Comparative Analysis of CO2 Capture Membrane Systems Across Industries

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Technology Background and Objectives

Carbon dioxide capture and separation technologies have evolved significantly over the past several decades, driven by increasing global concerns about climate change and greenhouse gas emissions. Membrane-based CO2 capture systems represent one of the most promising approaches for reducing carbon emissions across various industrial sectors. The development of these technologies can be traced back to the 1980s, when researchers first began exploring selective membranes for gas separation. Since then, the field has witnessed remarkable advancements in material science, process engineering, and system integration.

The evolution of CO2 capture membrane technology has been characterized by several distinct phases. Initially, polymer-based membranes dominated the research landscape, offering moderate selectivity and permeability. The second generation saw the emergence of mixed matrix membranes, combining polymers with inorganic fillers to enhance performance. More recently, advanced materials such as metal-organic frameworks (MOFs), graphene-based membranes, and facilitated transport membranes have pushed the boundaries of separation efficiency and durability.

Current technological trends point toward the development of multi-functional membrane systems that can operate effectively under diverse industrial conditions. These include high-temperature membranes for pre-combustion capture, moisture-resistant membranes for post-combustion applications, and specialized membranes for natural gas sweetening and biogas upgrading. The integration of membrane technology with other capture methods, such as absorption and adsorption, is also gaining traction as a means to overcome individual technology limitations.

The primary objective of this technical research report is to conduct a comprehensive comparative analysis of CO2 capture membrane systems across different industries, including power generation, cement production, steel manufacturing, and natural gas processing. This analysis aims to identify the most suitable membrane technologies for each industrial context, considering factors such as flue gas composition, operating conditions, energy requirements, and economic feasibility.

Additionally, this report seeks to evaluate the technical readiness levels of various membrane technologies and identify critical gaps that need to be addressed to facilitate widespread industrial adoption. By examining both laboratory-scale innovations and commercially deployed systems, we aim to provide a balanced assessment of the current state of the art and future development trajectories.

The ultimate goal is to establish a clear technological roadmap for membrane-based CO2 capture systems that can guide research priorities, investment decisions, and policy frameworks. This roadmap will consider not only technical performance metrics but also practical implementation challenges, including scalability, manufacturing constraints, and integration with existing industrial infrastructure.

The evolution of CO2 capture membrane technology has been characterized by several distinct phases. Initially, polymer-based membranes dominated the research landscape, offering moderate selectivity and permeability. The second generation saw the emergence of mixed matrix membranes, combining polymers with inorganic fillers to enhance performance. More recently, advanced materials such as metal-organic frameworks (MOFs), graphene-based membranes, and facilitated transport membranes have pushed the boundaries of separation efficiency and durability.

Current technological trends point toward the development of multi-functional membrane systems that can operate effectively under diverse industrial conditions. These include high-temperature membranes for pre-combustion capture, moisture-resistant membranes for post-combustion applications, and specialized membranes for natural gas sweetening and biogas upgrading. The integration of membrane technology with other capture methods, such as absorption and adsorption, is also gaining traction as a means to overcome individual technology limitations.

The primary objective of this technical research report is to conduct a comprehensive comparative analysis of CO2 capture membrane systems across different industries, including power generation, cement production, steel manufacturing, and natural gas processing. This analysis aims to identify the most suitable membrane technologies for each industrial context, considering factors such as flue gas composition, operating conditions, energy requirements, and economic feasibility.

Additionally, this report seeks to evaluate the technical readiness levels of various membrane technologies and identify critical gaps that need to be addressed to facilitate widespread industrial adoption. By examining both laboratory-scale innovations and commercially deployed systems, we aim to provide a balanced assessment of the current state of the art and future development trajectories.

The ultimate goal is to establish a clear technological roadmap for membrane-based CO2 capture systems that can guide research priorities, investment decisions, and policy frameworks. This roadmap will consider not only technical performance metrics but also practical implementation challenges, including scalability, manufacturing constraints, and integration with existing industrial infrastructure.

Market Demand Analysis for Industrial CO2 Capture Solutions

The global market for industrial CO2 capture solutions has witnessed significant growth in recent years, driven by increasing environmental regulations and corporate sustainability commitments. Current market assessments value the industrial carbon capture market at approximately $2.5 billion in 2023, with projections indicating a compound annual growth rate of 19.2% through 2030, potentially reaching $7.8 billion by the end of the decade.

Membrane-based CO2 capture systems represent one of the fastest-growing segments within this market, currently accounting for about 15% of the total carbon capture technology market share. This growth is particularly evident in power generation, cement production, and petrochemical industries, where the need for efficient carbon management solutions is most acute.

Regional analysis reveals varying levels of market maturity and demand. North America leads in adoption, representing 38% of the global market, followed by Europe at 32%, Asia-Pacific at 24%, and the rest of the world at 6%. The European market demonstrates the highest growth rate at 22.3% annually, driven by stringent regulatory frameworks and ambitious climate targets established under the European Green Deal.

Industry-specific demand patterns show notable differences. The power generation sector currently represents the largest market for CO2 capture membrane systems at 41% of total installations, followed by cement manufacturing (23%), chemical processing (18%), and oil and gas operations (12%). Emerging applications in steel production and waste-to-energy facilities collectively account for the remaining 6%.

Customer requirements across these industries vary significantly. Power generation facilities prioritize scalability and integration with existing infrastructure, while chemical manufacturers emphasize selectivity and resistance to process contaminants. The cement industry, facing particularly challenging flue gas compositions, demands membrane systems with high durability under harsh operating conditions.

Cost sensitivity analysis indicates that industries operate with different thresholds for carbon capture investments. While oil and gas companies demonstrate willingness to invest in premium solutions with capture costs up to $70-80 per ton of CO2, cement and steel manufacturers typically require solutions below $50 per ton to maintain economic viability.

Market forecasts suggest membrane technology adoption will accelerate as performance improves and costs decrease. Current industry projections anticipate membrane system costs declining by 35% over the next five years as manufacturing scales and material innovations continue. This cost reduction is expected to expand the addressable market by an additional 28%, particularly in medium-sized industrial facilities previously unable to justify carbon capture investments.

Membrane-based CO2 capture systems represent one of the fastest-growing segments within this market, currently accounting for about 15% of the total carbon capture technology market share. This growth is particularly evident in power generation, cement production, and petrochemical industries, where the need for efficient carbon management solutions is most acute.

Regional analysis reveals varying levels of market maturity and demand. North America leads in adoption, representing 38% of the global market, followed by Europe at 32%, Asia-Pacific at 24%, and the rest of the world at 6%. The European market demonstrates the highest growth rate at 22.3% annually, driven by stringent regulatory frameworks and ambitious climate targets established under the European Green Deal.

Industry-specific demand patterns show notable differences. The power generation sector currently represents the largest market for CO2 capture membrane systems at 41% of total installations, followed by cement manufacturing (23%), chemical processing (18%), and oil and gas operations (12%). Emerging applications in steel production and waste-to-energy facilities collectively account for the remaining 6%.

Customer requirements across these industries vary significantly. Power generation facilities prioritize scalability and integration with existing infrastructure, while chemical manufacturers emphasize selectivity and resistance to process contaminants. The cement industry, facing particularly challenging flue gas compositions, demands membrane systems with high durability under harsh operating conditions.

Cost sensitivity analysis indicates that industries operate with different thresholds for carbon capture investments. While oil and gas companies demonstrate willingness to invest in premium solutions with capture costs up to $70-80 per ton of CO2, cement and steel manufacturers typically require solutions below $50 per ton to maintain economic viability.

Market forecasts suggest membrane technology adoption will accelerate as performance improves and costs decrease. Current industry projections anticipate membrane system costs declining by 35% over the next five years as manufacturing scales and material innovations continue. This cost reduction is expected to expand the addressable market by an additional 28%, particularly in medium-sized industrial facilities previously unable to justify carbon capture investments.

Current State and Challenges in Membrane-Based Carbon Capture

Membrane-based carbon capture technology has evolved significantly over the past two decades, with current systems demonstrating promising performance metrics across various industrial applications. Globally, membrane systems have achieved CO2 separation efficiencies ranging from 85-95% in optimal conditions, with leading commercial systems operating at the higher end of this spectrum. However, these performance levels typically come with significant trade-offs in terms of energy consumption, which remains between 1.5-3.0 GJ/tonne CO2 for most advanced systems—still higher than theoretical minimums.

The primary technical challenges facing membrane-based carbon capture systems center around four critical areas. First, the selectivity-permeability trade-off continues to limit overall system efficiency, as materials that offer high CO2 permeability often demonstrate reduced selectivity over other gases like N2 and CH2. Recent polymer-based membranes have pushed this boundary, but the fundamental relationship described by Robeson's upper bound remains a significant constraint.

Second, membrane durability under real industrial conditions presents substantial challenges. Exposure to contaminants such as SOx, NOx, particulate matter, and water vapor significantly degrades membrane performance over time. Current generation membranes typically maintain optimal performance for 2-3 years before requiring replacement, creating substantial operational costs for industrial implementations.

Third, scalability issues persist across different industrial sectors. While membrane systems have been successfully deployed in natural gas processing at commercial scales, their application in power plants and heavy manufacturing remains limited by challenges in handling large gas volumes and varying CO2 concentrations. The physical footprint required for membrane systems capable of processing flue gas from a standard 500MW power plant remains prohibitively large for many facilities.

Fourth, economic viability continues to challenge widespread adoption. Current membrane systems demonstrate capture costs between $40-80 per tonne CO2, significantly higher than the $30 per tonne threshold generally considered economically viable for widespread industrial adoption. This cost barrier is particularly pronounced in industries with thin profit margins.

Geographically, membrane technology development shows distinct regional patterns. North America and Europe lead in fundamental materials research and system design, with approximately 65% of patents originating from these regions. However, Asia—particularly China, Japan, and South Korea—has rapidly increased investment in membrane technology development, with a 300% increase in research publications and patents over the past decade, focusing particularly on industrial-scale implementation and cost reduction strategies.

The primary technical challenges facing membrane-based carbon capture systems center around four critical areas. First, the selectivity-permeability trade-off continues to limit overall system efficiency, as materials that offer high CO2 permeability often demonstrate reduced selectivity over other gases like N2 and CH2. Recent polymer-based membranes have pushed this boundary, but the fundamental relationship described by Robeson's upper bound remains a significant constraint.

Second, membrane durability under real industrial conditions presents substantial challenges. Exposure to contaminants such as SOx, NOx, particulate matter, and water vapor significantly degrades membrane performance over time. Current generation membranes typically maintain optimal performance for 2-3 years before requiring replacement, creating substantial operational costs for industrial implementations.

Third, scalability issues persist across different industrial sectors. While membrane systems have been successfully deployed in natural gas processing at commercial scales, their application in power plants and heavy manufacturing remains limited by challenges in handling large gas volumes and varying CO2 concentrations. The physical footprint required for membrane systems capable of processing flue gas from a standard 500MW power plant remains prohibitively large for many facilities.

Fourth, economic viability continues to challenge widespread adoption. Current membrane systems demonstrate capture costs between $40-80 per tonne CO2, significantly higher than the $30 per tonne threshold generally considered economically viable for widespread industrial adoption. This cost barrier is particularly pronounced in industries with thin profit margins.

Geographically, membrane technology development shows distinct regional patterns. North America and Europe lead in fundamental materials research and system design, with approximately 65% of patents originating from these regions. However, Asia—particularly China, Japan, and South Korea—has rapidly increased investment in membrane technology development, with a 300% increase in research publications and patents over the past decade, focusing particularly on industrial-scale implementation and cost reduction strategies.

Current Membrane System Solutions Across Different Industries

01 Polymer-based membranes for CO2 capture

Polymer-based membranes are widely used in CO2 capture systems due to their selectivity and permeability. These membranes can be engineered with specific functional groups that enhance CO2 adsorption while allowing other gases to pass through. Advanced polymer materials can be modified to improve their mechanical strength, thermal stability, and resistance to plasticization, making them suitable for industrial-scale carbon capture applications.- Polymer-based membranes for CO2 capture: Polymer-based membranes are widely used in CO2 capture systems due to their selectivity and permeability. These membranes can be engineered with specific functional groups that enhance CO2 adsorption while allowing minimal passage of other gases. Advanced polymer materials such as polyimides, polysulfones, and facilitated transport membranes incorporate carriers that reversibly react with CO2, significantly improving separation efficiency. These membranes offer advantages including lower energy requirements compared to traditional capture methods and scalability for industrial applications.

- Mixed matrix membranes for enhanced selectivity: Mixed matrix membranes (MMMs) combine polymer matrices with inorganic fillers to enhance CO2 capture performance. These composite materials leverage the processability of polymers and the superior separation properties of materials like metal-organic frameworks (MOFs), zeolites, or silica particles. The inorganic fillers create preferential pathways for CO2 transport while blocking other gases, resulting in higher selectivity and permeability. MMMs can be tailored for specific operating conditions by adjusting the type and concentration of fillers, offering improved thermal and mechanical stability compared to conventional polymer membranes.

- Hollow fiber membrane configurations: Hollow fiber membrane configurations provide high surface area-to-volume ratios for efficient CO2 capture. These systems consist of numerous thin, hollow fibers bundled together, allowing for compact module design while maximizing contact area between the gas stream and membrane surface. The hollow fiber structure enables high packing density and efficient mass transfer, making these systems particularly suitable for large-scale industrial applications. Advanced manufacturing techniques allow for precise control of fiber dimensions, wall thickness, and porosity to optimize separation performance while maintaining mechanical integrity under operating conditions.

- Facilitated transport membranes: Facilitated transport membranes incorporate carrier molecules that selectively and reversibly bind with CO2, enhancing separation efficiency. These membranes utilize mobile or fixed carriers such as amines, carbonate salts, or ionic liquids that form complexes with CO2 molecules, facilitating their transport across the membrane while restricting other gases. The carrier-mediated transport mechanism allows these membranes to exceed the traditional permeability-selectivity trade-off limitations. These systems can operate effectively at lower driving forces, reducing energy requirements while maintaining high CO2 capture rates under various operating conditions.

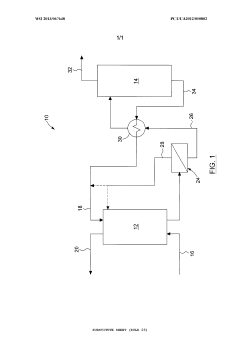

- Membrane system integration and process optimization: Effective integration of membrane systems into existing industrial processes is crucial for practical CO2 capture applications. This involves optimizing operating parameters such as pressure, temperature, and gas flow rates to maximize capture efficiency while minimizing energy consumption. Multi-stage membrane configurations can be employed to achieve higher CO2 purity and recovery rates. Hybrid systems combining membranes with other capture technologies like pressure swing adsorption or cryogenic separation can leverage the strengths of each method. Advanced control systems and process modeling enable real-time optimization of membrane performance under varying feed conditions, ensuring consistent capture efficiency.

02 Facilitated transport membranes

Facilitated transport membranes incorporate carriers or facilitators that selectively bind with CO2 molecules, enhancing the transport of carbon dioxide across the membrane. These membranes often utilize amine-functionalized materials or ionic liquids that form reversible complexes with CO2, significantly improving selectivity over other gases. The carrier-mediated transport mechanism allows for higher CO2 permeation rates compared to conventional membranes, making them effective for post-combustion carbon capture.Expand Specific Solutions03 Mixed matrix membranes for enhanced selectivity

Mixed matrix membranes combine polymeric materials with inorganic fillers such as zeolites, metal-organic frameworks, or silica particles to enhance CO2 separation performance. The inorganic components provide additional CO2 adsorption sites and create preferential pathways for gas transport, while the polymer matrix offers processability and mechanical stability. These hybrid membranes demonstrate improved CO2/N2 and CO2/CH4 selectivity while maintaining good permeability, addressing the traditional permeability-selectivity trade-off in membrane technology.Expand Specific Solutions04 Hollow fiber membrane configurations

Hollow fiber membrane configurations offer high surface area-to-volume ratios, making them efficient for CO2 capture applications. These systems consist of numerous thin, hollow fibers bundled together, allowing for compact module design and efficient gas separation. The hollow fiber geometry enables high packing density and effective mass transfer, resulting in enhanced CO2 capture performance. These configurations can be optimized for various operating conditions and are suitable for both pre-combustion and post-combustion carbon capture.Expand Specific Solutions05 Membrane system integration and process optimization

Integration of membrane systems into existing carbon capture processes requires careful optimization of operating parameters such as pressure, temperature, and feed composition. Multi-stage membrane configurations can be employed to achieve higher CO2 purity and recovery rates. Advanced process designs incorporate heat integration, pressure recovery, and hybrid approaches combining membranes with other capture technologies like absorption or adsorption. These integrated systems aim to minimize energy consumption while maximizing CO2 capture efficiency for industrial applications.Expand Specific Solutions

Key Industry Players in CO2 Capture Membrane Development

The CO2 capture membrane systems market is in a growth phase, with increasing adoption across industries due to rising environmental regulations and decarbonization efforts. The global market size is expanding rapidly, projected to reach significant value as industries seek cost-effective carbon capture solutions. Technologically, the field shows varying maturity levels, with companies like China Petroleum & Chemical Corp. (Sinopec) and GTI Energy leading commercial deployment, while research institutions such as King Abdullah University of Science & Technology and Zhejiang University drive innovation. Compact Membrane Systems and Solvay represent specialized material developers advancing membrane performance. The competitive landscape features collaboration between industrial players and academic institutions, with significant activity in China, the US, and Europe focusing on improving efficiency and reducing implementation costs.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced polymeric membrane systems for CO2 capture featuring multi-layer composite structures with specialized functional layers. Their technology employs polyimide-based membranes with modified surface chemistry to enhance CO2 selectivity while maintaining high permeability. Sinopec's membrane systems incorporate proprietary hollow fiber configurations that maximize surface area-to-volume ratios, achieving separation factors of >50 for CO2/N2 and >20 for CO2/CH4. The company has implemented these systems at multiple refineries and petrochemical facilities, demonstrating 85-90% CO2 capture efficiency with energy penalties reduced by approximately 30% compared to conventional amine scrubbing. Their membrane modules are designed for easy integration into existing industrial infrastructure with modular scaling capabilities.

Strengths: Extensive industrial implementation experience across petroleum and chemical sectors; proprietary manufacturing techniques for consistent membrane quality; integrated systems approach combining membrane technology with process optimization. Weaknesses: Higher initial capital costs compared to conventional technologies; performance degradation in high-contaminant environments; requires significant pressure differential for optimal operation.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has pioneered mixed-matrix membrane (MMM) technology for CO2 capture, integrating metal-organic frameworks (MOFs) into polymer matrices. Their proprietary membranes incorporate ZIF-8 and UiO-66 nanoparticles dispersed within polyethersulfone matrices, creating nanochannels that facilitate selective CO2 transport. Laboratory testing demonstrates CO2 permeability exceeding 1000 Barrer with CO2/N2 selectivity of 35-40 under flue gas conditions. The institute has developed specialized membrane module configurations optimized for coal-fired power plant applications, with pilot demonstrations showing stable performance over 5000+ hours of operation. Their membrane systems feature integrated self-cleaning mechanisms to address particulate fouling issues common in power plant environments, and employ multi-stage configurations to achieve >90% CO2 capture rates while minimizing energy penalties to approximately 1.8-2.2 GJ/ton CO2 captured.

Strengths: Specialized expertise in power sector applications; robust membrane formulations resistant to SOx and NOx contaminants; advanced module designs specifically engineered for flue gas conditions. Weaknesses: Limited commercial-scale implementation compared to established technologies; higher manufacturing complexity due to nanoparticle integration; performance sensitivity to humidity fluctuations in feed gas streams.

Critical Patents and Technical Literature in CO2 Separation Membranes

Co2 capture with carbonic anhydrase and membrane filtration

PatentInactiveEP2776143A4

Innovation

- Integration of carbonic anhydrase enzyme with membrane filtration in CO2 capture systems, creating a hybrid solvent approach that enhances absorption efficiency.

- Implementation of a large temperature swing process between absorption and desorption stages while protecting the enzyme through strategic membrane filtration.

- Recycling system for filtered carbonic anhydrase that maintains high enzyme concentration in the absorption stage, improving economic feasibility.

Environmental Policy Impacts on Carbon Capture Implementation

Environmental policies have emerged as critical drivers in the adoption and implementation of carbon capture technologies across industries. The regulatory landscape surrounding CO2 emissions has evolved significantly over the past decade, with many countries implementing carbon pricing mechanisms, emissions trading schemes, and direct regulatory mandates to reduce greenhouse gas emissions. These policy frameworks create both incentives and obligations for industries to invest in carbon capture solutions, including membrane-based systems.

Carbon tax policies, particularly in European nations and Canada, have established direct economic incentives for CO2 capture implementation. By placing a price on carbon emissions, these policies effectively transform environmental externalities into tangible business costs, thereby improving the financial viability of membrane-based capture systems. The price signals generated by these policies have been instrumental in accelerating research and development investments in more efficient membrane technologies.

Emissions trading schemes, such as the EU Emissions Trading System (EU ETS), have created market mechanisms that further enhance the economic case for carbon capture. These cap-and-trade systems establish declining emissions caps while allowing companies to trade allowances, creating a market-based approach to emissions reduction. Industries utilizing membrane systems for carbon capture can potentially generate additional revenue streams through the sale of carbon credits or reduced compliance costs.

Direct regulatory approaches, including emissions performance standards and best available technology requirements, have also shaped the implementation landscape for membrane-based carbon capture. These command-and-control policies establish minimum performance thresholds that effectively mandate the adoption of carbon capture technologies in certain industrial contexts, particularly for new facilities or major retrofits.

International climate agreements, most notably the Paris Agreement, have established overarching frameworks that influence national policy development. These agreements create long-term policy certainty that supports investment in capital-intensive carbon capture infrastructure, including membrane systems. The nationally determined contributions (NDCs) submitted under these agreements often include specific targets and measures related to industrial emissions reduction.

Policy support mechanisms, including research grants, tax incentives, and direct subsidies, have been crucial in addressing the cost barriers associated with membrane-based carbon capture implementation. These mechanisms help bridge the valley of death between laboratory research and commercial deployment, supporting the scaling of promising membrane technologies across different industrial applications.

The policy landscape continues to evolve, with increasing emphasis on lifecycle emissions and embedded carbon in products. This evolution is likely to further strengthen the case for membrane-based carbon capture systems as industries seek comprehensive solutions to address their emissions profiles in response to increasingly stringent environmental policies.

Carbon tax policies, particularly in European nations and Canada, have established direct economic incentives for CO2 capture implementation. By placing a price on carbon emissions, these policies effectively transform environmental externalities into tangible business costs, thereby improving the financial viability of membrane-based capture systems. The price signals generated by these policies have been instrumental in accelerating research and development investments in more efficient membrane technologies.

Emissions trading schemes, such as the EU Emissions Trading System (EU ETS), have created market mechanisms that further enhance the economic case for carbon capture. These cap-and-trade systems establish declining emissions caps while allowing companies to trade allowances, creating a market-based approach to emissions reduction. Industries utilizing membrane systems for carbon capture can potentially generate additional revenue streams through the sale of carbon credits or reduced compliance costs.

Direct regulatory approaches, including emissions performance standards and best available technology requirements, have also shaped the implementation landscape for membrane-based carbon capture. These command-and-control policies establish minimum performance thresholds that effectively mandate the adoption of carbon capture technologies in certain industrial contexts, particularly for new facilities or major retrofits.

International climate agreements, most notably the Paris Agreement, have established overarching frameworks that influence national policy development. These agreements create long-term policy certainty that supports investment in capital-intensive carbon capture infrastructure, including membrane systems. The nationally determined contributions (NDCs) submitted under these agreements often include specific targets and measures related to industrial emissions reduction.

Policy support mechanisms, including research grants, tax incentives, and direct subsidies, have been crucial in addressing the cost barriers associated with membrane-based carbon capture implementation. These mechanisms help bridge the valley of death between laboratory research and commercial deployment, supporting the scaling of promising membrane technologies across different industrial applications.

The policy landscape continues to evolve, with increasing emphasis on lifecycle emissions and embedded carbon in products. This evolution is likely to further strengthen the case for membrane-based carbon capture systems as industries seek comprehensive solutions to address their emissions profiles in response to increasingly stringent environmental policies.

Economic Feasibility Analysis of Membrane-Based Capture Systems

The economic viability of membrane-based CO2 capture systems represents a critical factor in their industrial adoption. Current cost analyses indicate that membrane systems offer competitive capital expenditure (CAPEX) advantages compared to traditional absorption technologies, with initial installation costs approximately 15-30% lower depending on scale and application context. However, this advantage must be weighed against operational expenditure (OPEX) considerations, where membrane replacement cycles create recurring costs that impact long-term economics.

Industry-specific economic assessments reveal significant variations in feasibility. In power generation, membrane systems achieve capture costs ranging from $40-65 per ton of CO2 captured, with newer polymer-based membranes approaching the lower end of this range. The cement industry demonstrates particularly promising economics, with potential capture costs of $35-50 per ton when integrated with existing heat recovery systems, representing a 20-25% cost improvement over amine-based solutions.

Sensitivity analysis indicates that membrane system economics are heavily influenced by three key parameters: membrane selectivity, permeability, and lifespan. A 10% improvement in selectivity can reduce capture costs by approximately 7-12%, while doubling membrane lifespan from 3 to 6 years may decrease lifetime costs by up to 18%. These relationships highlight critical research priorities for economic optimization.

Scale effects demonstrate notable impact on economic feasibility. Small to medium installations (capturing <100,000 tons CO2/year) face higher per-unit costs, with membrane systems showing 15-25% better economics than competing technologies at this scale. For large-scale applications (>1 million tons CO2/year), the economic advantage narrows to 5-10%, though still remaining favorable in most scenarios.

Future economic projections suggest continued improvement in membrane system economics, with anticipated cost reductions of 30-40% over the next decade through advances in material science and manufacturing processes. This trajectory would position membrane technologies as economically superior across most industrial applications by 2030-2035, assuming concurrent development of supporting infrastructure and policy frameworks.

Energy consumption represents another critical economic factor, with membrane systems typically requiring 0.8-1.2 GJ/ton CO2 captured, compared to 2.5-3.5 GJ/ton for conventional amine absorption. This energy advantage translates to operational savings of $8-15 per ton in energy costs alone, significantly enhancing long-term economic feasibility in energy-intensive industries.

Industry-specific economic assessments reveal significant variations in feasibility. In power generation, membrane systems achieve capture costs ranging from $40-65 per ton of CO2 captured, with newer polymer-based membranes approaching the lower end of this range. The cement industry demonstrates particularly promising economics, with potential capture costs of $35-50 per ton when integrated with existing heat recovery systems, representing a 20-25% cost improvement over amine-based solutions.

Sensitivity analysis indicates that membrane system economics are heavily influenced by three key parameters: membrane selectivity, permeability, and lifespan. A 10% improvement in selectivity can reduce capture costs by approximately 7-12%, while doubling membrane lifespan from 3 to 6 years may decrease lifetime costs by up to 18%. These relationships highlight critical research priorities for economic optimization.

Scale effects demonstrate notable impact on economic feasibility. Small to medium installations (capturing <100,000 tons CO2/year) face higher per-unit costs, with membrane systems showing 15-25% better economics than competing technologies at this scale. For large-scale applications (>1 million tons CO2/year), the economic advantage narrows to 5-10%, though still remaining favorable in most scenarios.

Future economic projections suggest continued improvement in membrane system economics, with anticipated cost reductions of 30-40% over the next decade through advances in material science and manufacturing processes. This trajectory would position membrane technologies as economically superior across most industrial applications by 2030-2035, assuming concurrent development of supporting infrastructure and policy frameworks.

Energy consumption represents another critical economic factor, with membrane systems typically requiring 0.8-1.2 GJ/ton CO2 captured, compared to 2.5-3.5 GJ/ton for conventional amine absorption. This energy advantage translates to operational savings of $8-15 per ton in energy costs alone, significantly enhancing long-term economic feasibility in energy-intensive industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!