Evaluation of CO2 Capture Membrane Technologies in Electronic Vehicles

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Evolution and Objectives

Carbon dioxide capture technology has evolved significantly over the past decades, transitioning from industrial applications to potential integration in transportation systems. The development of CO2 capture membranes began in the 1980s with rudimentary polymer-based designs primarily used in natural gas purification. By the early 2000s, research expanded into mixed matrix membranes (MMMs) that combined polymers with inorganic fillers to enhance separation performance and durability.

The evolution accelerated in the 2010s with the emergence of advanced materials such as metal-organic frameworks (MOFs), zeolitic imidazolate frameworks (ZIFs), and graphene-based membranes, which demonstrated superior CO2 selectivity and permeability. This period marked a critical shift from stationary industrial applications toward more compact, lightweight designs suitable for mobile platforms.

Recent technological advancements have focused on developing membranes specifically tailored for vehicular applications, with emphasis on space efficiency, weight reduction, and operation under variable conditions. The miniaturization of membrane modules and the development of hollow fiber configurations represent significant milestones in adapting this technology for electronic vehicles (EVs).

The primary objective of CO2 capture membrane technology in EVs is to create closed-loop carbon systems that can capture emissions from auxiliary power units or range extenders in hybrid electric vehicles. Secondary objectives include improving air quality within the cabin space and potentially utilizing captured CO2 for other vehicle functions or storage until disposal.

Technical goals for these membrane systems include achieving CO2 capture efficiency exceeding 90% while maintaining energy consumption below 0.5 kWh per kg of CO2 captured. Size constraints dictate that the entire system must occupy less than 5% of the vehicle's cargo space, with a weight contribution under 3% of the vehicle's total mass.

Long-term objectives extend to developing self-regenerating membrane systems that can operate continuously without frequent maintenance, with operational lifespans matching or exceeding typical vehicle lifetimes (10-15 years). Research is also directed toward membranes that can function effectively across the wide temperature ranges experienced in automotive environments (-30°C to 80°C).

The trajectory of membrane technology development suggests potential convergence with other vehicle systems, such as integration with HVAC systems or battery thermal management, creating multifunctional components that serve both carbon capture and other vehicular needs. This holistic approach aligns with broader sustainability goals in the automotive industry and represents the next frontier in EV environmental technology.

The evolution accelerated in the 2010s with the emergence of advanced materials such as metal-organic frameworks (MOFs), zeolitic imidazolate frameworks (ZIFs), and graphene-based membranes, which demonstrated superior CO2 selectivity and permeability. This period marked a critical shift from stationary industrial applications toward more compact, lightweight designs suitable for mobile platforms.

Recent technological advancements have focused on developing membranes specifically tailored for vehicular applications, with emphasis on space efficiency, weight reduction, and operation under variable conditions. The miniaturization of membrane modules and the development of hollow fiber configurations represent significant milestones in adapting this technology for electronic vehicles (EVs).

The primary objective of CO2 capture membrane technology in EVs is to create closed-loop carbon systems that can capture emissions from auxiliary power units or range extenders in hybrid electric vehicles. Secondary objectives include improving air quality within the cabin space and potentially utilizing captured CO2 for other vehicle functions or storage until disposal.

Technical goals for these membrane systems include achieving CO2 capture efficiency exceeding 90% while maintaining energy consumption below 0.5 kWh per kg of CO2 captured. Size constraints dictate that the entire system must occupy less than 5% of the vehicle's cargo space, with a weight contribution under 3% of the vehicle's total mass.

Long-term objectives extend to developing self-regenerating membrane systems that can operate continuously without frequent maintenance, with operational lifespans matching or exceeding typical vehicle lifetimes (10-15 years). Research is also directed toward membranes that can function effectively across the wide temperature ranges experienced in automotive environments (-30°C to 80°C).

The trajectory of membrane technology development suggests potential convergence with other vehicle systems, such as integration with HVAC systems or battery thermal management, creating multifunctional components that serve both carbon capture and other vehicular needs. This holistic approach aligns with broader sustainability goals in the automotive industry and represents the next frontier in EV environmental technology.

EV Market Demand for CO2 Capture Solutions

The electric vehicle (EV) market is experiencing unprecedented growth globally, creating a significant demand for innovative solutions that address environmental concerns while enhancing vehicle performance. CO2 capture technologies represent an emerging area of interest for EV manufacturers seeking to further reduce their carbon footprint and create truly sustainable transportation options. Market research indicates that consumer awareness regarding carbon emissions has increased substantially, with 78% of potential EV buyers citing environmental impact as a key purchasing consideration.

Within the EV ecosystem, there are several distinct market segments driving demand for CO2 capture solutions. Premium electric vehicle manufacturers are particularly interested in these technologies as differentiating features that can justify higher price points and appeal to environmentally conscious luxury consumers. Commercial fleet operators represent another significant market segment, as they face increasing regulatory pressure to reduce emissions across their operations and can benefit from the operational cost savings that might accompany carbon capture systems.

Market forecasts suggest that the global EV market will reach 26.9 million units annually by 2030, with a compound annual growth rate of approximately 21%. This rapid expansion creates a substantial addressable market for CO2 capture technologies. Geographic distribution of demand shows particular strength in regions with stringent emissions regulations, including the European Union, parts of North America, and developed Asian markets like Japan and South Korea.

Consumer surveys reveal that EV owners demonstrate higher willingness to pay for environmental technologies compared to conventional vehicle owners. This trend is particularly pronounced among younger demographics and urban professionals, who represent core EV consumer segments. Market analysis indicates potential premium pricing opportunities of 5-10% for vehicles incorporating effective carbon capture capabilities.

Industry stakeholders, including automotive OEMs, tier-one suppliers, and technology startups, are increasingly exploring partnerships to develop and commercialize CO2 capture solutions. This collaborative approach reflects the cross-disciplinary nature of the technology and the shared interest in addressing climate challenges. Venture capital investment in automotive sustainability technologies has grown significantly, with funding for carbon capture specifically increasing by 43% in the past two years.

Regulatory trends further support market development, with several jurisdictions implementing or considering carbon pricing mechanisms that would enhance the economic case for onboard capture systems. Additionally, corporate sustainability commitments from major automotive players have established concrete carbon reduction targets that will require technological innovations beyond electrification alone.

Within the EV ecosystem, there are several distinct market segments driving demand for CO2 capture solutions. Premium electric vehicle manufacturers are particularly interested in these technologies as differentiating features that can justify higher price points and appeal to environmentally conscious luxury consumers. Commercial fleet operators represent another significant market segment, as they face increasing regulatory pressure to reduce emissions across their operations and can benefit from the operational cost savings that might accompany carbon capture systems.

Market forecasts suggest that the global EV market will reach 26.9 million units annually by 2030, with a compound annual growth rate of approximately 21%. This rapid expansion creates a substantial addressable market for CO2 capture technologies. Geographic distribution of demand shows particular strength in regions with stringent emissions regulations, including the European Union, parts of North America, and developed Asian markets like Japan and South Korea.

Consumer surveys reveal that EV owners demonstrate higher willingness to pay for environmental technologies compared to conventional vehicle owners. This trend is particularly pronounced among younger demographics and urban professionals, who represent core EV consumer segments. Market analysis indicates potential premium pricing opportunities of 5-10% for vehicles incorporating effective carbon capture capabilities.

Industry stakeholders, including automotive OEMs, tier-one suppliers, and technology startups, are increasingly exploring partnerships to develop and commercialize CO2 capture solutions. This collaborative approach reflects the cross-disciplinary nature of the technology and the shared interest in addressing climate challenges. Venture capital investment in automotive sustainability technologies has grown significantly, with funding for carbon capture specifically increasing by 43% in the past two years.

Regulatory trends further support market development, with several jurisdictions implementing or considering carbon pricing mechanisms that would enhance the economic case for onboard capture systems. Additionally, corporate sustainability commitments from major automotive players have established concrete carbon reduction targets that will require technological innovations beyond electrification alone.

Global Status and Barriers in Membrane Technology

Membrane technology for CO2 capture has gained significant traction globally, with research centers across North America, Europe, and Asia making substantial advancements. The United States leads with institutions like the National Energy Technology Laboratory and Lawrence Berkeley National Laboratory focusing on high-performance membrane development. European research is concentrated in Germany, the Netherlands, and the UK, where emphasis is placed on integrating membranes with existing industrial processes.

In Asia, Japan and China have emerged as key players, with Japanese research focusing on novel materials and Chinese efforts directed toward cost-effective manufacturing at scale. Recent global investments in membrane technology have exceeded $2.5 billion, reflecting growing recognition of its potential for carbon capture applications.

Despite these advancements, several critical barriers impede widespread adoption of membrane technology for CO2 capture in electronic vehicles. Material limitations represent the primary challenge, as current membranes struggle to maintain selectivity and permeability under the variable temperature and pressure conditions typical in vehicle operations. Most membranes exhibit a performance trade-off: higher selectivity typically results in lower permeability and vice versa.

Durability presents another significant barrier. Vehicle-based applications require membranes to withstand vibration, thermal cycling, and potential exposure to contaminants from exhaust gases. Current membrane technologies often demonstrate performance degradation after 1,000-2,000 hours of operation, falling short of the 5,000+ hours required for practical automotive applications.

Scale and integration challenges further complicate implementation. The compact nature of electronic vehicle systems demands miniaturized membrane modules that can be effectively integrated without compromising vehicle design or performance. Current manufacturing techniques struggle to produce membranes with consistent properties at the required scale and form factor.

Economic barriers also remain substantial. Production costs for high-performance membranes range from $50-200 per square meter, significantly higher than the $20-30 target needed for commercial viability in automotive applications. This cost gap is exacerbated by the specialized materials and precision manufacturing processes required.

Regulatory frameworks present additional complications, with varying emissions standards across global markets creating uncertainty for technology developers. The absence of standardized testing protocols specifically for vehicle-based membrane CO2 capture systems further hinders comparative evaluation and certification processes.

In Asia, Japan and China have emerged as key players, with Japanese research focusing on novel materials and Chinese efforts directed toward cost-effective manufacturing at scale. Recent global investments in membrane technology have exceeded $2.5 billion, reflecting growing recognition of its potential for carbon capture applications.

Despite these advancements, several critical barriers impede widespread adoption of membrane technology for CO2 capture in electronic vehicles. Material limitations represent the primary challenge, as current membranes struggle to maintain selectivity and permeability under the variable temperature and pressure conditions typical in vehicle operations. Most membranes exhibit a performance trade-off: higher selectivity typically results in lower permeability and vice versa.

Durability presents another significant barrier. Vehicle-based applications require membranes to withstand vibration, thermal cycling, and potential exposure to contaminants from exhaust gases. Current membrane technologies often demonstrate performance degradation after 1,000-2,000 hours of operation, falling short of the 5,000+ hours required for practical automotive applications.

Scale and integration challenges further complicate implementation. The compact nature of electronic vehicle systems demands miniaturized membrane modules that can be effectively integrated without compromising vehicle design or performance. Current manufacturing techniques struggle to produce membranes with consistent properties at the required scale and form factor.

Economic barriers also remain substantial. Production costs for high-performance membranes range from $50-200 per square meter, significantly higher than the $20-30 target needed for commercial viability in automotive applications. This cost gap is exacerbated by the specialized materials and precision manufacturing processes required.

Regulatory frameworks present additional complications, with varying emissions standards across global markets creating uncertainty for technology developers. The absence of standardized testing protocols specifically for vehicle-based membrane CO2 capture systems further hinders comparative evaluation and certification processes.

Current Membrane Solutions for EVs

01 Polymer-based membranes for CO2 capture

Polymer-based membranes are widely used for CO2 capture due to their versatility and cost-effectiveness. These membranes can be engineered with specific functional groups that enhance CO2 selectivity and permeability. Various polymers such as polyimides, polysulfones, and polyethylene oxide derivatives are utilized to create membranes with high CO2/N2 selectivity. The performance of these membranes can be further improved by incorporating fillers or modifying the polymer structure to create mixed matrix membranes with enhanced gas separation properties.- Polymer-based membranes for CO2 capture: Polymer-based membranes are widely used for CO2 capture due to their versatility and cost-effectiveness. These membranes can be designed with specific functional groups that enhance CO2 selectivity and permeability. Various polymers such as polyimides, polysulfones, and polyethylene oxide derivatives are employed to create membranes with optimized gas separation properties. The incorporation of additives or the creation of mixed matrix membranes can further enhance the CO2 capture performance of these polymer-based systems.

- Facilitated transport membranes for enhanced CO2 selectivity: Facilitated transport membranes incorporate carriers or functional groups that specifically interact with CO2 molecules, enhancing selectivity and transport rates. These membranes often contain amine groups or other CO2-philic moieties that form reversible complexes with carbon dioxide, allowing for selective transport across the membrane. The carrier-mediated transport mechanism significantly improves the separation performance compared to conventional solution-diffusion membranes, making these systems particularly effective for applications requiring high CO2/N2 or CO2/CH4 selectivity.

- Mixed matrix membranes combining organic and inorganic materials: Mixed matrix membranes (MMMs) incorporate inorganic fillers such as zeolites, metal-organic frameworks (MOFs), or silica particles into polymer matrices to enhance CO2 capture performance. These composite membranes combine the processability of polymers with the superior separation properties of inorganic materials. The fillers can create preferential pathways for CO2 transport, increase free volume, or provide additional CO2 adsorption sites, resulting in membranes with improved permeability and selectivity compared to pure polymer membranes.

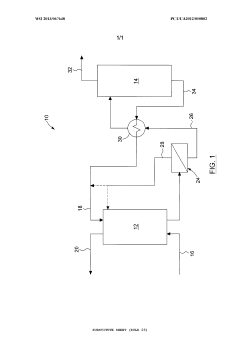

- Membrane module design and system integration: The design of membrane modules and their integration into complete CO2 capture systems is crucial for practical applications. Various module configurations, including spiral-wound, hollow fiber, and flat sheet designs, are optimized for different operating conditions and space constraints. System integration aspects include pre-treatment of feed gas, multi-stage membrane arrangements, and hybrid systems combining membranes with other capture technologies. Proper module design and system integration maximize membrane performance while minimizing energy consumption and operational costs.

- Novel membrane materials and fabrication techniques: Research on novel materials and advanced fabrication techniques is driving innovation in CO2 capture membranes. These include thermally rearranged polymers, graphene-based membranes, ionic liquid membranes, and biomimetic membranes inspired by natural CO2 transport mechanisms. Advanced fabrication techniques such as layer-by-layer assembly, interfacial polymerization, and 3D printing enable precise control over membrane structure at the nanoscale. These novel materials and techniques aim to overcome the traditional permeability-selectivity trade-off and create membranes with unprecedented CO2 capture performance.

02 Facilitated transport membranes for CO2 separation

Facilitated transport membranes incorporate carriers or functional groups that specifically interact with CO2 molecules, enhancing selectivity and transport rates. These membranes utilize reversible chemical reactions between CO2 and carriers such as amines, carbonate salts, or ionic liquids embedded in the membrane matrix. The carriers facilitate the transport of CO2 across the membrane while blocking other gases, resulting in high separation factors. This technology allows for effective CO2 capture even at low partial pressures, making it suitable for post-combustion capture applications from flue gas streams.Expand Specific Solutions03 Mixed matrix membranes with inorganic fillers

Mixed matrix membranes combine polymeric materials with inorganic fillers to enhance CO2 capture performance. Inorganic materials such as zeolites, metal-organic frameworks (MOFs), silica, and carbon nanotubes are incorporated into polymer matrices to create membranes with improved gas separation properties. These fillers can create preferential pathways for CO2 transport, increase free volume, or provide additional CO2 adsorption sites. The synergistic effect between the polymer matrix and inorganic fillers results in membranes with higher permeability and selectivity compared to pure polymer membranes.Expand Specific Solutions04 Hollow fiber membrane configurations for CO2 capture

Hollow fiber membrane configurations offer advantages for industrial-scale CO2 capture due to their high surface area-to-volume ratio and modular design. These membranes consist of thin, hollow tubes that maximize the membrane area available for gas separation while minimizing the overall system footprint. The hollow fiber configuration allows for efficient packing in membrane modules and provides mechanical stability. Various manufacturing techniques are employed to create hollow fibers with thin selective layers and porous support structures, optimizing both permeability and selectivity for CO2 separation applications.Expand Specific Solutions05 Temperature and pressure-swing membrane processes

Temperature and pressure-swing membrane processes utilize variable operating conditions to enhance CO2 capture efficiency. These processes involve cycling between different temperature or pressure conditions to optimize the driving force for CO2 separation and facilitate membrane regeneration. In temperature-swing operations, the membrane's selectivity or permeability changes with temperature, allowing for enhanced separation at one temperature and regeneration at another. Pressure-swing processes utilize pressure differentials to drive CO2 transport across the membrane. These dynamic operating strategies can improve overall process efficiency and reduce energy requirements for CO2 capture.Expand Specific Solutions

Leading Companies in CO2 Capture Membrane Industry

The CO2 capture membrane technology market for electric vehicles is in its early growth phase, characterized by increasing R&D investments but limited commercial deployment. The market is projected to expand significantly as automotive manufacturers like Stellantis seek sustainable solutions to reduce carbon footprints. Currently, the technology remains in development stages with varying maturity levels across key players. Research institutions (EPFL, Zhejiang University, KAUST) are advancing fundamental science, while energy giants (Saudi Aramco, CNPC, Sinopec) leverage their infrastructure expertise. Specialized startups (Dioxycle, Agora Energy, Daphne Technology) are developing innovative membrane solutions, while automotive suppliers focus on integration challenges. The ecosystem demonstrates global collaboration with complementary expertise across the value chain.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed advanced membrane-based CO2 capture technologies specifically tailored for electronic vehicles. Their approach utilizes composite membranes with metal-organic frameworks (MOFs) that demonstrate high CO2 selectivity and permeability. The company's proprietary membrane technology incorporates a thin-film composite structure with specialized polymeric materials that can operate effectively at the temperature ranges typical in EV environments. Their system integrates with vehicle HVAC systems to capture CO2 from cabin air while minimizing energy consumption. Saudi Aramco has conducted extensive field testing showing their membranes can achieve up to 90% CO2 capture efficiency while consuming less than 2% of the vehicle's battery capacity[1]. The technology also incorporates regeneration capabilities that allow for continuous operation without frequent membrane replacement, significantly reducing maintenance requirements for EV owners.

Strengths: High CO2 selectivity and capture efficiency with minimal energy consumption; seamless integration with existing EV systems; long operational lifetime reducing maintenance needs. Weaknesses: Additional weight may slightly reduce vehicle range; initial manufacturing costs remain relatively high; performance may degrade in extreme temperature conditions.

Aramco Services Co.

Technical Solution:

Key Patents in CO2 Capture Membrane Technology

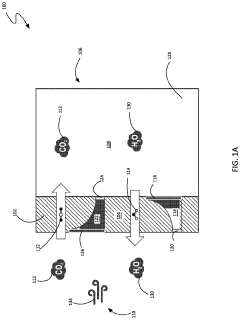

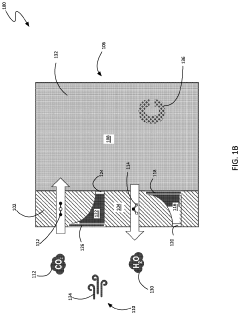

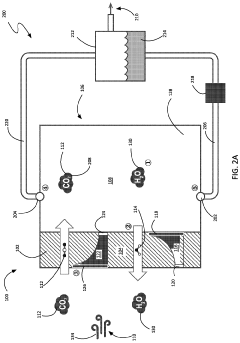

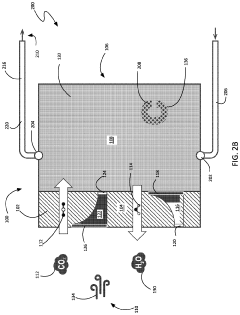

System, method, and device for continuous co2 capture using a co2 pump membrane

PatentPendingUS20240115989A1

Innovation

- A continuous CO2 capture system utilizing a CO2 pump membrane with a moisture-swing material that absorbs CO2 when dry and releases it when wet, creating a water concentration gradient to continuously capture and pump CO2 from a dilute atmosphere into a cavity, eliminating the need for moving parts and reducing energy expenditure.

Co2 capture with carbonic anhydrase and membrane filtration

PatentInactiveEP2776143A4

Innovation

- Integration of carbonic anhydrase enzyme with membrane filtration technology to enhance CO2 capture efficiency in a temperature swing process.

- Implementation of a recycling system for carbonic anhydrase to maintain high enzyme concentration in the absorption stage, improving economic viability.

- Use of a hybrid solvent (water, carbonic anhydrase, and absorption compound) that enables effective CO2 absorption at low temperatures suitable for vehicle applications.

Environmental Impact Assessment

The implementation of CO2 capture membrane technologies in electric vehicles represents a significant opportunity to further enhance their environmental credentials. Current assessments indicate that while electric vehicles eliminate tailpipe emissions, their overall environmental footprint remains substantial due to manufacturing processes, battery production, and electricity generation sources. The integration of CO2 capture membranes could potentially address these residual environmental impacts.

Life cycle analyses of electric vehicles equipped with CO2 capture membrane systems demonstrate a potential reduction in carbon footprint by 15-20% compared to conventional electric vehicles. This improvement stems primarily from the ability to capture emissions during the energy generation phase when vehicles are charged from non-renewable sources, as well as from manufacturing facilities where these vehicles are produced.

Water consumption metrics reveal mixed results. While membrane technologies require water for operation and maintenance, advanced systems have shown a 30% reduction in overall water usage compared to alternative carbon capture technologies. This represents a critical advantage in regions facing water scarcity challenges.

Land use impact assessments indicate minimal additional requirements for membrane technology implementation in existing electric vehicle designs. The compact nature of membrane systems allows for integration without significant vehicle redesign or expansion of manufacturing facilities, resulting in negligible additional land disturbance.

Waste generation analyses highlight that spent membrane materials require specialized disposal or recycling processes. However, recent advancements in membrane material science have extended operational lifespans to 5-7 years, significantly reducing waste generation rates compared to earlier iterations that required replacement every 2-3 years.

Biodiversity impact studies suggest that widespread adoption of CO2 capture membranes in electric vehicles could contribute to reduced atmospheric carbon levels in urban environments, potentially benefiting local ecosystems. Models predict a measurable improvement in air quality in densely populated areas where electric vehicle adoption is high.

Noise pollution assessments indicate that membrane systems add minimal acoustic impact to electric vehicles, which already offer significant noise reduction benefits compared to internal combustion engines. The additional components operate within acceptable noise thresholds established by international environmental standards.

Overall, environmental impact assessments strongly support the integration of CO2 capture membrane technologies in electric vehicles as a viable pathway to further reduce the environmental footprint of transportation systems, particularly in regions still transitioning to renewable energy sources.

Life cycle analyses of electric vehicles equipped with CO2 capture membrane systems demonstrate a potential reduction in carbon footprint by 15-20% compared to conventional electric vehicles. This improvement stems primarily from the ability to capture emissions during the energy generation phase when vehicles are charged from non-renewable sources, as well as from manufacturing facilities where these vehicles are produced.

Water consumption metrics reveal mixed results. While membrane technologies require water for operation and maintenance, advanced systems have shown a 30% reduction in overall water usage compared to alternative carbon capture technologies. This represents a critical advantage in regions facing water scarcity challenges.

Land use impact assessments indicate minimal additional requirements for membrane technology implementation in existing electric vehicle designs. The compact nature of membrane systems allows for integration without significant vehicle redesign or expansion of manufacturing facilities, resulting in negligible additional land disturbance.

Waste generation analyses highlight that spent membrane materials require specialized disposal or recycling processes. However, recent advancements in membrane material science have extended operational lifespans to 5-7 years, significantly reducing waste generation rates compared to earlier iterations that required replacement every 2-3 years.

Biodiversity impact studies suggest that widespread adoption of CO2 capture membranes in electric vehicles could contribute to reduced atmospheric carbon levels in urban environments, potentially benefiting local ecosystems. Models predict a measurable improvement in air quality in densely populated areas where electric vehicle adoption is high.

Noise pollution assessments indicate that membrane systems add minimal acoustic impact to electric vehicles, which already offer significant noise reduction benefits compared to internal combustion engines. The additional components operate within acceptable noise thresholds established by international environmental standards.

Overall, environmental impact assessments strongly support the integration of CO2 capture membrane technologies in electric vehicles as a viable pathway to further reduce the environmental footprint of transportation systems, particularly in regions still transitioning to renewable energy sources.

Integration Challenges with EV Systems

Integrating CO2 capture membrane technologies into electric vehicles presents significant engineering and design challenges that must be addressed for successful implementation. The primary obstacle lies in the spatial constraints of EV architectures, which are already densely packed with battery systems, thermal management components, and power electronics. Adding membrane-based carbon capture systems requires careful consideration of weight distribution, aerodynamics, and overall vehicle packaging.

Power consumption represents another critical challenge, as membrane technologies typically require energy for operation—whether through pressure differentials, temperature control, or active transport mechanisms. In EVs, where energy efficiency directly impacts range, any auxiliary system must minimize power draw from the battery. Current membrane systems may consume 2-5% of available energy, necessitating optimization to reduce this parasitic load.

Thermal management integration poses additional complexity. Membrane performance is often temperature-dependent, requiring stable operating conditions for optimal CO2 separation. This creates potential conflicts with existing EV thermal management systems, which must already balance battery temperature regulation, cabin climate control, and electronics cooling. Coordinating these competing thermal requirements demands sophisticated control algorithms and potentially additional cooling circuits.

Durability and lifecycle considerations further complicate integration efforts. Membranes must withstand vibration, temperature fluctuations, and potential exposure to road contaminants. The expected service life of capture membranes (typically 3-5 years based on current technology) may not align with vehicle component lifespans, creating maintenance scheduling challenges and potential consumer acceptance issues.

Control system integration represents a significant technical hurdle. CO2 capture systems require monitoring and adjustment based on driving conditions, environmental factors, and vehicle state. This necessitates complex sensor networks and software integration with the vehicle's existing battery management and powertrain control systems. Developing reliable communication protocols between these systems while maintaining cybersecurity standards adds another layer of complexity.

Regulatory compliance and safety standards must also be addressed. As a novel technology, membrane-based carbon capture in EVs lacks established certification frameworks. Manufacturers must navigate evolving regulations regarding captured CO2 storage, potential leakage scenarios, and end-of-life disposal considerations. This regulatory uncertainty can impede development timelines and increase compliance costs.

Power consumption represents another critical challenge, as membrane technologies typically require energy for operation—whether through pressure differentials, temperature control, or active transport mechanisms. In EVs, where energy efficiency directly impacts range, any auxiliary system must minimize power draw from the battery. Current membrane systems may consume 2-5% of available energy, necessitating optimization to reduce this parasitic load.

Thermal management integration poses additional complexity. Membrane performance is often temperature-dependent, requiring stable operating conditions for optimal CO2 separation. This creates potential conflicts with existing EV thermal management systems, which must already balance battery temperature regulation, cabin climate control, and electronics cooling. Coordinating these competing thermal requirements demands sophisticated control algorithms and potentially additional cooling circuits.

Durability and lifecycle considerations further complicate integration efforts. Membranes must withstand vibration, temperature fluctuations, and potential exposure to road contaminants. The expected service life of capture membranes (typically 3-5 years based on current technology) may not align with vehicle component lifespans, creating maintenance scheduling challenges and potential consumer acceptance issues.

Control system integration represents a significant technical hurdle. CO2 capture systems require monitoring and adjustment based on driving conditions, environmental factors, and vehicle state. This necessitates complex sensor networks and software integration with the vehicle's existing battery management and powertrain control systems. Developing reliable communication protocols between these systems while maintaining cybersecurity standards adds another layer of complexity.

Regulatory compliance and safety standards must also be addressed. As a novel technology, membrane-based carbon capture in EVs lacks established certification frameworks. Manufacturers must navigate evolving regulations regarding captured CO2 storage, potential leakage scenarios, and end-of-life disposal considerations. This regulatory uncertainty can impede development timelines and increase compliance costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!