Evaluating Coating Methods on CO2 Capture Membrane Performance

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Coating Technology Background and Objectives

Carbon dioxide capture technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical applications in response to growing environmental concerns. Membrane-based CO2 capture represents one of the most promising approaches due to its energy efficiency, operational flexibility, and reduced environmental footprint compared to conventional absorption methods. The evolution of membrane technology for CO2 separation began in the 1980s with rudimentary polymer membranes, progressing through various material innovations including mixed matrix membranes, facilitated transport membranes, and most recently, advanced composite structures.

The coating methods applied to these membranes have emerged as a critical factor determining their performance characteristics. Early coating techniques primarily focused on simple dip-coating processes, while contemporary approaches incorporate precision methods such as chemical vapor deposition, layer-by-layer assembly, and interfacial polymerization. This technological progression has been driven by the increasing demand for higher CO2 selectivity, improved permeability, and enhanced membrane durability under industrial conditions.

Current technological trends indicate a convergence toward multi-functional coating strategies that simultaneously address multiple performance parameters. These include the development of anti-fouling surfaces, self-healing capabilities, and stimuli-responsive features that can adapt to changing operational conditions. The integration of nanotechnology into coating processes has opened new possibilities for precise control over membrane surface properties at the molecular level.

The primary objective of this technical research is to comprehensively evaluate various coating methodologies and their impact on CO2 capture membrane performance. Specifically, this investigation aims to establish quantitative relationships between coating parameters (thickness, composition, application technique) and key performance indicators including CO2/N2 selectivity, permeability, mechanical stability, and long-term operational reliability.

Secondary objectives include identifying optimal coating conditions for different membrane substrate materials, assessing scalability challenges for promising coating technologies, and exploring novel hybrid approaches that combine complementary coating methods. The research also seeks to develop standardized protocols for characterizing coated membrane surfaces to facilitate meaningful comparisons across different studies and technologies.

The ultimate goal is to establish a systematic framework for selecting and optimizing coating methods based on specific application requirements, thereby accelerating the development and deployment of next-generation CO2 capture membranes. This framework will incorporate considerations of technical performance, economic viability, and environmental sustainability to ensure holistic evaluation of coating technologies for industrial implementation.

The coating methods applied to these membranes have emerged as a critical factor determining their performance characteristics. Early coating techniques primarily focused on simple dip-coating processes, while contemporary approaches incorporate precision methods such as chemical vapor deposition, layer-by-layer assembly, and interfacial polymerization. This technological progression has been driven by the increasing demand for higher CO2 selectivity, improved permeability, and enhanced membrane durability under industrial conditions.

Current technological trends indicate a convergence toward multi-functional coating strategies that simultaneously address multiple performance parameters. These include the development of anti-fouling surfaces, self-healing capabilities, and stimuli-responsive features that can adapt to changing operational conditions. The integration of nanotechnology into coating processes has opened new possibilities for precise control over membrane surface properties at the molecular level.

The primary objective of this technical research is to comprehensively evaluate various coating methodologies and their impact on CO2 capture membrane performance. Specifically, this investigation aims to establish quantitative relationships between coating parameters (thickness, composition, application technique) and key performance indicators including CO2/N2 selectivity, permeability, mechanical stability, and long-term operational reliability.

Secondary objectives include identifying optimal coating conditions for different membrane substrate materials, assessing scalability challenges for promising coating technologies, and exploring novel hybrid approaches that combine complementary coating methods. The research also seeks to develop standardized protocols for characterizing coated membrane surfaces to facilitate meaningful comparisons across different studies and technologies.

The ultimate goal is to establish a systematic framework for selecting and optimizing coating methods based on specific application requirements, thereby accelerating the development and deployment of next-generation CO2 capture membranes. This framework will incorporate considerations of technical performance, economic viability, and environmental sustainability to ensure holistic evaluation of coating technologies for industrial implementation.

Market Analysis for CO2 Capture Membrane Applications

The global market for CO2 capture membrane technologies is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations indicate that the carbon capture and storage (CCS) sector is projected to reach $7 billion by 2026, with membrane technologies representing approximately 18% of this market. This growth trajectory is supported by the Paris Agreement targets and subsequent national policies aimed at reducing greenhouse gas emissions across industrial sectors.

Membrane-based carbon capture systems are gaining traction particularly in power generation, cement production, and natural gas processing industries. These sectors collectively account for over 60% of global CO2 emissions from industrial sources. The power generation sector remains the largest potential market for membrane applications, with coal and natural gas power plants seeking cost-effective solutions to comply with stricter emission standards.

Regional analysis reveals that North America and Europe currently lead in membrane technology adoption, primarily due to favorable regulatory frameworks and carbon pricing mechanisms. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth rates exceeding 15%. This growth is fueled by rapid industrialization coupled with increasing environmental consciousness and governmental support for clean technologies.

End-user segmentation shows that large industrial facilities with continuous emission profiles are the primary adopters of membrane technologies. These users value the relatively lower energy requirements and operational flexibility of membrane systems compared to traditional amine-based capture methods. The total addressable market for industrial applications of CO2 capture membranes is estimated at $3.5 billion by 2030.

Market penetration analysis indicates that coating methods significantly impact market acceptance of membrane technologies. Membranes with advanced coating techniques that demonstrate higher selectivity and durability command premium pricing, typically 30-40% above standard offerings. This price differential highlights the market's willingness to pay for performance enhancements derived from superior coating methodologies.

Customer demand patterns show increasing preference for membrane solutions that offer not only effective CO2 capture but also reduced energy penalties and operational simplicity. Market surveys indicate that potential adopters prioritize membrane longevity and resistance to contaminants, both factors heavily influenced by coating quality and methodology. The market increasingly values total cost of ownership over initial capital expenditure, creating opportunities for premium membrane products with advanced coating technologies that deliver superior long-term performance.

Membrane-based carbon capture systems are gaining traction particularly in power generation, cement production, and natural gas processing industries. These sectors collectively account for over 60% of global CO2 emissions from industrial sources. The power generation sector remains the largest potential market for membrane applications, with coal and natural gas power plants seeking cost-effective solutions to comply with stricter emission standards.

Regional analysis reveals that North America and Europe currently lead in membrane technology adoption, primarily due to favorable regulatory frameworks and carbon pricing mechanisms. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth rates exceeding 15%. This growth is fueled by rapid industrialization coupled with increasing environmental consciousness and governmental support for clean technologies.

End-user segmentation shows that large industrial facilities with continuous emission profiles are the primary adopters of membrane technologies. These users value the relatively lower energy requirements and operational flexibility of membrane systems compared to traditional amine-based capture methods. The total addressable market for industrial applications of CO2 capture membranes is estimated at $3.5 billion by 2030.

Market penetration analysis indicates that coating methods significantly impact market acceptance of membrane technologies. Membranes with advanced coating techniques that demonstrate higher selectivity and durability command premium pricing, typically 30-40% above standard offerings. This price differential highlights the market's willingness to pay for performance enhancements derived from superior coating methodologies.

Customer demand patterns show increasing preference for membrane solutions that offer not only effective CO2 capture but also reduced energy penalties and operational simplicity. Market surveys indicate that potential adopters prioritize membrane longevity and resistance to contaminants, both factors heavily influenced by coating quality and methodology. The market increasingly values total cost of ownership over initial capital expenditure, creating opportunities for premium membrane products with advanced coating technologies that deliver superior long-term performance.

Current Coating Methods and Technical Challenges

The membrane coating landscape for CO2 capture has evolved significantly over the past decade, with several methods now established as industry standards. Dip coating remains one of the most widely utilized approaches due to its simplicity and cost-effectiveness. This method involves immersing a porous substrate into a polymer solution and withdrawing it at a controlled rate, allowing for the formation of a thin selective layer. However, dip coating faces challenges in achieving uniform thickness across complex geometries and often requires multiple coating cycles to eliminate defects.

Spin coating has gained prominence for flat sheet membranes, offering excellent thickness control through adjustment of rotation speed and solution viscosity. This method enables the production of ultra-thin selective layers (down to 100 nm), which significantly enhance gas permeation rates. The primary limitation lies in its applicability only to flat substrates and difficulty in scaling to industrial production volumes.

Spray coating represents a versatile alternative that can accommodate various substrate geometries, including hollow fibers and tubular membranes. Recent advancements in spray nozzle technology and automated movement systems have improved coating uniformity. Nevertheless, challenges persist in controlling droplet size distribution and preventing nozzle clogging when working with high-viscosity solutions.

Chemical vapor deposition (CVD) has emerged as a premium coating method for creating defect-free selective layers. This solvent-free approach allows for precise control of membrane thickness at the nanometer scale and excellent conformality. The high equipment costs and energy requirements, however, limit widespread industrial adoption despite superior performance characteristics.

Layer-by-layer (LbL) assembly has gained attention for its ability to create highly tailored membrane structures with precise control over composition at the molecular level. This method involves alternating deposition of oppositely charged polyelectrolytes, enabling the incorporation of various functional materials. While LbL offers unprecedented control over membrane architecture, the time-intensive nature of the process presents significant scaling challenges.

Technical challenges common across coating methods include adhesion issues between the selective layer and substrate, particularly under high-pressure operating conditions. Many membranes exhibit the "trade-off" phenomenon between permeability and selectivity, where improvements in one parameter typically come at the expense of the other. Additionally, maintaining long-term stability under industrial conditions remains problematic, with membrane performance often degrading due to plasticization, compaction, or chemical attack from impurities in gas streams.

Spin coating has gained prominence for flat sheet membranes, offering excellent thickness control through adjustment of rotation speed and solution viscosity. This method enables the production of ultra-thin selective layers (down to 100 nm), which significantly enhance gas permeation rates. The primary limitation lies in its applicability only to flat substrates and difficulty in scaling to industrial production volumes.

Spray coating represents a versatile alternative that can accommodate various substrate geometries, including hollow fibers and tubular membranes. Recent advancements in spray nozzle technology and automated movement systems have improved coating uniformity. Nevertheless, challenges persist in controlling droplet size distribution and preventing nozzle clogging when working with high-viscosity solutions.

Chemical vapor deposition (CVD) has emerged as a premium coating method for creating defect-free selective layers. This solvent-free approach allows for precise control of membrane thickness at the nanometer scale and excellent conformality. The high equipment costs and energy requirements, however, limit widespread industrial adoption despite superior performance characteristics.

Layer-by-layer (LbL) assembly has gained attention for its ability to create highly tailored membrane structures with precise control over composition at the molecular level. This method involves alternating deposition of oppositely charged polyelectrolytes, enabling the incorporation of various functional materials. While LbL offers unprecedented control over membrane architecture, the time-intensive nature of the process presents significant scaling challenges.

Technical challenges common across coating methods include adhesion issues between the selective layer and substrate, particularly under high-pressure operating conditions. Many membranes exhibit the "trade-off" phenomenon between permeability and selectivity, where improvements in one parameter typically come at the expense of the other. Additionally, maintaining long-term stability under industrial conditions remains problematic, with membrane performance often degrading due to plasticization, compaction, or chemical attack from impurities in gas streams.

Comparative Analysis of Current Coating Methodologies

01 Membrane material composition for CO2 capture

Various materials can be used to create membranes with high CO2 selectivity and permeability. These include polymeric membranes, mixed matrix membranes incorporating nanomaterials, and facilitated transport membranes. The composition of the membrane material significantly affects its performance in terms of CO2 capture efficiency, with certain polymers and composite materials showing enhanced separation properties and stability under different operating conditions.- Membrane material composition for CO2 capture: Various materials can be used to create membranes with enhanced CO2 capture performance. These include polymeric membranes, mixed matrix membranes incorporating inorganic fillers, and composite materials. The selection of appropriate materials can significantly improve selectivity, permeability, and overall capture efficiency. Advanced polymer blends and functionalized materials can be tailored to have specific affinity for CO2 molecules, enhancing separation from other gases.

- Membrane structure optimization: The physical structure of CO2 capture membranes plays a crucial role in their performance. Optimizing parameters such as membrane thickness, pore size distribution, surface area, and morphology can enhance gas separation efficiency. Multilayer structures, hollow fiber configurations, and supported thin films are common approaches to balance the trade-off between permeability and selectivity. Structural modifications can reduce mass transfer resistance and improve mechanical stability under operating conditions.

- Surface modification techniques: Surface modification of membranes can significantly enhance CO2 capture performance. Techniques include chemical functionalization, plasma treatment, grafting of CO2-philic groups, and coating with selective layers. These modifications can increase CO2 affinity, improve selectivity over other gases, and enhance membrane durability. Surface treatments can also help mitigate common issues such as plasticization and aging that typically reduce membrane performance over time.

- Operating conditions and performance enhancement: The performance of CO2 capture membranes is significantly influenced by operating conditions such as temperature, pressure, humidity, and feed gas composition. Optimizing these parameters can enhance separation efficiency and membrane lifespan. Techniques such as temperature swing, pressure swing, and vacuum-assisted operations can improve driving forces for separation. Additionally, pre-treatment of feed gas streams and management of concentration polarization can prevent membrane fouling and maintain high performance over extended periods.

- Novel membrane system designs: Innovative system designs can overcome limitations of conventional membrane modules for CO2 capture. These include multi-stage cascade systems, hybrid processes combining membranes with other separation technologies, and intensified process configurations. Advanced module designs with optimized flow patterns can minimize concentration polarization and improve mass transfer. Integration of membranes with renewable energy sources or waste heat utilization can enhance the sustainability and economic viability of the capture process.

02 Membrane structure optimization

The physical structure of CO2 capture membranes can be optimized to enhance performance. This includes developing thin-film composite membranes, hollow fiber configurations, and membranes with controlled porosity. Structural modifications such as creating asymmetric membranes with a thin selective layer supported by a porous substrate can significantly improve gas permeation rates while maintaining selectivity. Advanced manufacturing techniques allow for precise control of membrane thickness and morphology.Expand Specific Solutions03 Surface modification techniques

Surface modifications can enhance membrane performance for CO2 capture. Techniques include chemical functionalization, plasma treatment, and coating with selective layers. These modifications can increase CO2 affinity, improve selectivity over other gases, and enhance membrane durability. Surface-modified membranes often show improved resistance to plasticization and fouling, leading to more stable long-term performance in industrial applications.Expand Specific Solutions04 Operating conditions and performance enhancement

The performance of CO2 capture membranes is significantly affected by operating conditions such as temperature, pressure, and feed gas composition. Optimizing these parameters can enhance separation efficiency and membrane lifespan. Techniques such as temperature swing operation, pressure modulation, and feed gas pretreatment can improve CO2 capture rates. Additionally, incorporating sweep gases or vacuum on the permeate side can increase the driving force for separation.Expand Specific Solutions05 Hybrid and integrated membrane systems

Hybrid systems combining membranes with other CO2 capture technologies can achieve superior performance. These include membrane-absorption hybrid processes, membrane-cryogenic separation, and multi-stage membrane configurations. Integrated systems can overcome the limitations of single-technology approaches, offering improved energy efficiency and capture rates. Process integration strategies also include heat and pressure recovery systems to minimize energy consumption in large-scale applications.Expand Specific Solutions

Leading Companies and Research Institutions in CO2 Capture

The CO2 capture membrane technology market is currently in a growth phase, with increasing global focus on carbon reduction driving demand. The market size is expanding rapidly, projected to reach significant scale as industries seek efficient carbon capture solutions. Technologically, the field shows varying maturity levels across different coating methodologies. Leading players like Air Liquide, Sinopec, and China Petroleum & Chemical Corp. are advancing commercial applications, while research institutions such as CNRS, Tianjin University, and Dalian Institute of Chemical Physics are developing next-generation membrane technologies. Companies like Schlumberger and EDF are integrating these solutions into broader energy services. The competitive landscape features collaboration between industrial giants and specialized research entities, with increasing patent activity indicating technology acceleration.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to membrane coating for CO2 capture focusing on thermally rearranged (TR) polymer membranes. Their coating methodology involves a precise solution casting process followed by thermal treatment at controlled temperatures (350-450°C) to induce molecular rearrangement and create optimized free volume elements ideal for CO2 transport. The coating process begins with application of a precursor polymer (typically polyimide derivatives) onto porous supports, followed by a proprietary thermal conversion protocol that transforms the chemical structure while maintaining membrane integrity. This results in a dense selective layer approximately 1-3 μm thick with exceptional gas separation properties. Sinopec's membranes demonstrate CO2 permeability of 500-1000 Barrer with CO2/N2 selectivity of 25-35 under typical flue gas conditions. A key innovation is their gradient heating approach that minimizes defect formation during the thermal rearrangement process, resulting in membranes with excellent mechanical properties and chemical resistance. The company has successfully scaled this technology to pilot demonstration units processing up to 50 Nm³/h of flue gas.

Strengths: Excellent thermal and chemical stability; good resistance to plasticization; relatively simple manufacturing process once optimized. Weaknesses: High energy requirements for thermal treatment phase; limited flexibility in membrane properties; moderate selectivity compared to some facilitated transport membranes.

Air Liquide SA

Technical Solution: Air Liquide has pioneered a hybrid coating approach for CO2 capture membranes combining facilitated transport mechanisms with robust physical barriers. Their technology employs a proprietary dip-coating process to apply amine-functionalized polymers onto hollow fiber supports, creating membranes with exceptional CO2 affinity. The coating methodology involves precise control of solution viscosity, withdrawal speed, and curing conditions to achieve optimal layer thickness (typically 0.5-2 μm). A key innovation is their multi-stage coating process that creates gradient structures with decreasing pore sizes from the support interface to the outer surface, maximizing both permeability and selectivity. Air Liquide's membranes incorporate mobile carrier molecules within the coating matrix that selectively bind with CO2, facilitating its transport across the membrane while rejecting other gases. Their industrial implementation includes specialized coating equipment capable of handling membrane modules up to 10 inches in diameter with coating uniformity variation less than 5% across the entire surface area.

Strengths: Excellent balance between selectivity and permeability; proven durability in industrial environments; established manufacturing infrastructure for large-scale production. Weaknesses: Higher energy requirements for regeneration compared to some competing technologies; performance sensitivity to humidity variations; limited effectiveness at very low CO2 partial pressures.

Key Patents and Innovations in Membrane Coating Technology

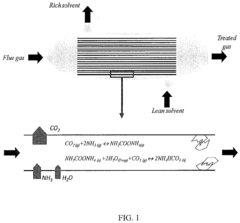

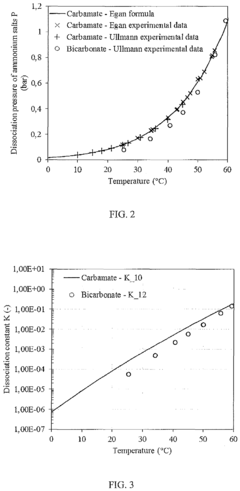

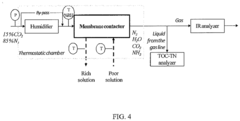

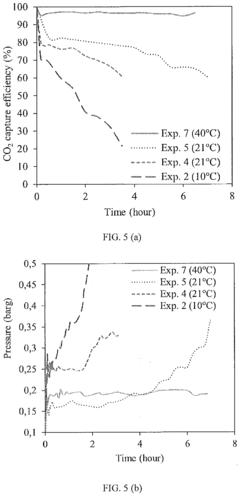

Method for co2 capture with a membrane contactor

PatentActiveEP3412356A1

Innovation

- Incorporating a steam (water vapor) partial-pressure of at least 1200 Pa in the gas stream to delay ammonium crystal formation on the membrane surface, reduce pressure increase, and extend membrane lifespan, while maintaining CO2 capture efficiency over time.

Co2 capture with carbonic anhydrase and membrane filtration

PatentInactiveEP2776143A4

Innovation

- Membrane filtration of carbonic anhydrase between absorption and desorption stages to protect the enzyme from temperature degradation during the large temperature swing process.

- Recycling of filtered carbonic anhydrase back to the absorption stage to maintain high enzyme concentration, improving CO2 capture efficiency and reducing operational costs.

- Implementation of a hybrid solvent system combining carbonic anhydrase, water, and absorption compounds to enhance CO2 capture performance through enzymatic acceleration of CO2 hydration.

Environmental Impact and Sustainability Assessment

The environmental footprint of CO2 capture membrane technologies extends far beyond their operational efficiency. When evaluating coating methods for these membranes, a comprehensive sustainability assessment becomes essential to ensure that the environmental benefits of carbon capture are not offset by negative impacts elsewhere in the lifecycle.

Current coating methodologies for CO2 capture membranes vary significantly in their environmental implications. Solvent-based coating techniques often involve volatile organic compounds (VOCs) that contribute to air pollution and pose health risks. In contrast, water-based coating systems demonstrate reduced environmental toxicity but may require higher energy inputs for drying processes. Recent life cycle assessments indicate that solventless coating methods, such as vapor deposition techniques, offer promising environmental advantages despite their higher initial energy requirements.

The sustainability of membrane coating processes must be evaluated across multiple dimensions. Material sourcing represents a critical concern, particularly for coatings incorporating rare earth elements or precious metals as selectivity enhancers. The geographical concentration of these resources raises questions about supply chain resilience and geopolitical dependencies. Additionally, coating durability directly impacts membrane replacement frequency, with longer-lasting coatings significantly reducing waste generation and resource consumption over the system's operational lifetime.

Energy consumption during coating application emerges as another vital consideration. Advanced plasma-enhanced coating methods may consume substantial electricity during application but can yield membranes with extended operational lifespans and improved capture efficiency. This illustrates the importance of considering full lifecycle impacts rather than focusing solely on manufacturing-phase energy inputs.

Water usage patterns vary dramatically between coating technologies. Traditional solution casting methods may require substantial water volumes for both application and cleaning processes, while newer spray pyrolysis techniques demonstrate significantly reduced water footprints. In water-stressed regions, this factor may prove decisive in technology selection despite other performance considerations.

End-of-life management presents perhaps the most overlooked aspect of membrane sustainability. The complex composite nature of coated membranes often complicates recycling efforts. Promising developments in designing for disassembly and material recovery are emerging, with bioinspired coatings showing particular potential for biodegradability without compromising capture performance. These innovations could transform the sustainability profile of next-generation membrane technologies by closing material loops and minimizing waste streams.

Current coating methodologies for CO2 capture membranes vary significantly in their environmental implications. Solvent-based coating techniques often involve volatile organic compounds (VOCs) that contribute to air pollution and pose health risks. In contrast, water-based coating systems demonstrate reduced environmental toxicity but may require higher energy inputs for drying processes. Recent life cycle assessments indicate that solventless coating methods, such as vapor deposition techniques, offer promising environmental advantages despite their higher initial energy requirements.

The sustainability of membrane coating processes must be evaluated across multiple dimensions. Material sourcing represents a critical concern, particularly for coatings incorporating rare earth elements or precious metals as selectivity enhancers. The geographical concentration of these resources raises questions about supply chain resilience and geopolitical dependencies. Additionally, coating durability directly impacts membrane replacement frequency, with longer-lasting coatings significantly reducing waste generation and resource consumption over the system's operational lifetime.

Energy consumption during coating application emerges as another vital consideration. Advanced plasma-enhanced coating methods may consume substantial electricity during application but can yield membranes with extended operational lifespans and improved capture efficiency. This illustrates the importance of considering full lifecycle impacts rather than focusing solely on manufacturing-phase energy inputs.

Water usage patterns vary dramatically between coating technologies. Traditional solution casting methods may require substantial water volumes for both application and cleaning processes, while newer spray pyrolysis techniques demonstrate significantly reduced water footprints. In water-stressed regions, this factor may prove decisive in technology selection despite other performance considerations.

End-of-life management presents perhaps the most overlooked aspect of membrane sustainability. The complex composite nature of coated membranes often complicates recycling efforts. Promising developments in designing for disassembly and material recovery are emerging, with bioinspired coatings showing particular potential for biodegradability without compromising capture performance. These innovations could transform the sustainability profile of next-generation membrane technologies by closing material loops and minimizing waste streams.

Scalability and Industrial Implementation Considerations

The transition from laboratory-scale membrane coating techniques to industrial-scale production represents a significant challenge in CO2 capture technology implementation. Current coating methods such as dip coating, spin coating, and spray coating demonstrate varying degrees of scalability potential. Dip coating offers simplicity and uniform coverage but faces challenges in handling large membrane areas efficiently. Spin coating, while precise for laboratory applications, presents substantial limitations for industrial-scale implementation due to size constraints and material wastage.

Spray coating emerges as a promising scalable approach, with established precedents in adjacent industries such as automotive and construction. Industrial spray systems can process continuous sheets of membrane substrate, though maintaining coating uniformity across large areas requires sophisticated control systems and environmental parameters management. Roll-to-roll processing represents another viable pathway for industrial implementation, potentially enabling continuous production of coated membranes at commercially viable rates.

Material consumption efficiency varies significantly between coating methods, directly impacting economic viability. Laboratory-scale techniques typically exhibit material utilization rates of 30-60%, while optimized industrial processes can achieve 70-90% efficiency. This differential translates to substantial cost implications when scaled to industrial production volumes. Additionally, solvent recovery systems become economically justified at industrial scales, further improving sustainability metrics and operational costs.

Quality control mechanisms must evolve alongside production scaling. In-line monitoring systems utilizing optical, spectroscopic, or electrical measurement techniques can provide real-time feedback on coating thickness, defect presence, and performance characteristics. These systems enable adaptive process control to maintain consistent membrane quality during continuous production.

Energy requirements for coating processes vary by method, with thermal curing or solvent evaporation representing significant energy inputs. Process integration opportunities exist for utilizing waste heat from adjacent industrial processes, potentially improving overall energy efficiency. Water consumption also warrants consideration, particularly for aqueous-based coating formulations or cleaning processes.

Regulatory compliance presents another dimension of implementation complexity. Chemical handling, solvent emissions, and waste management protocols must align with increasingly stringent environmental regulations. Forward-looking membrane coating facilities should anticipate regulatory evolution and design flexible systems capable of adaptation to emerging requirements.

Capital investment requirements for industrial-scale membrane coating facilities vary based on production capacity targets and technology selection. Initial estimates suggest investment ranges of $10-50 million for facilities capable of producing 100,000-500,000 m² of membrane annually, with economies of scale becoming evident above these production volumes.

Spray coating emerges as a promising scalable approach, with established precedents in adjacent industries such as automotive and construction. Industrial spray systems can process continuous sheets of membrane substrate, though maintaining coating uniformity across large areas requires sophisticated control systems and environmental parameters management. Roll-to-roll processing represents another viable pathway for industrial implementation, potentially enabling continuous production of coated membranes at commercially viable rates.

Material consumption efficiency varies significantly between coating methods, directly impacting economic viability. Laboratory-scale techniques typically exhibit material utilization rates of 30-60%, while optimized industrial processes can achieve 70-90% efficiency. This differential translates to substantial cost implications when scaled to industrial production volumes. Additionally, solvent recovery systems become economically justified at industrial scales, further improving sustainability metrics and operational costs.

Quality control mechanisms must evolve alongside production scaling. In-line monitoring systems utilizing optical, spectroscopic, or electrical measurement techniques can provide real-time feedback on coating thickness, defect presence, and performance characteristics. These systems enable adaptive process control to maintain consistent membrane quality during continuous production.

Energy requirements for coating processes vary by method, with thermal curing or solvent evaporation representing significant energy inputs. Process integration opportunities exist for utilizing waste heat from adjacent industrial processes, potentially improving overall energy efficiency. Water consumption also warrants consideration, particularly for aqueous-based coating formulations or cleaning processes.

Regulatory compliance presents another dimension of implementation complexity. Chemical handling, solvent emissions, and waste management protocols must align with increasingly stringent environmental regulations. Forward-looking membrane coating facilities should anticipate regulatory evolution and design flexible systems capable of adaptation to emerging requirements.

Capital investment requirements for industrial-scale membrane coating facilities vary based on production capacity targets and technology selection. Initial estimates suggest investment ranges of $10-50 million for facilities capable of producing 100,000-500,000 m² of membrane annually, with economies of scale becoming evident above these production volumes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!