiency advantages over traditional amine-based absorption methods. Industrial sectors including power generation, cement manufacturing, steel production, and chemical processing represent the primary demand sources, collectively accounting for over 70% of global CO2 emissions from industrial processes.

Regional analysis reveals varying market dynamics, with North America leading in technology adoption due to established carbon pricing mechanisms and tax incentives. The European Union follows closely with its ambitious European Green Deal and Emissions Trading System driving implementation. Asia-Pacific represents the fastest-growing market segment, particularly in China and India, where rapid industrialization coincides with increasing environmental commitments.

End-user surveys indicate specific performance requirements for CO2 capture membranes across different industries. Power generation facilities prioritize scalability and integration with existing infrastructure, while cement and steel manufacturers emphasize temperature resistance and durability in harsh operating environments. Chemical processing industries focus on selectivity parameters to maintain product purity.

Cost sensitivity analysis reveals that potential adopters consider both capital expenditure and operational costs, with the economic threshold for widespread adoption estimated at capture costs below 40-50 USD per ton of CO2. Current membrane technologies typically operate at 60-80 USD per ton, highlighting the need for optimization of key membrane parameters to reduce costs.

Market forecasts suggest that membrane technologies optimized for specific industrial applications could capture 25-30% of the total carbon capture market by 2030, representing a significant opportunity for specialized solutions. This growth is contingent upon achieving performance improvements in selectivity, permeability, and durability parameters that directly impact operational efficiency and cost-effectiveness.

Membrane-based CO2 capture solutions specifically are gaining traction due to their energy efficiency advantages over traditional amine-based absorption methods. Industrial sectors including power generation, cement manufacturing, steel production, and chemical processing represent the primary demand sources, collectively accounting for over 70% of global CO2 emissions from industrial processes.

Regional analysis reveals varying market dynamics, with North America leading in technology adoption due to established carbon pricing mechanisms and tax incentives. The European Union follows closely with its ambitious European Green Deal and Emissions Trading System driving implementation. Asia-Pacific represents the fastest-growing market segment, particularly in China and India, where rapid industrialization coincides with increasing environmental commitments.

End-user surveys indicate specific performance requirements for CO2 capture membranes across different industries. Power generation facilities prioritize scalability and integration with existing infrastructure, while cement and steel manufacturers emphasize temperature resistance and durability in harsh operating environments. Chemical processing industries focus on selectivity parameters to maintain product purity.

Cost sensitivity analysis reveals that potential adopters consider both capital expenditure and operational costs, with the economic threshold for widespread adoption estimated at capture costs below 40-50 USD per ton of CO2. Current membrane technologies typically operate at 60-80 USD per ton, highlighting the need for optimization of key membrane parameters to reduce costs.

Market forecasts suggest that membrane technologies optimized for specific industrial applications could capture 25-30% of the total carbon capture market by 2030, representing a significant opportunity for specialized solutions. This growth is contingent upon achieving performance improvements in selectivity, permeability, and durability parameters that directly impact operational efficiency and cost-effectiveness.

Current Status and Challenges in Membrane-Based CO2 Capture

Membrane-based CO2 capture technology has emerged as a promising alternative to conventional absorption methods due to its lower energy consumption, reduced environmental impact, and operational flexibility. Currently, polymeric membranes dominate the commercial landscape, with materials such as polyimides, polysulfones, and cellulose acetate being widely deployed. These membranes typically achieve CO2/N2 selectivity of 20-50 and CO2 permeability ranging from 10 to 500 Barrer, depending on the specific polymer composition and structure.

Despite significant progress, membrane-based CO2 capture faces several critical challenges. The fundamental trade-off between permeability and selectivity, known as Robeson's upper bound, continues to limit membrane performance. As permeability increases, selectivity typically decreases, making it difficult to simultaneously achieve high throughput and high purity. This relationship has constrained industrial adoption, particularly for large-scale applications where both parameters are crucial for economic viability.

Material stability presents another significant hurdle. Many high-performance membranes suffer from plasticization when exposed to high CO2 partial pressures, leading to swelling, reduced selectivity, and shortened operational lifespans. Additionally, membrane fouling caused by particulates, water vapor, and other contaminants in flue gas streams significantly impairs long-term performance, necessitating frequent replacement or regeneration cycles.

Scalability remains a persistent challenge for membrane technology. While laboratory-scale membranes demonstrate promising performance, translating these results to industrial-scale modules with thousands of square meters of membrane area introduces manufacturing complexities and performance inconsistencies. Current fabrication techniques struggle to produce defect-free membranes at scale while maintaining uniform thickness and structural integrity.

Geographically, membrane research for CO2 capture is concentrated in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading in patent filings and research publications. European research centers have focused on developing mixed matrix membranes, while North American institutions have pioneered facilitated transport membranes. Asian research groups have made significant contributions to thermally rearranged polymers and ultra-thin film composites.

Economic barriers further complicate widespread adoption. Current membrane systems for CO2 capture typically cost between $40-60 per ton of CO2 captured, which remains higher than the target of $30 per ton needed for commercial viability in many applications. This cost challenge is exacerbated by the need for multi-stage membrane processes to achieve high CO2 purity, increasing both capital and operational expenditures.

Despite significant progress, membrane-based CO2 capture faces several critical challenges. The fundamental trade-off between permeability and selectivity, known as Robeson's upper bound, continues to limit membrane performance. As permeability increases, selectivity typically decreases, making it difficult to simultaneously achieve high throughput and high purity. This relationship has constrained industrial adoption, particularly for large-scale applications where both parameters are crucial for economic viability.

Material stability presents another significant hurdle. Many high-performance membranes suffer from plasticization when exposed to high CO2 partial pressures, leading to swelling, reduced selectivity, and shortened operational lifespans. Additionally, membrane fouling caused by particulates, water vapor, and other contaminants in flue gas streams significantly impairs long-term performance, necessitating frequent replacement or regeneration cycles.

Scalability remains a persistent challenge for membrane technology. While laboratory-scale membranes demonstrate promising performance, translating these results to industrial-scale modules with thousands of square meters of membrane area introduces manufacturing complexities and performance inconsistencies. Current fabrication techniques struggle to produce defect-free membranes at scale while maintaining uniform thickness and structural integrity.

Geographically, membrane research for CO2 capture is concentrated in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading in patent filings and research publications. European research centers have focused on developing mixed matrix membranes, while North American institutions have pioneered facilitated transport membranes. Asian research groups have made significant contributions to thermally rearranged polymers and ultra-thin film composites.

Economic barriers further complicate widespread adoption. Current membrane systems for CO2 capture typically cost between $40-60 per ton of CO2 captured, which remains higher than the target of $30 per ton needed for commercial viability in many applications. This cost challenge is exacerbated by the need for multi-stage membrane processes to achieve high CO2 purity, increasing both capital and operational expenditures.

Current Parameter Optimization Approaches for CO2 Membranes

01 Membrane material composition for CO2 capture

The composition of membrane materials significantly affects CO2 capture efficiency. Various polymers, composites, and hybrid materials are used to create membranes with high CO2 selectivity. These materials include facilitated transport membranes, mixed matrix membranes, and polymer blends that are specifically designed to enhance CO2 permeability while maintaining selectivity over other gases. The material composition directly influences the membrane's ability to separate CO2 from gas mixtures effectively.- Membrane material composition for CO2 capture: The composition of membrane materials plays a crucial role in CO2 capture efficiency. Various polymers, composites, and hybrid materials are used to create membranes with high CO2 selectivity. These materials include facilitated transport membranes, mixed matrix membranes, and polymer blends that are specifically designed to enhance CO2 permeability while maintaining selectivity over other gases. The material composition directly affects the membrane's performance parameters such as permeance, selectivity, and stability under different operating conditions.

- Membrane structure and morphology optimization: The structural design and morphology of CO2 capture membranes significantly impact their performance. Key parameters include membrane thickness, pore size distribution, surface area, and the presence of functional groups. Hollow fiber, flat sheet, and spiral wound configurations offer different advantages in terms of packing density and mass transfer efficiency. Advanced manufacturing techniques are employed to create asymmetric structures with thin selective layers supported by porous substrates, optimizing both mechanical stability and gas transport properties.

- Transport mechanisms and kinetic parameters: Understanding the transport mechanisms of CO2 through membranes is essential for optimizing capture performance. Key parameters include diffusion coefficients, sorption coefficients, and activation energies for permeation. Different mechanisms such as solution-diffusion, facilitated transport, and molecular sieving govern how CO2 molecules move through the membrane matrix. The relationship between operating conditions (temperature, pressure, humidity) and these transport parameters determines the overall separation efficiency and energy requirements of the membrane system.

- Membrane stability and durability factors: Long-term stability and durability are critical parameters for industrial application of CO2 capture membranes. Key factors include chemical resistance to contaminants in flue gas, thermal stability at operating temperatures, mechanical strength under pressure differentials, and resistance to plasticization. Membranes must maintain their separation performance over extended periods while exposed to harsh conditions including acidic components, particulates, and varying humidity levels. Stability parameters are typically evaluated through accelerated aging tests and long-term performance monitoring.

- Process integration and operational parameters: The integration of membrane systems into CO2 capture processes requires optimization of several operational parameters. These include feed gas composition, operating pressure and temperature, sweep gas flow rate, and stage configuration. Multi-stage membrane systems with appropriate recycle streams can enhance overall capture efficiency. The trade-off between energy consumption, capture rate, and product purity must be carefully balanced. Process intensification approaches such as hybrid membrane-absorption systems can further improve performance by combining the advantages of different separation technologies.

02 Membrane structure and morphology parameters

The physical structure and morphology of CO2 capture membranes are critical parameters affecting performance. Key structural factors include pore size distribution, membrane thickness, surface area, and the presence of functional groups. Thin-film composite structures, hollow fiber configurations, and supported membranes offer different advantages in terms of mechanical stability and gas transport properties. Optimizing these structural parameters can significantly enhance CO2 separation efficiency and membrane durability under various operating conditions.Expand Specific Solutions03 Transport mechanisms and permeability-selectivity trade-off

CO2 capture membranes operate through various transport mechanisms including solution-diffusion, facilitated transport, and molecular sieving. A fundamental challenge is the permeability-selectivity trade-off, where increasing CO2 permeability often results in decreased selectivity over other gases. Advanced membrane designs aim to overcome this limitation through innovative approaches such as incorporating CO2-philic groups, using facilitated transport carriers, or developing mixed matrix membranes that combine the benefits of polymeric and inorganic materials to achieve both high permeability and selectivity.Expand Specific Solutions04 Operating conditions and performance stability

The performance of CO2 capture membranes is significantly influenced by operating conditions including temperature, pressure, humidity, and feed gas composition. Membranes must maintain stable performance under varying conditions and resist plasticization, which can occur at high CO2 partial pressures. Thermal and chemical stability are essential for long-term operation, particularly in industrial settings where membranes may be exposed to contaminants. Developing membranes that maintain high performance under realistic operating conditions remains a key challenge in the field.Expand Specific Solutions05 Membrane module design and system integration

The design of membrane modules and their integration into larger CO2 capture systems significantly impact overall performance. Key parameters include module configuration (spiral wound, hollow fiber, flat sheet), packing density, flow patterns, and pressure drop considerations. Effective module design maximizes membrane area while minimizing energy consumption and footprint. System integration aspects include pre-treatment requirements, multi-stage configurations, and hybrid systems that combine membrane technology with other capture methods to achieve optimal performance and cost-effectiveness for specific applications.Expand Specific Solutions

Leading Organizations in CO2 Capture Membrane Development

The CO2 capture membrane optimization market is in a growth phase, characterized by increasing research intensity and expanding applications across energy and industrial sectors. The market is projected to reach significant scale as carbon capture technologies become critical for emissions reduction strategies globally. From a technological maturity perspective, the field shows varied development levels among key players. Academic institutions like King Abdullah University of Science & Technology, Tianjin University, and Arizona State University are advancing fundamental research, while industrial entities including Air Liquide, China Petroleum & Chemical Corp., and Korea Electric Power Corp. are focusing on practical applications and scaling. Research collaborations between academic and industrial players, particularly in membrane material development and process optimization, are accelerating technological advancement toward commercial viability.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced membrane technology for CO2 capture focusing on key parameters optimization. Their approach utilizes composite membranes with tailored polymer matrices that enhance CO2 selectivity while maintaining high permeability. The company's MEDAL™ membrane technology incorporates precise control of membrane thickness (typically 0.1-1.0 μm for selective layer) and porosity optimization (30-60%) to maximize gas separation efficiency. Air Liquide's research has identified that operating temperature (optimally 25-45°C) and pressure differential (3-20 bar) significantly impact membrane performance. Their proprietary surface modification techniques enhance CO2 affinity through incorporation of amine-functionalized groups that facilitate selective CO2 transport across the membrane. The company has also developed computational models to predict membrane performance based on material composition and operating conditions, allowing for rapid parameter optimization without extensive physical testing.

Strengths: Industry-leading expertise in gas separation technologies with established commercial-scale implementation capabilities. Their integrated approach combining material science and process engineering enables practical solutions. Weaknesses: Their membrane technologies may require significant pressure differentials to operate efficiently, potentially increasing energy consumption in certain applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed innovative mixed matrix membranes (MMMs) for CO2 capture with precisely controlled parameters. Their technology combines polymer matrices (typically polyimide or PEBAX) with inorganic fillers like metal-organic frameworks (MOFs) at optimized loading ratios (3-7 wt%). Sinopec's research has determined that particle size distribution (50-200 nm) and dispersion homogeneity are critical for maximizing CO2/N2 selectivity while maintaining high permeability. Their membranes feature controlled thickness gradients (0.2-2.0 μm) and surface modifications using amino-silane coupling agents to enhance CO2 affinity. Sinopec has established that operating pressure (optimally 5-15 bar) and feed gas humidity (30-60% RH) significantly impact separation performance. Their proprietary manufacturing process ensures consistent pore size distribution and mechanical stability under industrial conditions, with membranes demonstrating CO2 permeability of 500-1500 Barrer while maintaining CO2/N2 selectivity above 40.

Strengths: Extensive industrial infrastructure and integration capabilities allow for rapid scaling of membrane technologies. Their approach combines fundamental research with practical engineering solutions for real-world applications. Weaknesses: Their membranes may face challenges in maintaining performance under the harsh conditions typical in petroleum and chemical processing environments, potentially requiring frequent replacement.

Critical Parameters Analysis for Membrane Performance Enhancement

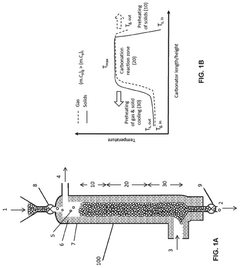

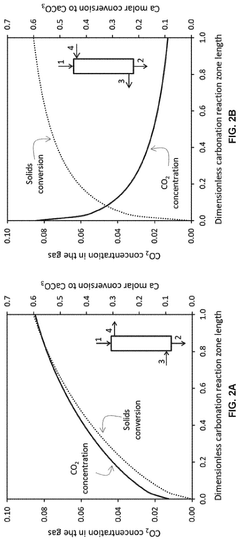

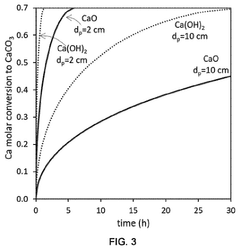

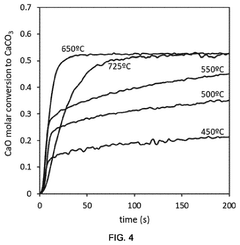

Co2 capture method using a countercurrent moving bed reactor

PatentPendingUS20250256241A1

Innovation

- A countercurrent moving bed reactor system using Ca(OH)2 and/or CaO solids in a packed bed configuration, with controlled gas-solid contact and residence time, achieving optimal carbonation temperatures between 600-700°C for high CO2 concentrations and ambient temperatures for low concentrations, utilizing heat exchange and humidity to manage temperature and efficiency.

Environmental Impact Assessment of Membrane-Based Carbon Capture

The environmental implications of membrane-based carbon capture technologies extend far beyond their primary function of CO2 separation. When evaluating these systems holistically, several critical environmental factors must be considered to ensure that the solution does not create more problems than it solves.

Energy consumption represents one of the most significant environmental considerations for membrane-based capture systems. While membranes generally require less energy than traditional amine scrubbing technologies, they still demand substantial power for compression and maintaining operational conditions. This energy footprint varies considerably depending on membrane material selection, system configuration, and operational parameters.

Life cycle assessment (LCA) studies indicate that membrane production processes involve environmental impacts through raw material extraction, polymer synthesis, and manufacturing. Polymeric membranes typically demonstrate lower embodied carbon than ceramic alternatives, though their shorter operational lifespan may offset this advantage. The environmental payback period—when emissions avoided exceed those generated during manufacturing—ranges from 3-18 months depending on system efficiency.

Water usage presents another critical environmental dimension. Unlike solvent-based systems that require significant water for regeneration, membrane technologies operate with minimal water requirements. This advantage becomes particularly valuable in water-stressed regions where competing demands for industrial water use create additional environmental pressures.

Waste generation and disposal considerations must address membrane replacement schedules and end-of-life management. Current membrane technologies typically require replacement every 3-5 years, generating polymer waste streams that present recycling challenges due to their composite nature and potential contamination from operational exposure.

Secondary emissions from membrane systems warrant careful monitoring. While CO2 is the primary target, membranes may inadvertently release other greenhouse gases or volatile organic compounds depending on feed gas composition and membrane selectivity characteristics. These potential emissions must be quantified when calculating the net environmental benefit of implementation.

Land use requirements for membrane systems compare favorably to alternative carbon capture technologies, with typical installations requiring 40-60% less physical footprint than equivalent amine-based systems. This spatial efficiency reduces habitat disruption and allows for more flexible installation options, including retrofitting existing industrial facilities.

Energy consumption represents one of the most significant environmental considerations for membrane-based capture systems. While membranes generally require less energy than traditional amine scrubbing technologies, they still demand substantial power for compression and maintaining operational conditions. This energy footprint varies considerably depending on membrane material selection, system configuration, and operational parameters.

Life cycle assessment (LCA) studies indicate that membrane production processes involve environmental impacts through raw material extraction, polymer synthesis, and manufacturing. Polymeric membranes typically demonstrate lower embodied carbon than ceramic alternatives, though their shorter operational lifespan may offset this advantage. The environmental payback period—when emissions avoided exceed those generated during manufacturing—ranges from 3-18 months depending on system efficiency.

Water usage presents another critical environmental dimension. Unlike solvent-based systems that require significant water for regeneration, membrane technologies operate with minimal water requirements. This advantage becomes particularly valuable in water-stressed regions where competing demands for industrial water use create additional environmental pressures.

Waste generation and disposal considerations must address membrane replacement schedules and end-of-life management. Current membrane technologies typically require replacement every 3-5 years, generating polymer waste streams that present recycling challenges due to their composite nature and potential contamination from operational exposure.

Secondary emissions from membrane systems warrant careful monitoring. While CO2 is the primary target, membranes may inadvertently release other greenhouse gases or volatile organic compounds depending on feed gas composition and membrane selectivity characteristics. These potential emissions must be quantified when calculating the net environmental benefit of implementation.

Land use requirements for membrane systems compare favorably to alternative carbon capture technologies, with typical installations requiring 40-60% less physical footprint than equivalent amine-based systems. This spatial efficiency reduces habitat disruption and allows for more flexible installation options, including retrofitting existing industrial facilities.

Techno-Economic Analysis of Membrane CO2 Capture Systems

The techno-economic analysis of membrane CO2 capture systems requires a comprehensive evaluation of both technical performance and economic viability. This analysis is crucial for determining whether membrane-based carbon capture technologies can compete with established alternatives such as amine scrubbing or pressure swing adsorption.

Capital expenditure (CAPEX) for membrane systems primarily includes the membrane modules, supporting structures, compression equipment, and installation costs. Current estimates place membrane system CAPEX between $800-1,500 per kW for power plant applications, with the membrane material itself accounting for 30-40% of this cost. Economies of scale significantly impact these figures, with larger installations generally achieving lower per-unit costs.

Operating expenditure (OPEX) is dominated by energy requirements for gas compression and maintaining pressure differentials across the membrane. For typical membrane systems, energy penalties range from 0.2-0.5 GJ/tonne CO2 captured, translating to approximately $15-30 per tonne CO2 in energy costs alone. Membrane replacement costs, typically required every 3-5 years depending on operating conditions, add another significant component to OPEX calculations.

Levelized cost of CO2 capture (LCCC) integrates these factors over the system lifetime, currently estimated at $40-80 per tonne CO2 for membrane systems. This positions membranes competitively against amine scrubbing ($50-100/tonne) for certain applications, particularly where space constraints or modularity requirements favor membrane technology.

Sensitivity analysis reveals that membrane performance parameters significantly impact economics. A 10% improvement in CO2 permeability can reduce LCCC by approximately 7-9%, while similar improvements in selectivity yield 5-7% cost reductions. This underscores the importance of material optimization in driving economic viability.

Process integration opportunities present additional economic advantages. Waste heat utilization from adjacent processes can reduce compression energy requirements by 15-25%, while optimized pressure management strategies can further decrease operating costs by 10-15%. These integration benefits are particularly pronounced in industrial settings with existing high-pressure gas streams.

Future cost reduction pathways primarily involve advances in membrane materials, manufacturing scale-up, and process optimization. Analysis suggests that next-generation membrane materials could potentially reduce LCCC to $30-50 per tonne CO2 by 2030, making membrane capture increasingly competitive across broader application scenarios.

Capital expenditure (CAPEX) for membrane systems primarily includes the membrane modules, supporting structures, compression equipment, and installation costs. Current estimates place membrane system CAPEX between $800-1,500 per kW for power plant applications, with the membrane material itself accounting for 30-40% of this cost. Economies of scale significantly impact these figures, with larger installations generally achieving lower per-unit costs.

Operating expenditure (OPEX) is dominated by energy requirements for gas compression and maintaining pressure differentials across the membrane. For typical membrane systems, energy penalties range from 0.2-0.5 GJ/tonne CO2 captured, translating to approximately $15-30 per tonne CO2 in energy costs alone. Membrane replacement costs, typically required every 3-5 years depending on operating conditions, add another significant component to OPEX calculations.

Levelized cost of CO2 capture (LCCC) integrates these factors over the system lifetime, currently estimated at $40-80 per tonne CO2 for membrane systems. This positions membranes competitively against amine scrubbing ($50-100/tonne) for certain applications, particularly where space constraints or modularity requirements favor membrane technology.

Sensitivity analysis reveals that membrane performance parameters significantly impact economics. A 10% improvement in CO2 permeability can reduce LCCC by approximately 7-9%, while similar improvements in selectivity yield 5-7% cost reductions. This underscores the importance of material optimization in driving economic viability.

Process integration opportunities present additional economic advantages. Waste heat utilization from adjacent processes can reduce compression energy requirements by 15-25%, while optimized pressure management strategies can further decrease operating costs by 10-15%. These integration benefits are particularly pronounced in industrial settings with existing high-pressure gas streams.

Future cost reduction pathways primarily involve advances in membrane materials, manufacturing scale-up, and process optimization. Analysis suggests that next-generation membrane materials could potentially reduce LCCC to $30-50 per tonne CO2 by 2030, making membrane capture increasingly competitive across broader application scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!