Technical Study of CO2 Capture Membrane Integration in Industries

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Technology Background and Objectives

Carbon dioxide capture and separation technologies have evolved significantly over the past decades, driven by the urgent need to mitigate greenhouse gas emissions and combat climate change. Membrane-based CO2 capture represents one of the most promising approaches due to its energy efficiency, operational simplicity, and potential for cost-effectiveness at scale. The historical development of membrane technology for gas separation began in the 1970s with the commercialization of polymeric membranes, but significant advancements in CO2-selective membranes have only emerged in the last two decades.

The evolution of membrane materials has progressed from conventional polymeric membranes to advanced mixed matrix membranes (MMMs), facilitated transport membranes, and more recently, two-dimensional nanomaterial-based membranes. Each generation has addressed specific limitations of its predecessors, gradually improving selectivity, permeability, and stability under industrial conditions. The technological trajectory clearly indicates a shift toward multifunctional membrane systems that can operate effectively in the harsh environments typical of industrial emissions.

Current research objectives in CO2 capture membrane technology focus on developing membranes with simultaneously high CO2 permeability and CO2/N2 selectivity, while maintaining mechanical and chemical stability under real-world industrial conditions. Specifically, the field aims to achieve membranes with CO2 permeability exceeding 1000 Barrer and CO2/N2 selectivity above 40, which would represent a significant improvement over current commercial options.

Another critical objective is reducing the energy penalty associated with CO2 capture to below 1 GJ/ton CO2, compared to the 3-4 GJ/ton typical of conventional amine scrubbing technologies. This energy reduction is essential for making carbon capture economically viable across various industries, particularly in energy-intensive sectors like cement, steel, and power generation.

The integration of membrane technology into existing industrial infrastructure presents unique challenges that current research aims to address. These include developing modular and retrofittable membrane systems, improving membrane resistance to contaminants present in flue gases (SOx, NOx, particulates), and extending membrane lifetime under continuous operation to 3-5 years minimum.

Looking forward, the field is moving toward hybrid systems that combine membrane separation with other capture technologies to maximize efficiency. The ultimate goal is to develop membrane systems capable of capturing CO2 at costs below $30/ton by 2030, making widespread industrial adoption economically feasible and supporting global decarbonization efforts in line with Paris Agreement targets.

The evolution of membrane materials has progressed from conventional polymeric membranes to advanced mixed matrix membranes (MMMs), facilitated transport membranes, and more recently, two-dimensional nanomaterial-based membranes. Each generation has addressed specific limitations of its predecessors, gradually improving selectivity, permeability, and stability under industrial conditions. The technological trajectory clearly indicates a shift toward multifunctional membrane systems that can operate effectively in the harsh environments typical of industrial emissions.

Current research objectives in CO2 capture membrane technology focus on developing membranes with simultaneously high CO2 permeability and CO2/N2 selectivity, while maintaining mechanical and chemical stability under real-world industrial conditions. Specifically, the field aims to achieve membranes with CO2 permeability exceeding 1000 Barrer and CO2/N2 selectivity above 40, which would represent a significant improvement over current commercial options.

Another critical objective is reducing the energy penalty associated with CO2 capture to below 1 GJ/ton CO2, compared to the 3-4 GJ/ton typical of conventional amine scrubbing technologies. This energy reduction is essential for making carbon capture economically viable across various industries, particularly in energy-intensive sectors like cement, steel, and power generation.

The integration of membrane technology into existing industrial infrastructure presents unique challenges that current research aims to address. These include developing modular and retrofittable membrane systems, improving membrane resistance to contaminants present in flue gases (SOx, NOx, particulates), and extending membrane lifetime under continuous operation to 3-5 years minimum.

Looking forward, the field is moving toward hybrid systems that combine membrane separation with other capture technologies to maximize efficiency. The ultimate goal is to develop membrane systems capable of capturing CO2 at costs below $30/ton by 2030, making widespread industrial adoption economically feasible and supporting global decarbonization efforts in line with Paris Agreement targets.

Industrial Market Demand for Carbon Capture Solutions

The global carbon capture market is experiencing unprecedented growth, driven by increasing regulatory pressures and corporate sustainability commitments. Current market valuations place the carbon capture industry at approximately $2 billion, with projections indicating expansion to $7 billion by 2030. This represents a compound annual growth rate of nearly 15%, significantly outpacing many traditional industrial sectors. The demand is particularly pronounced in heavy emission industries including power generation, cement manufacturing, steel production, and chemical processing, which collectively account for over 60% of global industrial CO2 emissions.

Industrial stakeholders are increasingly recognizing carbon capture not merely as a compliance requirement but as a strategic business imperative. A recent survey of Fortune 500 manufacturing companies revealed that 78% have incorporated carbon reduction technologies into their five-year strategic plans, with membrane-based capture solutions specifically mentioned by 42% of respondents as a priority technology pathway.

The cement industry represents one of the most promising markets for carbon capture membrane technology, as it contributes approximately 8% of global CO2 emissions while facing limited alternative decarbonization options. Similarly, the steel industry, responsible for roughly 7% of global emissions, has demonstrated willingness to invest in capture technologies, with major producers committing over $1.5 billion to carbon reduction initiatives in the past three years.

Regional analysis indicates varying market maturity, with European industries demonstrating the highest adoption rates due to stringent emissions regulations and carbon pricing mechanisms. The European carbon price, currently hovering around €80 per tonne, has created economic incentives that make carbon capture increasingly viable. North American markets show strong growth potential, particularly following recent legislative support through the Inflation Reduction Act, which significantly enhances tax credits for carbon capture implementations.

Customer requirements are evolving beyond simple capture efficiency metrics. Industrial adopters now prioritize solutions offering minimal energy penalties, operational flexibility, and integration capabilities with existing infrastructure. Membrane technologies are particularly valued for their scalability and relatively small physical footprint compared to alternative capture methods.

Market forecasts suggest that industries facing the highest carbon taxes and with the fewest alternative decarbonization options will drive initial adoption. The retrofit market segment is expected to grow at 18% annually through 2028, outpacing new installation implementations, as companies seek to extend the operational life of existing assets while reducing their carbon footprint.

Industrial stakeholders are increasingly recognizing carbon capture not merely as a compliance requirement but as a strategic business imperative. A recent survey of Fortune 500 manufacturing companies revealed that 78% have incorporated carbon reduction technologies into their five-year strategic plans, with membrane-based capture solutions specifically mentioned by 42% of respondents as a priority technology pathway.

The cement industry represents one of the most promising markets for carbon capture membrane technology, as it contributes approximately 8% of global CO2 emissions while facing limited alternative decarbonization options. Similarly, the steel industry, responsible for roughly 7% of global emissions, has demonstrated willingness to invest in capture technologies, with major producers committing over $1.5 billion to carbon reduction initiatives in the past three years.

Regional analysis indicates varying market maturity, with European industries demonstrating the highest adoption rates due to stringent emissions regulations and carbon pricing mechanisms. The European carbon price, currently hovering around €80 per tonne, has created economic incentives that make carbon capture increasingly viable. North American markets show strong growth potential, particularly following recent legislative support through the Inflation Reduction Act, which significantly enhances tax credits for carbon capture implementations.

Customer requirements are evolving beyond simple capture efficiency metrics. Industrial adopters now prioritize solutions offering minimal energy penalties, operational flexibility, and integration capabilities with existing infrastructure. Membrane technologies are particularly valued for their scalability and relatively small physical footprint compared to alternative capture methods.

Market forecasts suggest that industries facing the highest carbon taxes and with the fewest alternative decarbonization options will drive initial adoption. The retrofit market segment is expected to grow at 18% annually through 2028, outpacing new installation implementations, as companies seek to extend the operational life of existing assets while reducing their carbon footprint.

Current Membrane Technology Status and Barriers

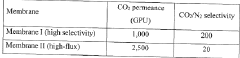

Membrane technology for CO2 capture has evolved significantly over the past two decades, with current commercial membranes achieving CO2 permeance of 1,000-3,000 GPU and CO2/N2 selectivity of 20-50. Despite these advances, widespread industrial implementation remains limited due to several persistent barriers.

The primary technical challenge facing membrane technology is the inherent trade-off between permeability and selectivity. High-performance membranes struggle to maintain selectivity when permeability is increased, limiting overall capture efficiency. This fundamental limitation has proven difficult to overcome despite extensive research into novel materials.

Material stability presents another significant barrier, particularly in industrial environments with harsh conditions. Membrane performance often degrades when exposed to high temperatures, acidic gases (SOx, NOx), particulate matter, and water vapor commonly found in flue gas streams. Current polymeric membranes typically operate optimally below 100°C, restricting their application in high-temperature industrial processes.

Scaling membrane systems for large industrial applications introduces additional complications. The massive gas volumes in power plants and industrial facilities require enormous membrane surface areas, creating challenges in module design, pressure drop management, and uniform flow distribution. Current manufacturing capabilities struggle to produce consistent, defect-free membranes at the scale required for major industrial applications.

Economic barriers further impede adoption, with membrane systems facing high capital costs (approximately $40-60 per m² of membrane area) and significant operational expenses related to compression requirements. The energy penalty associated with creating the necessary pressure differential across membranes can consume 15-25% of a plant's output, undermining the technology's sustainability benefits.

The competitive landscape presents additional challenges, as established CO2 capture technologies like amine scrubbing benefit from decades of optimization and industry familiarity. Membrane technology must demonstrate clear advantages in efficiency, cost, or environmental impact to displace these incumbent solutions.

Regulatory uncertainty regarding carbon pricing and emissions standards creates market hesitancy, as potential adopters struggle to justify investment without clear policy frameworks. This uncertainty has slowed research funding and commercial deployment of membrane technologies across various industries.

Integration challenges with existing industrial infrastructure represent a final significant barrier. Retrofitting membrane systems into established plants requires careful engineering to address space constraints, process interruptions, and compatibility with existing systems. The lack of standardized designs and limited real-world implementation examples further complicates integration planning and risk assessment.

The primary technical challenge facing membrane technology is the inherent trade-off between permeability and selectivity. High-performance membranes struggle to maintain selectivity when permeability is increased, limiting overall capture efficiency. This fundamental limitation has proven difficult to overcome despite extensive research into novel materials.

Material stability presents another significant barrier, particularly in industrial environments with harsh conditions. Membrane performance often degrades when exposed to high temperatures, acidic gases (SOx, NOx), particulate matter, and water vapor commonly found in flue gas streams. Current polymeric membranes typically operate optimally below 100°C, restricting their application in high-temperature industrial processes.

Scaling membrane systems for large industrial applications introduces additional complications. The massive gas volumes in power plants and industrial facilities require enormous membrane surface areas, creating challenges in module design, pressure drop management, and uniform flow distribution. Current manufacturing capabilities struggle to produce consistent, defect-free membranes at the scale required for major industrial applications.

Economic barriers further impede adoption, with membrane systems facing high capital costs (approximately $40-60 per m² of membrane area) and significant operational expenses related to compression requirements. The energy penalty associated with creating the necessary pressure differential across membranes can consume 15-25% of a plant's output, undermining the technology's sustainability benefits.

The competitive landscape presents additional challenges, as established CO2 capture technologies like amine scrubbing benefit from decades of optimization and industry familiarity. Membrane technology must demonstrate clear advantages in efficiency, cost, or environmental impact to displace these incumbent solutions.

Regulatory uncertainty regarding carbon pricing and emissions standards creates market hesitancy, as potential adopters struggle to justify investment without clear policy frameworks. This uncertainty has slowed research funding and commercial deployment of membrane technologies across various industries.

Integration challenges with existing industrial infrastructure represent a final significant barrier. Retrofitting membrane systems into established plants requires careful engineering to address space constraints, process interruptions, and compatibility with existing systems. The lack of standardized designs and limited real-world implementation examples further complicates integration planning and risk assessment.

Current Industrial Integration Solutions for CO2 Capture Membranes

01 Polymer-based membranes for CO2 capture

Polymer-based membranes are widely used for CO2 capture due to their versatility and processability. These membranes can be engineered with specific functional groups that enhance CO2 selectivity and permeability. Various polymers such as polyimides, polysulfones, and facilitated transport membranes incorporate amine groups or other CO2-philic moieties to improve capture efficiency. The polymer structure can be modified to create optimal free volume and gas diffusion pathways, balancing selectivity and permeability for effective carbon capture applications.- Polymer-based membranes for CO2 capture: Polymer-based membranes are widely used for CO2 capture due to their versatility and tunable properties. These membranes can be designed with specific functional groups that enhance CO2 selectivity and permeability. Various polymers such as polyimides, polysulfones, and polyethylene oxide derivatives are employed in these membranes. The polymer structure can be modified to create free volume elements that facilitate CO2 transport while blocking larger gas molecules, resulting in improved separation performance.

- Mixed matrix membranes incorporating fillers: Mixed matrix membranes combine polymeric materials with inorganic fillers to enhance CO2 capture performance. These fillers include metal-organic frameworks (MOFs), zeolites, silica, and carbon-based materials that create preferential pathways for CO2 transport. The incorporation of these fillers can significantly improve membrane selectivity, permeability, and mechanical stability. The interface between the polymer matrix and fillers plays a crucial role in determining the overall performance of these membranes for carbon dioxide separation.

- Facilitated transport membranes: Facilitated transport membranes contain carriers or functional groups that reversibly react with CO2, enhancing its transport across the membrane. These membranes typically incorporate amine groups, carbonate salts, or other CO2-philic moieties that form complexes with carbon dioxide molecules. The carrier-mediated transport mechanism allows these membranes to achieve high CO2 selectivity over other gases like nitrogen and methane. The performance of facilitated transport membranes can be optimized by controlling the carrier concentration, membrane thickness, and operating conditions.

- Hollow fiber and thin-film composite membranes: Hollow fiber and thin-film composite membrane configurations are designed to maximize the surface area available for CO2 capture while minimizing material usage. Hollow fiber membranes consist of small tubular structures with high packing density, while thin-film composite membranes feature an ultrathin selective layer supported on a porous substrate. These configurations enhance mass transfer efficiency and reduce the overall footprint of membrane separation systems. The structural parameters of these membranes, such as fiber diameter, wall thickness, and selective layer composition, can be optimized for specific CO2 capture applications.

- Membrane system integration and process optimization: Effective CO2 capture requires proper integration of membrane systems into existing processes and optimization of operating parameters. This includes multi-stage membrane configurations, hybrid systems combining membranes with other capture technologies, and process control strategies to handle variations in feed composition and flow rates. Membrane modules can be arranged in series or parallel to achieve desired separation performance. Additionally, pre-treatment of feed gas, temperature and pressure management, and prevention of membrane fouling are critical aspects of system design that impact the overall efficiency and economics of membrane-based CO2 capture.

02 Mixed matrix membranes with fillers for enhanced performance

Mixed matrix membranes combine polymeric materials with inorganic or organic fillers to enhance CO2 capture performance. These fillers include metal-organic frameworks (MOFs), zeolites, silica, and carbon-based materials that create preferential pathways for CO2 transport while blocking other gases. The incorporation of these fillers improves membrane selectivity, permeability, and mechanical stability. The synergistic effect between the polymer matrix and fillers results in membranes with superior separation properties compared to conventional polymer membranes, making them promising for industrial carbon capture applications.Expand Specific Solutions03 Facilitated transport membranes with CO2 carriers

Facilitated transport membranes incorporate specific carrier molecules that reversibly react with CO2, enhancing selectivity and transport rates. These carriers, such as amines, carbonate salts, or ionic liquids, form complexes with CO2 molecules, facilitating their transport across the membrane while rejecting other gases. The carrier-mediated transport mechanism allows these membranes to overcome the traditional permeability-selectivity trade-off. The membranes can be designed with fixed or mobile carriers, with the latter providing higher CO2 flux but potentially suffering from carrier leaching issues during long-term operation.Expand Specific Solutions04 Membrane module design and system integration

The design of membrane modules and their integration into capture systems significantly impacts CO2 separation efficiency. Various module configurations, including spiral-wound, hollow fiber, and flat sheet designs, offer different advantages in terms of packing density, pressure drop, and fouling resistance. System integration aspects include multi-stage membrane arrangements, hybrid systems combining membranes with other capture technologies, and process optimization to handle varying feed compositions and flow rates. Proper module design and system integration are crucial for scaling up membrane-based CO2 capture technology for industrial applications.Expand Specific Solutions05 Membrane stability and fouling resistance

Enhancing membrane stability and fouling resistance is critical for long-term CO2 capture performance. Membranes must withstand harsh operating conditions including high temperatures, pressures, and the presence of contaminants in flue gas streams. Various approaches to improve stability include crosslinking of polymer chains, incorporation of thermally stable materials, and surface modifications to prevent plasticization. Anti-fouling strategies involve the development of hydrophilic or hydrophobic surface treatments, incorporation of antimicrobial agents, and design of self-cleaning membrane surfaces to maintain separation performance over extended periods of operation.Expand Specific Solutions

Leading Companies and Research Institutions in Membrane-Based Carbon Capture

The CO2 capture membrane integration market is currently in a growth phase, with increasing global focus on carbon reduction technologies. The market size is expanding rapidly, driven by industrial decarbonization initiatives and stringent environmental regulations. From a technological maturity perspective, the landscape shows varied development stages across key players. Companies like Membrane Technology & Research and Sinopec Guangzhou Engineering are leading with commercial-ready solutions, while research institutions such as Tianjin University, EPFL, and Arizona State University are advancing fundamental membrane technologies. Chinese energy giants (Sinopec, CHN Energy) and Korean utilities (KEPCO, Korea Western Power) are strategically investing in membrane integration for their industrial facilities, indicating growing industry adoption. The competitive landscape reflects a blend of established energy corporations, specialized technology providers, and academic research centers collaborating to overcome implementation challenges.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive CO2 capture membrane integration system focused on petroleum refining and petrochemical applications. Their technology employs composite hollow fiber membranes with a thin selective layer of polyimide or polysulfone materials on porous supports. The system operates in a multi-stage configuration to achieve both high purity and recovery rates. Sinopec's approach integrates membrane units directly with existing process streams, particularly targeting high-pressure, high-CO2-concentration sources within refineries. Their membrane modules are designed to withstand harsh industrial conditions, including resistance to hydrocarbon contaminants and sulfur compounds common in refinery environments. The company has implemented this technology at several of their refineries, demonstrating CO2 capture rates of 85-95% with captured CO2 being utilized for enhanced oil recovery operations. The system includes specialized pre-treatment to remove particulates and condensable hydrocarbons that could damage membrane surfaces.

Strengths: Highly resistant to hydrocarbon and sulfur contaminants; integration expertise with existing refinery infrastructure; established CO2 utilization pathways through company's oil production operations; and significant scale-up experience. Weaknesses: Higher capital costs compared to some competing technologies; membranes require periodic replacement; and system optimization still needed for lower-concentration CO2 streams.

Membrane Technology & Research, Inc.

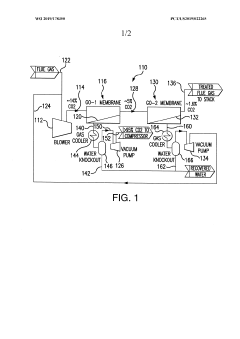

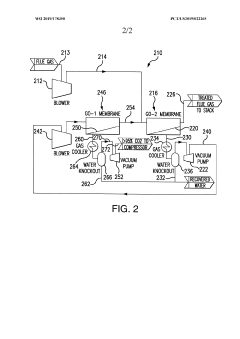

Technical Solution: MTR has developed advanced polymeric membranes specifically designed for CO2 capture from industrial flue gases. Their proprietary Polaris™ membrane technology utilizes selective polymer materials that allow CO2 to permeate while blocking other gases. The system employs a two-stage membrane process: the first stage captures CO2 from flue gas, while the second stage further concentrates it to over 95% purity suitable for sequestration or utilization. MTR's membrane modules are packaged in spiral-wound configurations that maximize surface area while minimizing footprint. Their integrated systems include pre-treatment units to remove particulates and cool gas streams to optimal operating temperatures (typically 30-60°C). The technology has been demonstrated at pilot scale (capturing 20-50 tonnes CO2/day) at coal-fired power plants and cement facilities, showing capture rates of 90% with significantly lower energy penalties compared to conventional amine scrubbing.

Strengths: Lower energy consumption (30-40% less than amine systems); modular design allowing scalability and retrofitting to existing plants; no toxic chemicals required; minimal water usage; and operational simplicity with few moving parts. Weaknesses: Performance can degrade in the presence of certain contaminants; membrane replacement costs over time; and potential pressure drop issues requiring additional compression energy.

Key Patents and Technical Innovations in CO2 Separation Membranes

Energy integrated type high-temperature carbon dioxide trapping and in-situ conversion device and method

PatentPendingCN119869210A

Innovation

- An energy-integrated high-temperature carbon dioxide capture and in-situ conversion device is designed. By setting a bed of catalytic material and a steam coil in the reactor, the heat released from the reaction process is used to recover the heat released by the reaction process and regenerate the catalytic material in the regenerator to achieve efficient capture and in-situ conversion of carbon dioxide.

Energy efficient membrane-based process for co 2 capture

PatentWO2019178350A1

Innovation

- The implementation of a membrane-based process using high CO2/N2 selectivity graphene oxide (GO) membranes in a two-stage separation system, where a first stage high selectivity membrane is followed by a second stage high flux membrane to efficiently capture CO2 from power plant flue gases, reducing energy consumption and costs.

Economic Feasibility and Cost Analysis of Membrane-Based Carbon Capture

The economic viability of membrane-based carbon capture technologies represents a critical factor in their industrial adoption. Current cost analyses indicate that membrane systems offer capital expenditure advantages compared to traditional amine-based absorption technologies, with initial installation costs approximately 15-30% lower depending on scale and application context. However, these capital savings must be evaluated against operational considerations that impact long-term economic performance.

Operational expenditure analysis reveals that membrane systems typically consume 0.5-0.8 GJ/tonne CO2 captured, representing a significant energy efficiency improvement over first-generation amine systems (3.0-4.2 GJ/tonne CO2). This translates to potential operational cost savings of 30-45% in energy-intensive industries. Nevertheless, membrane replacement costs—occurring every 3-5 years depending on operating conditions—must be factored into long-term financial models.

Sensitivity analyses demonstrate that membrane technology economics are particularly responsive to three key variables: membrane selectivity, permeability, and manufacturing costs. Recent advances in material science have improved the performance-cost ratio, with next-generation membranes showing 40% higher CO2/N2 selectivity at comparable production costs. Industry projections suggest further cost reductions of 15-25% are achievable within the next five years through manufacturing scale economies and material innovations.

Integration costs vary significantly across industrial sectors. Cement production facilities face integration costs of $50-80 per tonne of annual CO2 capture capacity, while steel production and power generation sectors experience costs of $65-95 and $70-110 respectively. These variations stem from differences in flue gas composition, space constraints, and existing infrastructure compatibility.

Levelized cost of carbon capture (LCCC) calculations indicate current membrane systems achieve $40-65 per tonne CO2 captured, positioning them competitively against alternative capture technologies. However, this metric remains above carbon pricing in most jurisdictions, highlighting the continued need for policy support mechanisms to bridge the economic gap.

Return on investment timelines currently range from 7-12 years for most industrial applications, with significant variation based on regional energy prices, carbon pricing mechanisms, and available subsidies. Financial modeling suggests that achieving ROI periods below 5 years—generally considered the industrial adoption threshold—requires either carbon prices exceeding $70/tonne or further technological improvements reducing capture costs by approximately 30%.

Operational expenditure analysis reveals that membrane systems typically consume 0.5-0.8 GJ/tonne CO2 captured, representing a significant energy efficiency improvement over first-generation amine systems (3.0-4.2 GJ/tonne CO2). This translates to potential operational cost savings of 30-45% in energy-intensive industries. Nevertheless, membrane replacement costs—occurring every 3-5 years depending on operating conditions—must be factored into long-term financial models.

Sensitivity analyses demonstrate that membrane technology economics are particularly responsive to three key variables: membrane selectivity, permeability, and manufacturing costs. Recent advances in material science have improved the performance-cost ratio, with next-generation membranes showing 40% higher CO2/N2 selectivity at comparable production costs. Industry projections suggest further cost reductions of 15-25% are achievable within the next five years through manufacturing scale economies and material innovations.

Integration costs vary significantly across industrial sectors. Cement production facilities face integration costs of $50-80 per tonne of annual CO2 capture capacity, while steel production and power generation sectors experience costs of $65-95 and $70-110 respectively. These variations stem from differences in flue gas composition, space constraints, and existing infrastructure compatibility.

Levelized cost of carbon capture (LCCC) calculations indicate current membrane systems achieve $40-65 per tonne CO2 captured, positioning them competitively against alternative capture technologies. However, this metric remains above carbon pricing in most jurisdictions, highlighting the continued need for policy support mechanisms to bridge the economic gap.

Return on investment timelines currently range from 7-12 years for most industrial applications, with significant variation based on regional energy prices, carbon pricing mechanisms, and available subsidies. Financial modeling suggests that achieving ROI periods below 5 years—generally considered the industrial adoption threshold—requires either carbon prices exceeding $70/tonne or further technological improvements reducing capture costs by approximately 30%.

Environmental Impact and Sustainability Assessment of Membrane Technologies

The integration of CO2 capture membrane technologies in industrial processes represents a significant advancement in sustainable development practices. These technologies offer substantial environmental benefits compared to conventional carbon capture methods, primarily through reduced energy consumption and minimized chemical usage. Life cycle assessments indicate that membrane-based systems can achieve up to 30% lower carbon footprints than amine scrubbing when evaluated across their entire operational lifespan.

Water conservation emerges as another critical environmental advantage of membrane technologies. Traditional carbon capture systems typically consume 0.7-2.5 liters of water per kilogram of CO2 captured, while advanced membrane systems require only 0.2-0.5 liters, representing a significant reduction in water footprint for water-stressed regions where industrial facilities operate.

Land use efficiency also favors membrane technologies, which generally require 40-60% less physical space than equivalent absorption column installations. This compact footprint makes membrane systems particularly valuable for retrofitting existing industrial facilities where space constraints often present significant challenges for carbon capture implementation.

From a materials sustainability perspective, modern CO2 capture membranes increasingly incorporate bio-based polymers and environmentally benign materials. Recent innovations include membranes manufactured using up to 35% recycled or renewable materials, significantly reducing their embodied carbon and environmental impact during production phases.

Waste generation represents another dimension where membrane technologies demonstrate superior environmental performance. Unlike solvent-based systems that generate hazardous waste streams requiring specialized disposal, membrane systems produce minimal secondary waste. The primary waste consists of spent membrane modules, many of which can now be recycled through specialized polymer recovery programs.

Long-term environmental resilience must also be considered when evaluating these technologies. Membrane systems demonstrate remarkable adaptability to changing industrial conditions and can be scaled incrementally as carbon reduction targets become more stringent. This adaptability ensures continued environmental benefits even as regulatory frameworks evolve.

When integrated into comprehensive industrial sustainability strategies, CO2 capture membranes contribute to multiple environmental objectives simultaneously. Beyond direct carbon reduction, these systems support broader industrial ecology principles by enabling carbon utilization pathways and promoting circular economy approaches to carbon management across industrial value chains.

Water conservation emerges as another critical environmental advantage of membrane technologies. Traditional carbon capture systems typically consume 0.7-2.5 liters of water per kilogram of CO2 captured, while advanced membrane systems require only 0.2-0.5 liters, representing a significant reduction in water footprint for water-stressed regions where industrial facilities operate.

Land use efficiency also favors membrane technologies, which generally require 40-60% less physical space than equivalent absorption column installations. This compact footprint makes membrane systems particularly valuable for retrofitting existing industrial facilities where space constraints often present significant challenges for carbon capture implementation.

From a materials sustainability perspective, modern CO2 capture membranes increasingly incorporate bio-based polymers and environmentally benign materials. Recent innovations include membranes manufactured using up to 35% recycled or renewable materials, significantly reducing their embodied carbon and environmental impact during production phases.

Waste generation represents another dimension where membrane technologies demonstrate superior environmental performance. Unlike solvent-based systems that generate hazardous waste streams requiring specialized disposal, membrane systems produce minimal secondary waste. The primary waste consists of spent membrane modules, many of which can now be recycled through specialized polymer recovery programs.

Long-term environmental resilience must also be considered when evaluating these technologies. Membrane systems demonstrate remarkable adaptability to changing industrial conditions and can be scaled incrementally as carbon reduction targets become more stringent. This adaptability ensures continued environmental benefits even as regulatory frameworks evolve.

When integrated into comprehensive industrial sustainability strategies, CO2 capture membranes contribute to multiple environmental objectives simultaneously. Beyond direct carbon reduction, these systems support broader industrial ecology principles by enabling carbon utilization pathways and promoting circular economy approaches to carbon management across industrial value chains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!