Sodium Bisulfate Advantages in Large-Scale Manufacturing Processes

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate Overview and Applications

Sodium bisulfate, also known as sodium hydrogen sulfate or sodium acid sulfate, is a versatile chemical compound with the formula NaHSO4. This white, crystalline solid is widely used in various industrial applications due to its unique properties and cost-effectiveness. As a strong acid salt, sodium bisulfate exhibits both acidic and reducing characteristics, making it valuable in large-scale manufacturing processes across multiple sectors.

In the food industry, sodium bisulfate serves as an effective pH control agent and preservative. It is commonly used in beverages, baked goods, and processed foods to regulate acidity levels and extend shelf life. The compound's ability to inhibit microbial growth makes it particularly useful in food safety applications, helping to prevent spoilage and maintain product quality during storage and transportation.

The water treatment sector extensively utilizes sodium bisulfate for its pH adjustment capabilities. In swimming pools and spas, it acts as a pH reducer, helping to maintain optimal water conditions for swimmer comfort and disinfection efficacy. Additionally, it plays a crucial role in industrial wastewater treatment, where it aids in neutralizing alkaline effluents and precipitating heavy metals.

In the textile industry, sodium bisulfate finds applications in dyeing and printing processes. It serves as a reducing agent, facilitating the fixation of dyes to fabrics and improving color fastness. The compound's ability to remove excess chlorine from textiles also makes it valuable in the production of chlorine-free fabrics.

The metal processing industry benefits from sodium bisulfate's ability to clean and pickle metal surfaces. It effectively removes rust, scale, and other impurities from metal components, preparing them for further processing or coating applications. This property is particularly useful in the production of galvanized steel and other corrosion-resistant materials.

In the pharmaceutical sector, sodium bisulfate is employed as an excipient in various drug formulations. Its pH-lowering properties make it useful in creating stable drug preparations and enhancing the solubility of certain active pharmaceutical ingredients. Furthermore, it plays a role in the synthesis of certain pharmaceutical compounds.

The personal care and cosmetics industry utilizes sodium bisulfate in products such as bath salts and effervescent tablets. Its acidic nature contributes to the fizzing effect in these products, while also providing mild exfoliating properties in some skincare formulations.

Given its wide range of applications and beneficial properties, sodium bisulfate continues to be a valuable chemical in large-scale manufacturing processes across diverse industries. Its versatility, cost-effectiveness, and relative safety compared to stronger acids make it an attractive option for many industrial applications, contributing to improved product quality, process efficiency, and environmental compliance.

In the food industry, sodium bisulfate serves as an effective pH control agent and preservative. It is commonly used in beverages, baked goods, and processed foods to regulate acidity levels and extend shelf life. The compound's ability to inhibit microbial growth makes it particularly useful in food safety applications, helping to prevent spoilage and maintain product quality during storage and transportation.

The water treatment sector extensively utilizes sodium bisulfate for its pH adjustment capabilities. In swimming pools and spas, it acts as a pH reducer, helping to maintain optimal water conditions for swimmer comfort and disinfection efficacy. Additionally, it plays a crucial role in industrial wastewater treatment, where it aids in neutralizing alkaline effluents and precipitating heavy metals.

In the textile industry, sodium bisulfate finds applications in dyeing and printing processes. It serves as a reducing agent, facilitating the fixation of dyes to fabrics and improving color fastness. The compound's ability to remove excess chlorine from textiles also makes it valuable in the production of chlorine-free fabrics.

The metal processing industry benefits from sodium bisulfate's ability to clean and pickle metal surfaces. It effectively removes rust, scale, and other impurities from metal components, preparing them for further processing or coating applications. This property is particularly useful in the production of galvanized steel and other corrosion-resistant materials.

In the pharmaceutical sector, sodium bisulfate is employed as an excipient in various drug formulations. Its pH-lowering properties make it useful in creating stable drug preparations and enhancing the solubility of certain active pharmaceutical ingredients. Furthermore, it plays a role in the synthesis of certain pharmaceutical compounds.

The personal care and cosmetics industry utilizes sodium bisulfate in products such as bath salts and effervescent tablets. Its acidic nature contributes to the fizzing effect in these products, while also providing mild exfoliating properties in some skincare formulations.

Given its wide range of applications and beneficial properties, sodium bisulfate continues to be a valuable chemical in large-scale manufacturing processes across diverse industries. Its versatility, cost-effectiveness, and relative safety compared to stronger acids make it an attractive option for many industrial applications, contributing to improved product quality, process efficiency, and environmental compliance.

Industrial Demand Analysis

The industrial demand for sodium bisulfate in large-scale manufacturing processes has been steadily increasing due to its versatile applications and cost-effectiveness. This compound, also known as sodium hydrogen sulfate, finds extensive use across various sectors, including water treatment, metal finishing, food processing, and textile industries.

In the water treatment sector, sodium bisulfate is widely employed for pH adjustment and dechlorination. As global water scarcity concerns grow and regulations on water quality become more stringent, the demand for efficient water treatment chemicals like sodium bisulfate is expected to rise significantly. The compound's ability to effectively lower pH levels in industrial wastewater and swimming pools makes it a preferred choice for many manufacturers.

The metal finishing industry represents another major consumer of sodium bisulfate. Its use in metal cleaning, pickling, and surface treatment processes has led to a substantial increase in demand. As the automotive and aerospace industries continue to expand, the need for high-quality metal finishing solutions is projected to drive further growth in sodium bisulfate consumption.

In the food processing sector, sodium bisulfate serves as a preservative and pH control agent. With the global population growth and increasing demand for processed foods, the market for food-grade sodium bisulfate is anticipated to experience steady growth. Its effectiveness in preventing microbial growth and extending shelf life makes it an essential ingredient for many food manufacturers.

The textile industry also contributes significantly to the industrial demand for sodium bisulfate. Its application in dyeing processes, particularly as a reducing agent and pH adjuster, has led to increased adoption among textile manufacturers. As the global textile market expands, driven by fast fashion trends and growing populations in developing countries, the demand for sodium bisulfate in this sector is expected to rise.

Environmental regulations and sustainability concerns are further driving the demand for sodium bisulfate in large-scale manufacturing processes. Its role in reducing harmful emissions and improving waste management practices aligns with the growing emphasis on environmentally friendly industrial operations. This trend is likely to sustain and potentially increase the demand for sodium bisulfate across various industries.

The cost-effectiveness of sodium bisulfate compared to alternative chemicals also contributes to its growing industrial demand. As manufacturers seek to optimize their production costs while maintaining product quality, the economic advantages of sodium bisulfate make it an attractive option for many large-scale processes.

In the water treatment sector, sodium bisulfate is widely employed for pH adjustment and dechlorination. As global water scarcity concerns grow and regulations on water quality become more stringent, the demand for efficient water treatment chemicals like sodium bisulfate is expected to rise significantly. The compound's ability to effectively lower pH levels in industrial wastewater and swimming pools makes it a preferred choice for many manufacturers.

The metal finishing industry represents another major consumer of sodium bisulfate. Its use in metal cleaning, pickling, and surface treatment processes has led to a substantial increase in demand. As the automotive and aerospace industries continue to expand, the need for high-quality metal finishing solutions is projected to drive further growth in sodium bisulfate consumption.

In the food processing sector, sodium bisulfate serves as a preservative and pH control agent. With the global population growth and increasing demand for processed foods, the market for food-grade sodium bisulfate is anticipated to experience steady growth. Its effectiveness in preventing microbial growth and extending shelf life makes it an essential ingredient for many food manufacturers.

The textile industry also contributes significantly to the industrial demand for sodium bisulfate. Its application in dyeing processes, particularly as a reducing agent and pH adjuster, has led to increased adoption among textile manufacturers. As the global textile market expands, driven by fast fashion trends and growing populations in developing countries, the demand for sodium bisulfate in this sector is expected to rise.

Environmental regulations and sustainability concerns are further driving the demand for sodium bisulfate in large-scale manufacturing processes. Its role in reducing harmful emissions and improving waste management practices aligns with the growing emphasis on environmentally friendly industrial operations. This trend is likely to sustain and potentially increase the demand for sodium bisulfate across various industries.

The cost-effectiveness of sodium bisulfate compared to alternative chemicals also contributes to its growing industrial demand. As manufacturers seek to optimize their production costs while maintaining product quality, the economic advantages of sodium bisulfate make it an attractive option for many large-scale processes.

Current Manufacturing Challenges

Large-scale manufacturing processes face numerous challenges in today's rapidly evolving industrial landscape. One of the primary issues is the need for increased efficiency and cost-effectiveness in production. As global competition intensifies, manufacturers are under constant pressure to optimize their processes and reduce operational expenses without compromising product quality.

Environmental concerns and regulatory compliance pose significant challenges for many industries. Stricter environmental regulations require manufacturers to adopt cleaner production methods and reduce their carbon footprint. This often necessitates substantial investments in new technologies and equipment, which can be financially burdensome for some companies.

Quality control and consistency in large-scale production remain ongoing challenges. Maintaining uniform product quality across massive production runs is crucial but often difficult to achieve. Variations in raw materials, equipment performance, and human factors can all contribute to inconsistencies in the final product.

Supply chain management and logistics present another set of challenges in large-scale manufacturing. Ensuring a steady supply of raw materials, managing inventory effectively, and coordinating complex distribution networks are critical for maintaining smooth operations. Disruptions in the supply chain can lead to production delays and increased costs.

The integration of advanced technologies, such as automation and artificial intelligence, into existing manufacturing processes is a significant challenge. While these technologies offer tremendous potential for improving efficiency and productivity, their implementation often requires substantial investment and can be disruptive to established workflows.

Workforce management and skill development are also crucial challenges. As manufacturing processes become more technologically advanced, there is a growing need for skilled workers who can operate and maintain sophisticated equipment. Many industries face difficulties in recruiting and retaining qualified personnel.

Energy consumption and resource management pose additional challenges. Large-scale manufacturing processes often require significant amounts of energy and resources. Optimizing energy usage and minimizing waste are essential for both cost reduction and environmental sustainability.

In this context, the use of sodium bisulfate in manufacturing processes presents an opportunity to address some of these challenges. Its potential advantages in improving efficiency, reducing environmental impact, and enhancing product quality make it an attractive option for many industries seeking to overcome current manufacturing hurdles.

Environmental concerns and regulatory compliance pose significant challenges for many industries. Stricter environmental regulations require manufacturers to adopt cleaner production methods and reduce their carbon footprint. This often necessitates substantial investments in new technologies and equipment, which can be financially burdensome for some companies.

Quality control and consistency in large-scale production remain ongoing challenges. Maintaining uniform product quality across massive production runs is crucial but often difficult to achieve. Variations in raw materials, equipment performance, and human factors can all contribute to inconsistencies in the final product.

Supply chain management and logistics present another set of challenges in large-scale manufacturing. Ensuring a steady supply of raw materials, managing inventory effectively, and coordinating complex distribution networks are critical for maintaining smooth operations. Disruptions in the supply chain can lead to production delays and increased costs.

The integration of advanced technologies, such as automation and artificial intelligence, into existing manufacturing processes is a significant challenge. While these technologies offer tremendous potential for improving efficiency and productivity, their implementation often requires substantial investment and can be disruptive to established workflows.

Workforce management and skill development are also crucial challenges. As manufacturing processes become more technologically advanced, there is a growing need for skilled workers who can operate and maintain sophisticated equipment. Many industries face difficulties in recruiting and retaining qualified personnel.

Energy consumption and resource management pose additional challenges. Large-scale manufacturing processes often require significant amounts of energy and resources. Optimizing energy usage and minimizing waste are essential for both cost reduction and environmental sustainability.

In this context, the use of sodium bisulfate in manufacturing processes presents an opportunity to address some of these challenges. Its potential advantages in improving efficiency, reducing environmental impact, and enhancing product quality make it an attractive option for many industries seeking to overcome current manufacturing hurdles.

Sodium Bisulfate Process Integration

01 Use in water treatment and pH adjustment

Sodium bisulfate is commonly used in water treatment processes for pH adjustment and as a disinfectant. It can effectively lower the pH of water, making it useful in swimming pools, spas, and industrial water treatment applications. The compound helps maintain proper water chemistry and can prevent the growth of harmful microorganisms.- Use of sodium bisulfate in oral care products: Sodium bisulfate is utilized in oral care formulations such as toothpaste, mouthwash, and dental rinses. It acts as a pH adjuster and can help in reducing bacterial growth in the oral cavity. The compound's acidic nature contributes to its effectiveness in maintaining oral hygiene and freshness.

- Application in water treatment and purification: Sodium bisulfate is employed in water treatment processes for pH adjustment and as a disinfectant. It can effectively lower the pH of water, making it useful in swimming pool maintenance and industrial water treatment systems. The compound also aids in removing chloramines and other impurities from water.

- Use as a cleaning and descaling agent: Sodium bisulfate is utilized in various cleaning and descaling applications. Its acidic properties make it effective in removing mineral deposits, rust, and other stubborn stains. It is commonly used in household and industrial cleaning products, particularly for bathroom and kitchen surfaces.

- Application in food processing and preservation: Sodium bisulfate finds applications in the food industry as a preservative and pH regulator. It can inhibit microbial growth and extend the shelf life of certain food products. The compound is also used in meat processing to control pathogens and improve food safety.

- Use in agricultural and horticultural applications: Sodium bisulfate is employed in agriculture and horticulture for soil pH adjustment and as a fertilizer additive. It can help in reducing soil alkalinity and improving nutrient uptake by plants. The compound is also used in animal feed additives to enhance digestibility and control pathogens.

02 Application in food processing and preservation

Sodium bisulfate finds applications in the food industry as a preservative and pH regulator. It can be used to prevent microbial growth, extend shelf life, and maintain the quality of various food products. The compound is particularly effective in controlling the growth of bacteria, yeasts, and molds in food processing environments.Expand Specific Solutions03 Use in cleaning and disinfection products

Sodium bisulfate is utilized in the formulation of cleaning and disinfection products due to its acidic properties and ability to kill microorganisms. It can be found in household cleaners, industrial degreasers, and sanitizing solutions. The compound's effectiveness in removing mineral deposits and its compatibility with other cleaning agents make it a versatile ingredient in various cleaning applications.Expand Specific Solutions04 Application in agriculture and soil treatment

Sodium bisulfate is used in agriculture for soil treatment and pH adjustment. It can help lower soil pH, making it beneficial for growing acid-loving plants. The compound can also be used to treat alkaline soils and improve nutrient availability for plants. Additionally, it may be employed in the treatment of animal waste and as a component in fertilizer formulations.Expand Specific Solutions05 Use in industrial processes and manufacturing

Sodium bisulfate has various industrial applications, including metal surface treatment, textile processing, and as a reagent in chemical manufacturing. It can be used as a pickling agent for metals, a reducing agent in certain chemical reactions, and as a component in the production of dyes and pigments. The compound's acidic nature and chemical properties make it valuable in diverse industrial processes.Expand Specific Solutions

Key Manufacturers and Suppliers

The sodium bisulfate market in large-scale manufacturing processes is in a growth phase, driven by increasing industrial applications and environmental regulations. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, sodium bisulfate production is mature, but innovations in application methods and purification processes are ongoing. Key players like Kemira Oyj, China Petroleum & Chemical Corp., and Sumitomo Metal Mining Co. Ltd. are investing in R&D to improve efficiency and reduce environmental impact. Emerging companies such as Paqell BV are introducing novel biological desulfurization technologies, indicating a shift towards more sustainable production methods in the industry.

Kemira Oyj

Technical Solution: Kemira Oyj has pioneered the use of sodium bisulfate in water treatment and pulp and paper manufacturing processes. Their innovative approach involves the application of sodium bisulfate as a pH control agent and a source of sulfate ions in various industrial processes. Kemira has developed a proprietary dosing system that allows for precise and automated addition of sodium bisulfate, ensuring optimal pH levels and sulfate concentrations throughout the manufacturing process[2]. The company has also implemented advanced process control algorithms that adjust sodium bisulfate dosage based on real-time water quality parameters, resulting in significant improvements in process efficiency and product quality[4]. Furthermore, Kemira's technology includes a novel formulation of sodium bisulfate that enhances its stability and dissolution properties, making it more effective in large-scale applications[6].

Strengths: Precise pH control, improved process efficiency, and enhanced product quality. Weaknesses: Potential corrosion issues in equipment and the need for specialized handling and storage facilities.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed innovative applications of sodium bisulfate in oil and gas processing. Their technology focuses on using sodium bisulfate as a cost-effective and efficient alternative to traditional acidizing agents in well stimulation and enhanced oil recovery processes. Sinopec's approach involves a proprietary formulation of sodium bisulfate that improves its penetration and reactivity in reservoir formations[7]. The company has also implemented advanced injection systems that allow for precise control of sodium bisulfate concentration and flow rate, optimizing its effectiveness in dissolving scale and improving formation permeability[9]. Additionally, Sinopec has developed a novel process for on-site generation of sodium bisulfate, reducing transportation costs and improving safety in remote locations[11].

Strengths: Cost-effective alternative to traditional acids, improved well stimulation efficiency, and on-site generation capabilities. Weaknesses: Potential limitations in high-temperature reservoirs and the need for specialized handling equipment.

Innovative Sodium Bisulfate Technologies

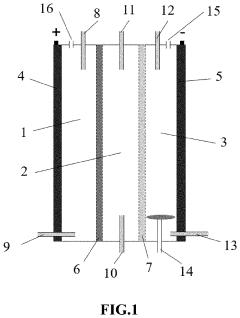

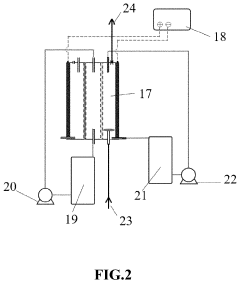

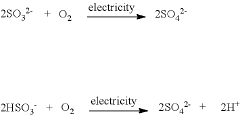

Method and apparatus for capturing carbon dioxide and producing sulfuric acid by sodium bisulfate

PatentActiveUS20210371282A1

Innovation

- A three-format electrodialysis apparatus is used to convert sodium bisulfate solutions into sulfuric acid and capture carbon dioxide from flue gas, employing an anion and cation exchange membrane system to generate sulfuric acid and sodium hydroxide, which absorbs CO2, thereby enhancing the value of desulfurized products and improving flue gas treatment efficiency.

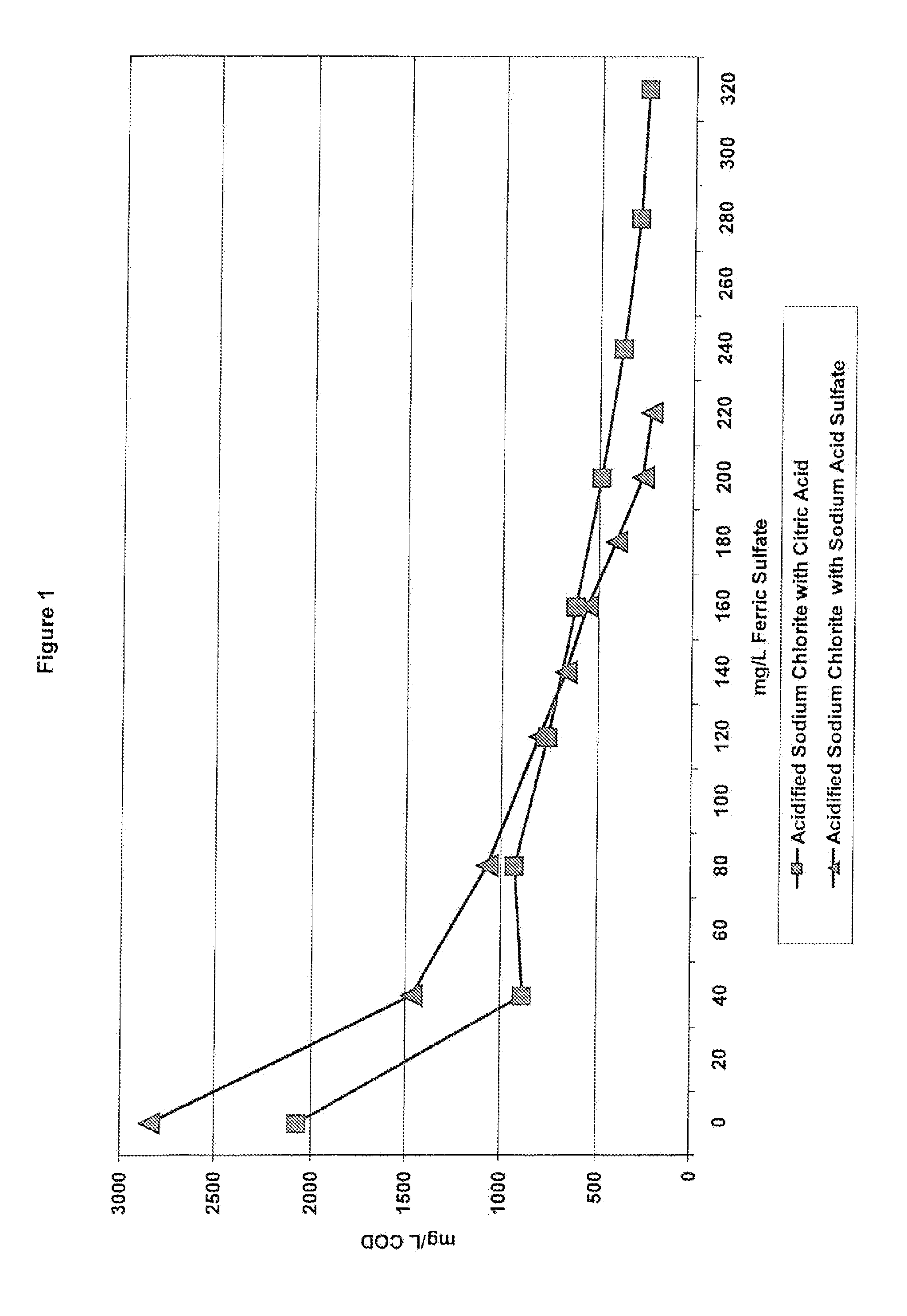

Oxidation method and compositions therefor

PatentActiveUS20100227004A1

Innovation

- Sodium acid sulfate, which provides the bisulfate ion, is used as an acid activator in a two-part oxidizing system with metal chlorite, forming an effective antimicrobial oxidizing composition that reduces ion concentration, energy consumption, and solid waste, while being environmentally friendly and safe for food contact surfaces.

Environmental Impact Assessment

The use of sodium bisulfate in large-scale manufacturing processes necessitates a comprehensive environmental impact assessment. This chemical compound, while beneficial for various industrial applications, can have significant effects on the surrounding ecosystem if not properly managed.

One of the primary environmental concerns associated with sodium bisulfate is its potential to alter the pH of aquatic environments. When released into water bodies, it can cause acidification, leading to detrimental effects on aquatic flora and fauna. This impact is particularly pronounced in freshwater ecosystems, where even slight changes in pH can disrupt the delicate balance of microbial communities and affect the survival of fish and other aquatic organisms.

Air quality is another crucial aspect to consider in the environmental impact assessment of sodium bisulfate usage. While the compound itself is not volatile, the manufacturing processes involving sodium bisulfate may release sulfur dioxide as a byproduct. Sulfur dioxide is a known air pollutant that contributes to the formation of acid rain and can have adverse effects on human respiratory health, particularly in areas surrounding manufacturing facilities.

Soil contamination is also a potential risk associated with the large-scale use of sodium bisulfate. Improper handling, storage, or disposal of the compound can lead to soil acidification, affecting plant growth and soil microbial activity. This, in turn, can have cascading effects on local ecosystems and agricultural productivity in affected areas.

The assessment must also consider the lifecycle impact of sodium bisulfate production and use. This includes evaluating the environmental footprint of raw material extraction, transportation, and the energy consumption associated with its manufacturing process. Additionally, the potential for recycling or reusing sodium bisulfate in industrial processes should be explored to minimize waste and reduce overall environmental impact.

Water resource management is a critical component of the environmental impact assessment. Large-scale manufacturing processes utilizing sodium bisulfate often require significant water inputs, both for the production of the compound and its subsequent applications. The assessment should evaluate the strain on local water resources and propose strategies for efficient water use and treatment of effluents to minimize environmental impact.

Biodiversity impacts must also be carefully evaluated, particularly in sensitive ecosystems near manufacturing facilities. The assessment should include studies on the potential effects of sodium bisulfate on local flora and fauna, including any endangered or protected species that may be present in the area.

Lastly, the environmental impact assessment should propose mitigation strategies and best practices for the responsible use of sodium bisulfate in large-scale manufacturing. This may include recommendations for closed-loop systems, advanced effluent treatment technologies, and stringent monitoring protocols to ensure compliance with environmental regulations and minimize ecological disruption.

One of the primary environmental concerns associated with sodium bisulfate is its potential to alter the pH of aquatic environments. When released into water bodies, it can cause acidification, leading to detrimental effects on aquatic flora and fauna. This impact is particularly pronounced in freshwater ecosystems, where even slight changes in pH can disrupt the delicate balance of microbial communities and affect the survival of fish and other aquatic organisms.

Air quality is another crucial aspect to consider in the environmental impact assessment of sodium bisulfate usage. While the compound itself is not volatile, the manufacturing processes involving sodium bisulfate may release sulfur dioxide as a byproduct. Sulfur dioxide is a known air pollutant that contributes to the formation of acid rain and can have adverse effects on human respiratory health, particularly in areas surrounding manufacturing facilities.

Soil contamination is also a potential risk associated with the large-scale use of sodium bisulfate. Improper handling, storage, or disposal of the compound can lead to soil acidification, affecting plant growth and soil microbial activity. This, in turn, can have cascading effects on local ecosystems and agricultural productivity in affected areas.

The assessment must also consider the lifecycle impact of sodium bisulfate production and use. This includes evaluating the environmental footprint of raw material extraction, transportation, and the energy consumption associated with its manufacturing process. Additionally, the potential for recycling or reusing sodium bisulfate in industrial processes should be explored to minimize waste and reduce overall environmental impact.

Water resource management is a critical component of the environmental impact assessment. Large-scale manufacturing processes utilizing sodium bisulfate often require significant water inputs, both for the production of the compound and its subsequent applications. The assessment should evaluate the strain on local water resources and propose strategies for efficient water use and treatment of effluents to minimize environmental impact.

Biodiversity impacts must also be carefully evaluated, particularly in sensitive ecosystems near manufacturing facilities. The assessment should include studies on the potential effects of sodium bisulfate on local flora and fauna, including any endangered or protected species that may be present in the area.

Lastly, the environmental impact assessment should propose mitigation strategies and best practices for the responsible use of sodium bisulfate in large-scale manufacturing. This may include recommendations for closed-loop systems, advanced effluent treatment technologies, and stringent monitoring protocols to ensure compliance with environmental regulations and minimize ecological disruption.

Cost-Benefit Analysis

The cost-benefit analysis of using sodium bisulfate in large-scale manufacturing processes reveals significant advantages that contribute to its growing popularity in various industries. From an economic perspective, sodium bisulfate offers a cost-effective alternative to many traditional chemicals used in manufacturing. Its relatively low production costs and widespread availability make it an attractive option for businesses looking to optimize their operational expenses.

One of the primary benefits of sodium bisulfate is its versatility. It can be used in multiple applications across different manufacturing sectors, including water treatment, metal finishing, and food processing. This multi-functionality allows companies to streamline their chemical inventories, potentially reducing storage costs and simplifying procurement processes. Additionally, the use of a single chemical for various purposes can lead to economies of scale in purchasing and handling.

In terms of process efficiency, sodium bisulfate demonstrates notable advantages. Its high solubility in water enables rapid dissolution and integration into manufacturing processes, reducing production time and energy consumption. This characteristic is particularly beneficial in continuous flow systems, where quick reactions and minimal downtime are crucial for maintaining high productivity levels.

The environmental impact of sodium bisulfate usage also factors into the cost-benefit analysis. Compared to some alternative chemicals, sodium bisulfate often has a lower environmental footprint, which can translate to reduced costs associated with waste treatment and disposal. Furthermore, its effectiveness in pH adjustment and as a cleaning agent can lead to improved product quality and reduced defect rates, ultimately saving on material costs and minimizing waste.

From a safety standpoint, while sodium bisulfate requires proper handling, it generally poses fewer risks than some more hazardous alternatives. This can result in lower insurance premiums and reduced costs related to safety equipment and specialized training. The relatively stable nature of sodium bisulfate also contributes to longer shelf life, potentially decreasing inventory turnover costs and the risk of expired chemicals.

However, it is important to consider potential drawbacks in the cost-benefit analysis. Initial implementation costs may be incurred when switching to sodium bisulfate, including equipment modifications and staff training. Additionally, while generally cost-effective, market fluctuations in raw material prices can impact the long-term economic benefits of using sodium bisulfate.

In conclusion, the cost-benefit analysis of sodium bisulfate in large-scale manufacturing processes predominantly favors its adoption. The combination of economic advantages, process efficiencies, environmental benefits, and safety considerations often outweighs the potential drawbacks, making it a valuable chemical in modern manufacturing operations.

One of the primary benefits of sodium bisulfate is its versatility. It can be used in multiple applications across different manufacturing sectors, including water treatment, metal finishing, and food processing. This multi-functionality allows companies to streamline their chemical inventories, potentially reducing storage costs and simplifying procurement processes. Additionally, the use of a single chemical for various purposes can lead to economies of scale in purchasing and handling.

In terms of process efficiency, sodium bisulfate demonstrates notable advantages. Its high solubility in water enables rapid dissolution and integration into manufacturing processes, reducing production time and energy consumption. This characteristic is particularly beneficial in continuous flow systems, where quick reactions and minimal downtime are crucial for maintaining high productivity levels.

The environmental impact of sodium bisulfate usage also factors into the cost-benefit analysis. Compared to some alternative chemicals, sodium bisulfate often has a lower environmental footprint, which can translate to reduced costs associated with waste treatment and disposal. Furthermore, its effectiveness in pH adjustment and as a cleaning agent can lead to improved product quality and reduced defect rates, ultimately saving on material costs and minimizing waste.

From a safety standpoint, while sodium bisulfate requires proper handling, it generally poses fewer risks than some more hazardous alternatives. This can result in lower insurance premiums and reduced costs related to safety equipment and specialized training. The relatively stable nature of sodium bisulfate also contributes to longer shelf life, potentially decreasing inventory turnover costs and the risk of expired chemicals.

However, it is important to consider potential drawbacks in the cost-benefit analysis. Initial implementation costs may be incurred when switching to sodium bisulfate, including equipment modifications and staff training. Additionally, while generally cost-effective, market fluctuations in raw material prices can impact the long-term economic benefits of using sodium bisulfate.

In conclusion, the cost-benefit analysis of sodium bisulfate in large-scale manufacturing processes predominantly favors its adoption. The combination of economic advantages, process efficiencies, environmental benefits, and safety considerations often outweighs the potential drawbacks, making it a valuable chemical in modern manufacturing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!