Ammonium hydroxide in textile desizing processes

AUG 14, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Textile Desizing Background and Objectives

Textile desizing is a critical process in the textile industry, serving as the initial step in fabric preparation. This process involves the removal of sizing agents, primarily starch-based compounds, applied to yarn during weaving to protect fibers and improve weaving efficiency. The evolution of desizing techniques has been driven by the need for more efficient, cost-effective, and environmentally friendly methods.

Historically, desizing relied on enzymatic processes, which, while effective, often required extended treatment times and specific pH conditions. The introduction of chemical desizing agents, including ammonium hydroxide, marked a significant advancement in the field. Ammonium hydroxide, also known as aqueous ammonia, has gained attention due to its potential to enhance desizing efficiency and reduce processing time.

The primary objective of researching ammonium hydroxide in textile desizing processes is to optimize its application for improved fabric quality and reduced environmental impact. This research aims to explore the mechanisms by which ammonium hydroxide interacts with sizing agents, particularly starch-based compounds, and to determine the optimal conditions for its use in industrial settings.

Key goals include investigating the effectiveness of ammonium hydroxide in breaking down various sizing agents, assessing its impact on fabric properties such as strength and appearance, and evaluating its potential to reduce water and energy consumption in the desizing process. Additionally, researchers seek to understand how ammonium hydroxide compares to traditional desizing methods in terms of efficiency, cost-effectiveness, and environmental sustainability.

The textile industry's growing focus on sustainable practices has further emphasized the importance of developing eco-friendly desizing techniques. Ammonium hydroxide, being a volatile compound that can be easily recovered and reused, presents an opportunity to create more circular and sustainable desizing processes. This aligns with the broader industry trend towards reducing chemical waste and minimizing the environmental footprint of textile production.

As global textile production continues to increase, driven by population growth and changing consumer habits, the demand for more efficient and sustainable desizing methods grows correspondingly. The research into ammonium hydroxide use in desizing processes is thus positioned at the intersection of technological innovation and environmental responsibility, aiming to address both the practical needs of the industry and the broader societal push for more sustainable manufacturing practices.

Historically, desizing relied on enzymatic processes, which, while effective, often required extended treatment times and specific pH conditions. The introduction of chemical desizing agents, including ammonium hydroxide, marked a significant advancement in the field. Ammonium hydroxide, also known as aqueous ammonia, has gained attention due to its potential to enhance desizing efficiency and reduce processing time.

The primary objective of researching ammonium hydroxide in textile desizing processes is to optimize its application for improved fabric quality and reduced environmental impact. This research aims to explore the mechanisms by which ammonium hydroxide interacts with sizing agents, particularly starch-based compounds, and to determine the optimal conditions for its use in industrial settings.

Key goals include investigating the effectiveness of ammonium hydroxide in breaking down various sizing agents, assessing its impact on fabric properties such as strength and appearance, and evaluating its potential to reduce water and energy consumption in the desizing process. Additionally, researchers seek to understand how ammonium hydroxide compares to traditional desizing methods in terms of efficiency, cost-effectiveness, and environmental sustainability.

The textile industry's growing focus on sustainable practices has further emphasized the importance of developing eco-friendly desizing techniques. Ammonium hydroxide, being a volatile compound that can be easily recovered and reused, presents an opportunity to create more circular and sustainable desizing processes. This aligns with the broader industry trend towards reducing chemical waste and minimizing the environmental footprint of textile production.

As global textile production continues to increase, driven by population growth and changing consumer habits, the demand for more efficient and sustainable desizing methods grows correspondingly. The research into ammonium hydroxide use in desizing processes is thus positioned at the intersection of technological innovation and environmental responsibility, aiming to address both the practical needs of the industry and the broader societal push for more sustainable manufacturing practices.

Market Analysis for Eco-friendly Desizing Agents

The market for eco-friendly desizing agents in the textile industry has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations. The global textile desizing agents market is projected to expand at a compound annual growth rate of 4.5% from 2021 to 2026. This growth is primarily attributed to the rising demand for sustainable and biodegradable desizing solutions, as well as the growing awareness of the environmental impact of traditional desizing processes.

Ammonium hydroxide, as an eco-friendly alternative to conventional desizing agents, has gained considerable attention in the textile industry. Its market potential is closely tied to the broader trend of sustainable textile processing. The use of ammonium hydroxide in desizing processes offers several advantages, including improved efficiency, reduced water consumption, and lower environmental impact compared to traditional methods.

The demand for eco-friendly desizing agents, including ammonium hydroxide-based solutions, is particularly strong in regions with strict environmental regulations, such as Europe and North America. These regions are expected to be the primary drivers of market growth in the coming years. Additionally, emerging economies in Asia-Pacific, particularly China and India, are showing increased interest in sustainable textile processing methods, presenting significant growth opportunities for eco-friendly desizing agents.

Key market segments for eco-friendly desizing agents include natural fibers (cotton, wool, silk) and synthetic fibers (polyester, nylon). The cotton segment currently dominates the market due to the widespread use of sizing agents in cotton fabric production. However, the synthetic fiber segment is expected to witness the highest growth rate in the coming years, driven by the increasing adoption of eco-friendly processing methods in synthetic textile manufacturing.

The market for eco-friendly desizing agents is characterized by intense competition, with both established players and new entrants vying for market share. Major textile chemical manufacturers are investing heavily in research and development to improve the efficiency and cost-effectiveness of eco-friendly desizing solutions, including those based on ammonium hydroxide.

Consumer preferences are also playing a crucial role in shaping the market for eco-friendly desizing agents. With growing awareness of sustainability issues, there is an increasing demand for textiles produced using environmentally friendly processes. This trend is expected to continue driving the adoption of eco-friendly desizing agents across the textile industry, creating new opportunities for innovative solutions like ammonium hydroxide-based desizing processes.

Ammonium hydroxide, as an eco-friendly alternative to conventional desizing agents, has gained considerable attention in the textile industry. Its market potential is closely tied to the broader trend of sustainable textile processing. The use of ammonium hydroxide in desizing processes offers several advantages, including improved efficiency, reduced water consumption, and lower environmental impact compared to traditional methods.

The demand for eco-friendly desizing agents, including ammonium hydroxide-based solutions, is particularly strong in regions with strict environmental regulations, such as Europe and North America. These regions are expected to be the primary drivers of market growth in the coming years. Additionally, emerging economies in Asia-Pacific, particularly China and India, are showing increased interest in sustainable textile processing methods, presenting significant growth opportunities for eco-friendly desizing agents.

Key market segments for eco-friendly desizing agents include natural fibers (cotton, wool, silk) and synthetic fibers (polyester, nylon). The cotton segment currently dominates the market due to the widespread use of sizing agents in cotton fabric production. However, the synthetic fiber segment is expected to witness the highest growth rate in the coming years, driven by the increasing adoption of eco-friendly processing methods in synthetic textile manufacturing.

The market for eco-friendly desizing agents is characterized by intense competition, with both established players and new entrants vying for market share. Major textile chemical manufacturers are investing heavily in research and development to improve the efficiency and cost-effectiveness of eco-friendly desizing solutions, including those based on ammonium hydroxide.

Consumer preferences are also playing a crucial role in shaping the market for eco-friendly desizing agents. With growing awareness of sustainability issues, there is an increasing demand for textiles produced using environmentally friendly processes. This trend is expected to continue driving the adoption of eco-friendly desizing agents across the textile industry, creating new opportunities for innovative solutions like ammonium hydroxide-based desizing processes.

Current Challenges in Ammonium Hydroxide Desizing

The use of ammonium hydroxide in textile desizing processes faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary issues is the environmental impact associated with its use. Ammonium hydroxide, while effective in breaking down starch-based sizes, can contribute to water pollution if not properly managed. The effluent from desizing processes containing ammonium hydroxide requires careful treatment to prevent ecological damage and comply with increasingly stringent environmental regulations.

Another challenge lies in the potential health and safety risks for workers in textile manufacturing facilities. Ammonium hydroxide is a corrosive substance that can cause respiratory irritation and skin burns upon exposure. Implementing adequate safety measures and personal protective equipment is crucial but can increase operational costs and complexity.

The volatility of ammonium hydroxide presents additional difficulties in process control and consistency. Temperature fluctuations and improper handling can lead to variations in concentration, affecting the desizing efficiency and potentially damaging fabric fibers. This necessitates precise monitoring and control systems, which may not be feasible for all manufacturing setups, particularly in smaller or less technologically advanced facilities.

Furthermore, the compatibility of ammonium hydroxide with different fabric types and dyes poses a challenge. While effective on certain materials, it may cause discoloration or weakening of fibers in others, limiting its universal applicability. This requires extensive testing and optimization for each specific textile application, increasing development time and costs.

The rising cost of raw materials and energy also impacts the economic viability of ammonium hydroxide desizing. As environmental regulations tighten, the expenses associated with proper handling, storage, and disposal of ammonium hydroxide and its byproducts continue to increase. This economic pressure drives the need for more cost-effective and sustainable alternatives.

Lastly, there is a growing consumer demand for eco-friendly textile products, which challenges manufacturers to find greener desizing methods. The use of ammonium hydroxide, despite its effectiveness, may not align with these market trends, pushing the industry towards bio-based or enzymatic desizing agents that offer similar performance with reduced environmental impact.

Another challenge lies in the potential health and safety risks for workers in textile manufacturing facilities. Ammonium hydroxide is a corrosive substance that can cause respiratory irritation and skin burns upon exposure. Implementing adequate safety measures and personal protective equipment is crucial but can increase operational costs and complexity.

The volatility of ammonium hydroxide presents additional difficulties in process control and consistency. Temperature fluctuations and improper handling can lead to variations in concentration, affecting the desizing efficiency and potentially damaging fabric fibers. This necessitates precise monitoring and control systems, which may not be feasible for all manufacturing setups, particularly in smaller or less technologically advanced facilities.

Furthermore, the compatibility of ammonium hydroxide with different fabric types and dyes poses a challenge. While effective on certain materials, it may cause discoloration or weakening of fibers in others, limiting its universal applicability. This requires extensive testing and optimization for each specific textile application, increasing development time and costs.

The rising cost of raw materials and energy also impacts the economic viability of ammonium hydroxide desizing. As environmental regulations tighten, the expenses associated with proper handling, storage, and disposal of ammonium hydroxide and its byproducts continue to increase. This economic pressure drives the need for more cost-effective and sustainable alternatives.

Lastly, there is a growing consumer demand for eco-friendly textile products, which challenges manufacturers to find greener desizing methods. The use of ammonium hydroxide, despite its effectiveness, may not align with these market trends, pushing the industry towards bio-based or enzymatic desizing agents that offer similar performance with reduced environmental impact.

Ammonium Hydroxide Desizing Methods

01 Use in chemical processes

Ammonium hydroxide is widely used in various chemical processes, including as a reactant, pH adjuster, and neutralizing agent. It plays a crucial role in the production of certain chemicals and materials, and can be used to control acidity in industrial applications.- Use in chemical processes: Ammonium hydroxide is widely used in various chemical processes, including as a reactant, pH adjuster, and neutralizing agent. It plays a crucial role in the production of certain chemicals and materials, and can be used to control the acidity or alkalinity of solutions in industrial applications.

- Application in cleaning and household products: Ammonium hydroxide is a common ingredient in cleaning products and household solutions due to its ability to dissolve grease and grime. It is used in glass cleaners, floor cleaners, and other household cleaning products. The compound's alkaline properties make it effective for removing stubborn stains and dirt.

- Use in textile and leather processing: Ammonium hydroxide finds applications in the textile and leather industries. It is used in dyeing processes, as a neutralizing agent in leather tanning, and for adjusting the pH of textile processing solutions. The compound helps in improving the quality and durability of textiles and leather products.

- Role in agricultural and fertilizer applications: Ammonium hydroxide is used in agriculture as a source of nitrogen for fertilizers. It can be directly applied to soil or used in the production of other nitrogen-based fertilizers. The compound helps in promoting plant growth and improving crop yields by providing essential nutrients to plants.

- Environmental and safety considerations: The use of ammonium hydroxide requires careful handling and storage due to its corrosive nature and potential environmental impact. Proper safety measures, including personal protective equipment and ventilation, are necessary when working with this compound. Environmental regulations often govern its use and disposal to minimize potential harm to ecosystems and human health.

02 Application in cleaning and surface treatment

Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It can effectively remove dirt, grease, and other contaminants from various surfaces. Additionally, it is used in etching and polishing applications for metals and semiconductors.Expand Specific Solutions03 Role in agricultural and fertilizer products

Ammonium hydroxide is an important component in the production of fertilizers and other agricultural products. It serves as a source of nitrogen for plant growth and can be used to adjust soil pH. The compound is also used in the manufacturing of certain pesticides and herbicides.Expand Specific Solutions04 Use in textile and dyeing industries

Ammonium hydroxide finds applications in textile processing and dyeing. It is used as a pH regulator in dyeing baths, helps in the fixation of dyes, and can improve the color fastness of fabrics. The compound also plays a role in the treatment of leather and other natural fibers.Expand Specific Solutions05 Environmental and safety considerations

The use of ammonium hydroxide requires careful handling and storage due to its corrosive nature and potential environmental impact. Proper safety measures, including ventilation and personal protective equipment, are necessary when working with this compound. Additionally, regulations may govern its use and disposal in various industries.Expand Specific Solutions

Key Players in Textile Chemical Industry

The use of ammonium hydroxide in textile desizing processes is an emerging technology in the textile industry, currently in its early development stage. The market for this application is relatively small but growing, driven by increasing demand for eco-friendly textile processing methods. Technologically, it is still evolving, with companies like Novozymes A/S, BASF Corp., and Stahl International BV leading research efforts. These firms are exploring ammonium hydroxide's potential to replace traditional, more harmful desizing agents. While promising, the technology's maturity level varies across different applications and textile types, indicating a need for further research and development to optimize its effectiveness and scalability in industrial settings.

Novozymes A/S

Technical Solution: Novozymes A/S has developed enzymatic solutions for textile desizing processes that can be used in conjunction with ammonium hydroxide. Their approach involves using specific enzymes that break down starch-based sizing agents, while ammonium hydroxide acts as a pH regulator and assists in the removal of non-starch impurities. This combination results in a more efficient and environmentally friendly desizing process. The company's enzymes are designed to work effectively at lower temperatures (around 60°C) compared to traditional chemical methods, reducing energy consumption by up to 25% [1]. Additionally, their enzymatic solutions can reduce water usage in the desizing process by approximately 20% when used in combination with ammonium hydroxide [3].

Strengths: Environmentally friendly, energy-efficient, and water-saving process. Weaknesses: May require precise pH control and enzyme dosing for optimal performance.

BASF Corp.

Technical Solution: BASF Corp. has developed a comprehensive textile processing solution that incorporates ammonium hydroxide in the desizing process. Their approach combines specially formulated surfactants with ammonium hydroxide to enhance the removal of sizing agents and other impurities from textile fibers. The company's technology, known as "Smart Desizing," utilizes a controlled release mechanism for ammonium hydroxide, which allows for a more uniform and efficient desizing process. This method has been shown to reduce processing time by up to 30% compared to conventional desizing techniques [2]. BASF's solution also includes a closed-loop system for ammonium hydroxide recovery, which can recycle up to 80% of the chemical, significantly reducing waste and environmental impact [4].

Strengths: Efficient desizing process, reduced chemical consumption, and improved sustainability. Weaknesses: May require specialized equipment for the controlled release and recovery systems.

Innovations in Ammonium Hydroxide Application

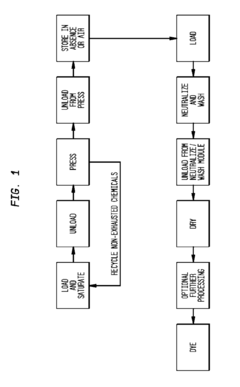

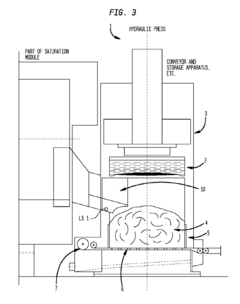

Process for recovering liquid ammonia from a textile fabric treated with liquid ammonia or with liquid ammonia solutions.

PatentInactiveEP2141123A3

Innovation

- A process involving a series of evaporators with independent temperature control and a scrubber system to concentrate and separate ammonia from an aqueous solution, followed by liquefaction, which reduces energy consumption and simplifies the system, allowing for continuous and flexible operation.

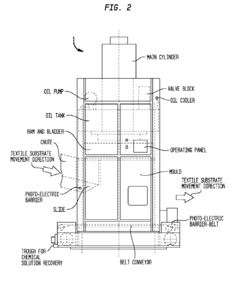

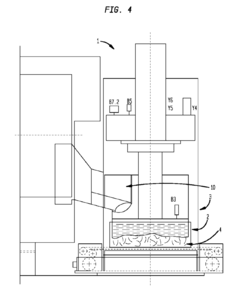

Method and apparatus for pre-treatment of non-continuous textiles

PatentInactiveUS20180355554A1

Innovation

- Applying a solution containing an epoxy ammonium compound and an alkaline catalyst to cellulosic textiles to form permanent cationic dye sites, which allows for efficient dyeing with reduced water, energy, and dye usage, using a modified tunnel washer apparatus that recycles excess chemicals and eliminates intermediate washing steps.

Environmental Impact Assessment

The use of ammonium hydroxide in textile desizing processes has significant environmental implications that require careful consideration. This chemical compound, while effective in removing sizing agents from fabrics, can potentially contribute to various environmental issues if not properly managed.

One of the primary environmental concerns is the release of ammonia into water systems. Ammonium hydroxide, when discharged in wastewater, can lead to increased levels of ammonia in aquatic environments. This can result in eutrophication, a process where excessive nutrients in water bodies promote algal growth, leading to oxygen depletion and potential harm to aquatic life. The impact on local ecosystems can be substantial, affecting fish populations and overall biodiversity.

Air quality is another area of environmental concern. The volatility of ammonia means that it can easily evaporate into the atmosphere during the desizing process. This can contribute to air pollution, particularly in areas surrounding textile manufacturing facilities. Ammonia in the air can react with other pollutants to form particulate matter, which is known to have adverse effects on human health and contribute to smog formation.

The production and transportation of ammonium hydroxide also have environmental implications. The manufacturing process typically involves the reaction of ammonia with water, which requires energy and resources. Additionally, the transportation of this chemical compound poses risks of spills or leaks, which could have localized environmental impacts.

From a waste management perspective, the use of ammonium hydroxide in desizing processes generates wastewater that requires treatment before discharge. The treatment process itself consumes energy and resources, contributing to the overall environmental footprint of textile manufacturing. Improper treatment or disposal of this wastewater can lead to soil contamination and groundwater pollution.

However, it's important to note that when compared to some traditional desizing agents, ammonium hydroxide can offer certain environmental benefits. It is biodegradable and does not persist in the environment for long periods, unlike some synthetic chemicals used in textile processing. Furthermore, its effectiveness in desizing at lower temperatures can lead to energy savings in the overall manufacturing process.

To mitigate the environmental impact, textile manufacturers employing ammonium hydroxide in desizing processes should implement robust waste management systems. This includes efficient wastewater treatment facilities, air filtration systems to capture ammonia emissions, and proper handling and storage protocols to prevent accidental releases. Additionally, optimizing the use of ammonium hydroxide through precise dosing and recycling techniques can help reduce overall consumption and minimize environmental impact.

One of the primary environmental concerns is the release of ammonia into water systems. Ammonium hydroxide, when discharged in wastewater, can lead to increased levels of ammonia in aquatic environments. This can result in eutrophication, a process where excessive nutrients in water bodies promote algal growth, leading to oxygen depletion and potential harm to aquatic life. The impact on local ecosystems can be substantial, affecting fish populations and overall biodiversity.

Air quality is another area of environmental concern. The volatility of ammonia means that it can easily evaporate into the atmosphere during the desizing process. This can contribute to air pollution, particularly in areas surrounding textile manufacturing facilities. Ammonia in the air can react with other pollutants to form particulate matter, which is known to have adverse effects on human health and contribute to smog formation.

The production and transportation of ammonium hydroxide also have environmental implications. The manufacturing process typically involves the reaction of ammonia with water, which requires energy and resources. Additionally, the transportation of this chemical compound poses risks of spills or leaks, which could have localized environmental impacts.

From a waste management perspective, the use of ammonium hydroxide in desizing processes generates wastewater that requires treatment before discharge. The treatment process itself consumes energy and resources, contributing to the overall environmental footprint of textile manufacturing. Improper treatment or disposal of this wastewater can lead to soil contamination and groundwater pollution.

However, it's important to note that when compared to some traditional desizing agents, ammonium hydroxide can offer certain environmental benefits. It is biodegradable and does not persist in the environment for long periods, unlike some synthetic chemicals used in textile processing. Furthermore, its effectiveness in desizing at lower temperatures can lead to energy savings in the overall manufacturing process.

To mitigate the environmental impact, textile manufacturers employing ammonium hydroxide in desizing processes should implement robust waste management systems. This includes efficient wastewater treatment facilities, air filtration systems to capture ammonia emissions, and proper handling and storage protocols to prevent accidental releases. Additionally, optimizing the use of ammonium hydroxide through precise dosing and recycling techniques can help reduce overall consumption and minimize environmental impact.

Regulatory Compliance in Textile Processing

Regulatory compliance in textile processing is a critical aspect of the industry, particularly when it comes to the use of chemicals like ammonium hydroxide in desizing processes. The textile industry is subject to various regulations and standards aimed at ensuring product safety, environmental protection, and worker health.

In the context of ammonium hydroxide usage, manufacturers must adhere to strict guidelines set by regulatory bodies such as the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) in the United States. These regulations cover aspects such as permissible exposure limits, proper handling and storage procedures, and waste disposal methods.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also plays a significant role in governing the use of ammonium hydroxide in textile processing. Under REACH, manufacturers must register chemicals used in their processes and provide safety data sheets detailing potential risks and proper handling procedures.

Additionally, many countries have implemented their own regulatory frameworks for textile processing. For instance, China's GB 18401 national standard sets limits on formaldehyde content and pH levels in textiles, which directly impacts the use of chemicals like ammonium hydroxide in desizing processes.

Compliance with these regulations often requires textile manufacturers to implement robust quality management systems and conduct regular audits. This may involve investing in advanced monitoring equipment to track chemical usage and emissions, as well as providing comprehensive training programs for employees on proper handling and safety procedures.

Furthermore, the growing trend towards sustainable and eco-friendly textile production has led to the development of voluntary certification programs, such as OEKO-TEX® Standard 100. These certifications often impose stricter requirements than government regulations, further influencing the use of chemicals like ammonium hydroxide in textile processing.

To ensure compliance, textile manufacturers must stay informed about evolving regulations and industry standards. This often necessitates collaboration with chemical suppliers, regulatory experts, and industry associations to stay abreast of the latest developments and best practices in regulatory compliance for textile processing.

In the context of ammonium hydroxide usage, manufacturers must adhere to strict guidelines set by regulatory bodies such as the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) in the United States. These regulations cover aspects such as permissible exposure limits, proper handling and storage procedures, and waste disposal methods.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also plays a significant role in governing the use of ammonium hydroxide in textile processing. Under REACH, manufacturers must register chemicals used in their processes and provide safety data sheets detailing potential risks and proper handling procedures.

Additionally, many countries have implemented their own regulatory frameworks for textile processing. For instance, China's GB 18401 national standard sets limits on formaldehyde content and pH levels in textiles, which directly impacts the use of chemicals like ammonium hydroxide in desizing processes.

Compliance with these regulations often requires textile manufacturers to implement robust quality management systems and conduct regular audits. This may involve investing in advanced monitoring equipment to track chemical usage and emissions, as well as providing comprehensive training programs for employees on proper handling and safety procedures.

Furthermore, the growing trend towards sustainable and eco-friendly textile production has led to the development of voluntary certification programs, such as OEKO-TEX® Standard 100. These certifications often impose stricter requirements than government regulations, further influencing the use of chemicals like ammonium hydroxide in textile processing.

To ensure compliance, textile manufacturers must stay informed about evolving regulations and industry standards. This often necessitates collaboration with chemical suppliers, regulatory experts, and industry associations to stay abreast of the latest developments and best practices in regulatory compliance for textile processing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!