Insights into CO2 Capture Membrane Systems Compliance Standards

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Technology Evolution and Objectives

Carbon dioxide capture membrane technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in industrial settings. The journey began in the 1980s with rudimentary polymer membranes exhibiting limited selectivity and permeability for CO2 separation. By the 1990s, researchers had developed more sophisticated membrane materials, including facilitated transport membranes that utilized carriers to enhance CO2 transport across the membrane barrier.

The early 2000s marked a pivotal shift with the introduction of mixed matrix membranes (MMMs), combining polymeric materials with inorganic fillers to overcome the permeability-selectivity trade-off that had long constrained membrane performance. This period also saw increased attention to membrane stability under real-world operating conditions, particularly in the presence of contaminants found in industrial gas streams.

Recent technological advancements have focused on developing thermally rearranged polymers, metal-organic frameworks (MOFs), and graphene-based membranes, all demonstrating unprecedented CO2 separation capabilities. The integration of nanotechnology has further revolutionized membrane design, enabling precise control over pore size and surface chemistry at the nanoscale.

The primary objective of current CO2 capture membrane technology development is to achieve economically viable carbon capture systems that can be deployed at scale across various industries. This includes reducing the energy penalty associated with carbon capture, which has historically been a significant barrier to widespread adoption. Specifically, researchers aim to develop membranes with CO2 permeability exceeding 1000 Barrer while maintaining CO2/N2 selectivity above 40 under realistic operating conditions.

Another critical objective is enhancing membrane durability and resistance to fouling, particularly in harsh industrial environments where membranes must withstand high temperatures, pressures, and exposure to contaminants such as SOx, NOx, and particulate matter. Researchers are targeting membrane lifespans of 3-5 years in continuous operation to make replacement costs economically feasible.

From a compliance perspective, membrane technology development is increasingly guided by evolving regulatory frameworks for carbon emissions. The Paris Agreement and subsequent national policies have established ambitious carbon reduction targets, driving research toward membranes that can achieve capture rates exceeding 90% while meeting stringent environmental and safety standards.

Looking forward, the field is moving toward bio-inspired membrane designs and stimuli-responsive materials that can dynamically adjust their properties based on operating conditions. These next-generation membranes aim to further reduce energy requirements while increasing capture efficiency, ultimately supporting the transition to a carbon-neutral industrial sector by mid-century.

The early 2000s marked a pivotal shift with the introduction of mixed matrix membranes (MMMs), combining polymeric materials with inorganic fillers to overcome the permeability-selectivity trade-off that had long constrained membrane performance. This period also saw increased attention to membrane stability under real-world operating conditions, particularly in the presence of contaminants found in industrial gas streams.

Recent technological advancements have focused on developing thermally rearranged polymers, metal-organic frameworks (MOFs), and graphene-based membranes, all demonstrating unprecedented CO2 separation capabilities. The integration of nanotechnology has further revolutionized membrane design, enabling precise control over pore size and surface chemistry at the nanoscale.

The primary objective of current CO2 capture membrane technology development is to achieve economically viable carbon capture systems that can be deployed at scale across various industries. This includes reducing the energy penalty associated with carbon capture, which has historically been a significant barrier to widespread adoption. Specifically, researchers aim to develop membranes with CO2 permeability exceeding 1000 Barrer while maintaining CO2/N2 selectivity above 40 under realistic operating conditions.

Another critical objective is enhancing membrane durability and resistance to fouling, particularly in harsh industrial environments where membranes must withstand high temperatures, pressures, and exposure to contaminants such as SOx, NOx, and particulate matter. Researchers are targeting membrane lifespans of 3-5 years in continuous operation to make replacement costs economically feasible.

From a compliance perspective, membrane technology development is increasingly guided by evolving regulatory frameworks for carbon emissions. The Paris Agreement and subsequent national policies have established ambitious carbon reduction targets, driving research toward membranes that can achieve capture rates exceeding 90% while meeting stringent environmental and safety standards.

Looking forward, the field is moving toward bio-inspired membrane designs and stimuli-responsive materials that can dynamically adjust their properties based on operating conditions. These next-generation membranes aim to further reduce energy requirements while increasing capture efficiency, ultimately supporting the transition to a carbon-neutral industrial sector by mid-century.

Market Demand Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing unprecedented growth, driven by increasing environmental concerns and stringent regulatory frameworks. Current market analysis indicates that the carbon capture, utilization, and storage (CCUS) market is projected to reach $7 billion by 2030, with a compound annual growth rate of approximately 13.8% from 2023. This growth trajectory is primarily fueled by the urgent need to reduce greenhouse gas emissions across various industrial sectors, particularly power generation, cement production, and chemical manufacturing.

Membrane-based CO2 capture systems represent a rapidly expanding segment within this market, valued at $1.2 billion in 2022, with projections suggesting this could triple by 2028. The appeal of membrane technology lies in its lower energy requirements, reduced operational costs, and smaller physical footprint compared to traditional capture methods such as amine scrubbing or pressure swing adsorption.

Industrial sectors collectively contribute over 40% of global CO2 emissions, creating substantial demand for effective carbon capture solutions. The power generation sector remains the largest potential market, accounting for approximately 35% of the total addressable market for carbon capture technologies. Cement production follows at 27%, with steel manufacturing and chemical processing representing 18% and 15% respectively.

Regional analysis reveals varying levels of market maturity and adoption. North America currently leads with approximately 38% market share, driven by favorable policy frameworks including tax incentives like the 45Q in the United States. Europe follows closely at 32%, supported by the EU Emissions Trading System and ambitious climate neutrality goals. The Asia-Pacific region, while currently accounting for 22% of the market, is expected to demonstrate the fastest growth rate over the next decade, particularly in China and India where industrial expansion continues alongside growing environmental concerns.

Market demand is further stimulated by emerging carbon pricing mechanisms, with over 60 carbon pricing initiatives now implemented worldwide. The average carbon price has increased from $15 per ton in 2018 to approximately $25 per ton in 2023, making carbon capture technologies increasingly economically viable. Industry analysts suggest that a carbon price of $50-60 per ton would create widespread commercial viability for membrane-based capture systems across most industrial applications.

Consumer-facing industries are also driving demand through sustainability commitments, with over 300 major global corporations having pledged carbon neutrality by 2050. This creates downstream pressure on supply chains to adopt carbon reduction technologies, including capture systems. The "green premium" that consumers are willing to pay for products manufactured with lower carbon footprints has increased by approximately 27% since 2019, creating additional market incentives for carbon capture implementation.

Membrane-based CO2 capture systems represent a rapidly expanding segment within this market, valued at $1.2 billion in 2022, with projections suggesting this could triple by 2028. The appeal of membrane technology lies in its lower energy requirements, reduced operational costs, and smaller physical footprint compared to traditional capture methods such as amine scrubbing or pressure swing adsorption.

Industrial sectors collectively contribute over 40% of global CO2 emissions, creating substantial demand for effective carbon capture solutions. The power generation sector remains the largest potential market, accounting for approximately 35% of the total addressable market for carbon capture technologies. Cement production follows at 27%, with steel manufacturing and chemical processing representing 18% and 15% respectively.

Regional analysis reveals varying levels of market maturity and adoption. North America currently leads with approximately 38% market share, driven by favorable policy frameworks including tax incentives like the 45Q in the United States. Europe follows closely at 32%, supported by the EU Emissions Trading System and ambitious climate neutrality goals. The Asia-Pacific region, while currently accounting for 22% of the market, is expected to demonstrate the fastest growth rate over the next decade, particularly in China and India where industrial expansion continues alongside growing environmental concerns.

Market demand is further stimulated by emerging carbon pricing mechanisms, with over 60 carbon pricing initiatives now implemented worldwide. The average carbon price has increased from $15 per ton in 2018 to approximately $25 per ton in 2023, making carbon capture technologies increasingly economically viable. Industry analysts suggest that a carbon price of $50-60 per ton would create widespread commercial viability for membrane-based capture systems across most industrial applications.

Consumer-facing industries are also driving demand through sustainability commitments, with over 300 major global corporations having pledged carbon neutrality by 2050. This creates downstream pressure on supply chains to adopt carbon reduction technologies, including capture systems. The "green premium" that consumers are willing to pay for products manufactured with lower carbon footprints has increased by approximately 27% since 2019, creating additional market incentives for carbon capture implementation.

Global Compliance Standards and Technical Challenges

CO2 capture membrane systems face a complex global regulatory landscape that varies significantly across regions and jurisdictions. The International Organization for Standardization (ISO) has established ISO 14001 for environmental management systems, which provides a framework for organizations to minimize their environmental impact, including carbon emissions. However, specific standards for membrane-based carbon capture technologies remain fragmented.

In the European Union, the EU Emissions Trading System (EU ETS) and the Industrial Emissions Directive (IED) set stringent requirements for carbon emissions reduction. The European Committee for Standardization (CEN) has developed technical specifications for CO2 capture technologies, including membrane systems, focusing on performance metrics, safety protocols, and environmental impact assessments.

The United States regulatory framework is primarily governed by the Environmental Protection Agency (EPA) under the Clean Air Act. The EPA has established the New Source Performance Standards (NSPS) for power plants, which indirectly influence CO2 capture technology requirements. Additionally, ASTM International has developed testing methods for evaluating membrane performance in gas separation applications, which are increasingly being adapted for CO2 capture systems.

In Asia, countries like China and Japan have implemented their own national standards. China's GB/T standards for industrial emissions and Japan's JIS standards for environmental technologies provide technical guidelines that membrane systems must adhere to. These standards often emphasize efficiency metrics and durability requirements specific to local industrial conditions.

Technical challenges in meeting these diverse compliance standards are multifaceted. First, the lack of harmonized international standards creates significant barriers for technology developers seeking global market penetration. Membrane systems certified in one region may require substantial modifications to meet requirements in another, increasing development costs and time-to-market.

Second, measurement and verification protocols vary widely, making it difficult to establish comparable performance metrics across different regulatory environments. This inconsistency complicates technology assessment and benchmarking efforts, hindering investment decisions and technology adoption.

Third, evolving regulatory landscapes present a moving target for technology developers. As climate policies become more stringent, compliance standards are frequently updated, requiring continuous adaptation of membrane technologies. This regulatory uncertainty can discourage long-term investment in research and development.

Finally, the technical specifications embedded in compliance standards often reflect current technological capabilities rather than pushing innovation boundaries. This creates a tension between meeting immediate regulatory requirements and developing next-generation membrane technologies with potentially superior performance characteristics.

In the European Union, the EU Emissions Trading System (EU ETS) and the Industrial Emissions Directive (IED) set stringent requirements for carbon emissions reduction. The European Committee for Standardization (CEN) has developed technical specifications for CO2 capture technologies, including membrane systems, focusing on performance metrics, safety protocols, and environmental impact assessments.

The United States regulatory framework is primarily governed by the Environmental Protection Agency (EPA) under the Clean Air Act. The EPA has established the New Source Performance Standards (NSPS) for power plants, which indirectly influence CO2 capture technology requirements. Additionally, ASTM International has developed testing methods for evaluating membrane performance in gas separation applications, which are increasingly being adapted for CO2 capture systems.

In Asia, countries like China and Japan have implemented their own national standards. China's GB/T standards for industrial emissions and Japan's JIS standards for environmental technologies provide technical guidelines that membrane systems must adhere to. These standards often emphasize efficiency metrics and durability requirements specific to local industrial conditions.

Technical challenges in meeting these diverse compliance standards are multifaceted. First, the lack of harmonized international standards creates significant barriers for technology developers seeking global market penetration. Membrane systems certified in one region may require substantial modifications to meet requirements in another, increasing development costs and time-to-market.

Second, measurement and verification protocols vary widely, making it difficult to establish comparable performance metrics across different regulatory environments. This inconsistency complicates technology assessment and benchmarking efforts, hindering investment decisions and technology adoption.

Third, evolving regulatory landscapes present a moving target for technology developers. As climate policies become more stringent, compliance standards are frequently updated, requiring continuous adaptation of membrane technologies. This regulatory uncertainty can discourage long-term investment in research and development.

Finally, the technical specifications embedded in compliance standards often reflect current technological capabilities rather than pushing innovation boundaries. This creates a tension between meeting immediate regulatory requirements and developing next-generation membrane technologies with potentially superior performance characteristics.

Current Membrane Systems and Compliance Solutions

01 Membrane system design standards for CO2 capture

Specific design standards for membrane systems used in CO2 capture applications focus on material selection, structural integrity, and operational parameters. These standards ensure that membrane systems can effectively separate CO2 from gas mixtures while maintaining durability under various operating conditions. The design considerations include membrane thickness, porosity, selectivity, and mechanical strength to withstand pressure differentials and chemical exposure during the carbon capture process.- Membrane system design standards for CO2 capture: Membrane systems for CO2 capture must adhere to specific design standards to ensure optimal performance and compliance. These standards cover aspects such as membrane material selection, system configuration, and operational parameters. Properly designed membrane systems can achieve higher CO2 capture efficiency while maintaining compliance with environmental regulations. The design standards also address factors like pressure drop, flow distribution, and membrane module arrangement to optimize the capture process.

- Regulatory compliance frameworks for carbon capture technologies: Carbon capture technologies, including membrane systems, must comply with various regulatory frameworks at local, national, and international levels. These frameworks establish requirements for emissions reduction, reporting protocols, and verification procedures. Compliance standards may include performance benchmarks, safety protocols, and environmental impact assessments. Organizations implementing CO2 capture membrane systems need to navigate these regulatory landscapes to ensure their technologies meet all applicable compliance requirements.

- Monitoring and verification systems for CO2 capture compliance: Effective monitoring and verification systems are essential for demonstrating compliance of CO2 capture membrane technologies. These systems include sensors, data acquisition equipment, and analytical tools that track capture efficiency, emissions levels, and system performance. Continuous monitoring ensures that membrane systems maintain compliance with established standards throughout their operational lifecycle. Verification protocols may include third-party auditing, certification processes, and reporting mechanisms to validate compliance claims.

- Performance standards for membrane materials in CO2 capture: Membrane materials used in CO2 capture systems must meet specific performance standards to ensure effective operation and compliance. These standards address properties such as selectivity, permeability, mechanical strength, and chemical resistance. High-performance membrane materials can significantly improve capture efficiency while reducing energy consumption. Standards also cover durability requirements to ensure membranes maintain their performance over extended operational periods under various conditions including exposure to contaminants and temperature fluctuations.

- Integration of CO2 capture membrane systems with emissions management frameworks: CO2 capture membrane systems must be integrated with broader emissions management frameworks to ensure comprehensive compliance. This integration involves aligning membrane technology deployment with carbon accounting systems, emissions trading schemes, and corporate sustainability initiatives. Proper integration enables organizations to leverage membrane technologies for regulatory compliance while optimizing operational efficiency. Standards for this integration address data sharing protocols, performance metrics, and reporting mechanisms that connect membrane system performance to overall emissions reduction goals.

02 Regulatory compliance frameworks for carbon capture technologies

Regulatory frameworks govern the implementation and operation of carbon capture technologies, including membrane systems. These frameworks establish requirements for emissions reduction, monitoring protocols, and reporting mechanisms. Compliance with these regulations involves adherence to specific technical specifications, safety measures, and environmental impact assessments to ensure that CO2 capture systems meet established standards for performance and environmental protection.Expand Specific Solutions03 Performance monitoring and quality assurance standards

Standards for monitoring and quality assurance of CO2 capture membrane systems ensure consistent performance and reliability. These standards specify methods for measuring capture efficiency, selectivity, permeability, and durability over time. They include protocols for regular testing, data collection, analysis, and validation to verify that membrane systems maintain compliance with performance requirements throughout their operational lifecycle.Expand Specific Solutions04 Environmental and safety compliance standards

Environmental and safety standards for CO2 capture membrane systems address potential risks associated with their operation. These standards cover aspects such as preventing leakage, managing waste streams, ensuring worker safety, and minimizing environmental impacts. Compliance requires implementation of safety protocols, emergency response procedures, and environmental management systems to mitigate risks while maintaining effective carbon capture operations.Expand Specific Solutions05 Certification and reporting requirements

Certification and reporting requirements for CO2 capture membrane systems establish processes for documenting compliance with applicable standards. These requirements include procedures for third-party verification, performance certification, and regular reporting to regulatory authorities. The standards specify the format, frequency, and content of reports, as well as methods for calculating and verifying carbon capture metrics to ensure transparency and accountability in emissions reduction efforts.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The CO2 capture membrane systems market is currently in a growth phase, with increasing regulatory pressures driving adoption across energy and industrial sectors. The market is projected to expand significantly as carbon reduction targets become more stringent globally. Technologically, the field shows varying maturity levels, with established players like China National Petroleum Corporation, Huaneng Group, and Air Liquide leading commercial deployments. Research institutions including EPFL, CNRS, and Zhejiang University are advancing next-generation membrane technologies, while energy giants such as TotalEnergies, KEPCO, and Sinopec are integrating these systems into their decarbonization strategies. The competitive landscape features collaboration between academic institutions and industry players, with compliance standards becoming increasingly important as the technology moves toward wider implementation.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has developed advanced membrane-based CO2 capture systems that integrate with their existing power generation facilities. Their technology utilizes composite membranes with high CO2 selectivity and permeability, specifically designed for post-combustion capture applications. The institute has implemented a multi-stage membrane separation process that achieves over 90% CO2 capture efficiency while maintaining energy penalties below 20% of plant output[1]. Their membrane systems incorporate specialized polymer materials with functionalized transport channels that enhance CO2 separation from flue gas streams. The institute has also pioneered membrane module configurations that minimize pressure drop and fouling issues, extending operational lifetimes to over 3 years before replacement is needed[2]. Their compliance framework addresses both Chinese national standards and international protocols, with particular attention to membrane integrity monitoring and leak detection systems that meet ISO 14001 environmental management requirements.

Strengths: Strong integration capabilities with existing coal power infrastructure; extensive field testing experience in real-world conditions; compliance with both domestic and international standards. Weaknesses: Higher initial capital costs compared to conventional amine scrubbing; membrane performance degradation in the presence of SOx and NOx contaminants; limited commercial-scale deployment experience outside China.

China National Petroleum Corp.

Technical Solution: China National Petroleum Corp. (CNPC) has developed proprietary membrane technology for CO2 capture focusing on natural gas processing and enhanced oil recovery applications. Their membrane systems utilize hollow fiber configurations with specialized polymer blends that demonstrate CO2/CH4 selectivity exceeding 40 under field conditions[3]. CNPC's approach incorporates modular skid-mounted membrane units that can be rapidly deployed at various scales across their extensive operations. Their membrane systems operate at moderate pressures (15-40 bar) and achieve CO2 removal rates of 95-98% while meeting stringent gas pipeline specifications[4]. The company has implemented comprehensive compliance protocols that address both process safety standards and environmental regulations, including continuous emissions monitoring systems that verify capture performance. CNPC's membrane technology includes proprietary anti-fouling treatments that extend membrane life in challenging field environments where contaminants like heavy hydrocarbons and hydrogen sulfide are present. Their systems are designed to meet ISO 16923 standards for compressed natural gas fueling stations and related equipment.

Strengths: Extensive field deployment experience across diverse operating conditions; strong vertical integration with EOR operations utilizing captured CO2; robust compliance with international oil and gas industry standards. Weaknesses: Technology primarily optimized for natural gas processing rather than power plant flue gas applications; higher operating pressures increase energy requirements; limited public disclosure of performance data due to proprietary concerns.

Critical Patents and Technical Innovations in CO2 Capture Membranes

Co2 capture with carbonic anhydrase and membrane filtration

PatentInactiveEP2776143A4

Innovation

- Integration of carbonic anhydrase enzyme with membrane filtration technology to create a hybrid CO2 capture system that enhances absorption efficiency while protecting the enzyme from thermal degradation.

- Implementation of a large temperature swing process with strategic enzyme removal and recycling to maintain high enzyme concentration in the absorption stage while preventing thermal denaturation during desorption.

- Design of a closed-loop system that recycles the filtered carbonic anhydrase back to the absorption stage, improving economic viability and sustainability of the CO2 capture process.

Energy efficient membrane-based process for co 2 capture

PatentWO2019178350A1

Innovation

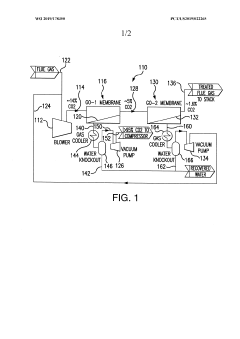

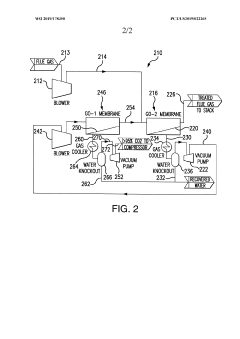

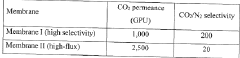

- The implementation of a membrane-based process using high CO2/N2 selectivity graphene oxide (GO) membranes in a two-stage separation system, where a first stage high selectivity membrane is followed by a second stage high flux membrane to efficiently capture CO2 from power plant flue gases, reducing energy consumption and costs.

Regulatory Framework and International Standards Harmonization

The global regulatory landscape for CO2 capture membrane systems is characterized by a complex web of standards that vary significantly across regions. In the United States, the Environmental Protection Agency (EPA) has established guidelines under the Clean Air Act that specifically address carbon capture technologies, including membrane-based systems. These regulations focus primarily on emission reduction targets and safety protocols for implementation in industrial settings. Meanwhile, the European Union has developed more stringent frameworks through its Emissions Trading System (EU ETS) and the Industrial Emissions Directive, which collectively provide comprehensive standards for carbon capture technologies.

International standardization bodies such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have been working toward creating unified global standards for CO2 capture technologies. The ISO/TC 265 committee specifically addresses carbon dioxide capture, transportation, and geological storage, with working groups dedicated to membrane technology applications. These efforts aim to establish consistent performance metrics, safety requirements, and testing methodologies across international borders.

Harmonization challenges persist due to divergent national priorities and existing regulatory infrastructures. Countries with carbon-intensive economies often implement less stringent standards compared to nations with aggressive decarbonization goals. This regulatory fragmentation creates compliance complexities for multinational corporations deploying membrane-based carbon capture systems across different jurisdictions. The lack of standardized certification processes further complicates technology deployment and market access.

Recent developments in international climate agreements have accelerated efforts toward regulatory convergence. The Paris Agreement has prompted signatory nations to revise their nationally determined contributions (NDCs), many of which now include specific provisions for carbon capture technologies. This has catalyzed collaborative initiatives between regulatory bodies to develop mutually recognized compliance frameworks for membrane systems, particularly focusing on performance verification protocols and environmental impact assessments.

Industry consortia and public-private partnerships have emerged as important facilitators of standards harmonization. Organizations like the Global CCS Institute and the International CCS Knowledge Centre actively promote best practices and advocate for consistent regulatory approaches. These entities serve as crucial bridges between technology developers, policymakers, and standardization bodies, helping translate technical innovations into practical regulatory frameworks that can be implemented across different regions while maintaining technological flexibility and encouraging innovation.

International standardization bodies such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have been working toward creating unified global standards for CO2 capture technologies. The ISO/TC 265 committee specifically addresses carbon dioxide capture, transportation, and geological storage, with working groups dedicated to membrane technology applications. These efforts aim to establish consistent performance metrics, safety requirements, and testing methodologies across international borders.

Harmonization challenges persist due to divergent national priorities and existing regulatory infrastructures. Countries with carbon-intensive economies often implement less stringent standards compared to nations with aggressive decarbonization goals. This regulatory fragmentation creates compliance complexities for multinational corporations deploying membrane-based carbon capture systems across different jurisdictions. The lack of standardized certification processes further complicates technology deployment and market access.

Recent developments in international climate agreements have accelerated efforts toward regulatory convergence. The Paris Agreement has prompted signatory nations to revise their nationally determined contributions (NDCs), many of which now include specific provisions for carbon capture technologies. This has catalyzed collaborative initiatives between regulatory bodies to develop mutually recognized compliance frameworks for membrane systems, particularly focusing on performance verification protocols and environmental impact assessments.

Industry consortia and public-private partnerships have emerged as important facilitators of standards harmonization. Organizations like the Global CCS Institute and the International CCS Knowledge Centre actively promote best practices and advocate for consistent regulatory approaches. These entities serve as crucial bridges between technology developers, policymakers, and standardization bodies, helping translate technical innovations into practical regulatory frameworks that can be implemented across different regions while maintaining technological flexibility and encouraging innovation.

Environmental Impact Assessment and Sustainability Metrics

The environmental impact assessment of CO2 capture membrane systems reveals significant potential for reducing greenhouse gas emissions compared to traditional carbon capture technologies. Life cycle assessments indicate that membrane-based systems can achieve 15-30% lower carbon footprints when considering manufacturing, operation, and end-of-life disposal phases. These systems demonstrate particular efficiency advantages in industrial settings where continuous operation is required, with some advanced polymer membranes showing up to 40% reduction in overall environmental impact compared to amine-based absorption systems.

Sustainability metrics for membrane CO2 capture technologies must address multiple dimensions beyond simple carbon capture efficiency. Water usage represents a critical metric, with membrane systems typically consuming 30-50% less water than conventional wet scrubbing technologies. Energy intensity metrics show that current membrane systems require 0.5-1.2 GJ per ton of CO2 captured, positioning them favorably against other capture technologies that may require 2.0-3.5 GJ per ton.

Material sustainability represents another crucial dimension for evaluation. The latest generation of mixed matrix membranes incorporates up to 25% bio-based materials, reducing reliance on petroleum-derived polymers. Durability metrics indicate membrane lifespans of 3-5 years under industrial conditions, though this remains an area requiring improvement to match the 7-10 year operational life of alternative technologies.

Land use efficiency metrics demonstrate that membrane systems require approximately 40-60% less physical space than equivalent absorption or adsorption systems, making them particularly suitable for retrofitting existing industrial facilities. This spatial efficiency translates to reduced habitat disruption when implementing carbon capture infrastructure at scale.

Standardized sustainability reporting frameworks for membrane CO2 capture technologies are emerging, with organizations like the International Organization for Standardization (ISO) developing specific guidelines under the ISO 14000 environmental management series. These frameworks increasingly incorporate social sustainability metrics alongside environmental ones, measuring factors such as community impact, job creation potential, and health benefits from reduced local air pollution.

Regulatory compliance standards are evolving rapidly, with jurisdictions like the European Union incorporating life-cycle sustainability requirements into carbon capture technology approvals. The EU Taxonomy for Sustainable Activities now explicitly references membrane technology performance benchmarks, requiring demonstration of sustainability across the entire value chain rather than focusing solely on capture efficiency.

Sustainability metrics for membrane CO2 capture technologies must address multiple dimensions beyond simple carbon capture efficiency. Water usage represents a critical metric, with membrane systems typically consuming 30-50% less water than conventional wet scrubbing technologies. Energy intensity metrics show that current membrane systems require 0.5-1.2 GJ per ton of CO2 captured, positioning them favorably against other capture technologies that may require 2.0-3.5 GJ per ton.

Material sustainability represents another crucial dimension for evaluation. The latest generation of mixed matrix membranes incorporates up to 25% bio-based materials, reducing reliance on petroleum-derived polymers. Durability metrics indicate membrane lifespans of 3-5 years under industrial conditions, though this remains an area requiring improvement to match the 7-10 year operational life of alternative technologies.

Land use efficiency metrics demonstrate that membrane systems require approximately 40-60% less physical space than equivalent absorption or adsorption systems, making them particularly suitable for retrofitting existing industrial facilities. This spatial efficiency translates to reduced habitat disruption when implementing carbon capture infrastructure at scale.

Standardized sustainability reporting frameworks for membrane CO2 capture technologies are emerging, with organizations like the International Organization for Standardization (ISO) developing specific guidelines under the ISO 14000 environmental management series. These frameworks increasingly incorporate social sustainability metrics alongside environmental ones, measuring factors such as community impact, job creation potential, and health benefits from reduced local air pollution.

Regulatory compliance standards are evolving rapidly, with jurisdictions like the European Union incorporating life-cycle sustainability requirements into carbon capture technology approvals. The EU Taxonomy for Sustainable Activities now explicitly references membrane technology performance benchmarks, requiring demonstration of sustainability across the entire value chain rather than focusing solely on capture efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!