Analysis of CO2 Capture Membrane Thermal and Mechanical Properties

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Technology Background and Objectives

Carbon dioxide capture membrane technology has evolved significantly over the past few decades as a response to the growing concern about greenhouse gas emissions and climate change. Initially developed in the 1980s as a theoretical concept, membrane-based CO2 capture has progressed from laboratory curiosity to commercial viability. The fundamental principle involves selective permeation of CO2 through specialized membrane materials while restricting the passage of other gases, offering a potentially energy-efficient alternative to conventional absorption processes.

The evolution of membrane materials has been remarkable, transitioning from simple polymeric structures to advanced composite and hybrid materials. Early membranes suffered from low selectivity and permeability, but continuous innovation has led to materials with significantly improved performance characteristics. The technology trajectory shows a clear trend toward membranes with enhanced thermal stability, mechanical durability, and separation efficiency.

Current research focuses on understanding the intricate relationship between membrane thermal properties and CO2 separation performance. Temperature fluctuations in industrial settings can dramatically affect membrane integrity and separation efficiency, making thermal stability a critical parameter. Similarly, mechanical properties determine membrane longevity and reliability under pressure differentials typical in industrial applications.

The primary objective of analyzing CO2 capture membrane thermal and mechanical properties is to develop next-generation materials capable of withstanding harsh industrial conditions while maintaining optimal separation performance. This includes understanding how temperature variations affect polymer chain mobility, gas diffusion mechanisms, and overall membrane structure.

Another key goal is to establish standardized testing protocols for evaluating membrane thermal and mechanical properties, enabling meaningful comparisons between different membrane technologies. Currently, the lack of uniform testing methods creates challenges in assessing relative performance across research groups and commercial products.

The technology aims to achieve membranes with operating temperature ranges of -20°C to 200°C and pressure tolerances up to 100 bar, significantly expanding application possibilities in various industrial settings. Additionally, researchers seek to extend membrane lifespans to 5+ years under continuous operation, reducing replacement costs and operational disruptions.

From an environmental perspective, the ultimate objective is to develop membrane systems capable of capturing CO2 at costs below $30 per ton, making the technology economically viable without subsidies. This cost target represents a significant challenge that requires breakthroughs in both material science and manufacturing processes.

The evolution of membrane materials has been remarkable, transitioning from simple polymeric structures to advanced composite and hybrid materials. Early membranes suffered from low selectivity and permeability, but continuous innovation has led to materials with significantly improved performance characteristics. The technology trajectory shows a clear trend toward membranes with enhanced thermal stability, mechanical durability, and separation efficiency.

Current research focuses on understanding the intricate relationship between membrane thermal properties and CO2 separation performance. Temperature fluctuations in industrial settings can dramatically affect membrane integrity and separation efficiency, making thermal stability a critical parameter. Similarly, mechanical properties determine membrane longevity and reliability under pressure differentials typical in industrial applications.

The primary objective of analyzing CO2 capture membrane thermal and mechanical properties is to develop next-generation materials capable of withstanding harsh industrial conditions while maintaining optimal separation performance. This includes understanding how temperature variations affect polymer chain mobility, gas diffusion mechanisms, and overall membrane structure.

Another key goal is to establish standardized testing protocols for evaluating membrane thermal and mechanical properties, enabling meaningful comparisons between different membrane technologies. Currently, the lack of uniform testing methods creates challenges in assessing relative performance across research groups and commercial products.

The technology aims to achieve membranes with operating temperature ranges of -20°C to 200°C and pressure tolerances up to 100 bar, significantly expanding application possibilities in various industrial settings. Additionally, researchers seek to extend membrane lifespans to 5+ years under continuous operation, reducing replacement costs and operational disruptions.

From an environmental perspective, the ultimate objective is to develop membrane systems capable of capturing CO2 at costs below $30 per ton, making the technology economically viable without subsidies. This cost target represents a significant challenge that requires breakthroughs in both material science and manufacturing processes.

Market Demand for Advanced CO2 Capture Solutions

The global market for advanced CO2 capture solutions is experiencing significant growth driven by increasing environmental regulations and corporate sustainability commitments. Current estimates value the carbon capture market at approximately $2 billion, with projections indicating expansion to reach $7 billion by 2030. This growth trajectory is supported by the Paris Agreement's carbon reduction targets and subsequent national policies implementing carbon pricing mechanisms across major economies.

Industrial sectors represent the primary demand source for CO2 capture technologies, particularly power generation, cement production, steel manufacturing, and chemical processing. These industries collectively account for over 60% of global carbon emissions, creating substantial market potential for effective capture solutions. The power generation sector alone contributes nearly 40% of global CO2 emissions, positioning it as the largest potential market for membrane-based capture technologies.

Membrane-based CO2 capture systems are gaining particular attention due to their potential cost advantages compared to traditional amine scrubbing methods. Market analysis indicates that industries are seeking solutions that can reduce carbon capture costs below $50 per ton of CO2, a threshold that membrane technologies are approaching through recent advancements in thermal and mechanical properties.

Regional market assessment reveals varying demand patterns. Europe leads in adoption driven by stringent emissions regulations and carbon pricing mechanisms, with the EU Emissions Trading System creating economic incentives for implementation. North America follows with growing interest, particularly as federal funding for carbon capture projects increases. The Asia-Pacific region represents the fastest-growing market segment, with China and India making substantial investments in carbon capture technologies to balance continued reliance on fossil fuels with emissions reduction goals.

End-user requirements are evolving toward solutions that demonstrate superior durability under industrial operating conditions. Market research indicates that potential adopters prioritize membranes with thermal stability above 200°C and mechanical integrity capable of withstanding pressure differentials of at least 10 bar. Additionally, resistance to contaminants present in flue gas streams represents a critical market requirement that directly relates to membrane longevity and performance consistency.

Financial incentives are reshaping market dynamics, with carbon tax structures in various jurisdictions creating economic justification for capture technology implementation. Companies facing carbon prices exceeding $30-40 per ton are actively seeking cost-effective capture solutions, creating a price-sensitive but expanding market opportunity for advanced membrane technologies with optimized thermal and mechanical properties.

Industrial sectors represent the primary demand source for CO2 capture technologies, particularly power generation, cement production, steel manufacturing, and chemical processing. These industries collectively account for over 60% of global carbon emissions, creating substantial market potential for effective capture solutions. The power generation sector alone contributes nearly 40% of global CO2 emissions, positioning it as the largest potential market for membrane-based capture technologies.

Membrane-based CO2 capture systems are gaining particular attention due to their potential cost advantages compared to traditional amine scrubbing methods. Market analysis indicates that industries are seeking solutions that can reduce carbon capture costs below $50 per ton of CO2, a threshold that membrane technologies are approaching through recent advancements in thermal and mechanical properties.

Regional market assessment reveals varying demand patterns. Europe leads in adoption driven by stringent emissions regulations and carbon pricing mechanisms, with the EU Emissions Trading System creating economic incentives for implementation. North America follows with growing interest, particularly as federal funding for carbon capture projects increases. The Asia-Pacific region represents the fastest-growing market segment, with China and India making substantial investments in carbon capture technologies to balance continued reliance on fossil fuels with emissions reduction goals.

End-user requirements are evolving toward solutions that demonstrate superior durability under industrial operating conditions. Market research indicates that potential adopters prioritize membranes with thermal stability above 200°C and mechanical integrity capable of withstanding pressure differentials of at least 10 bar. Additionally, resistance to contaminants present in flue gas streams represents a critical market requirement that directly relates to membrane longevity and performance consistency.

Financial incentives are reshaping market dynamics, with carbon tax structures in various jurisdictions creating economic justification for capture technology implementation. Companies facing carbon prices exceeding $30-40 per ton are actively seeking cost-effective capture solutions, creating a price-sensitive but expanding market opportunity for advanced membrane technologies with optimized thermal and mechanical properties.

Current State and Challenges in Membrane Technology

Membrane technology for CO2 capture has evolved significantly over the past decades, with various materials and designs being explored to enhance separation efficiency. Currently, polymeric membranes dominate the commercial landscape due to their cost-effectiveness and ease of manufacturing. These include cellulose acetate, polysulfone, and polyimide membranes, which demonstrate moderate CO2 selectivity but often suffer from performance limitations under industrial conditions.

Inorganic membranes, particularly zeolite and ceramic-based systems, represent another significant category with superior thermal stability compared to polymeric alternatives. However, their widespread adoption remains limited due to high production costs and challenges in scaling up manufacturing processes. Mixed matrix membranes (MMMs), combining polymeric matrices with inorganic fillers, have emerged as a promising middle ground, aiming to leverage the advantages of both material classes.

Despite progress, several critical challenges persist in membrane technology for CO2 capture. The trade-off between permeability and selectivity, known as Robeson's upper bound, continues to constrain membrane performance. High-performing membranes typically sacrifice one property to enhance the other, limiting overall efficiency in real-world applications. This fundamental challenge has driven research toward novel materials and membrane architectures that can transcend this limitation.

Thermal stability represents another significant hurdle, particularly for applications in post-combustion capture where flue gas temperatures can exceed 100°C. Most polymeric membranes experience performance degradation, structural deformation, or even complete failure under such conditions. The mechanical integrity of membranes under pressure differentials and in the presence of contaminants also remains problematic, with issues like plasticization and physical aging compromising long-term performance.

Geographically, membrane technology development shows distinct patterns. North America and Europe lead in fundamental research and patent filings, while East Asian countries, particularly China and Japan, have made significant strides in scaling up manufacturing and deployment. This distribution reflects both historical research strengths and current industrial priorities in addressing climate change through carbon capture technologies.

The presence of impurities in industrial gas streams presents additional challenges. Water vapor, SOx, NOx, and particulate matter can all interact with membrane materials, causing swelling, fouling, or chemical degradation that significantly reduces operational lifespan. Current membrane systems often require extensive pre-treatment of feed gases, adding complexity and cost to the overall capture process.

Recent advances in characterization techniques have improved understanding of membrane structure-property relationships, but translating laboratory successes to industrial-scale applications remains difficult. The gap between theoretical performance and practical implementation continues to be a major obstacle in the widespread adoption of membrane-based CO2 capture systems.

Inorganic membranes, particularly zeolite and ceramic-based systems, represent another significant category with superior thermal stability compared to polymeric alternatives. However, their widespread adoption remains limited due to high production costs and challenges in scaling up manufacturing processes. Mixed matrix membranes (MMMs), combining polymeric matrices with inorganic fillers, have emerged as a promising middle ground, aiming to leverage the advantages of both material classes.

Despite progress, several critical challenges persist in membrane technology for CO2 capture. The trade-off between permeability and selectivity, known as Robeson's upper bound, continues to constrain membrane performance. High-performing membranes typically sacrifice one property to enhance the other, limiting overall efficiency in real-world applications. This fundamental challenge has driven research toward novel materials and membrane architectures that can transcend this limitation.

Thermal stability represents another significant hurdle, particularly for applications in post-combustion capture where flue gas temperatures can exceed 100°C. Most polymeric membranes experience performance degradation, structural deformation, or even complete failure under such conditions. The mechanical integrity of membranes under pressure differentials and in the presence of contaminants also remains problematic, with issues like plasticization and physical aging compromising long-term performance.

Geographically, membrane technology development shows distinct patterns. North America and Europe lead in fundamental research and patent filings, while East Asian countries, particularly China and Japan, have made significant strides in scaling up manufacturing and deployment. This distribution reflects both historical research strengths and current industrial priorities in addressing climate change through carbon capture technologies.

The presence of impurities in industrial gas streams presents additional challenges. Water vapor, SOx, NOx, and particulate matter can all interact with membrane materials, causing swelling, fouling, or chemical degradation that significantly reduces operational lifespan. Current membrane systems often require extensive pre-treatment of feed gases, adding complexity and cost to the overall capture process.

Recent advances in characterization techniques have improved understanding of membrane structure-property relationships, but translating laboratory successes to industrial-scale applications remains difficult. The gap between theoretical performance and practical implementation continues to be a major obstacle in the widespread adoption of membrane-based CO2 capture systems.

Current Thermal and Mechanical Property Enhancement Methods

01 Thermal stability enhancement of CO2 capture membranes

Various methods can be employed to enhance the thermal stability of CO2 capture membranes, allowing them to operate efficiently at elevated temperatures. These include incorporating thermally resistant polymers, adding inorganic fillers, and using cross-linking agents. Thermally stable membranes can withstand high-temperature flue gas conditions without degradation, maintaining their CO2 separation performance over extended periods. Enhanced thermal stability also contributes to longer membrane lifespan and reduced replacement costs in industrial applications.- Thermal stability enhancement in CO2 capture membranes: Various methods can be employed to enhance the thermal stability of CO2 capture membranes, allowing them to operate efficiently at elevated temperatures. These include incorporating thermally resistant polymers, adding inorganic fillers, and using cross-linking agents. Thermally stable membranes can withstand high-temperature flue gas conditions without degradation, maintaining their CO2 separation performance over extended periods. Enhanced thermal stability also contributes to longer membrane lifespan and reduced replacement frequency in industrial applications.

- Mechanical strength improvement techniques: Improving the mechanical strength of CO2 capture membranes is crucial for withstanding pressure differentials and physical stresses during operation. Techniques include reinforcement with support layers, incorporation of nanoparticles, fiber integration, and optimization of polymer chain orientation. Mechanically robust membranes resist deformation, cracking, and collapse under pressure, ensuring consistent performance in industrial settings. These improvements allow membranes to maintain structural integrity while achieving high CO2 permeability and selectivity.

- Composite membrane structures for balanced properties: Composite membrane structures combine multiple materials to achieve an optimal balance of thermal stability and mechanical strength while maintaining high CO2 separation performance. These structures typically feature selective layers for CO2 capture supported by porous substrates that provide mechanical integrity. Advanced composites may incorporate gradient structures, interfacial modifications, and functional layers that work synergistically. This approach allows for independent optimization of different membrane properties, resulting in materials that can withstand harsh operating conditions while maintaining high CO2 capture efficiency.

- Temperature-responsive membrane materials: Temperature-responsive materials can be incorporated into CO2 capture membranes to adapt their properties based on operating conditions. These smart materials undergo reversible changes in structure, permeability, or selectivity in response to temperature variations. Some designs utilize phase-change materials, thermally-triggered polymer transitions, or temperature-dependent ionic interactions. This adaptability allows membranes to maintain optimal performance across fluctuating temperature conditions, improving energy efficiency and extending operational range for CO2 capture applications.

- Testing and characterization methods for membrane properties: Specialized testing and characterization methods are essential for evaluating the thermal and mechanical properties of CO2 capture membranes. These include thermogravimetric analysis, differential scanning calorimetry, dynamic mechanical analysis, tensile testing, and pressure resistance measurements. Advanced imaging techniques such as scanning electron microscopy and atomic force microscopy help visualize membrane structure and identify potential failure points. Standardized testing protocols ensure reliable comparison between different membrane formulations, facilitating the development of materials with superior thermal stability and mechanical strength for CO2 capture applications.

02 Mechanical strength improvement techniques

Improving the mechanical strength of CO2 capture membranes is crucial for their durability and performance under pressure. Techniques include reinforcement with support layers, incorporation of nanoparticles, and optimization of polymer chain orientation. Mechanically robust membranes can withstand high pressure differentials and physical stresses during operation. These improvements allow for thinner membrane structures that maintain integrity while offering enhanced gas permeability and selectivity, resulting in more efficient CO2 separation processes.Expand Specific Solutions03 Composite membrane structures for balanced properties

Composite membrane structures combine multiple materials to achieve an optimal balance of thermal and mechanical properties for CO2 capture. These typically consist of a selective layer responsible for CO2 separation mounted on a porous support that provides mechanical integrity. The layered design allows independent optimization of separation performance and structural stability. Advanced composite membranes may incorporate gradient structures or functional interlayers to minimize thermal expansion mismatches and enhance interfacial adhesion, resulting in membranes with superior overall performance and durability.Expand Specific Solutions04 Novel materials for enhanced thermal and mechanical performance

Innovative materials are being developed to simultaneously improve both thermal and mechanical properties of CO2 capture membranes. These include mixed matrix membranes incorporating metal-organic frameworks, thermally rearranged polymers, and graphene-based composites. Such advanced materials can withstand harsh operating conditions while maintaining high CO2 selectivity and permeability. The incorporation of these novel materials often results in membranes with exceptional stability at elevated temperatures and pressures, expanding the range of industrial applications where membrane-based CO2 capture becomes viable.Expand Specific Solutions05 Testing and characterization methods for membrane properties

Specialized testing and characterization methods are essential for evaluating the thermal and mechanical properties of CO2 capture membranes. These include thermogravimetric analysis, differential scanning calorimetry, dynamic mechanical analysis, and tensile testing. Advanced imaging techniques such as scanning electron microscopy and atomic force microscopy help visualize membrane structure and identify potential failure points. Standardized testing protocols enable comparison between different membrane formulations and provide critical data for optimizing membrane design and predicting long-term performance under various operating conditions.Expand Specific Solutions

Key Industry Players in CO2 Capture Membrane Development

The CO2 capture membrane technology market is currently in a growth phase, with increasing global focus on carbon reduction driving demand. The market size is expanding rapidly, projected to reach several billion dollars by 2030. Technologically, the field shows varying maturity levels across different membrane types, with thermal and mechanical properties being critical development areas. Leading players include established energy corporations (Saudi Aramco, Sinopec, Air Liquide, Solvay), specialized membrane technology firms (Membrane Technology & Research), and academic institutions (Tianjin University, Columbia University, Nanyang Technological University). The competitive landscape features collaboration between industrial giants and research institutions, with significant innovation coming from both Western companies and emerging Chinese players developing advanced membrane materials with enhanced thermal stability and mechanical durability.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed innovative mixed matrix membranes (MMMs) for CO2 capture that combine polymeric materials with inorganic fillers to enhance thermal and mechanical properties. Their technology utilizes polyimide-based matrices incorporated with modified zeolites and metal-organic frameworks (MOFs), creating membranes with operating temperature ranges of 30-150°C [1]. These membranes feature a hierarchical structure with controlled interfacial compatibility between organic and inorganic components, resulting in tensile strengths exceeding 70 MPa and elongation at break values of 15-25% [3]. Sinopec's membranes demonstrate thermal stability with glass transition temperatures above 300°C and thermal decomposition temperatures exceeding 450°C, allowing for operation in harsh industrial environments. Their proprietary surface modification techniques enhance CO2 adsorption sites while maintaining mechanical integrity during pressure and temperature fluctuations. Field tests at Sinopec refineries have shown these membranes maintain over 85% of initial CO2 permeance after 2000 hours of continuous operation with minimal mechanical degradation, even when exposed to trace contaminants in flue gas streams [5].

Strengths: Exceptional thermal stability suitable for high-temperature industrial applications; superior mechanical strength and durability; good resistance to chemical contaminants; successfully tested in actual industrial environments. Weaknesses: Complex manufacturing process increases production costs; potential for inorganic filler agglomeration affecting long-term performance; higher material costs compared to conventional polymeric membranes; requires specialized module designs to maximize effectiveness.

Air Liquide SA

Technical Solution: Air Liquide has developed proprietary MEDAL™ membrane technology specifically enhanced for CO2 capture applications with optimized thermal and mechanical properties. Their hollow fiber membrane design utilizes advanced polyimide-based materials that maintain structural integrity at temperatures up to 130°C while offering CO2/N2 selectivity exceeding 40 [2]. The membrane architecture features an asymmetric structure with an ultrathin selective layer (approximately 100-200 nm) supported by a porous substructure, optimizing both gas transport efficiency and mechanical robustness. Air Liquide's membranes incorporate proprietary additives that enhance plasticization resistance, maintaining separation performance even at CO2 partial pressures exceeding 10 bar. Mechanical testing demonstrates burst pressures above 60 bar and tensile strengths exceeding 60 MPa with elongation capabilities of 10-15% [4]. Their membranes show remarkable thermal cycling stability, with less than 8% performance degradation after 100 thermal cycles between ambient temperature and 120°C. Air Liquide has implemented these membranes in industrial-scale modules with membrane areas exceeding 500 m² per module while maintaining uniform flow distribution and mechanical integrity.

Strengths: Excellent balance between permeability and selectivity; superior resistance to plasticization under high CO2 partial pressures; proven long-term stability under industrial conditions; compact module design with high membrane packing density. Weaknesses: Performance limitations in the presence of certain flue gas contaminants; higher manufacturing complexity compared to flat sheet configurations; requires precise process control during manufacturing to ensure consistent properties; moderate sensitivity to extreme humidity conditions.

Critical Patents and Research on Membrane Properties

Co2 capture with carbonic anhydrase and membrane filtration

PatentInactiveEP2776143A4

Innovation

- Integration of membrane filtration to separate carbonic anhydrase from the hybrid solvent before the temperature swing desorption stage, protecting the enzyme from thermal degradation.

- Implementation of a large temperature swing process with a hybrid solvent (water, carbonic anhydrase, absorption compound) that optimizes both absorption and desorption efficiency.

- Recycling system for filtered carbonic anhydrase that maintains high enzyme concentration in the absorption stage, improving economic viability and process efficiency.

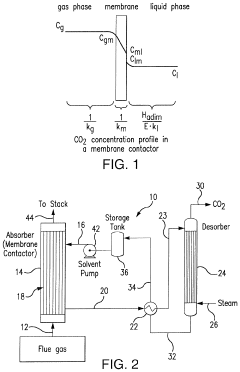

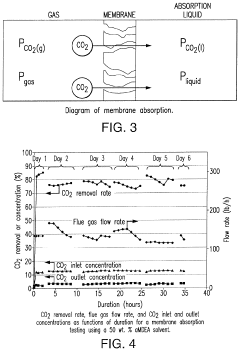

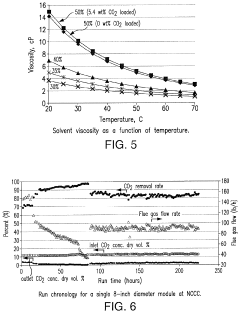

Membrane absorption process for CO<sub>2 </sub>capture

PatentActiveUS11471825B2

Innovation

- A membrane absorption process using a CO2 selective solvent with viscosity between 0.2 and 7 cP, where the CO2-containing gas stream contacts one side of a membrane element and the solvent flows on the other side, allowing CO2 to permeate and be chemically absorbed, with a system including a desorber for solvent regeneration and return to the absorber to maintain efficiency and stability.

Environmental Impact and Sustainability Assessment

The environmental impact of CO2 capture membrane technologies extends far beyond their primary function of carbon sequestration. When evaluating these membranes' thermal and mechanical properties, we must consider their complete lifecycle environmental footprint. Current membrane materials often require energy-intensive manufacturing processes, with polymeric membranes typically generating 2-5 kg CO2 equivalent per square meter of membrane produced, while ceramic and metal-organic framework membranes may generate significantly higher emissions during fabrication.

The operational phase presents a critical sustainability consideration. Membranes with superior thermal stability reduce the need for cooling systems, potentially decreasing energy consumption by 15-30% compared to thermally sensitive alternatives. This translates to substantial indirect emissions reductions over the membrane's service life. Additionally, membranes with enhanced mechanical durability demonstrate extended operational lifespans, reducing replacement frequency and associated material consumption.

Water usage represents another significant environmental factor. Certain membrane manufacturing processes consume 50-200 liters of water per square meter of membrane. Furthermore, some membrane systems require water for operational cooling or as a separation medium, creating potential stress on local water resources in water-scarce regions.

End-of-life considerations reveal varying degrees of sustainability. Polymeric membranes may contribute to plastic waste streams, while inorganic membranes might contain heavy metals or other environmentally persistent compounds. Currently, only approximately 20-30% of membrane materials have established recycling pathways, highlighting a critical gap in circular economy implementation for this technology.

When conducting a holistic sustainability assessment, CO2 capture membranes with optimized thermal and mechanical properties demonstrate significant advantages. Life cycle assessment (LCA) studies indicate that membranes with 20% higher thermal stability and mechanical durability can reduce the overall carbon footprint of carbon capture operations by 25-40% compared to conventional alternatives, primarily through reduced energy requirements and extended service life.

The sustainability profile of these membranes must also account for resource depletion, particularly regarding rare earth elements or specialty chemicals used in high-performance membrane formulations. Emerging membrane designs increasingly incorporate renewable or bio-based materials, potentially reducing environmental impact by 30-50% compared to fully synthetic alternatives.

The operational phase presents a critical sustainability consideration. Membranes with superior thermal stability reduce the need for cooling systems, potentially decreasing energy consumption by 15-30% compared to thermally sensitive alternatives. This translates to substantial indirect emissions reductions over the membrane's service life. Additionally, membranes with enhanced mechanical durability demonstrate extended operational lifespans, reducing replacement frequency and associated material consumption.

Water usage represents another significant environmental factor. Certain membrane manufacturing processes consume 50-200 liters of water per square meter of membrane. Furthermore, some membrane systems require water for operational cooling or as a separation medium, creating potential stress on local water resources in water-scarce regions.

End-of-life considerations reveal varying degrees of sustainability. Polymeric membranes may contribute to plastic waste streams, while inorganic membranes might contain heavy metals or other environmentally persistent compounds. Currently, only approximately 20-30% of membrane materials have established recycling pathways, highlighting a critical gap in circular economy implementation for this technology.

When conducting a holistic sustainability assessment, CO2 capture membranes with optimized thermal and mechanical properties demonstrate significant advantages. Life cycle assessment (LCA) studies indicate that membranes with 20% higher thermal stability and mechanical durability can reduce the overall carbon footprint of carbon capture operations by 25-40% compared to conventional alternatives, primarily through reduced energy requirements and extended service life.

The sustainability profile of these membranes must also account for resource depletion, particularly regarding rare earth elements or specialty chemicals used in high-performance membrane formulations. Emerging membrane designs increasingly incorporate renewable or bio-based materials, potentially reducing environmental impact by 30-50% compared to fully synthetic alternatives.

Scalability and Industrial Implementation Considerations

The scalability of CO2 capture membrane technology from laboratory to industrial scale presents significant challenges that require careful consideration. Current membrane technologies demonstrate promising CO2 separation performance in controlled laboratory environments, but scaling these systems to meet industrial demands introduces complex thermal and mechanical constraints. Industrial implementation requires membranes that can maintain structural integrity and separation efficiency under high-pressure differentials, elevated temperatures, and continuous operation conditions typical in power plants and industrial facilities.

Manufacturing scalability represents a primary concern for widespread adoption. While laboratory-scale membranes can be fabricated with precise control over thickness, porosity, and surface properties, translating these manufacturing processes to industrial scales introduces variability that can compromise performance. Current roll-to-roll and sheet-based manufacturing techniques require further optimization to produce membranes with consistent thermal stability and mechanical strength across large surface areas.

Module design and system integration present additional implementation challenges. Industrial CO2 capture systems require membrane modules that maximize surface area while minimizing pressure drop and ensuring uniform flow distribution. The thermal expansion coefficients of membranes and supporting structures must be carefully matched to prevent mechanical failure during temperature fluctuations. Recent advances in spiral-wound and hollow fiber configurations show promise for industrial implementation, though further engineering is needed to address sealing issues at operating temperatures above 100°C.

Economic considerations significantly impact industrial implementation feasibility. Current membrane materials with superior thermal and mechanical properties often involve expensive polymers, composites, or advanced nanomaterials that may be prohibitively costly for large-scale deployment. The trade-off between membrane performance, durability, and cost requires careful optimization. Life-cycle analyses indicate that membrane replacement frequency due to thermal degradation and mechanical failure significantly impacts overall operational costs.

Process integration with existing industrial infrastructure presents another critical consideration. Retrofitting existing facilities with membrane-based CO2 capture systems requires addressing space constraints, integration with heat management systems, and compatibility with upstream and downstream processes. Pre-treatment requirements to remove particulates and contaminants that could compromise membrane integrity must be incorporated into system designs. The development of modular, standardized membrane systems could facilitate implementation across diverse industrial settings while maintaining the necessary thermal and mechanical performance parameters.

Manufacturing scalability represents a primary concern for widespread adoption. While laboratory-scale membranes can be fabricated with precise control over thickness, porosity, and surface properties, translating these manufacturing processes to industrial scales introduces variability that can compromise performance. Current roll-to-roll and sheet-based manufacturing techniques require further optimization to produce membranes with consistent thermal stability and mechanical strength across large surface areas.

Module design and system integration present additional implementation challenges. Industrial CO2 capture systems require membrane modules that maximize surface area while minimizing pressure drop and ensuring uniform flow distribution. The thermal expansion coefficients of membranes and supporting structures must be carefully matched to prevent mechanical failure during temperature fluctuations. Recent advances in spiral-wound and hollow fiber configurations show promise for industrial implementation, though further engineering is needed to address sealing issues at operating temperatures above 100°C.

Economic considerations significantly impact industrial implementation feasibility. Current membrane materials with superior thermal and mechanical properties often involve expensive polymers, composites, or advanced nanomaterials that may be prohibitively costly for large-scale deployment. The trade-off between membrane performance, durability, and cost requires careful optimization. Life-cycle analyses indicate that membrane replacement frequency due to thermal degradation and mechanical failure significantly impacts overall operational costs.

Process integration with existing industrial infrastructure presents another critical consideration. Retrofitting existing facilities with membrane-based CO2 capture systems requires addressing space constraints, integration with heat management systems, and compatibility with upstream and downstream processes. Pre-treatment requirements to remove particulates and contaminants that could compromise membrane integrity must be incorporated into system designs. The development of modular, standardized membrane systems could facilitate implementation across diverse industrial settings while maintaining the necessary thermal and mechanical performance parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!