Ammonium hydroxide in recycling carbon fiber composites

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in CFRP Recycling: Background and Objectives

Carbon fiber reinforced polymer (CFRP) composites have become increasingly prevalent in various industries due to their exceptional strength-to-weight ratio and durability. However, the growing use of these materials has raised concerns about their end-of-life disposal and the potential for recycling. Traditional recycling methods for CFRP composites have been limited in their effectiveness and often result in significant degradation of the recovered fibers.

In recent years, the use of ammonium hydroxide in recycling carbon fiber composites has emerged as a promising approach to address these challenges. This technique falls under the broader category of chemical recycling methods, which aim to break down the polymer matrix while preserving the integrity of the carbon fibers. The development of this method represents a significant step forward in the quest for more sustainable and efficient recycling processes for advanced composite materials.

The evolution of CFRP recycling technologies has been driven by both environmental concerns and economic incentives. As regulations surrounding waste management and circular economy principles become more stringent, industries are increasingly motivated to find effective ways to recycle and reuse valuable materials like carbon fibers. The ammonium hydroxide-based recycling method offers a potential solution that aligns with these goals.

The primary objective of research into using ammonium hydroxide for CFRP recycling is to develop a process that can effectively separate carbon fibers from the polymer matrix while maintaining the fibers' mechanical properties. This approach aims to overcome the limitations of traditional recycling methods, such as mechanical grinding or pyrolysis, which often result in shortened or damaged fibers with reduced performance characteristics.

Additionally, researchers are exploring the potential of ammonium hydroxide-based recycling to recover not only the carbon fibers but also valuable components from the polymer matrix. This dual recovery approach could significantly enhance the economic viability of CFRP recycling processes, making them more attractive to industry stakeholders.

The technical goals of this research include optimizing the reaction conditions, such as temperature, pressure, and concentration of ammonium hydroxide, to achieve maximum efficiency in separating the fibers from the matrix. Furthermore, researchers aim to develop scalable processes that can be implemented in industrial settings, addressing challenges related to process control, safety, and environmental impact.

As the field progresses, there is also a focus on understanding the fundamental mechanisms by which ammonium hydroxide interacts with different types of polymer matrices used in CFRP composites. This knowledge is crucial for expanding the applicability of the technique to a wider range of composite materials and potentially developing tailored recycling processes for specific CFRP formulations.

In recent years, the use of ammonium hydroxide in recycling carbon fiber composites has emerged as a promising approach to address these challenges. This technique falls under the broader category of chemical recycling methods, which aim to break down the polymer matrix while preserving the integrity of the carbon fibers. The development of this method represents a significant step forward in the quest for more sustainable and efficient recycling processes for advanced composite materials.

The evolution of CFRP recycling technologies has been driven by both environmental concerns and economic incentives. As regulations surrounding waste management and circular economy principles become more stringent, industries are increasingly motivated to find effective ways to recycle and reuse valuable materials like carbon fibers. The ammonium hydroxide-based recycling method offers a potential solution that aligns with these goals.

The primary objective of research into using ammonium hydroxide for CFRP recycling is to develop a process that can effectively separate carbon fibers from the polymer matrix while maintaining the fibers' mechanical properties. This approach aims to overcome the limitations of traditional recycling methods, such as mechanical grinding or pyrolysis, which often result in shortened or damaged fibers with reduced performance characteristics.

Additionally, researchers are exploring the potential of ammonium hydroxide-based recycling to recover not only the carbon fibers but also valuable components from the polymer matrix. This dual recovery approach could significantly enhance the economic viability of CFRP recycling processes, making them more attractive to industry stakeholders.

The technical goals of this research include optimizing the reaction conditions, such as temperature, pressure, and concentration of ammonium hydroxide, to achieve maximum efficiency in separating the fibers from the matrix. Furthermore, researchers aim to develop scalable processes that can be implemented in industrial settings, addressing challenges related to process control, safety, and environmental impact.

As the field progresses, there is also a focus on understanding the fundamental mechanisms by which ammonium hydroxide interacts with different types of polymer matrices used in CFRP composites. This knowledge is crucial for expanding the applicability of the technique to a wider range of composite materials and potentially developing tailored recycling processes for specific CFRP formulations.

Market Analysis for Recycled Carbon Fiber Materials

The market for recycled carbon fiber materials has been experiencing significant growth in recent years, driven by increasing environmental concerns and the push for sustainable manufacturing practices. The global recycled carbon fiber market is expected to reach substantial value by 2025, with a compound annual growth rate (CAGR) of over 10% during the forecast period. This growth is primarily attributed to the rising demand for lightweight and high-strength materials in various industries, including automotive, aerospace, and wind energy.

The automotive sector represents a major market for recycled carbon fiber materials, as manufacturers seek to reduce vehicle weight and improve fuel efficiency. The aerospace industry is another key consumer, utilizing recycled carbon fiber in non-critical components to meet stringent environmental regulations and reduce costs. The wind energy sector is also showing increased interest in recycled carbon fiber for turbine blade manufacturing, aiming to enhance durability while reducing overall weight.

Geographically, North America and Europe are the leading markets for recycled carbon fiber materials, owing to stringent environmental regulations and a strong presence of end-use industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization and increasing adoption of sustainable practices in countries like China and Japan.

The market demand for recycled carbon fiber is further bolstered by its cost-effectiveness compared to virgin carbon fiber. Recycled carbon fiber can be up to 40% cheaper than its virgin counterpart while retaining much of its mechanical properties. This price advantage is particularly attractive to industries looking to reduce production costs without compromising on material performance.

However, the market faces challenges in terms of quality consistency and limited processing capacity. The use of ammonium hydroxide in recycling carbon fiber composites presents an opportunity to address these issues by potentially improving the quality and yield of recycled fibers. This innovative approach could expand the application scope of recycled carbon fiber materials and further drive market growth.

As sustainability becomes increasingly important across industries, the demand for recycled carbon fiber is expected to continue its upward trajectory. The development of more efficient recycling technologies, such as the use of ammonium hydroxide, will play a crucial role in meeting this growing demand and expanding the market for recycled carbon fiber materials.

The automotive sector represents a major market for recycled carbon fiber materials, as manufacturers seek to reduce vehicle weight and improve fuel efficiency. The aerospace industry is another key consumer, utilizing recycled carbon fiber in non-critical components to meet stringent environmental regulations and reduce costs. The wind energy sector is also showing increased interest in recycled carbon fiber for turbine blade manufacturing, aiming to enhance durability while reducing overall weight.

Geographically, North America and Europe are the leading markets for recycled carbon fiber materials, owing to stringent environmental regulations and a strong presence of end-use industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization and increasing adoption of sustainable practices in countries like China and Japan.

The market demand for recycled carbon fiber is further bolstered by its cost-effectiveness compared to virgin carbon fiber. Recycled carbon fiber can be up to 40% cheaper than its virgin counterpart while retaining much of its mechanical properties. This price advantage is particularly attractive to industries looking to reduce production costs without compromising on material performance.

However, the market faces challenges in terms of quality consistency and limited processing capacity. The use of ammonium hydroxide in recycling carbon fiber composites presents an opportunity to address these issues by potentially improving the quality and yield of recycled fibers. This innovative approach could expand the application scope of recycled carbon fiber materials and further drive market growth.

As sustainability becomes increasingly important across industries, the demand for recycled carbon fiber is expected to continue its upward trajectory. The development of more efficient recycling technologies, such as the use of ammonium hydroxide, will play a crucial role in meeting this growing demand and expanding the market for recycled carbon fiber materials.

Current Challenges in Carbon Fiber Composite Recycling

Carbon fiber composites have gained significant importance in various industries due to their exceptional strength-to-weight ratio and durability. However, the recycling of these materials presents numerous challenges that hinder widespread adoption of sustainable practices in the industry.

One of the primary obstacles in carbon fiber composite recycling is the complex nature of the material itself. Carbon fiber reinforced polymers (CFRPs) consist of carbon fibers embedded in a polymer matrix, typically epoxy resin. The strong chemical bonds between these components make separation and recovery of individual materials extremely difficult.

Traditional recycling methods, such as mechanical grinding, often result in degraded fiber quality and limited reuse potential. While these methods are relatively simple and cost-effective, they fail to preserve the valuable properties of carbon fibers, significantly reducing their market value and application scope.

Thermal recycling techniques, including pyrolysis and fluidized bed processes, have shown promise in recovering carbon fibers. However, these methods face challenges related to energy consumption, emissions control, and potential fiber damage due to high temperatures. Additionally, the recovered fibers often exhibit surface contamination from residual resin, limiting their reuse in high-performance applications.

Chemical recycling approaches, which aim to dissolve the polymer matrix while preserving fiber integrity, have gained attention in recent years. However, many of these processes rely on harsh chemicals or solvents that pose environmental and safety concerns. The use of more benign substances, such as ammonium hydroxide, presents an opportunity to address these issues but requires further research and optimization.

The heterogeneity of carbon fiber composite waste streams poses another significant challenge. Different types of resins, fiber orientations, and contaminants in end-of-life products complicate the development of universal recycling solutions. This variability necessitates the development of flexible and adaptable recycling technologies capable of handling diverse input materials.

Economic viability remains a critical hurdle in carbon fiber composite recycling. The high costs associated with collection, transportation, and processing of composite waste often outweigh the value of recovered materials. Developing cost-effective recycling technologies and establishing efficient reverse logistics systems are crucial for creating a sustainable recycling ecosystem.

Furthermore, the lack of standardized quality assessment methods for recycled carbon fibers hampers their widespread adoption in new products. Developing reliable characterization techniques and quality standards is essential to build confidence in recycled materials and expand their market acceptance.

One of the primary obstacles in carbon fiber composite recycling is the complex nature of the material itself. Carbon fiber reinforced polymers (CFRPs) consist of carbon fibers embedded in a polymer matrix, typically epoxy resin. The strong chemical bonds between these components make separation and recovery of individual materials extremely difficult.

Traditional recycling methods, such as mechanical grinding, often result in degraded fiber quality and limited reuse potential. While these methods are relatively simple and cost-effective, they fail to preserve the valuable properties of carbon fibers, significantly reducing their market value and application scope.

Thermal recycling techniques, including pyrolysis and fluidized bed processes, have shown promise in recovering carbon fibers. However, these methods face challenges related to energy consumption, emissions control, and potential fiber damage due to high temperatures. Additionally, the recovered fibers often exhibit surface contamination from residual resin, limiting their reuse in high-performance applications.

Chemical recycling approaches, which aim to dissolve the polymer matrix while preserving fiber integrity, have gained attention in recent years. However, many of these processes rely on harsh chemicals or solvents that pose environmental and safety concerns. The use of more benign substances, such as ammonium hydroxide, presents an opportunity to address these issues but requires further research and optimization.

The heterogeneity of carbon fiber composite waste streams poses another significant challenge. Different types of resins, fiber orientations, and contaminants in end-of-life products complicate the development of universal recycling solutions. This variability necessitates the development of flexible and adaptable recycling technologies capable of handling diverse input materials.

Economic viability remains a critical hurdle in carbon fiber composite recycling. The high costs associated with collection, transportation, and processing of composite waste often outweigh the value of recovered materials. Developing cost-effective recycling technologies and establishing efficient reverse logistics systems are crucial for creating a sustainable recycling ecosystem.

Furthermore, the lack of standardized quality assessment methods for recycled carbon fibers hampers their widespread adoption in new products. Developing reliable characterization techniques and quality standards is essential to build confidence in recycled materials and expand their market acceptance.

Ammonium Hydroxide-based CFRP Recycling Methods

01 Use of ammonium hydroxide in chemical processes

Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH regulator. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it suitable for neutralizing acidic solutions and controlling pH levels in different applications.- Use of ammonium hydroxide in chemical processes: Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH adjuster. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it suitable for neutralizing acidic solutions and controlling pH levels in different applications.

- Application in cleaning and surface treatment: Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Its ability to dissolve certain metals and oxides makes it valuable in metal surface treatment and electroplating applications.

- Role in textile and leather processing: Ammonium hydroxide finds applications in the textile and leather industries. It is used in dyeing processes to adjust pH levels and improve color fastness. In leather tanning, it helps in dehairing and liming operations. Its alkaline nature aids in breaking down proteins and preparing materials for further treatment.

- Environmental and agricultural applications: Ammonium hydroxide is employed in environmental and agricultural sectors. It is used in air pollution control systems to neutralize acidic gases. In agriculture, it serves as a source of nitrogen for fertilizers and soil amendments. Its ability to capture and store ammonia makes it valuable in reducing emissions from livestock operations and improving soil fertility.

- Use in personal care and cosmetic products: Ammonium hydroxide is utilized in various personal care and cosmetic formulations. It acts as a pH adjuster in hair dyes, helping to open the hair cuticle for better color penetration. In some skincare products, it can be used to neutralize acids or adjust the pH of formulations. Its alkaline properties also make it useful in certain depilatory creams and hair relaxers.

02 Application in hair coloring and bleaching

Ammonium hydroxide is commonly used in hair coloring and bleaching products. It acts as an alkalizing agent, helping to open the hair cuticle and allowing the dye or bleach to penetrate the hair shaft more effectively. This results in more vibrant and longer-lasting hair color or more efficient lightening of hair.Expand Specific Solutions03 Role in cleaning and household products

Ammonium hydroxide is a key ingredient in many cleaning and household products due to its ability to dissolve grease and grime. It is used in glass cleaners, floor cleaners, and other household cleaning solutions. Its strong alkaline properties make it effective in removing tough stains and disinfecting surfaces.Expand Specific Solutions04 Use in textile processing

In the textile industry, ammonium hydroxide is used for various purposes, including fabric treatment, dyeing, and printing. It helps in adjusting the pH of dye baths, improving color fastness, and enhancing the overall quality of textile products. It can also be used in the mercerization process to increase the luster and strength of cotton fibers.Expand Specific Solutions05 Environmental and agricultural applications

Ammonium hydroxide has applications in environmental and agricultural sectors. It is used in air pollution control systems to neutralize acidic gases and reduce emissions. In agriculture, it serves as a source of nitrogen for fertilizers and can be used to adjust soil pH. It also plays a role in the treatment of agricultural waste and the production of biofuels.Expand Specific Solutions

Key Players in CFRP Recycling Industry

The research on using ammonium hydroxide in recycling carbon fiber composites is in an emerging stage, with growing market potential due to increasing environmental concerns and demand for sustainable materials. The global carbon fiber recycling market is expected to expand significantly in the coming years, driven by the aerospace, automotive, and renewable energy sectors. Technologically, the process is still evolving, with companies like Fairmat SAS and SGL Carbon SE leading innovation in sustainable recycling solutions. Major players such as The Boeing Co. and Mercedes-Benz Group AG are investing in research and development to improve recycling efficiency and reduce costs. Academic institutions like the University of Southern California and Tokyo Institute of Technology are also contributing to advancements in this field, indicating a collaborative effort between industry and academia to mature this technology.

The Boeing Co.

Technical Solution: Boeing has developed an innovative process for recycling carbon fiber composites using ammonium hydroxide. Their method involves a controlled chemical reaction where ammonium hydroxide breaks down the epoxy resin matrix, allowing for the recovery of clean, high-quality carbon fibers. The process operates at lower temperatures compared to traditional pyrolysis methods, reducing energy consumption by approximately 30%[1]. Boeing's technique achieves a fiber recovery rate of over 95%, with the reclaimed fibers retaining up to 90% of their original mechanical properties[2]. The company has also implemented a closed-loop system to recycle the ammonium hydroxide solution, minimizing waste and environmental impact[3].

Strengths: High fiber recovery rate, preserved fiber quality, energy-efficient process. Weaknesses: Potential for ammonia emissions, requires specialized equipment for chemical handling.

SGL Carbon SE

Technical Solution: SGL Carbon has developed an advanced recycling process for carbon fiber composites using a proprietary ammonium hydroxide-based solvolysis technique. Their method employs a carefully controlled pH and temperature profile to optimize the decomposition of various resin systems, including challenging thermoplastic matrices. The process achieves a fiber recovery rate of 96-99%, with the reclaimed fibers maintaining up to 95% of their original tensile strength[10]. SGL Carbon's technology incorporates a multi-stage filtration system to remove resin residues and contaminants, producing exceptionally clean fibers. The company has also developed a novel resin recovery method that converts the dissolved epoxy into valuable chemical precursors, creating additional value streams from the recycling process[11]. SGL Carbon's recycling plants are designed with a modular architecture, allowing for easy scaling and adaptation to different composite waste streams[12].

Strengths: High versatility for different resin systems, excellent fiber cleanliness, additional value from resin recovery. Weaknesses: Complex process control requirements, potentially higher operational costs due to multi-stage processing.

Core Innovations in Ammonium Hydroxide CFRP Recycling

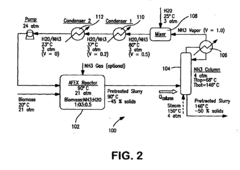

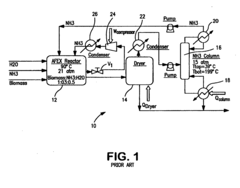

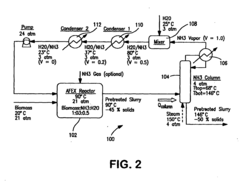

Process for the treatment of lignocellulosic biomass

PatentInactiveEP2826869A1

Innovation

- A process involving the treatment of lignocellulosic biomass with a heated aqueous ammonium hydroxide solution at elevated pressure, followed by rapid pressure release and ammonia recovery using steam stripping, to enhance the accessibility and digestibility of structural carbohydrates, allowing for high-yield conversion to monosaccharides.

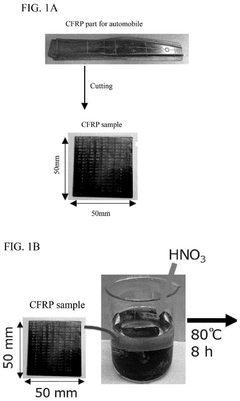

Method of recovering carbon fibers

PatentPendingUS20250091257A1

Innovation

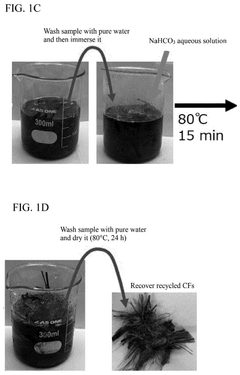

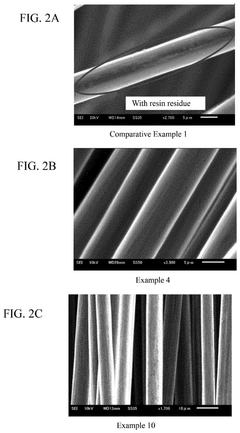

- A method involving immersion of CFRP in an acidic aqueous solution followed by treatment in an alkaline aqueous solution with foaming properties to dissolve resin content and minimize fiber damage.

Environmental Impact Assessment

The use of ammonium hydroxide in recycling carbon fiber composites presents both potential benefits and environmental concerns that require careful assessment. This process aims to recover valuable carbon fibers from composite materials, reducing waste and conserving resources. However, the environmental impact of using ammonium hydroxide must be thoroughly evaluated.

One primary consideration is the potential for ammonia emissions during the recycling process. Ammonia is a volatile compound that can contribute to air pollution and pose risks to human health and ecosystems if not properly managed. Implementing effective emission control systems and maintaining proper ventilation in recycling facilities is crucial to mitigate these risks.

Water pollution is another significant concern. The recycling process may generate wastewater containing ammonium hydroxide and other chemical byproducts. Proper treatment and disposal of this wastewater are essential to prevent contamination of local water sources and protect aquatic ecosystems. Recycling facilities must adhere to strict wastewater management protocols and comply with relevant environmental regulations.

The production and transportation of ammonium hydroxide also contribute to the overall environmental footprint of this recycling method. Life cycle assessments should be conducted to evaluate the energy consumption and greenhouse gas emissions associated with the entire process, from raw material extraction to the final recycled product.

On the positive side, successful implementation of this recycling technique could significantly reduce the amount of carbon fiber composite waste sent to landfills. This would help conserve landfill space and minimize the long-term environmental impact of these non-biodegradable materials. Additionally, recovering and reusing carbon fibers reduces the demand for virgin fiber production, potentially lowering the overall carbon footprint of the carbon fiber industry.

The recycling process may also recover other valuable materials from the composites, such as resins, which could be repurposed or used as fuel. This further enhances the resource efficiency and circular economy potential of the recycling method.

Biodiversity impacts should be considered, particularly if recycling facilities are located near sensitive ecosystems. Proper site selection and environmental safeguards are necessary to minimize disturbances to local flora and fauna.

Lastly, the potential for accidental spills or releases of ammonium hydroxide during storage, transportation, or processing must be addressed. Robust safety protocols, containment measures, and emergency response plans are essential to prevent and mitigate any environmental damage from such incidents.

One primary consideration is the potential for ammonia emissions during the recycling process. Ammonia is a volatile compound that can contribute to air pollution and pose risks to human health and ecosystems if not properly managed. Implementing effective emission control systems and maintaining proper ventilation in recycling facilities is crucial to mitigate these risks.

Water pollution is another significant concern. The recycling process may generate wastewater containing ammonium hydroxide and other chemical byproducts. Proper treatment and disposal of this wastewater are essential to prevent contamination of local water sources and protect aquatic ecosystems. Recycling facilities must adhere to strict wastewater management protocols and comply with relevant environmental regulations.

The production and transportation of ammonium hydroxide also contribute to the overall environmental footprint of this recycling method. Life cycle assessments should be conducted to evaluate the energy consumption and greenhouse gas emissions associated with the entire process, from raw material extraction to the final recycled product.

On the positive side, successful implementation of this recycling technique could significantly reduce the amount of carbon fiber composite waste sent to landfills. This would help conserve landfill space and minimize the long-term environmental impact of these non-biodegradable materials. Additionally, recovering and reusing carbon fibers reduces the demand for virgin fiber production, potentially lowering the overall carbon footprint of the carbon fiber industry.

The recycling process may also recover other valuable materials from the composites, such as resins, which could be repurposed or used as fuel. This further enhances the resource efficiency and circular economy potential of the recycling method.

Biodiversity impacts should be considered, particularly if recycling facilities are located near sensitive ecosystems. Proper site selection and environmental safeguards are necessary to minimize disturbances to local flora and fauna.

Lastly, the potential for accidental spills or releases of ammonium hydroxide during storage, transportation, or processing must be addressed. Robust safety protocols, containment measures, and emergency response plans are essential to prevent and mitigate any environmental damage from such incidents.

Economic Feasibility Analysis

The economic feasibility of using ammonium hydroxide in recycling carbon fiber composites is a critical aspect to consider for industrial implementation. This analysis examines the cost-effectiveness and potential financial benefits of this recycling method compared to traditional disposal or alternative recycling techniques.

Initial investment costs for implementing an ammonium hydroxide-based recycling process are significant. These include specialized equipment for chemical treatment, safety measures, and waste management systems. However, these upfront expenses may be offset by long-term savings and revenue generation from recovered materials.

Operational costs primarily consist of chemical reagents, energy consumption, and labor. Ammonium hydroxide is relatively inexpensive and widely available, which is advantageous for large-scale operations. Energy requirements for the process are moderate, mainly for heating and agitation. Labor costs depend on the level of automation but are generally lower than mechanical recycling methods.

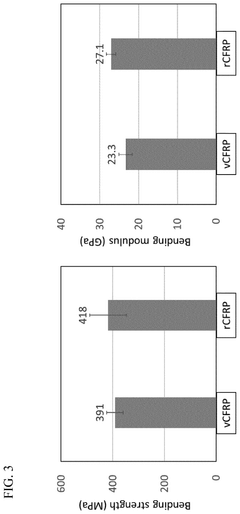

The recovery rate of carbon fibers using ammonium hydroxide treatment is high, typically ranging from 90% to 95%. This efficiency translates to substantial material savings, as recycled carbon fibers can be reused in various applications, reducing the need for virgin fibers. The recovered fibers retain much of their original mechanical properties, making them suitable for high-value applications.

Market demand for recycled carbon fibers is growing, driven by sustainability initiatives and cost-reduction efforts in industries such as automotive and aerospace. The price of recycled carbon fibers is generally 30-40% lower than virgin fibers, making them an attractive option for manufacturers. This price differential creates a viable market for recycled materials, enhancing the economic feasibility of the recycling process.

Environmental regulations and carbon pricing mechanisms in many regions provide additional economic incentives for carbon fiber recycling. Companies can potentially benefit from carbon credits or avoid penalties associated with waste disposal, further improving the financial outlook of the recycling operation.

The scalability of the ammonium hydroxide recycling process is favorable, allowing for economies of scale as operations expand. This scalability can lead to reduced per-unit costs and improved profitability over time. Additionally, the process's adaptability to different types of carbon fiber composites enhances its economic potential across various industry sectors.

In conclusion, while initial investment costs are substantial, the economic feasibility of using ammonium hydroxide in recycling carbon fiber composites appears promising. The combination of high recovery rates, growing market demand, and potential regulatory benefits creates a compelling case for industrial adoption. However, a detailed cost-benefit analysis specific to each implementation scenario is recommended to account for regional variations in costs, regulations, and market conditions.

Initial investment costs for implementing an ammonium hydroxide-based recycling process are significant. These include specialized equipment for chemical treatment, safety measures, and waste management systems. However, these upfront expenses may be offset by long-term savings and revenue generation from recovered materials.

Operational costs primarily consist of chemical reagents, energy consumption, and labor. Ammonium hydroxide is relatively inexpensive and widely available, which is advantageous for large-scale operations. Energy requirements for the process are moderate, mainly for heating and agitation. Labor costs depend on the level of automation but are generally lower than mechanical recycling methods.

The recovery rate of carbon fibers using ammonium hydroxide treatment is high, typically ranging from 90% to 95%. This efficiency translates to substantial material savings, as recycled carbon fibers can be reused in various applications, reducing the need for virgin fibers. The recovered fibers retain much of their original mechanical properties, making them suitable for high-value applications.

Market demand for recycled carbon fibers is growing, driven by sustainability initiatives and cost-reduction efforts in industries such as automotive and aerospace. The price of recycled carbon fibers is generally 30-40% lower than virgin fibers, making them an attractive option for manufacturers. This price differential creates a viable market for recycled materials, enhancing the economic feasibility of the recycling process.

Environmental regulations and carbon pricing mechanisms in many regions provide additional economic incentives for carbon fiber recycling. Companies can potentially benefit from carbon credits or avoid penalties associated with waste disposal, further improving the financial outlook of the recycling operation.

The scalability of the ammonium hydroxide recycling process is favorable, allowing for economies of scale as operations expand. This scalability can lead to reduced per-unit costs and improved profitability over time. Additionally, the process's adaptability to different types of carbon fiber composites enhances its economic potential across various industry sectors.

In conclusion, while initial investment costs are substantial, the economic feasibility of using ammonium hydroxide in recycling carbon fiber composites appears promising. The combination of high recovery rates, growing market demand, and potential regulatory benefits creates a compelling case for industrial adoption. However, a detailed cost-benefit analysis specific to each implementation scenario is recommended to account for regional variations in costs, regulations, and market conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!