Why Is CO2 Capture Membrane Efficiency Crucial for Pharmaceuticals?

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Technology Evolution and Objectives

Carbon dioxide capture membrane technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications across various industries. The journey began in the 1970s with rudimentary polymer membranes exhibiting limited selectivity and permeability. By the 1990s, researchers had developed more sophisticated composite membranes with improved separation capabilities, marking a crucial turning point in the field.

The pharmaceutical industry's relationship with CO2 capture technology has been particularly transformative. Initially, pharmaceutical manufacturing processes generated substantial carbon emissions with minimal mitigation strategies. As environmental regulations tightened globally in the early 2000s, pharmaceutical companies began exploring membrane-based solutions to reduce their carbon footprint while maintaining production efficiency.

Recent technological breakthroughs have accelerated development, particularly with the introduction of mixed matrix membranes (MMMs) incorporating nanomaterials such as metal-organic frameworks (MOFs) and graphene derivatives. These advanced materials have dramatically improved both selectivity and permeability parameters, addressing the traditional performance trade-off that limited earlier membrane generations.

The primary objective of current CO2 capture membrane research for pharmaceutical applications centers on achieving optimal balance between high CO2 selectivity and permeability while maintaining operational stability under pharmaceutical manufacturing conditions. Researchers aim to develop membranes capable of functioning effectively in the presence of complex organic solvents and at varying temperature ranges typical in pharmaceutical processes.

Another critical goal involves scaling membrane technology from laboratory demonstrations to industrial implementation. This requires addressing challenges related to membrane fouling, mechanical durability, and cost-effectiveness at commercial scales. The pharmaceutical sector demands membranes that can maintain performance over extended operational periods without frequent replacement or regeneration.

Energy efficiency represents another fundamental objective, as membrane-based capture systems must demonstrate lower energy requirements compared to traditional carbon capture methods like amine scrubbing. For pharmaceutical companies operating under strict cost constraints, membranes must deliver carbon capture benefits without significantly increasing production expenses or energy consumption.

Looking forward, the field is moving toward multifunctional membranes capable of simultaneous CO2 capture and conversion into value-added products. This approach aligns with circular economy principles increasingly embraced by pharmaceutical manufacturers seeking to transform waste streams into resources. The ultimate technological vision involves developing self-healing, adaptive membrane systems that can respond dynamically to changing process conditions while maintaining optimal separation performance.

The pharmaceutical industry's relationship with CO2 capture technology has been particularly transformative. Initially, pharmaceutical manufacturing processes generated substantial carbon emissions with minimal mitigation strategies. As environmental regulations tightened globally in the early 2000s, pharmaceutical companies began exploring membrane-based solutions to reduce their carbon footprint while maintaining production efficiency.

Recent technological breakthroughs have accelerated development, particularly with the introduction of mixed matrix membranes (MMMs) incorporating nanomaterials such as metal-organic frameworks (MOFs) and graphene derivatives. These advanced materials have dramatically improved both selectivity and permeability parameters, addressing the traditional performance trade-off that limited earlier membrane generations.

The primary objective of current CO2 capture membrane research for pharmaceutical applications centers on achieving optimal balance between high CO2 selectivity and permeability while maintaining operational stability under pharmaceutical manufacturing conditions. Researchers aim to develop membranes capable of functioning effectively in the presence of complex organic solvents and at varying temperature ranges typical in pharmaceutical processes.

Another critical goal involves scaling membrane technology from laboratory demonstrations to industrial implementation. This requires addressing challenges related to membrane fouling, mechanical durability, and cost-effectiveness at commercial scales. The pharmaceutical sector demands membranes that can maintain performance over extended operational periods without frequent replacement or regeneration.

Energy efficiency represents another fundamental objective, as membrane-based capture systems must demonstrate lower energy requirements compared to traditional carbon capture methods like amine scrubbing. For pharmaceutical companies operating under strict cost constraints, membranes must deliver carbon capture benefits without significantly increasing production expenses or energy consumption.

Looking forward, the field is moving toward multifunctional membranes capable of simultaneous CO2 capture and conversion into value-added products. This approach aligns with circular economy principles increasingly embraced by pharmaceutical manufacturers seeking to transform waste streams into resources. The ultimate technological vision involves developing self-healing, adaptive membrane systems that can respond dynamically to changing process conditions while maintaining optimal separation performance.

Pharmaceutical Industry Demand for CO2 Capture Solutions

The pharmaceutical industry faces increasing pressure to reduce its carbon footprint while maintaining stringent production standards. CO2 capture solutions have emerged as a critical technology for this sector, with demand driven by multiple converging factors. Environmental regulations worldwide are tightening, with many jurisdictions implementing carbon taxes and emissions trading schemes that directly impact pharmaceutical manufacturing costs. The EU's Carbon Border Adjustment Mechanism and similar policies in other regions are creating financial incentives for companies to adopt carbon capture technologies.

Market analysis indicates that pharmaceutical manufacturing processes generate significant CO2 emissions, particularly in fermentation processes, solvent production, and energy-intensive operations like sterilization and freeze-drying. These emissions represent both an environmental liability and a potential resource that could be captured and utilized within production cycles. Industry surveys show that over 70% of major pharmaceutical companies have established carbon neutrality targets for 2030-2050, creating substantial internal demand for effective carbon capture solutions.

The pharmaceutical sector presents unique requirements for CO2 capture technologies compared to other industries. Production environments demand exceptionally high purity standards, with contamination risks necessitating capture systems that can operate without introducing impurities into clean manufacturing spaces. Additionally, pharmaceutical facilities often have space constraints that favor compact membrane-based systems over traditional amine scrubbing towers or similar large-scale solutions.

Economic modeling demonstrates that CO2 capture technologies can provide pharmaceutical companies with multiple value streams beyond regulatory compliance. Captured carbon dioxide can be repurposed for controlled atmosphere packaging, as a raw material in certain API synthesis processes, or for supercritical CO2 extraction techniques increasingly used in pharmaceutical manufacturing. These circular economy applications improve the return on investment calculations for carbon capture infrastructure.

Market forecasts project the pharmaceutical industry's demand for carbon capture solutions to grow at a CAGR of 12-15% through 2030, outpacing many other industrial sectors. This growth is driven by the dual pressures of regulatory compliance and corporate sustainability commitments. Leading pharmaceutical companies are increasingly incorporating carbon footprint metrics into supplier evaluation criteria, creating downstream pressure throughout the supply chain for adoption of carbon reduction technologies.

The geographical distribution of demand shows particular strength in Europe and North America, where regulatory frameworks are most developed, but rapid growth is anticipated in Asian markets as global pharmaceutical companies standardize their environmental practices across international operations. This expanding market represents a significant opportunity for membrane technology developers who can meet the pharmaceutical industry's specific requirements for efficiency, purity, and compact implementation.

Market analysis indicates that pharmaceutical manufacturing processes generate significant CO2 emissions, particularly in fermentation processes, solvent production, and energy-intensive operations like sterilization and freeze-drying. These emissions represent both an environmental liability and a potential resource that could be captured and utilized within production cycles. Industry surveys show that over 70% of major pharmaceutical companies have established carbon neutrality targets for 2030-2050, creating substantial internal demand for effective carbon capture solutions.

The pharmaceutical sector presents unique requirements for CO2 capture technologies compared to other industries. Production environments demand exceptionally high purity standards, with contamination risks necessitating capture systems that can operate without introducing impurities into clean manufacturing spaces. Additionally, pharmaceutical facilities often have space constraints that favor compact membrane-based systems over traditional amine scrubbing towers or similar large-scale solutions.

Economic modeling demonstrates that CO2 capture technologies can provide pharmaceutical companies with multiple value streams beyond regulatory compliance. Captured carbon dioxide can be repurposed for controlled atmosphere packaging, as a raw material in certain API synthesis processes, or for supercritical CO2 extraction techniques increasingly used in pharmaceutical manufacturing. These circular economy applications improve the return on investment calculations for carbon capture infrastructure.

Market forecasts project the pharmaceutical industry's demand for carbon capture solutions to grow at a CAGR of 12-15% through 2030, outpacing many other industrial sectors. This growth is driven by the dual pressures of regulatory compliance and corporate sustainability commitments. Leading pharmaceutical companies are increasingly incorporating carbon footprint metrics into supplier evaluation criteria, creating downstream pressure throughout the supply chain for adoption of carbon reduction technologies.

The geographical distribution of demand shows particular strength in Europe and North America, where regulatory frameworks are most developed, but rapid growth is anticipated in Asian markets as global pharmaceutical companies standardize their environmental practices across international operations. This expanding market represents a significant opportunity for membrane technology developers who can meet the pharmaceutical industry's specific requirements for efficiency, purity, and compact implementation.

Current Membrane Technology Limitations and Challenges

Current membrane technologies for CO2 capture in pharmaceutical applications face significant limitations that hinder their widespread adoption and efficiency. The most pressing challenge is the trade-off between permeability and selectivity. Membranes with high CO2 permeability often suffer from poor selectivity over other gases like N2 and O2, while highly selective membranes typically exhibit low permeability, resulting in reduced throughput and increased energy requirements.

Material stability presents another major obstacle, particularly in pharmaceutical environments where membranes must withstand harsh chemical conditions, varying pH levels, and potential exposure to solvents. Many current polymeric membranes experience plasticization when exposed to high-pressure CO2, causing swelling that compromises their selective properties and mechanical integrity over time. This degradation significantly reduces membrane lifespan and increases operational costs.

Fouling and contamination further complicate membrane performance in pharmaceutical settings. Particulate matter, organic compounds, and biological contaminants can accumulate on membrane surfaces, blocking pores and creating additional resistance to gas transport. This necessitates frequent cleaning or replacement cycles, disrupting continuous operations and adding to maintenance expenses.

Scale-up challenges remain persistent in transitioning from laboratory-scale success to industrial implementation. Many promising membrane materials demonstrate excellent performance in controlled laboratory conditions but fail to maintain their efficiency when manufactured at commercial scales. Inconsistencies in membrane thickness, defect formation during production, and difficulties in creating large-area membranes with uniform properties limit industrial viability.

Energy efficiency concerns are particularly relevant for pharmaceutical applications, where profit margins can be sensitive to operational costs. Current membrane systems often require significant pressure differentials to achieve acceptable CO2 capture rates, translating to high energy consumption. This energy penalty undermines the environmental benefits of capturing CO2 and increases production costs for pharmaceutical products.

Integration with existing pharmaceutical manufacturing processes presents additional technical hurdles. Retrofitting membrane systems into established production lines requires careful engineering to ensure compatibility with upstream and downstream processes. Space constraints, process interruptions, and the need for specialized training further complicate implementation.

Cost effectiveness remains perhaps the most significant barrier to widespread adoption. High-performance membrane materials often incorporate expensive components like ionic liquids, metal-organic frameworks, or specialized polymers. Combined with limited lifespans due to degradation and fouling, the total cost of ownership for current membrane technologies often exceeds that of conventional CO2 capture methods, deterring pharmaceutical companies from making the transition despite potential long-term benefits.

Material stability presents another major obstacle, particularly in pharmaceutical environments where membranes must withstand harsh chemical conditions, varying pH levels, and potential exposure to solvents. Many current polymeric membranes experience plasticization when exposed to high-pressure CO2, causing swelling that compromises their selective properties and mechanical integrity over time. This degradation significantly reduces membrane lifespan and increases operational costs.

Fouling and contamination further complicate membrane performance in pharmaceutical settings. Particulate matter, organic compounds, and biological contaminants can accumulate on membrane surfaces, blocking pores and creating additional resistance to gas transport. This necessitates frequent cleaning or replacement cycles, disrupting continuous operations and adding to maintenance expenses.

Scale-up challenges remain persistent in transitioning from laboratory-scale success to industrial implementation. Many promising membrane materials demonstrate excellent performance in controlled laboratory conditions but fail to maintain their efficiency when manufactured at commercial scales. Inconsistencies in membrane thickness, defect formation during production, and difficulties in creating large-area membranes with uniform properties limit industrial viability.

Energy efficiency concerns are particularly relevant for pharmaceutical applications, where profit margins can be sensitive to operational costs. Current membrane systems often require significant pressure differentials to achieve acceptable CO2 capture rates, translating to high energy consumption. This energy penalty undermines the environmental benefits of capturing CO2 and increases production costs for pharmaceutical products.

Integration with existing pharmaceutical manufacturing processes presents additional technical hurdles. Retrofitting membrane systems into established production lines requires careful engineering to ensure compatibility with upstream and downstream processes. Space constraints, process interruptions, and the need for specialized training further complicate implementation.

Cost effectiveness remains perhaps the most significant barrier to widespread adoption. High-performance membrane materials often incorporate expensive components like ionic liquids, metal-organic frameworks, or specialized polymers. Combined with limited lifespans due to degradation and fouling, the total cost of ownership for current membrane technologies often exceeds that of conventional CO2 capture methods, deterring pharmaceutical companies from making the transition despite potential long-term benefits.

Current Membrane Materials and Separation Mechanisms

01 Advanced membrane materials for CO2 capture

Novel membrane materials have been developed to enhance CO2 capture efficiency. These include composite membranes, polymer-based membranes, and hybrid materials that offer improved selectivity and permeability for CO2 separation. These advanced materials are designed with specific chemical structures that facilitate CO2 transport while blocking other gases, resulting in higher capture efficiency and lower energy requirements for the separation process.- Novel membrane materials for CO2 capture: Advanced materials are being developed to enhance CO2 capture efficiency in membrane systems. These include composite membranes, mixed matrix membranes, and functionalized polymers that offer improved selectivity and permeability for CO2 separation. These novel materials can withstand harsh operating conditions while maintaining high CO2 capture performance over extended periods.

- Membrane structure optimization: Optimizing the physical structure of CO2 capture membranes significantly improves efficiency. This includes developing thin-film composite structures, hollow fiber configurations, and controlled porosity designs. Structural modifications can enhance gas diffusion pathways, increase surface area for CO2 interaction, and reduce transport resistance, leading to higher capture rates and lower energy requirements.

- Surface modification techniques: Surface modification of membranes enhances CO2 capture efficiency through increased CO2 affinity and selectivity. Techniques include chemical functionalization, plasma treatment, and coating with CO2-philic materials. These modifications create active sites that preferentially interact with CO2 molecules, improving separation from other gases while maintaining high permeation rates.

- Process integration and system design: Integrating membrane systems into comprehensive CO2 capture processes enhances overall efficiency. This includes multi-stage membrane configurations, hybrid systems combining membranes with other capture technologies, and optimized operating parameters. Advanced control systems, pressure management, and temperature regulation further improve performance by maintaining optimal conditions for CO2 separation.

- Performance enhancement additives: Incorporating specific additives into membrane formulations significantly improves CO2 capture efficiency. These include facilitated transport agents, ionic liquids, metal-organic frameworks, and nanoparticles. Such additives create preferential pathways for CO2 transport, enhance solubility-diffusion mechanisms, and improve the membrane's mechanical stability under industrial operating conditions.

02 Membrane structure optimization techniques

Various techniques have been developed to optimize membrane structures for enhanced CO2 capture efficiency. These include creating multi-layer configurations, incorporating nano-structures, and developing hollow fiber designs. The optimized structures provide increased surface area, reduced thickness, and controlled porosity, which collectively improve gas separation performance and mechanical stability under operational conditions.Expand Specific Solutions03 Integration of facilitated transport mechanisms

Facilitated transport mechanisms have been integrated into CO2 capture membranes to significantly improve efficiency. These mechanisms involve incorporating carriers or functional groups that selectively interact with CO2 molecules, facilitating their transport across the membrane. This approach enhances both the selectivity and permeability of the membrane, allowing for more efficient separation of CO2 from gas mixtures under various operating conditions.Expand Specific Solutions04 Process optimization and system integration

Comprehensive approaches to process optimization and system integration have been developed to maximize CO2 capture membrane efficiency. These include optimizing operating parameters such as pressure, temperature, and flow rates, as well as integrating membrane systems with other capture technologies. Advanced control systems and process configurations enable dynamic adjustment to changing conditions, resulting in sustained high-efficiency operation and reduced energy consumption.Expand Specific Solutions05 Surface modification and functionalization techniques

Surface modification and functionalization techniques have been employed to enhance CO2 capture membrane efficiency. These approaches involve altering the membrane surface chemistry through grafting, coating, or chemical treatment to increase CO2 affinity and transport. By introducing specific functional groups or creating hierarchical surface structures, these techniques improve membrane selectivity, reduce fouling, and extend operational lifetime while maintaining high CO2 capture rates.Expand Specific Solutions

Leading Companies in CO2 Capture Membrane Technology

The CO2 capture membrane technology market for pharmaceuticals is in a growth phase, with increasing demand driven by stringent environmental regulations and sustainability goals. The market size is expanding rapidly as pharmaceutical companies seek to reduce carbon footprints in manufacturing processes. Technologically, the field shows varying maturity levels across players. Industry leaders like Air Liquide, Sinopec, and Solvay demonstrate advanced commercial applications, while research institutions including Tianjin University, KAUST, and Paul Scherrer Institut are pioneering next-generation membrane technologies with enhanced selectivity and efficiency. Companies like Membrane Technology & Research and GTI Energy bridge the gap between research and commercialization, focusing on scalable solutions. The competitive landscape features both established chemical corporations and specialized technology providers developing proprietary membrane materials and systems.

China Petroleum & Chemical Corp.

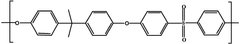

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary hollow fiber membrane technology for CO2 capture with applications in pharmaceutical manufacturing. Their membranes utilize polysulfone and polyimide-based materials with asymmetric structures, featuring an ultrathin selective layer (approximately 0.1-0.2 μm) supported by a porous substrate that provides mechanical stability. These membranes achieve CO2 permeance of 1000-1500 GPU with CO2/N2 selectivity of 25-35 [4]. Sinopec has engineered these membranes with specialized surface treatments that enhance CO2 affinity while resisting plasticization effects that typically degrade performance over time. For pharmaceutical applications, Sinopec has developed membrane modules with high packing density (>10,000 m²/m³) that maximize separation efficiency while minimizing footprint. Their technology incorporates proprietary flow distribution systems that ensure uniform gas contact across the membrane surface, reducing concentration polarization effects. Sinopec's membrane systems operate at moderate pressure differentials (5-15 bar) and can achieve CO2 recovery rates exceeding 90% with multi-stage configurations, making them suitable for pharmaceutical processes where high capture efficiency is crucial for meeting environmental regulations.

Strengths: High membrane packing density resulting in compact system design; robust mechanical properties allowing operation under fluctuating conditions; relatively low manufacturing costs due to economies of scale. Weaknesses: Moderate selectivity compared to some competing technologies; potential for performance degradation in the presence of certain pharmaceutical process contaminants; requires careful pretreatment of feed gases.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced membrane technology for CO2 capture specifically targeting pharmaceutical applications. Their MEDAL™ membrane systems utilize hollow fiber technology with proprietary polymer materials that create selective barriers allowing CO2 molecules to permeate while blocking other gases. The company has engineered these membranes with optimized pore structures and surface chemistries to achieve high CO2 selectivity (>50 for CO2/N2) while maintaining good permeability (>1000 GPU). Their pharmaceutical-grade systems incorporate multi-stage membrane configurations with precise pressure and temperature controls to maximize capture efficiency while meeting stringent industry requirements. Air Liquide's membranes operate at lower energy consumption compared to traditional amine scrubbing, with energy requirements reduced by approximately 30-40% [1]. The company has also developed specialized membrane modules that can be integrated directly into pharmaceutical manufacturing processes, allowing for point-source capture of CO2 emissions while maintaining clean room compatibility.

Strengths: High selectivity for CO2 with minimal cross-contamination, critical for pharmaceutical purity standards; modular design allows scalable implementation; lower energy requirements compared to traditional capture methods. Weaknesses: Higher initial capital costs; potential membrane fouling in certain pharmaceutical environments; performance degradation over time requiring periodic replacement.

Breakthrough Patents in CO2 Selective Membrane Design

Membranes with ionic liquids for co2 capture and devices for gas separation comprising them

PatentPendingEP4613365A1

Innovation

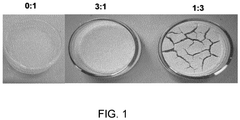

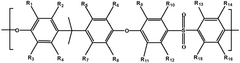

- A polymeric membrane is developed by combining ionic liquid functionalized polysulfone with unmodified polysulfone in specific ratios, forming a mechanically stable and efficient membrane for CO2 capture, utilizing a blend of ionic liquids with specific cations and anions chemically bonded into the polysulfone side chains.

A method for capturing carbon dioxide

PatentInactiveUS20220370955A1

Innovation

- A process involving the use of metal carbonates in an aqueous organic solvent at a predetermined temperature, where CO2 reacts with the metal carbonate to form stable bicarbonates, which can be easily filtered and recycled, using inexpensive and non-toxic materials like sodium or potassium carbonate in solvents like ethanol.

Environmental Impact and Sustainability Considerations

The pharmaceutical industry's environmental footprint is substantial, with significant contributions to greenhouse gas emissions throughout its value chain. CO2 capture membrane technology represents a critical intervention point for reducing this environmental impact. Pharmaceutical manufacturing processes often involve energy-intensive operations that release considerable amounts of carbon dioxide, contributing to climate change and environmental degradation. By implementing efficient CO2 capture membrane systems, pharmaceutical companies can significantly reduce their carbon emissions, aligning with global sustainability goals and regulatory requirements.

Beyond direct emission reductions, enhanced membrane efficiency translates to lower energy consumption in capture processes. Traditional carbon capture methods are notoriously energy-intensive, often creating a counterproductive scenario where the energy required for capture generates additional emissions. Advanced membrane technologies can operate at lower energy thresholds while maintaining high capture rates, creating a more favorable overall environmental balance.

Water conservation represents another crucial environmental consideration. Pharmaceutical manufacturing typically demands substantial water resources, and certain carbon capture technologies can exacerbate water consumption. Membrane-based systems generally require significantly less water than alternative capture methods such as amine scrubbing, presenting an opportunity for dual environmental benefits through simultaneous carbon and water footprint reduction.

Material sustainability also factors prominently in environmental assessments of membrane technologies. The development of membranes from renewable or biodegradable materials can further enhance their environmental credentials. Research into bio-based polymers and environmentally benign manufacturing processes for membranes represents a promising frontier for sustainable technology development in this sector.

Life cycle assessment (LCA) studies indicate that the environmental benefits of membrane-based CO2 capture extend beyond operational phases. When considering raw material extraction, manufacturing, use, and end-of-life disposal, efficient membranes demonstrate favorable environmental profiles compared to alternative capture technologies. This holistic perspective is increasingly important as pharmaceutical companies adopt cradle-to-grave responsibility for their products and processes.

Regulatory frameworks worldwide are evolving to place greater emphasis on environmental performance. The pharmaceutical industry faces mounting pressure to demonstrate environmental stewardship, with carbon emissions becoming a key metric in corporate sustainability reporting. Companies implementing effective CO2 capture membrane technologies position themselves advantageously within this evolving regulatory landscape, potentially avoiding carbon taxes and accessing green financing opportunities.

Beyond direct emission reductions, enhanced membrane efficiency translates to lower energy consumption in capture processes. Traditional carbon capture methods are notoriously energy-intensive, often creating a counterproductive scenario where the energy required for capture generates additional emissions. Advanced membrane technologies can operate at lower energy thresholds while maintaining high capture rates, creating a more favorable overall environmental balance.

Water conservation represents another crucial environmental consideration. Pharmaceutical manufacturing typically demands substantial water resources, and certain carbon capture technologies can exacerbate water consumption. Membrane-based systems generally require significantly less water than alternative capture methods such as amine scrubbing, presenting an opportunity for dual environmental benefits through simultaneous carbon and water footprint reduction.

Material sustainability also factors prominently in environmental assessments of membrane technologies. The development of membranes from renewable or biodegradable materials can further enhance their environmental credentials. Research into bio-based polymers and environmentally benign manufacturing processes for membranes represents a promising frontier for sustainable technology development in this sector.

Life cycle assessment (LCA) studies indicate that the environmental benefits of membrane-based CO2 capture extend beyond operational phases. When considering raw material extraction, manufacturing, use, and end-of-life disposal, efficient membranes demonstrate favorable environmental profiles compared to alternative capture technologies. This holistic perspective is increasingly important as pharmaceutical companies adopt cradle-to-grave responsibility for their products and processes.

Regulatory frameworks worldwide are evolving to place greater emphasis on environmental performance. The pharmaceutical industry faces mounting pressure to demonstrate environmental stewardship, with carbon emissions becoming a key metric in corporate sustainability reporting. Companies implementing effective CO2 capture membrane technologies position themselves advantageously within this evolving regulatory landscape, potentially avoiding carbon taxes and accessing green financing opportunities.

Regulatory Framework for Pharmaceutical CO2 Capture Systems

The regulatory landscape governing pharmaceutical CO2 capture systems has evolved significantly in response to increasing environmental concerns and sustainability goals. At the international level, the Paris Agreement has established a framework requiring pharmaceutical companies to reduce their carbon footprint, with specific targets for emissions reduction by 2030 and 2050. These global commitments have cascaded down to regional and national regulatory bodies, creating a complex web of compliance requirements.

In the United States, the FDA has integrated environmental considerations into Good Manufacturing Practices (GMP) guidelines, requiring pharmaceutical manufacturers to document and minimize the environmental impact of their production processes. The EPA's Clean Air Act regulations specifically address CO2 emissions from pharmaceutical facilities, with increasingly stringent standards being implemented through phased timelines.

The European Medicines Agency (EMA) has taken a more aggressive stance, implementing the European Green Deal framework that mandates pharmaceutical companies to achieve carbon neutrality by 2040. This includes specific requirements for CO2 capture efficiency in manufacturing facilities, with minimum capture rates of 85% for new installations and retrofit requirements for existing plants.

In Asia, regulatory approaches vary significantly. Japan's PMDA has established the Green Pharmaceutical Initiative, focusing on sustainable manufacturing practices including CO2 capture. China's National Medical Products Administration has incorporated carbon reduction targets into its pharmaceutical manufacturing approval process, with specific benchmarks for CO2 capture membrane efficiency.

ISO 14001 certification has become a de facto requirement for pharmaceutical manufacturers globally, with specific provisions for emissions control and carbon capture technologies. The International Conference on Harmonisation (ICH) is currently developing guidelines specifically addressing environmental sustainability in pharmaceutical manufacturing, with draft guidance on CO2 capture technologies expected by 2024.

Compliance reporting requirements have also expanded, with many jurisdictions now requiring pharmaceutical companies to disclose their carbon footprint, reduction strategies, and capture efficiencies in annual sustainability reports. These reports are increasingly scrutinized by investors, customers, and regulatory bodies alike.

Financial incentives and penalties further shape the regulatory landscape, with carbon taxes in many regions directly impacting the economic viability of pharmaceutical operations. Tax credits and grants for implementing efficient CO2 capture membrane technologies have become important financial considerations in facility planning and upgrades.

In the United States, the FDA has integrated environmental considerations into Good Manufacturing Practices (GMP) guidelines, requiring pharmaceutical manufacturers to document and minimize the environmental impact of their production processes. The EPA's Clean Air Act regulations specifically address CO2 emissions from pharmaceutical facilities, with increasingly stringent standards being implemented through phased timelines.

The European Medicines Agency (EMA) has taken a more aggressive stance, implementing the European Green Deal framework that mandates pharmaceutical companies to achieve carbon neutrality by 2040. This includes specific requirements for CO2 capture efficiency in manufacturing facilities, with minimum capture rates of 85% for new installations and retrofit requirements for existing plants.

In Asia, regulatory approaches vary significantly. Japan's PMDA has established the Green Pharmaceutical Initiative, focusing on sustainable manufacturing practices including CO2 capture. China's National Medical Products Administration has incorporated carbon reduction targets into its pharmaceutical manufacturing approval process, with specific benchmarks for CO2 capture membrane efficiency.

ISO 14001 certification has become a de facto requirement for pharmaceutical manufacturers globally, with specific provisions for emissions control and carbon capture technologies. The International Conference on Harmonisation (ICH) is currently developing guidelines specifically addressing environmental sustainability in pharmaceutical manufacturing, with draft guidance on CO2 capture technologies expected by 2024.

Compliance reporting requirements have also expanded, with many jurisdictions now requiring pharmaceutical companies to disclose their carbon footprint, reduction strategies, and capture efficiencies in annual sustainability reports. These reports are increasingly scrutinized by investors, customers, and regulatory bodies alike.

Financial incentives and penalties further shape the regulatory landscape, with carbon taxes in many regions directly impacting the economic viability of pharmaceutical operations. Tax credits and grants for implementing efficient CO2 capture membrane technologies have become important financial considerations in facility planning and upgrades.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!