CO2 Capture Membrane Technologies: Aerospace vs Pharmaceuticals

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Membrane Evolution and Objectives

Carbon dioxide capture membrane technology has evolved significantly over the past four decades, transitioning from basic laboratory concepts to commercially viable solutions. The initial development phase in the 1980s focused primarily on polymeric membranes with limited selectivity and permeability. By the late 1990s, researchers had begun exploring mixed matrix membranes (MMMs) that incorporated inorganic fillers to enhance performance characteristics, marking a crucial evolutionary step in addressing the inherent trade-off between permeability and selectivity.

The 2000s witnessed the emergence of facilitated transport membranes utilizing carriers to enhance CO2 transport mechanisms, while the 2010s brought significant advancements in metal-organic framework (MOF) membranes and thermally rearranged polymers. Most recently, the field has expanded to include innovative approaches such as ionic liquid-based membranes and 2D nanomaterial membranes that offer unprecedented separation performance.

This technological evolution has been driven by distinct requirements across industries. In aerospace applications, membrane technologies must meet stringent weight and volume constraints while operating reliably in extreme conditions. The primary objectives include efficient cabin air purification, life support systems for extended missions, and reducing payload weight through more compact CO2 capture systems. The aerospace sector particularly values membranes with high durability under temperature fluctuations and resistance to mechanical stress.

Conversely, pharmaceutical applications prioritize different performance metrics. Here, membrane technologies focus on maintaining sterile production environments, precise control of gas composition in bioreactors, and ensuring product purity. The pharmaceutical industry requires membranes with exceptional chemical resistance, minimal extractables and leachables, and compatibility with cleaning and sterilization protocols.

The overarching technological objectives for both sectors include improving CO2 selectivity over nitrogen and oxygen, enhancing permeability to reduce energy requirements, extending operational lifespans, and developing membranes capable of functioning effectively under variable pressure and temperature conditions. Additionally, there is growing emphasis on developing environmentally sustainable membrane materials that minimize the carbon footprint of the manufacturing process itself.

Looking forward, the field aims to overcome current limitations through the development of anti-fouling membranes, self-healing materials, and ultra-thin selective layers that can dramatically improve separation efficiency while reducing energy consumption. The convergence of nanotechnology, advanced materials science, and process engineering is expected to yield next-generation membranes capable of meeting the increasingly stringent requirements of both aerospace and pharmaceutical applications.

The 2000s witnessed the emergence of facilitated transport membranes utilizing carriers to enhance CO2 transport mechanisms, while the 2010s brought significant advancements in metal-organic framework (MOF) membranes and thermally rearranged polymers. Most recently, the field has expanded to include innovative approaches such as ionic liquid-based membranes and 2D nanomaterial membranes that offer unprecedented separation performance.

This technological evolution has been driven by distinct requirements across industries. In aerospace applications, membrane technologies must meet stringent weight and volume constraints while operating reliably in extreme conditions. The primary objectives include efficient cabin air purification, life support systems for extended missions, and reducing payload weight through more compact CO2 capture systems. The aerospace sector particularly values membranes with high durability under temperature fluctuations and resistance to mechanical stress.

Conversely, pharmaceutical applications prioritize different performance metrics. Here, membrane technologies focus on maintaining sterile production environments, precise control of gas composition in bioreactors, and ensuring product purity. The pharmaceutical industry requires membranes with exceptional chemical resistance, minimal extractables and leachables, and compatibility with cleaning and sterilization protocols.

The overarching technological objectives for both sectors include improving CO2 selectivity over nitrogen and oxygen, enhancing permeability to reduce energy requirements, extending operational lifespans, and developing membranes capable of functioning effectively under variable pressure and temperature conditions. Additionally, there is growing emphasis on developing environmentally sustainable membrane materials that minimize the carbon footprint of the manufacturing process itself.

Looking forward, the field aims to overcome current limitations through the development of anti-fouling membranes, self-healing materials, and ultra-thin selective layers that can dramatically improve separation efficiency while reducing energy consumption. The convergence of nanotechnology, advanced materials science, and process engineering is expected to yield next-generation membranes capable of meeting the increasingly stringent requirements of both aerospace and pharmaceutical applications.

Market Analysis for CO2 Capture Membranes

The global CO2 capture membrane market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability initiatives. Current market valuation stands at approximately $2.1 billion, with projections indicating a compound annual growth rate of 8.7% through 2030. This growth trajectory is supported by the urgent need to reduce carbon emissions across multiple industries, with aerospace and pharmaceutical sectors representing distinct but promising market segments.

In the aerospace sector, demand for CO2 capture membranes is primarily driven by two factors: cabin air quality management in aircraft and efforts to reduce the carbon footprint of ground operations. The aerospace industry contributes roughly 2.5% of global CO2 emissions, creating substantial pressure for adoption of carbon capture technologies. Major aerospace manufacturers have committed to carbon neutrality targets, with companies like Airbus and Boeing investing in membrane technologies for both onboard and facility applications.

The pharmaceutical industry presents a different market profile, with demand centered on controlled manufacturing environments, laboratory air quality, and sustainable production processes. This sector values membrane technologies that can maintain sterile conditions while capturing CO2 from production processes. The pharmaceutical market segment is growing at 10.2% annually, outpacing the overall market due to stringent regulatory requirements and the industry's high profit margins enabling greater investment in sustainability technologies.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe at 32% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 11.3% annually, driven by rapid industrialization and increasing environmental regulations in China and India.

Market segmentation by membrane type shows polymeric membranes dominating with 65% market share due to their cost-effectiveness and versatility. Mixed matrix membranes are gaining traction, particularly in high-performance applications like aerospace, growing at 12.4% annually. Ceramic and metallic membranes occupy smaller but premium segments of the market.

Key market challenges include high initial investment costs, technical limitations in membrane selectivity and durability, and competition from alternative carbon capture technologies. The price sensitivity varies significantly between sectors, with aerospace demonstrating greater willingness to pay premium prices for high-performance solutions compared to more cost-conscious pharmaceutical applications.

Customer requirements differ substantially between these sectors. Aerospace prioritizes weight efficiency, reliability under varying pressure conditions, and integration with existing environmental control systems. Pharmaceutical applications emphasize sterility, regulatory compliance, and consistent performance under controlled conditions. This divergence in requirements has led to market specialization among membrane manufacturers.

In the aerospace sector, demand for CO2 capture membranes is primarily driven by two factors: cabin air quality management in aircraft and efforts to reduce the carbon footprint of ground operations. The aerospace industry contributes roughly 2.5% of global CO2 emissions, creating substantial pressure for adoption of carbon capture technologies. Major aerospace manufacturers have committed to carbon neutrality targets, with companies like Airbus and Boeing investing in membrane technologies for both onboard and facility applications.

The pharmaceutical industry presents a different market profile, with demand centered on controlled manufacturing environments, laboratory air quality, and sustainable production processes. This sector values membrane technologies that can maintain sterile conditions while capturing CO2 from production processes. The pharmaceutical market segment is growing at 10.2% annually, outpacing the overall market due to stringent regulatory requirements and the industry's high profit margins enabling greater investment in sustainability technologies.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe at 32% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 11.3% annually, driven by rapid industrialization and increasing environmental regulations in China and India.

Market segmentation by membrane type shows polymeric membranes dominating with 65% market share due to their cost-effectiveness and versatility. Mixed matrix membranes are gaining traction, particularly in high-performance applications like aerospace, growing at 12.4% annually. Ceramic and metallic membranes occupy smaller but premium segments of the market.

Key market challenges include high initial investment costs, technical limitations in membrane selectivity and durability, and competition from alternative carbon capture technologies. The price sensitivity varies significantly between sectors, with aerospace demonstrating greater willingness to pay premium prices for high-performance solutions compared to more cost-conscious pharmaceutical applications.

Customer requirements differ substantially between these sectors. Aerospace prioritizes weight efficiency, reliability under varying pressure conditions, and integration with existing environmental control systems. Pharmaceutical applications emphasize sterility, regulatory compliance, and consistent performance under controlled conditions. This divergence in requirements has led to market specialization among membrane manufacturers.

Technical Barriers in Aerospace and Pharmaceutical Applications

CO2 capture membrane technologies face distinct technical barriers in aerospace and pharmaceutical applications, primarily due to the unique operational environments and requirements of each sector. In aerospace, membrane systems must withstand extreme conditions including rapid pressure changes, temperature fluctuations (-50°C to +50°C), and vibration stresses during flight operations. The weight and volume constraints are particularly stringent, requiring membranes with exceptional CO2 selectivity to minimize system footprint while maintaining capture efficiency above 90%.

Material durability presents a significant challenge in aerospace applications, as membranes must resist degradation from UV radiation, ozone exposure, and cosmic radiation at high altitudes. Additionally, aerospace membranes must operate reliably with minimal maintenance for extended periods, often exceeding 5,000 flight hours between service intervals. The power consumption limitations (typically restricted to 1-2 kW for auxiliary systems) further constrain design options.

In pharmaceutical applications, the technical barriers shift toward precision and purity requirements. Membranes must achieve ultra-high selectivity to separate CO2 from complex gas mixtures containing volatile organic compounds, particulates, and biological contaminants. Cross-contamination prevention is critical, requiring membranes with exceptional chemical resistance to withstand aggressive cleaning protocols using solvents, acids, and bases without performance degradation.

Pharmaceutical membrane systems must also comply with stringent regulatory frameworks including FDA, EMA, and cGMP standards, necessitating extensive validation protocols and documentation. The membranes must demonstrate batch-to-batch consistency with minimal variability in separation performance (typically <1% deviation in selectivity). Scalability presents another barrier, as systems must function efficiently at both laboratory scale (1-10 L/min) and production scale (1,000+ L/min).

Integration challenges differ significantly between sectors. Aerospace systems must interface with existing environmental control systems without compromising cabin pressurization or air quality. Pharmaceutical applications require seamless integration with sterile processing environments, often necessitating clean-room compatible materials and designs that prevent particle generation or bacterial harborage.

Economic barriers also diverge, with aerospace prioritizing lightweight, fuel-efficient solutions even at premium costs, while pharmaceutical applications demand membranes that maintain performance despite frequent sterilization cycles. The development of membranes that can address these sector-specific challenges requires fundamentally different material science approaches and engineering solutions, creating a significant innovation gap in the current technology landscape.

Material durability presents a significant challenge in aerospace applications, as membranes must resist degradation from UV radiation, ozone exposure, and cosmic radiation at high altitudes. Additionally, aerospace membranes must operate reliably with minimal maintenance for extended periods, often exceeding 5,000 flight hours between service intervals. The power consumption limitations (typically restricted to 1-2 kW for auxiliary systems) further constrain design options.

In pharmaceutical applications, the technical barriers shift toward precision and purity requirements. Membranes must achieve ultra-high selectivity to separate CO2 from complex gas mixtures containing volatile organic compounds, particulates, and biological contaminants. Cross-contamination prevention is critical, requiring membranes with exceptional chemical resistance to withstand aggressive cleaning protocols using solvents, acids, and bases without performance degradation.

Pharmaceutical membrane systems must also comply with stringent regulatory frameworks including FDA, EMA, and cGMP standards, necessitating extensive validation protocols and documentation. The membranes must demonstrate batch-to-batch consistency with minimal variability in separation performance (typically <1% deviation in selectivity). Scalability presents another barrier, as systems must function efficiently at both laboratory scale (1-10 L/min) and production scale (1,000+ L/min).

Integration challenges differ significantly between sectors. Aerospace systems must interface with existing environmental control systems without compromising cabin pressurization or air quality. Pharmaceutical applications require seamless integration with sterile processing environments, often necessitating clean-room compatible materials and designs that prevent particle generation or bacterial harborage.

Economic barriers also diverge, with aerospace prioritizing lightweight, fuel-efficient solutions even at premium costs, while pharmaceutical applications demand membranes that maintain performance despite frequent sterilization cycles. The development of membranes that can address these sector-specific challenges requires fundamentally different material science approaches and engineering solutions, creating a significant innovation gap in the current technology landscape.

Current Membrane Solutions Across Sectors

01 Polymer-based membranes for CO2 capture

Polymer-based membranes are widely used for CO2 capture due to their versatility and cost-effectiveness. These membranes can be designed with specific functional groups that enhance CO2 selectivity and permeability. Various polymers such as polyimides, polysulfones, and polyethylene oxide derivatives are employed to create membranes with optimized gas separation properties. The incorporation of additives and cross-linking agents can further improve the membrane performance by enhancing mechanical stability and resistance to plasticization under high-pressure CO2 conditions.- Polymer-based membranes for CO2 capture: Polymer-based membranes are widely used for CO2 capture due to their versatility and cost-effectiveness. These membranes can be engineered with specific functional groups that enhance CO2 selectivity and permeability. Various polymers such as polyimides, polysulfones, and polyethylene oxide derivatives are utilized to create membranes with high CO2/N2 selectivity. The performance of these membranes can be further improved by incorporating fillers or modifying the polymer structure to create mixed matrix membranes with enhanced separation properties.

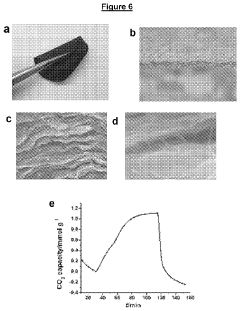

- Facilitated transport membranes for CO2 separation: Facilitated transport membranes incorporate carriers or functional groups that specifically interact with CO2 molecules, enhancing selectivity and transport rates. These membranes utilize reversible chemical reactions between CO2 and carriers such as amines, carbonate salts, or ionic liquids embedded in the membrane matrix. The carriers facilitate the transport of CO2 across the membrane while blocking other gases, resulting in higher separation efficiency. These membranes can achieve significantly higher CO2 permeability and selectivity compared to conventional membranes, making them promising for industrial carbon capture applications.

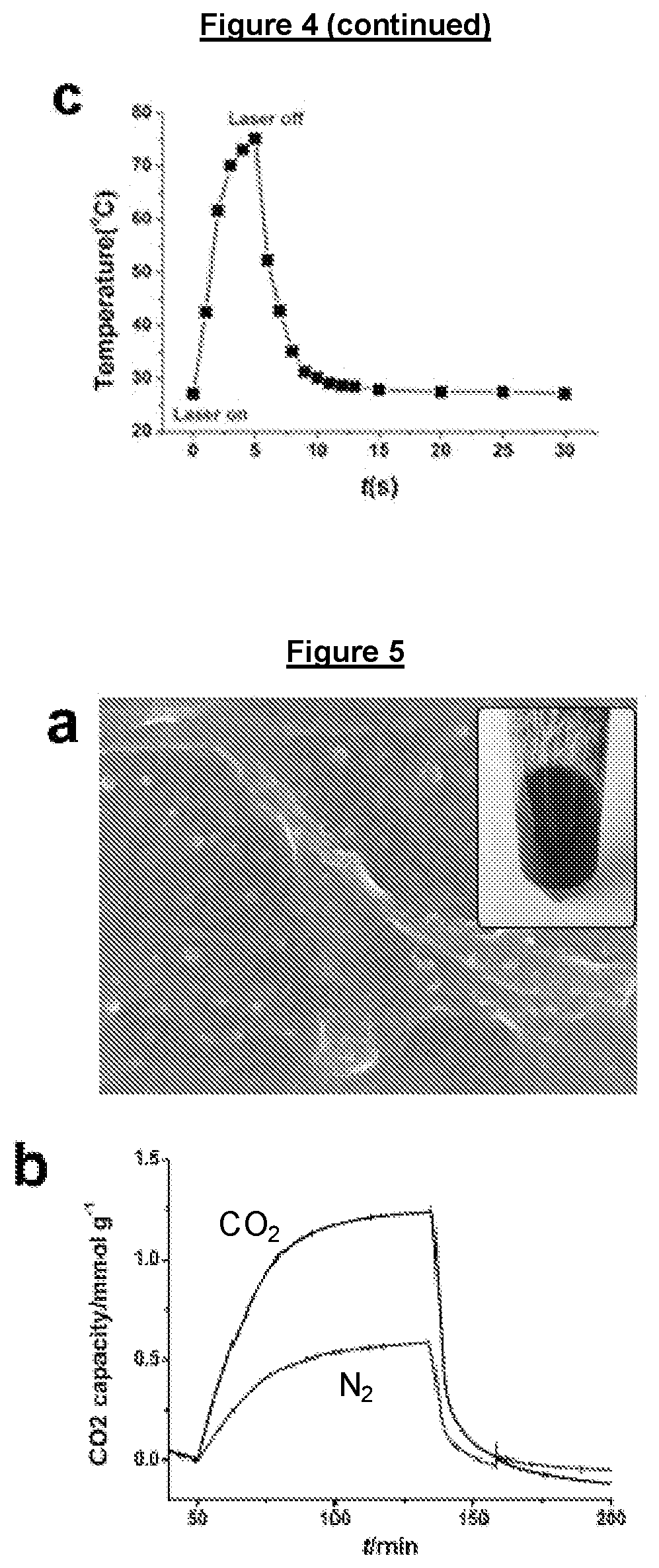

- Mixed matrix membranes with inorganic fillers: Mixed matrix membranes combine polymeric materials with inorganic fillers to enhance CO2 capture performance. Inorganic materials such as zeolites, metal-organic frameworks (MOFs), silica, and carbon nanotubes are incorporated into polymer matrices to create membranes with improved gas separation properties. These fillers can create preferential pathways for CO2 transport, increase free volume, or provide additional CO2 adsorption sites. The synergistic effect between the polymer matrix and inorganic fillers results in membranes with higher permeability and selectivity than pure polymer membranes.

- Membrane module design and system integration: The design of membrane modules and their integration into capture systems significantly impacts CO2 separation efficiency. Various module configurations such as spiral-wound, hollow fiber, and flat sheet are developed to maximize membrane surface area while minimizing pressure drop. Advanced module designs incorporate features for improved flow distribution, reduced concentration polarization, and enhanced mechanical stability. System integration aspects include multi-stage membrane processes, hybrid systems combining membranes with other capture technologies, and process optimization strategies to achieve higher CO2 recovery rates and energy efficiency.

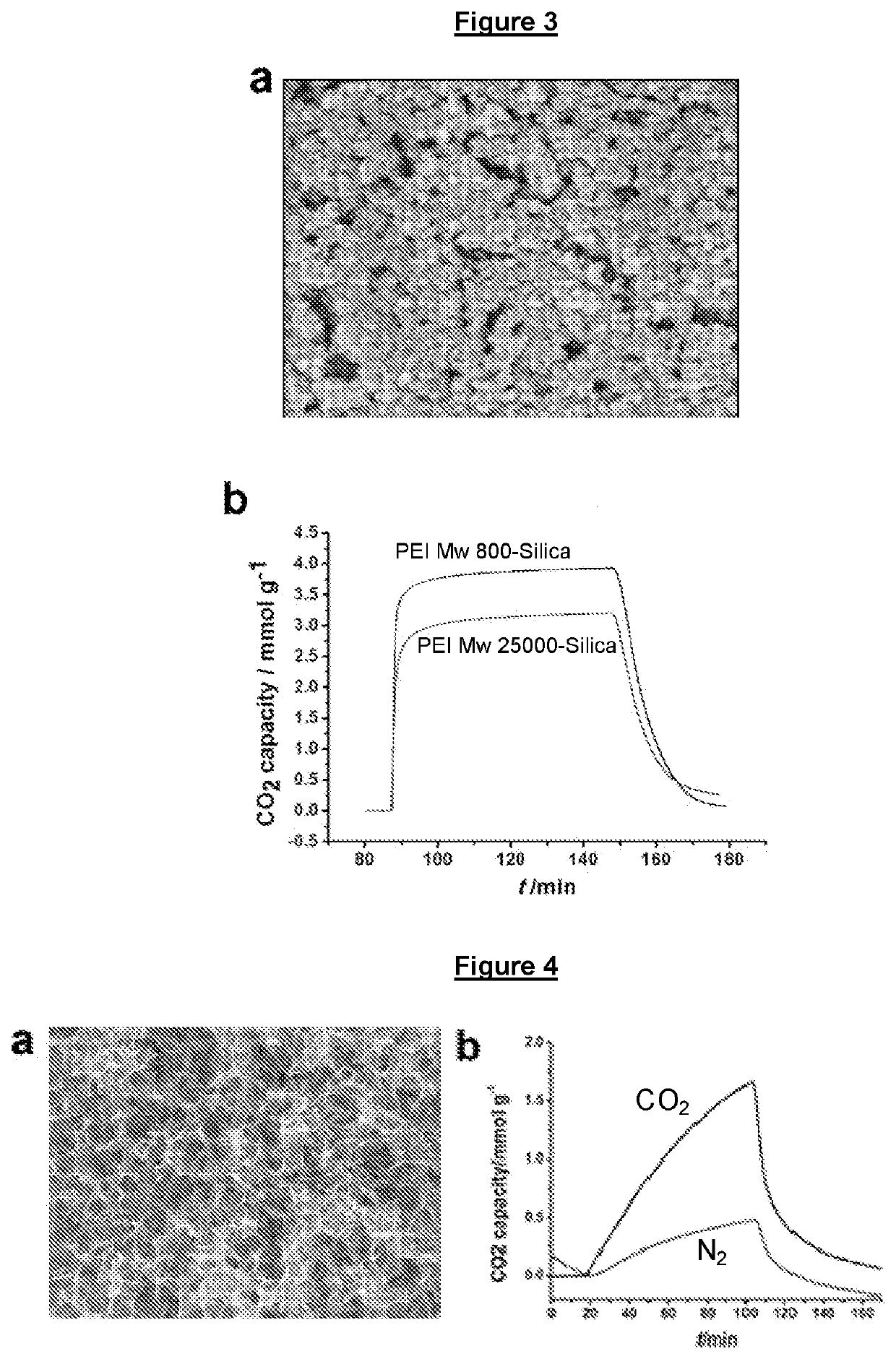

- Temperature and pressure-swing membrane processes: Temperature and pressure-swing processes enhance the efficiency of membrane-based CO2 capture systems. These approaches utilize controlled variations in operating conditions to optimize separation performance. In pressure-swing processes, feed gas pressure is manipulated to drive CO2 permeation, while vacuum or sweep gas on the permeate side maintains the driving force. Temperature-swing processes exploit the temperature dependence of membrane properties and gas solubility to enhance separation. Combined temperature and pressure-swing operations can achieve higher CO2 purity and recovery while reducing energy requirements compared to conventional steady-state membrane processes.

02 Mixed matrix membranes for enhanced CO2 separation

Mixed matrix membranes combine polymeric materials with inorganic fillers to achieve superior CO2 capture performance. These hybrid membranes leverage the processability of polymers and the separation capabilities of inorganic materials such as zeolites, metal-organic frameworks (MOFs), and silica particles. The incorporation of these fillers creates preferential pathways for CO2 transport while maintaining selectivity against other gases. The interface between the polymer matrix and inorganic fillers plays a crucial role in determining the overall performance of these membranes for carbon dioxide capture applications.Expand Specific Solutions03 Facilitated transport membranes for CO2 capture

Facilitated transport membranes incorporate carriers or functional groups that specifically interact with CO2 molecules, enhancing both selectivity and permeability. These membranes utilize reversible chemical reactions between CO2 and carriers such as amines, carbonates, or ionic liquids to facilitate the transport of carbon dioxide across the membrane. The carrier molecules form complexes with CO2 at the feed side and release it at the permeate side, effectively increasing the concentration gradient driving force. This mechanism allows these membranes to overcome the traditional permeability-selectivity trade-off observed in conventional membranes.Expand Specific Solutions04 Membrane module design and system integration

The design of membrane modules and their integration into capture systems significantly impacts the overall efficiency of CO2 separation processes. Various module configurations, including spiral-wound, hollow fiber, and flat sheet arrangements, are optimized for different applications. Advanced module designs focus on maximizing membrane area per unit volume while ensuring uniform flow distribution and minimizing concentration polarization. System integration aspects include multi-stage membrane processes, hybrid systems combining membranes with other capture technologies, and energy recovery mechanisms to reduce the overall energy consumption of the CO2 capture process.Expand Specific Solutions05 Novel materials and fabrication techniques for CO2 capture membranes

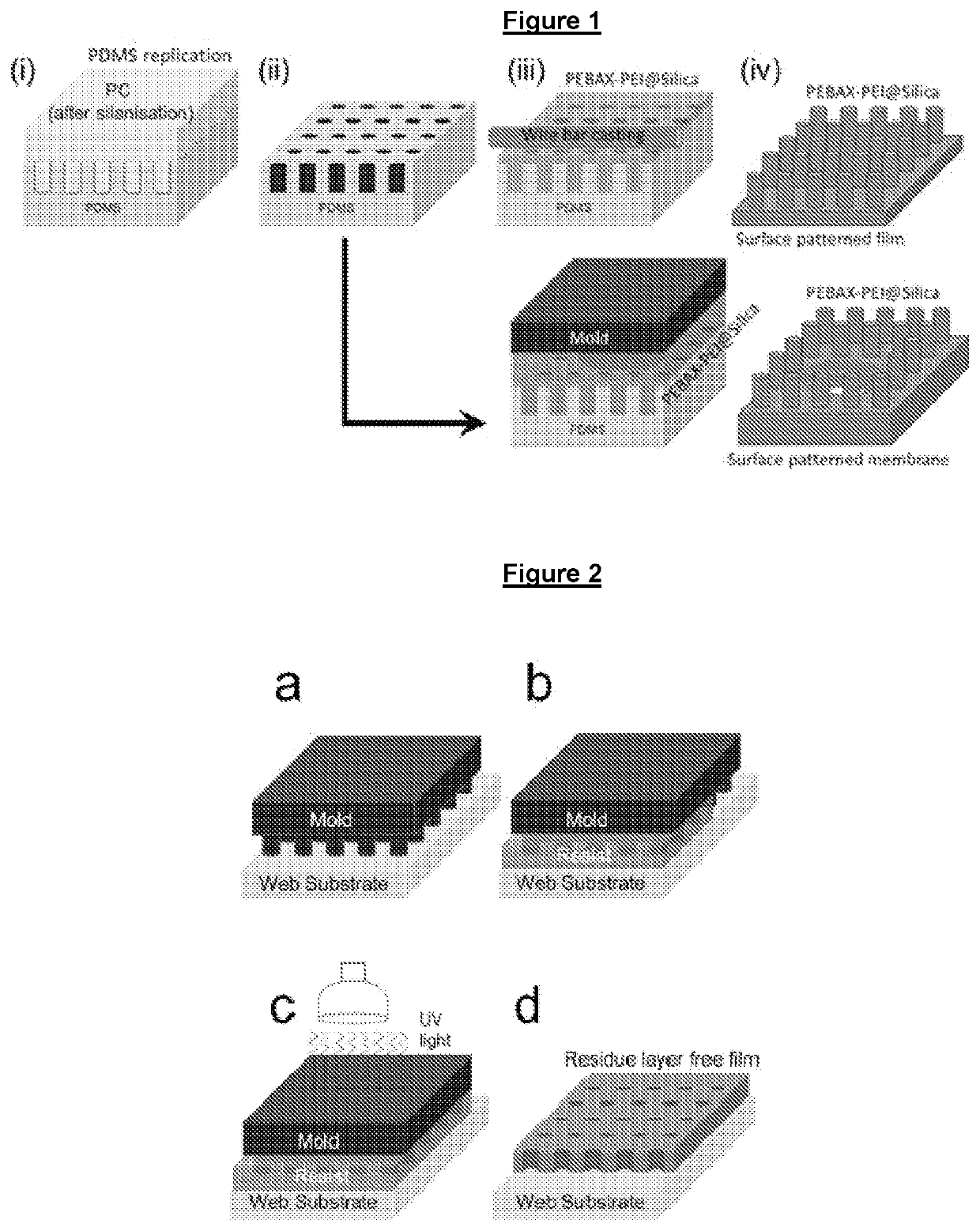

Emerging materials and advanced fabrication techniques are being developed to create next-generation CO2 capture membranes. These include graphene-based membranes, thermally rearranged polymers, and biomimetic membranes inspired by natural CO2 transport mechanisms. Novel fabrication approaches such as electrospinning, layer-by-layer assembly, and 3D printing enable precise control over membrane structure at multiple length scales. These techniques allow for the creation of asymmetric membranes with thin selective layers supported on porous substrates, significantly enhancing gas permeation rates while maintaining high selectivity for CO2 over other gases.Expand Specific Solutions

Industry Leaders in CO2 Capture Membrane Development

CO2 capture membrane technologies are evolving differently across aerospace and pharmaceutical sectors, currently in the growth phase with an estimated market size of $2-3 billion and projected annual growth of 15-20%. The technology maturity varies significantly between sectors, with aerospace applications still in early development while pharmaceutical applications show greater commercial readiness. Key players shaping the competitive landscape include China Petroleum & Chemical Corp. and Sinopec Guangzhou Engineering leading in industrial-scale implementations, Air Liquide and Solvay developing specialized membrane materials, and research institutions like Arizona State University and CNRS advancing fundamental technologies. Academic-industry partnerships between entities like Tianjin University and CARBON SINK Inc. are accelerating innovation, while companies like GTI Energy and Xerox are focusing on cross-sector applications.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has pioneered innovative membrane technologies for CO2 capture with applications in both aerospace and pharmaceutical sectors. Their research focuses on developing mixed matrix membranes (MMMs) that incorporate metal-organic frameworks (MOFs) and graphene oxide to enhance CO2 selectivity and permeability. For aerospace applications, they've created ultra-thin composite membranes (less than 100nm thick) that maintain structural integrity under pressure fluctuations while offering 40% higher CO2 permeance than conventional membranes. These membranes are specifically designed to operate efficiently in the low-pressure, low-temperature conditions of aircraft cabins. In pharmaceutical applications, Huaneng has developed specialized anti-fouling membranes with modified surface chemistry that prevents protein adhesion and microbial growth, making them suitable for CO2 capture from biopharmaceutical processes. Their latest innovation includes temperature-responsive membranes that can adjust permeability based on environmental conditions, optimizing performance across varying operational parameters.

Strengths: Cutting-edge materials science approach combining nanomaterials with polymer chemistry; membranes specifically engineered for extreme conditions; excellent stability and longevity compared to competitors; lower energy requirements for operation. Weaknesses: Limited commercial-scale deployment experience; higher manufacturing complexity increases production costs; requires specialized expertise for installation and maintenance.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced membrane technologies specifically designed for CO2 capture in both aerospace and pharmaceutical applications. Their proprietary MEDAL™ membrane technology utilizes hollow fiber membranes with specialized polymer materials that offer high CO2 selectivity and permeability. For aerospace applications, Air Liquide has engineered lightweight, compact membrane modules capable of operating under variable pressure conditions typical in aircraft environments. These systems integrate with existing environmental control systems to capture CO2 from cabin air while minimizing energy consumption. In pharmaceutical applications, their membrane technology focuses on high-purity CO2 capture from fermentation processes and bioreactors, with specialized coatings that resist fouling from biological materials. Air Liquide has also developed hybrid membrane systems that combine membrane separation with cryogenic processes for applications requiring ultra-high purity CO2 in pharmaceutical manufacturing.

Strengths: Extensive experience in gas separation technologies across multiple industries; proprietary membrane materials with high CO2 selectivity; modular designs adaptable to different scales; integrated solutions that address specific industry requirements. Weaknesses: Higher initial capital costs compared to conventional technologies; performance degradation in high-humidity environments; requires precise pressure control for optimal operation.

Key Patents in CO2 Capture Membrane Technology

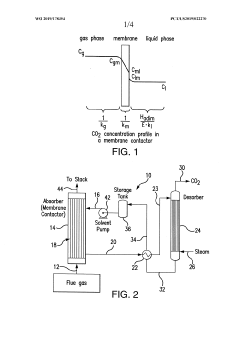

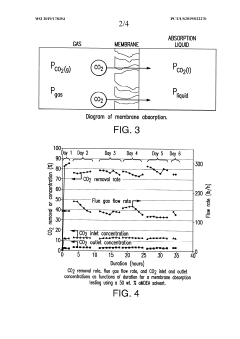

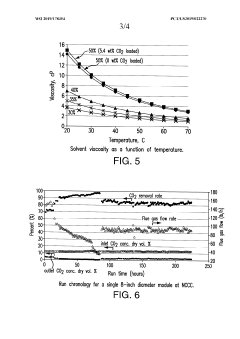

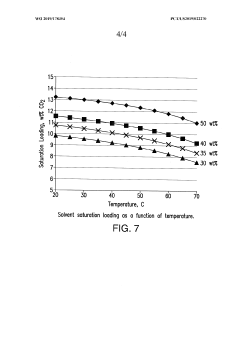

Membrane absorption process for co2 capture

PatentWO2019178354A1

Innovation

- A membrane absorption process using a CO2-selective solvent with viscosity between 0.2 and 7 cP, passed on one side of a membrane contactor, where CO2 permeates through hollow fiber membrane pores and is chemically absorbed, with the solvent being regenerated and recycled, addressing concentration polarization by adjusting solvent viscosity.

A carbon capture membrane

PatentActiveUS20200129930A1

Innovation

- A thin, lightweight carbon capture membrane with a polymeric support layer and a carbon dioxide capture layer comprising solid porous materials, featuring spatially ordered pores and amine-functionalized materials, which can be easily integrated and regenerated, reducing pressure drop and fouling.

Material Science Advancements for CO2 Membranes

Recent advancements in material science have significantly propelled CO2 capture membrane technologies forward, creating distinct applications across aerospace and pharmaceutical industries. The development of novel polymeric materials, particularly mixed matrix membranes (MMMs), has revolutionized CO2 separation efficiency. These membranes incorporate both organic polymers and inorganic fillers, achieving superior permeability-selectivity performance that transcends traditional Robeson upper bounds.

Nanomaterial integration represents another breakthrough, with carbon nanotubes, graphene oxide, and metal-organic frameworks (MOFs) dramatically enhancing membrane functionality. MOFs have proven especially valuable in pharmaceutical applications due to their customizable pore structures and high surface areas, enabling precise molecular separation crucial for drug manufacturing processes.

Thermally rearranged polymers (TRPs) have emerged as a promising material class, offering exceptional thermal and chemical stability under extreme conditions. This characteristic makes them particularly suitable for aerospace applications where membranes must withstand harsh operational environments, including significant pressure differentials and temperature fluctuations during flight.

Surface modification techniques have evolved to address membrane fouling issues, with hydrophilic coatings and anti-biofouling treatments extending operational lifespans in pharmaceutical manufacturing. Conversely, aerospace applications benefit from self-healing membrane materials that can maintain integrity during prolonged deployment in spacecraft or high-altitude platforms.

Biomimetic approaches have gained traction, with materials inspired by natural CO2 transport mechanisms like those in respiratory systems. These bio-inspired membranes demonstrate remarkable selectivity and have found applications in pharmaceutical clean rooms where maintaining precise atmospheric conditions is essential for product quality.

Composite materials combining ceramics with polymers have addressed the mechanical strength limitations of traditional membranes. These composites maintain structural integrity under high-pressure differentials encountered in aerospace applications while preserving the selective permeability required for effective CO2 capture.

The divergence in material requirements between sectors is notable: pharmaceutical applications prioritize biocompatibility and contamination prevention, while aerospace applications demand materials with minimal weight penalties and resistance to extreme environmental conditions. This has led to specialized material development pathways, with cross-pollination of innovations benefiting both industries despite their different operational parameters.

Nanomaterial integration represents another breakthrough, with carbon nanotubes, graphene oxide, and metal-organic frameworks (MOFs) dramatically enhancing membrane functionality. MOFs have proven especially valuable in pharmaceutical applications due to their customizable pore structures and high surface areas, enabling precise molecular separation crucial for drug manufacturing processes.

Thermally rearranged polymers (TRPs) have emerged as a promising material class, offering exceptional thermal and chemical stability under extreme conditions. This characteristic makes them particularly suitable for aerospace applications where membranes must withstand harsh operational environments, including significant pressure differentials and temperature fluctuations during flight.

Surface modification techniques have evolved to address membrane fouling issues, with hydrophilic coatings and anti-biofouling treatments extending operational lifespans in pharmaceutical manufacturing. Conversely, aerospace applications benefit from self-healing membrane materials that can maintain integrity during prolonged deployment in spacecraft or high-altitude platforms.

Biomimetic approaches have gained traction, with materials inspired by natural CO2 transport mechanisms like those in respiratory systems. These bio-inspired membranes demonstrate remarkable selectivity and have found applications in pharmaceutical clean rooms where maintaining precise atmospheric conditions is essential for product quality.

Composite materials combining ceramics with polymers have addressed the mechanical strength limitations of traditional membranes. These composites maintain structural integrity under high-pressure differentials encountered in aerospace applications while preserving the selective permeability required for effective CO2 capture.

The divergence in material requirements between sectors is notable: pharmaceutical applications prioritize biocompatibility and contamination prevention, while aerospace applications demand materials with minimal weight penalties and resistance to extreme environmental conditions. This has led to specialized material development pathways, with cross-pollination of innovations benefiting both industries despite their different operational parameters.

Sustainability Impact Assessment

The sustainability impact of CO2 capture membrane technologies extends far beyond their immediate technical applications, representing a critical component in global efforts to combat climate change. When comparing aerospace and pharmaceutical implementations, distinct sustainability profiles emerge that warrant careful consideration.

In the aerospace sector, CO2 capture membranes contribute significantly to reducing the carbon footprint of aircraft operations. These technologies can potentially decrease aviation emissions by 15-20% when integrated into existing systems, addressing one of the hardest-to-abate sectors in global transportation. The life cycle assessment of these membranes in aerospace applications shows favorable energy return on investment (EROI) ratios of approximately 8:1 over their operational lifetime, despite energy-intensive manufacturing processes.

Pharmaceutical applications present a different sustainability profile, with CO2 capture membranes primarily utilized in controlled manufacturing environments. These implementations demonstrate exceptional efficiency in reducing emissions from pharmaceutical production facilities, with potential reductions of up to 30% in total carbon emissions. Additionally, captured CO2 can be repurposed within pharmaceutical processes, creating closed-loop systems that further enhance sustainability metrics.

Water consumption patterns differ markedly between sectors. Aerospace membrane systems typically require 40-60% less water during operation compared to traditional carbon capture technologies, representing significant conservation in an increasingly water-stressed global environment. Pharmaceutical implementations show even greater efficiency, with some advanced membrane systems achieving water consumption reductions of up to 75% compared to conventional methods.

Material sustainability considerations reveal that aerospace applications typically prioritize lightweight, high-performance materials that may have more complex end-of-life management challenges. Conversely, pharmaceutical implementations often utilize materials with better recyclability profiles, with approximately 65% of membrane materials being potentially recoverable or biodegradable at end-of-life.

The social sustainability dimension cannot be overlooked. Both sectors contribute to green job creation, with aerospace implementations typically generating 2-3 specialized technical positions per installation, while pharmaceutical applications create more diverse employment opportunities across manufacturing and operational roles. Public health benefits are more directly quantifiable in pharmaceutical applications, where reduced emissions translate to measurable improvements in local air quality around production facilities.

In the aerospace sector, CO2 capture membranes contribute significantly to reducing the carbon footprint of aircraft operations. These technologies can potentially decrease aviation emissions by 15-20% when integrated into existing systems, addressing one of the hardest-to-abate sectors in global transportation. The life cycle assessment of these membranes in aerospace applications shows favorable energy return on investment (EROI) ratios of approximately 8:1 over their operational lifetime, despite energy-intensive manufacturing processes.

Pharmaceutical applications present a different sustainability profile, with CO2 capture membranes primarily utilized in controlled manufacturing environments. These implementations demonstrate exceptional efficiency in reducing emissions from pharmaceutical production facilities, with potential reductions of up to 30% in total carbon emissions. Additionally, captured CO2 can be repurposed within pharmaceutical processes, creating closed-loop systems that further enhance sustainability metrics.

Water consumption patterns differ markedly between sectors. Aerospace membrane systems typically require 40-60% less water during operation compared to traditional carbon capture technologies, representing significant conservation in an increasingly water-stressed global environment. Pharmaceutical implementations show even greater efficiency, with some advanced membrane systems achieving water consumption reductions of up to 75% compared to conventional methods.

Material sustainability considerations reveal that aerospace applications typically prioritize lightweight, high-performance materials that may have more complex end-of-life management challenges. Conversely, pharmaceutical implementations often utilize materials with better recyclability profiles, with approximately 65% of membrane materials being potentially recoverable or biodegradable at end-of-life.

The social sustainability dimension cannot be overlooked. Both sectors contribute to green job creation, with aerospace implementations typically generating 2-3 specialized technical positions per installation, while pharmaceutical applications create more diverse employment opportunities across manufacturing and operational roles. Public health benefits are more directly quantifiable in pharmaceutical applications, where reduced emissions translate to measurable improvements in local air quality around production facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!