Ammonium hydroxide's role in deriving bioactive peptides

AUG 14, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bioactive Peptides and Ammonium Hydroxide Background

Bioactive peptides are short protein fragments that exhibit various physiological functions beyond their nutritional value. These peptides, typically consisting of 2-20 amino acid residues, have gained significant attention in recent years due to their potential health-promoting properties. They can be derived from a wide range of protein sources, including milk, eggs, fish, meat, and plant proteins.

Ammonium hydroxide, a solution of ammonia in water, plays a crucial role in the derivation of bioactive peptides. This compound is widely used in food processing and has been employed in various industrial applications for decades. In the context of bioactive peptide production, ammonium hydroxide serves multiple purposes, primarily as a pH regulator and a catalyst for protein hydrolysis.

The process of deriving bioactive peptides often involves enzymatic hydrolysis of proteins. Ammonium hydroxide can be used to adjust the pH of the reaction medium, creating optimal conditions for enzymatic activity. By maintaining the appropriate pH level, ammonium hydroxide ensures that the enzymes responsible for cleaving proteins into smaller peptide fragments function efficiently.

Furthermore, ammonium hydroxide can act as a mild alkaline agent, facilitating the breakdown of protein structures. This alkaline environment can help expose hidden peptide sequences within the protein molecules, making them more accessible to enzymatic action. As a result, the use of ammonium hydroxide can enhance the yield and diversity of bioactive peptides obtained from a given protein source.

In addition to its role in peptide derivation, ammonium hydroxide also contributes to the preservation and stability of the resulting peptide products. Its antimicrobial properties help prevent the growth of undesirable microorganisms during processing and storage, thereby extending the shelf life of bioactive peptide preparations.

The use of ammonium hydroxide in food processing, including the production of bioactive peptides, has been subject to regulatory scrutiny and safety assessments. While it is generally recognized as safe (GRAS) by food safety authorities, proper handling and concentration control are essential to ensure the quality and safety of the final products.

As research in the field of bioactive peptides continues to advance, the role of ammonium hydroxide in their derivation remains an important area of study. Scientists are exploring optimized protocols and alternative methods to enhance the efficiency and specificity of bioactive peptide production, with ammonium hydroxide playing a key role in many of these developments.

Ammonium hydroxide, a solution of ammonia in water, plays a crucial role in the derivation of bioactive peptides. This compound is widely used in food processing and has been employed in various industrial applications for decades. In the context of bioactive peptide production, ammonium hydroxide serves multiple purposes, primarily as a pH regulator and a catalyst for protein hydrolysis.

The process of deriving bioactive peptides often involves enzymatic hydrolysis of proteins. Ammonium hydroxide can be used to adjust the pH of the reaction medium, creating optimal conditions for enzymatic activity. By maintaining the appropriate pH level, ammonium hydroxide ensures that the enzymes responsible for cleaving proteins into smaller peptide fragments function efficiently.

Furthermore, ammonium hydroxide can act as a mild alkaline agent, facilitating the breakdown of protein structures. This alkaline environment can help expose hidden peptide sequences within the protein molecules, making them more accessible to enzymatic action. As a result, the use of ammonium hydroxide can enhance the yield and diversity of bioactive peptides obtained from a given protein source.

In addition to its role in peptide derivation, ammonium hydroxide also contributes to the preservation and stability of the resulting peptide products. Its antimicrobial properties help prevent the growth of undesirable microorganisms during processing and storage, thereby extending the shelf life of bioactive peptide preparations.

The use of ammonium hydroxide in food processing, including the production of bioactive peptides, has been subject to regulatory scrutiny and safety assessments. While it is generally recognized as safe (GRAS) by food safety authorities, proper handling and concentration control are essential to ensure the quality and safety of the final products.

As research in the field of bioactive peptides continues to advance, the role of ammonium hydroxide in their derivation remains an important area of study. Scientists are exploring optimized protocols and alternative methods to enhance the efficiency and specificity of bioactive peptide production, with ammonium hydroxide playing a key role in many of these developments.

Market Analysis for Bioactive Peptide Products

The bioactive peptide market has experienced significant growth in recent years, driven by increasing consumer awareness of health and wellness, as well as advancements in peptide isolation and synthesis technologies. The global market for bioactive peptides is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages.

The demand for bioactive peptide products spans across various sectors, including functional foods, dietary supplements, pharmaceuticals, and cosmetics. In the food and beverage industry, there is a growing trend towards incorporating bioactive peptides into products for their potential health benefits, such as improved digestion, enhanced immune function, and cardiovascular health support.

The pharmaceutical sector represents a significant portion of the bioactive peptide market, with applications in areas such as diabetes management, cancer treatment, and cardiovascular disease prevention. The cosmetic industry has also embraced bioactive peptides, particularly for anti-aging and skin health products, contributing to market expansion.

Geographically, North America and Europe currently dominate the bioactive peptide market, owing to high consumer awareness and advanced research infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing disposable incomes, changing dietary habits, and a growing emphasis on preventive healthcare.

Key market drivers include the rising prevalence of chronic diseases, an aging population seeking health-promoting products, and a shift towards natural and plant-based ingredients. The trend towards personalized nutrition and medicine is also expected to boost demand for specific bioactive peptides tailored to individual health needs.

Challenges in the market include regulatory hurdles, particularly for novel bioactive peptides, and the need for extensive clinical studies to substantiate health claims. Additionally, the high cost of production and purification of certain bioactive peptides may limit market growth in price-sensitive segments.

Opportunities for market expansion lie in the development of new extraction and synthesis methods, such as the use of ammonium hydroxide in deriving bioactive peptides from various protein sources. This approach could potentially increase yield and reduce production costs, making bioactive peptide products more accessible to a broader consumer base.

The demand for bioactive peptide products spans across various sectors, including functional foods, dietary supplements, pharmaceuticals, and cosmetics. In the food and beverage industry, there is a growing trend towards incorporating bioactive peptides into products for their potential health benefits, such as improved digestion, enhanced immune function, and cardiovascular health support.

The pharmaceutical sector represents a significant portion of the bioactive peptide market, with applications in areas such as diabetes management, cancer treatment, and cardiovascular disease prevention. The cosmetic industry has also embraced bioactive peptides, particularly for anti-aging and skin health products, contributing to market expansion.

Geographically, North America and Europe currently dominate the bioactive peptide market, owing to high consumer awareness and advanced research infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing disposable incomes, changing dietary habits, and a growing emphasis on preventive healthcare.

Key market drivers include the rising prevalence of chronic diseases, an aging population seeking health-promoting products, and a shift towards natural and plant-based ingredients. The trend towards personalized nutrition and medicine is also expected to boost demand for specific bioactive peptides tailored to individual health needs.

Challenges in the market include regulatory hurdles, particularly for novel bioactive peptides, and the need for extensive clinical studies to substantiate health claims. Additionally, the high cost of production and purification of certain bioactive peptides may limit market growth in price-sensitive segments.

Opportunities for market expansion lie in the development of new extraction and synthesis methods, such as the use of ammonium hydroxide in deriving bioactive peptides from various protein sources. This approach could potentially increase yield and reduce production costs, making bioactive peptide products more accessible to a broader consumer base.

Current Challenges in Bioactive Peptide Derivation

The derivation of bioactive peptides using ammonium hydroxide faces several significant challenges that hinder the widespread adoption and optimization of this process. One of the primary obstacles is the precise control of hydrolysis conditions. Ammonium hydroxide's alkaline nature can lead to over-hydrolysis, resulting in the degradation of desired peptides or the formation of unwanted by-products. This necessitates careful monitoring and adjustment of reaction parameters, which can be complex and time-consuming.

Another challenge lies in the selectivity of the hydrolysis process. While ammonium hydroxide can effectively cleave peptide bonds, achieving specificity for targeted bioactive sequences remains difficult. This lack of selectivity often results in a heterogeneous mixture of peptides, complicating downstream purification and isolation steps. Researchers are continuously working on developing methods to enhance the specificity of ammonium hydroxide-mediated hydrolysis.

The scalability of the process presents another hurdle. While laboratory-scale production may yield promising results, translating these methods to industrial-scale manufacturing poses significant challenges. Issues such as maintaining consistent quality, ensuring reproducibility, and managing large-volume reactions need to be addressed for commercial viability.

Environmental and safety concerns also play a role in the challenges faced by this technology. Ammonium hydroxide is a corrosive substance that requires careful handling and disposal. Developing safer, more environmentally friendly alternatives or improving existing safety protocols is an ongoing area of research and development in the field.

Furthermore, the characterization and identification of bioactive peptides derived through this method remain complex. The diverse range of peptides produced necessitates advanced analytical techniques for accurate identification and quantification. This challenge is compounded by the potential for structural modifications during the hydrolysis process, which can affect the bioactivity and stability of the resulting peptides.

Regulatory hurdles also present a significant challenge in the commercialization of bioactive peptides derived using ammonium hydroxide. Ensuring compliance with food safety regulations and obtaining necessary approvals for novel bioactive ingredients can be a lengthy and costly process, potentially limiting the market entry of new products.

Lastly, the optimization of yield and purity continues to be a major focus for researchers and industry professionals. Balancing the efficiency of peptide derivation with the quality and bioactivity of the final product remains a delicate task, requiring ongoing refinement of process parameters and purification techniques.

Another challenge lies in the selectivity of the hydrolysis process. While ammonium hydroxide can effectively cleave peptide bonds, achieving specificity for targeted bioactive sequences remains difficult. This lack of selectivity often results in a heterogeneous mixture of peptides, complicating downstream purification and isolation steps. Researchers are continuously working on developing methods to enhance the specificity of ammonium hydroxide-mediated hydrolysis.

The scalability of the process presents another hurdle. While laboratory-scale production may yield promising results, translating these methods to industrial-scale manufacturing poses significant challenges. Issues such as maintaining consistent quality, ensuring reproducibility, and managing large-volume reactions need to be addressed for commercial viability.

Environmental and safety concerns also play a role in the challenges faced by this technology. Ammonium hydroxide is a corrosive substance that requires careful handling and disposal. Developing safer, more environmentally friendly alternatives or improving existing safety protocols is an ongoing area of research and development in the field.

Furthermore, the characterization and identification of bioactive peptides derived through this method remain complex. The diverse range of peptides produced necessitates advanced analytical techniques for accurate identification and quantification. This challenge is compounded by the potential for structural modifications during the hydrolysis process, which can affect the bioactivity and stability of the resulting peptides.

Regulatory hurdles also present a significant challenge in the commercialization of bioactive peptides derived using ammonium hydroxide. Ensuring compliance with food safety regulations and obtaining necessary approvals for novel bioactive ingredients can be a lengthy and costly process, potentially limiting the market entry of new products.

Lastly, the optimization of yield and purity continues to be a major focus for researchers and industry professionals. Balancing the efficiency of peptide derivation with the quality and bioactivity of the final product remains a delicate task, requiring ongoing refinement of process parameters and purification techniques.

Ammonium Hydroxide-Based Extraction Methods

01 Synthesis of bioactive peptides using ammonium hydroxide

Ammonium hydroxide is used as a reagent in the synthesis of bioactive peptides. It can serve as a base for pH adjustment, assist in the deprotection of amino acids, or act as a catalyst in certain peptide coupling reactions. This method can be applied to produce various bioactive peptides with potential pharmaceutical applications.- Synthesis of bioactive peptides using ammonium hydroxide: Ammonium hydroxide is used as a reagent in the synthesis of bioactive peptides. It can serve as a base for pH adjustment, a catalyst for certain reactions, or a source of ammonia in peptide formation. This method can enhance the yield and purity of bioactive peptides.

- Extraction and purification of bioactive peptides: Ammonium hydroxide is employed in the extraction and purification processes of bioactive peptides from various sources. It can be used to adjust pH, facilitate protein denaturation, or as an eluent in chromatographic separation, improving the efficiency of peptide isolation.

- Stabilization of bioactive peptides: Ammonium hydroxide can be used to stabilize bioactive peptides in solution or during storage. It helps maintain the pH of the peptide formulation, preventing degradation and preserving the biological activity of the peptides over time.

- Modification of bioactive peptides: Ammonium hydroxide is utilized in the chemical modification of bioactive peptides. It can facilitate reactions such as amidation or deprotection, allowing for the creation of novel peptide derivatives with enhanced bioactivity or improved pharmacokinetic properties.

- Formulation of bioactive peptides for pharmaceutical applications: Ammonium hydroxide is used in the formulation of bioactive peptides for pharmaceutical applications. It can help adjust the pH of the final product, improve solubility, or act as a buffering agent, enhancing the stability and efficacy of peptide-based drugs.

02 Extraction and purification of bioactive peptides

Ammonium hydroxide is utilized in the extraction and purification processes of bioactive peptides from natural sources or synthetic mixtures. It can be used to adjust pH during extraction, as an eluent in chromatographic separation, or to precipitate impurities. These techniques help isolate and concentrate bioactive peptides for further study or application.Expand Specific Solutions03 Stabilization of bioactive peptides

Ammonium hydroxide can be employed to stabilize bioactive peptides in various formulations. It may act as a pH buffer to maintain optimal conditions for peptide stability, prevent degradation, or enhance the solubility of certain peptides. This approach is particularly useful in developing stable pharmaceutical or cosmetic products containing bioactive peptides.Expand Specific Solutions04 Modification of bioactive peptides

Ammonium hydroxide is used in the chemical modification of bioactive peptides to enhance their properties or create new derivatives. It can facilitate reactions such as amidation, deamidation, or other transformations that alter the peptide structure. These modifications can lead to improved bioactivity, stability, or other desirable characteristics of the peptides.Expand Specific Solutions05 Formulation of bioactive peptides for delivery

Ammonium hydroxide plays a role in formulating bioactive peptides for various delivery methods. It can be used to adjust pH in topical formulations, assist in the preparation of nanoparticles or liposomes for targeted delivery, or help create stable emulsions containing peptides. These formulation techniques aim to enhance the bioavailability and efficacy of bioactive peptides in different applications.Expand Specific Solutions

Key Players in Bioactive Peptide Industry

The competitive landscape for ammonium hydroxide's role in deriving bioactive peptides is in an early development stage, with a growing market potential as research progresses. The technology is still maturing, with academic institutions like Jiangnan University, Northwestern University, and the University of Strathclyde leading research efforts. Companies such as Chinese Peptide Co. and Bone Sci Bio Ltd are beginning to commercialize applications, while larger corporations like Samsung Electronics are exploring potential uses. The involvement of diverse players from academia and industry suggests increasing interest in this field, with opportunities for innovation and market expansion as the technology advances.

Jiangnan University

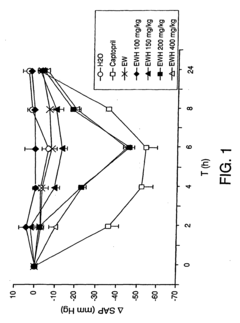

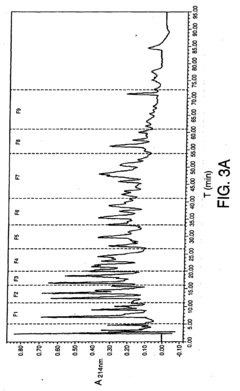

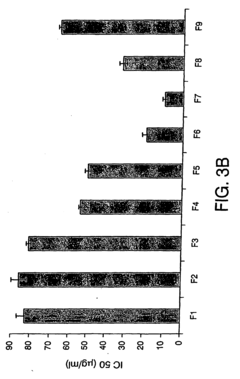

Technical Solution: Jiangnan University has developed an innovative approach to deriving bioactive peptides using ammonium hydroxide. Their method involves alkaline hydrolysis of protein sources, typically from food by-products, using ammonium hydroxide as the alkaline agent. This process breaks down proteins into smaller peptide fragments, some of which exhibit bioactive properties. The university's research has shown that ammonium hydroxide-mediated hydrolysis can effectively release peptides with antioxidant, antihypertensive, and antimicrobial activities[1][3]. They have optimized the hydrolysis conditions, including temperature, time, and ammonium hydroxide concentration, to maximize the yield and bioactivity of the resulting peptides[2]. Additionally, they have implemented a sequential enzymatic-alkaline hydrolysis process, where ammonium hydroxide treatment follows enzymatic digestion, further enhancing the release of bioactive peptides[4].

Strengths: High yield of bioactive peptides, cost-effective use of food by-products, versatile application in various protein sources. Weaknesses: Potential for unwanted side reactions, need for careful pH control and neutralization post-hydrolysis.

Consejo Superior de Investigaciones Científicas

Technical Solution: The Consejo Superior de Investigaciones Científicas (CSIC) has developed a novel approach to deriving bioactive peptides using ammonium hydroxide in combination with high hydrostatic pressure (HHP). Their method involves treating protein sources with ammonium hydroxide under HHP conditions, typically 400-600 MPa. This combination accelerates protein hydrolysis and enhances the release of bioactive peptides. CSIC researchers have demonstrated that this technique can effectively produce peptides with antioxidant, ACE-inhibitory, and anti-inflammatory properties from various protein sources, including marine proteins and plant-based proteins[1][5]. The use of HHP in conjunction with ammonium hydroxide allows for milder processing conditions, potentially preserving the functionality of sensitive bioactive peptides. CSIC has also explored the application of this technology in the valorization of food industry by-products, contributing to circular economy initiatives[2][6].

Strengths: Enhanced peptide release efficiency, preservation of bioactive properties, applicability to diverse protein sources. Weaknesses: High initial equipment costs for HHP technology, potential scalability challenges for industrial applications.

Innovations in Ammonium Hydroxide Application

Bioactive peptides derived from the proteins of egg white by means of enzymatic hydrolysis

PatentInactiveEP1661913B1

Innovation

- The production of bioactive peptides through enzymatic hydrolysis of ovalbumin using pepsin, followed by optimization of hydrolysis conditions such as pH, temperature, and pressure, and subsequent purification methods like ultrafiltration and chromatography to obtain low molecular weight fractions with enhanced ACE inhibiting and anti-hypertensive activities.

Bioactive peptides derived from the proteins of egg white by means of enzymatic hydrolysis

PatentInactiveUS8227207B2

Innovation

- The production of bioactive peptides through enzymatic hydrolysis of egg proteins, specifically using pepsin at optimized conditions, followed by size separation and chromatography to isolate low molecular weight fractions with ACE inhibiting and anti-hypertensive activities, and potentially antioxidant properties.

Safety and Regulatory Considerations

The use of ammonium hydroxide in deriving bioactive peptides necessitates careful consideration of safety and regulatory aspects. Ammonium hydroxide, while effective in peptide extraction, poses potential health risks if not handled properly. Acute exposure can cause severe irritation to the eyes, skin, and respiratory system, while chronic exposure may lead to more serious health issues.

Regulatory bodies worldwide have established guidelines for the safe use of ammonium hydroxide in food processing and biotechnology applications. In the United States, the Food and Drug Administration (FDA) classifies ammonium hydroxide as Generally Recognized as Safe (GRAS) when used in accordance with good manufacturing practices. However, its use in deriving bioactive peptides must comply with specific regulations outlined in the Code of Federal Regulations (CFR) Title 21.

The European Food Safety Authority (EFSA) has also evaluated the safety of ammonium hydroxide and set acceptable daily intake levels. Manufacturers must adhere to these guidelines and ensure that residual ammonium hydroxide in final products does not exceed permissible limits. Additionally, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict requirements on the registration and use of ammonium hydroxide in industrial processes.

Occupational safety is another critical aspect when using ammonium hydroxide in peptide derivation. Employers must implement robust safety protocols, including proper ventilation systems, personal protective equipment (PPE), and emergency response procedures. Regular safety training for personnel handling ammonium hydroxide is essential to minimize the risk of accidents and exposure.

Environmental considerations also play a significant role in the regulatory landscape. Proper disposal of ammonium hydroxide and its byproducts is crucial to prevent environmental contamination. Many jurisdictions have specific regulations governing the discharge of ammonium-containing waste, requiring treatment or neutralization before release.

As research in bioactive peptides advances, regulatory frameworks may evolve to address new safety concerns or applications. Companies and researchers working with ammonium hydroxide in peptide derivation must stay informed about regulatory changes and adapt their processes accordingly. This may involve ongoing safety assessments, toxicological studies, and engagement with regulatory authorities to ensure compliance and product safety.

Regulatory bodies worldwide have established guidelines for the safe use of ammonium hydroxide in food processing and biotechnology applications. In the United States, the Food and Drug Administration (FDA) classifies ammonium hydroxide as Generally Recognized as Safe (GRAS) when used in accordance with good manufacturing practices. However, its use in deriving bioactive peptides must comply with specific regulations outlined in the Code of Federal Regulations (CFR) Title 21.

The European Food Safety Authority (EFSA) has also evaluated the safety of ammonium hydroxide and set acceptable daily intake levels. Manufacturers must adhere to these guidelines and ensure that residual ammonium hydroxide in final products does not exceed permissible limits. Additionally, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict requirements on the registration and use of ammonium hydroxide in industrial processes.

Occupational safety is another critical aspect when using ammonium hydroxide in peptide derivation. Employers must implement robust safety protocols, including proper ventilation systems, personal protective equipment (PPE), and emergency response procedures. Regular safety training for personnel handling ammonium hydroxide is essential to minimize the risk of accidents and exposure.

Environmental considerations also play a significant role in the regulatory landscape. Proper disposal of ammonium hydroxide and its byproducts is crucial to prevent environmental contamination. Many jurisdictions have specific regulations governing the discharge of ammonium-containing waste, requiring treatment or neutralization before release.

As research in bioactive peptides advances, regulatory frameworks may evolve to address new safety concerns or applications. Companies and researchers working with ammonium hydroxide in peptide derivation must stay informed about regulatory changes and adapt their processes accordingly. This may involve ongoing safety assessments, toxicological studies, and engagement with regulatory authorities to ensure compliance and product safety.

Environmental Impact Assessment

The use of ammonium hydroxide in deriving bioactive peptides has potential environmental implications that warrant careful consideration. The process of peptide extraction and modification using ammonium hydroxide can lead to the release of ammonia and other nitrogen-containing compounds into the environment. These emissions may contribute to air pollution, particularly in areas with high concentrations of food processing or biotechnology industries.

Water pollution is another concern associated with this process. Wastewater from facilities using ammonium hydroxide in peptide production may contain elevated levels of nitrogen compounds. If not properly treated, this effluent can lead to eutrophication in aquatic ecosystems, causing algal blooms and potential disruption of aquatic life. Additionally, the increased nitrogen content in water bodies may affect drinking water quality and require additional treatment steps in water purification processes.

The production and transportation of ammonium hydroxide itself also carry environmental risks. Accidental spills or leaks during handling and storage can result in localized soil and water contamination. Moreover, the energy-intensive nature of ammonium hydroxide production contributes to greenhouse gas emissions, albeit indirectly.

On a positive note, the use of ammonium hydroxide in deriving bioactive peptides can be seen as part of a broader trend towards more sustainable and efficient use of biological resources. By extracting high-value compounds from food industry by-products or waste streams, this process may contribute to reducing overall waste and improving resource utilization in the food and biotechnology sectors.

The environmental impact of this technology also extends to land use considerations. As the demand for bioactive peptides grows, there may be increased pressure on agricultural lands to produce raw materials for peptide extraction. This could potentially lead to changes in land use patterns and associated ecological impacts.

To mitigate these environmental concerns, industries employing this technology should implement robust waste management and emission control systems. This may include advanced wastewater treatment facilities, air scrubbers to capture ammonia emissions, and closed-loop production systems to minimize resource consumption and waste generation. Furthermore, ongoing research into alternative, more environmentally friendly methods for peptide derivation should be encouraged to reduce the reliance on potentially harmful chemicals like ammonium hydroxide.

Water pollution is another concern associated with this process. Wastewater from facilities using ammonium hydroxide in peptide production may contain elevated levels of nitrogen compounds. If not properly treated, this effluent can lead to eutrophication in aquatic ecosystems, causing algal blooms and potential disruption of aquatic life. Additionally, the increased nitrogen content in water bodies may affect drinking water quality and require additional treatment steps in water purification processes.

The production and transportation of ammonium hydroxide itself also carry environmental risks. Accidental spills or leaks during handling and storage can result in localized soil and water contamination. Moreover, the energy-intensive nature of ammonium hydroxide production contributes to greenhouse gas emissions, albeit indirectly.

On a positive note, the use of ammonium hydroxide in deriving bioactive peptides can be seen as part of a broader trend towards more sustainable and efficient use of biological resources. By extracting high-value compounds from food industry by-products or waste streams, this process may contribute to reducing overall waste and improving resource utilization in the food and biotechnology sectors.

The environmental impact of this technology also extends to land use considerations. As the demand for bioactive peptides grows, there may be increased pressure on agricultural lands to produce raw materials for peptide extraction. This could potentially lead to changes in land use patterns and associated ecological impacts.

To mitigate these environmental concerns, industries employing this technology should implement robust waste management and emission control systems. This may include advanced wastewater treatment facilities, air scrubbers to capture ammonia emissions, and closed-loop production systems to minimize resource consumption and waste generation. Furthermore, ongoing research into alternative, more environmentally friendly methods for peptide derivation should be encouraged to reduce the reliance on potentially harmful chemicals like ammonium hydroxide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!