Ammonium hydroxide in modifying cellulose-derived aerogels

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellulose Aerogel Modification Background and Objectives

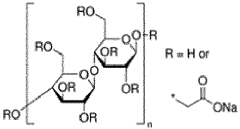

Cellulose aerogels have emerged as a promising class of advanced materials, garnering significant attention in recent years due to their unique properties and potential applications. These lightweight, highly porous structures are derived from cellulose, the most abundant natural polymer on Earth, making them an attractive option for sustainable and eco-friendly material development. The evolution of cellulose aerogel technology has been driven by the growing demand for high-performance materials with minimal environmental impact.

The primary objective of research into cellulose aerogel modification using ammonium hydroxide is to enhance the material's properties and expand its range of applications. Ammonium hydroxide, a common alkaline solution, has shown potential in altering the surface chemistry and structural characteristics of cellulose aerogels. This modification process aims to improve key attributes such as mechanical strength, hydrophobicity, and thermal insulation capabilities.

One of the main technological trends in this field is the development of more efficient and scalable production methods for cellulose aerogels. Traditional approaches often involve time-consuming and energy-intensive processes, limiting large-scale manufacturing. Recent advancements have focused on streamlining these procedures, with particular emphasis on environmentally friendly and cost-effective techniques.

The use of ammonium hydroxide in cellulose aerogel modification aligns with the broader trend of exploring green chemistry principles in materials science. This approach seeks to minimize the use of harmful chemicals and reduce waste generation during the production and modification of aerogels. By utilizing a relatively benign and readily available compound like ammonium hydroxide, researchers aim to develop more sustainable modification processes.

Another significant trend is the pursuit of multifunctional cellulose aerogels. By incorporating ammonium hydroxide treatment into the modification process, scientists aim to impart multiple desirable properties simultaneously. This could lead to the creation of versatile materials capable of addressing various challenges in fields such as environmental remediation, energy storage, and biomedical applications.

The expected technological goals of this research include achieving precise control over the aerogel's pore structure, enhancing its mechanical properties without compromising its low density, and improving its resistance to moisture and environmental degradation. Additionally, researchers aim to develop standardized protocols for ammonium hydroxide-based modification that can be easily replicated and scaled up for industrial production.

The primary objective of research into cellulose aerogel modification using ammonium hydroxide is to enhance the material's properties and expand its range of applications. Ammonium hydroxide, a common alkaline solution, has shown potential in altering the surface chemistry and structural characteristics of cellulose aerogels. This modification process aims to improve key attributes such as mechanical strength, hydrophobicity, and thermal insulation capabilities.

One of the main technological trends in this field is the development of more efficient and scalable production methods for cellulose aerogels. Traditional approaches often involve time-consuming and energy-intensive processes, limiting large-scale manufacturing. Recent advancements have focused on streamlining these procedures, with particular emphasis on environmentally friendly and cost-effective techniques.

The use of ammonium hydroxide in cellulose aerogel modification aligns with the broader trend of exploring green chemistry principles in materials science. This approach seeks to minimize the use of harmful chemicals and reduce waste generation during the production and modification of aerogels. By utilizing a relatively benign and readily available compound like ammonium hydroxide, researchers aim to develop more sustainable modification processes.

Another significant trend is the pursuit of multifunctional cellulose aerogels. By incorporating ammonium hydroxide treatment into the modification process, scientists aim to impart multiple desirable properties simultaneously. This could lead to the creation of versatile materials capable of addressing various challenges in fields such as environmental remediation, energy storage, and biomedical applications.

The expected technological goals of this research include achieving precise control over the aerogel's pore structure, enhancing its mechanical properties without compromising its low density, and improving its resistance to moisture and environmental degradation. Additionally, researchers aim to develop standardized protocols for ammonium hydroxide-based modification that can be easily replicated and scaled up for industrial production.

Market Analysis for Modified Cellulose Aerogels

The market for modified cellulose aerogels, particularly those treated with ammonium hydroxide, is experiencing significant growth driven by increasing demand for sustainable and high-performance materials across various industries. The global aerogel market, which includes cellulose-based aerogels, is projected to reach a substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages.

The automotive and aerospace sectors are emerging as key drivers for the adoption of modified cellulose aerogels. These industries are actively seeking lightweight materials with superior thermal insulation properties to improve fuel efficiency and reduce carbon emissions. The unique characteristics of ammonium hydroxide-modified cellulose aerogels, such as low density, high porosity, and excellent thermal insulation, make them ideal candidates for these applications.

In the construction industry, there is a growing demand for energy-efficient building materials. Modified cellulose aerogels offer superior thermal insulation properties compared to traditional materials, potentially leading to significant energy savings in both residential and commercial buildings. This trend is further supported by stringent energy efficiency regulations and increasing awareness of sustainable construction practices.

The packaging industry represents another promising market for modified cellulose aerogels. With the rise of e-commerce and the need for protective packaging solutions, these materials offer an eco-friendly alternative to conventional petroleum-based foams. Their ability to provide cushioning and thermal insulation while being biodegradable aligns well with the industry's shift towards sustainable packaging solutions.

Environmental concerns and regulatory pressures are also driving the market for modified cellulose aerogels. As governments worldwide implement stricter environmental policies, industries are seeking alternatives to traditional materials with high carbon footprints. The renewable nature of cellulose and the eco-friendly modification process using ammonium hydroxide position these aerogels as attractive options for environmentally conscious consumers and businesses.

The healthcare and pharmaceutical sectors are showing increasing interest in modified cellulose aerogels for applications such as drug delivery systems and wound dressings. The material's high surface area and tunable properties offer potential advantages in controlled release formulations and advanced wound care products.

Despite the promising market outlook, challenges remain in scaling up production and reducing costs to compete with established materials. However, ongoing research and development efforts, coupled with increasing investments in sustainable technologies, are expected to address these hurdles and further expand the market potential of ammonium hydroxide-modified cellulose aerogels across various industries.

The automotive and aerospace sectors are emerging as key drivers for the adoption of modified cellulose aerogels. These industries are actively seeking lightweight materials with superior thermal insulation properties to improve fuel efficiency and reduce carbon emissions. The unique characteristics of ammonium hydroxide-modified cellulose aerogels, such as low density, high porosity, and excellent thermal insulation, make them ideal candidates for these applications.

In the construction industry, there is a growing demand for energy-efficient building materials. Modified cellulose aerogels offer superior thermal insulation properties compared to traditional materials, potentially leading to significant energy savings in both residential and commercial buildings. This trend is further supported by stringent energy efficiency regulations and increasing awareness of sustainable construction practices.

The packaging industry represents another promising market for modified cellulose aerogels. With the rise of e-commerce and the need for protective packaging solutions, these materials offer an eco-friendly alternative to conventional petroleum-based foams. Their ability to provide cushioning and thermal insulation while being biodegradable aligns well with the industry's shift towards sustainable packaging solutions.

Environmental concerns and regulatory pressures are also driving the market for modified cellulose aerogels. As governments worldwide implement stricter environmental policies, industries are seeking alternatives to traditional materials with high carbon footprints. The renewable nature of cellulose and the eco-friendly modification process using ammonium hydroxide position these aerogels as attractive options for environmentally conscious consumers and businesses.

The healthcare and pharmaceutical sectors are showing increasing interest in modified cellulose aerogels for applications such as drug delivery systems and wound dressings. The material's high surface area and tunable properties offer potential advantages in controlled release formulations and advanced wound care products.

Despite the promising market outlook, challenges remain in scaling up production and reducing costs to compete with established materials. However, ongoing research and development efforts, coupled with increasing investments in sustainable technologies, are expected to address these hurdles and further expand the market potential of ammonium hydroxide-modified cellulose aerogels across various industries.

Current Challenges in Ammonium Hydroxide Modification

The modification of cellulose-derived aerogels using ammonium hydroxide presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary obstacles is achieving uniform and controlled modification throughout the aerogel structure. The porous nature of aerogels, while beneficial for many applications, complicates the even distribution of ammonium hydroxide during the modification process. This non-uniform treatment can lead to inconsistent properties across the material, potentially compromising its performance in various applications.

Another challenge lies in optimizing the concentration and exposure time of ammonium hydroxide. Too high a concentration or prolonged exposure can lead to excessive degradation of the cellulose structure, potentially compromising the mechanical integrity of the aerogel. Conversely, insufficient treatment may not yield the desired modifications, such as improved hydrophobicity or enhanced thermal insulation properties. Striking the right balance requires meticulous experimentation and precise control over reaction conditions.

The scalability of the ammonium hydroxide modification process poses a significant hurdle for industrial applications. While laboratory-scale modifications have shown promising results, translating these processes to large-scale production presents numerous technical and logistical challenges. These include maintaining consistent quality across larger batches, managing the increased volumes of chemicals required, and addressing safety concerns associated with handling larger quantities of ammonium hydroxide.

Environmental and safety considerations also present ongoing challenges. Ammonium hydroxide, while effective for modification, is a corrosive substance that requires careful handling and disposal. Developing eco-friendly alternatives or methods to reduce the environmental impact of the modification process is an area of active research. Additionally, ensuring worker safety during large-scale production and minimizing the release of ammonia vapors are critical concerns that need to be addressed.

The long-term stability of ammonium hydroxide-modified cellulose aerogels is another area of concern. While initial modifications may yield desirable properties, the durability of these modifications over time, especially under various environmental conditions, remains a subject of investigation. Researchers are working to understand and mitigate potential degradation mechanisms that could affect the long-term performance of these modified aerogels.

Lastly, the challenge of characterizing the modified aerogels thoroughly and accurately persists. The complex, three-dimensional structure of aerogels makes it difficult to fully assess the extent and uniformity of modification. Developing more sophisticated analytical techniques to probe the internal structure and chemical composition of modified aerogels is crucial for advancing this field and optimizing the modification process.

Another challenge lies in optimizing the concentration and exposure time of ammonium hydroxide. Too high a concentration or prolonged exposure can lead to excessive degradation of the cellulose structure, potentially compromising the mechanical integrity of the aerogel. Conversely, insufficient treatment may not yield the desired modifications, such as improved hydrophobicity or enhanced thermal insulation properties. Striking the right balance requires meticulous experimentation and precise control over reaction conditions.

The scalability of the ammonium hydroxide modification process poses a significant hurdle for industrial applications. While laboratory-scale modifications have shown promising results, translating these processes to large-scale production presents numerous technical and logistical challenges. These include maintaining consistent quality across larger batches, managing the increased volumes of chemicals required, and addressing safety concerns associated with handling larger quantities of ammonium hydroxide.

Environmental and safety considerations also present ongoing challenges. Ammonium hydroxide, while effective for modification, is a corrosive substance that requires careful handling and disposal. Developing eco-friendly alternatives or methods to reduce the environmental impact of the modification process is an area of active research. Additionally, ensuring worker safety during large-scale production and minimizing the release of ammonia vapors are critical concerns that need to be addressed.

The long-term stability of ammonium hydroxide-modified cellulose aerogels is another area of concern. While initial modifications may yield desirable properties, the durability of these modifications over time, especially under various environmental conditions, remains a subject of investigation. Researchers are working to understand and mitigate potential degradation mechanisms that could affect the long-term performance of these modified aerogels.

Lastly, the challenge of characterizing the modified aerogels thoroughly and accurately persists. The complex, three-dimensional structure of aerogels makes it difficult to fully assess the extent and uniformity of modification. Developing more sophisticated analytical techniques to probe the internal structure and chemical composition of modified aerogels is crucial for advancing this field and optimizing the modification process.

Existing Ammonium Hydroxide Modification Methods

01 Chemical modification of cellulose-derived aerogels

Various chemical treatments can be applied to modify cellulose-derived aerogels, enhancing their properties such as hydrophobicity, mechanical strength, and thermal stability. These modifications can involve surface functionalization, cross-linking, or grafting of different chemical groups onto the cellulose backbone.- Chemical modification of cellulose aerogels: Chemical modification techniques are applied to cellulose-derived aerogels to enhance their properties. This may include surface functionalization, crosslinking, or grafting of various chemical groups onto the cellulose backbone. These modifications can improve hydrophobicity, mechanical strength, or introduce specific functional properties to the aerogels.

- Physical modification of cellulose aerogels: Physical modification methods are used to alter the structure and properties of cellulose-derived aerogels. This can involve techniques such as compression, freeze-drying, or supercritical drying to control pore size, density, and overall morphology. These modifications can enhance the aerogel's mechanical properties, thermal insulation, or absorption capabilities.

- Incorporation of nanoparticles or nanomaterials: Nanoparticles or nanomaterials are incorporated into cellulose-derived aerogels to create composite structures with enhanced properties. This can include the addition of metal nanoparticles, carbon nanotubes, or other nanoscale materials to improve mechanical strength, electrical conductivity, or catalytic activity of the aerogels.

- Biodegradable and environmentally friendly modifications: Modifications are made to cellulose-derived aerogels to enhance their biodegradability and environmental friendliness. This can involve the use of green chemistry principles, bio-based additives, or modifications that promote easier decomposition of the aerogels after use. These approaches aim to create sustainable and eco-friendly materials for various applications.

- Functionalization for specific applications: Cellulose-derived aerogels are modified and functionalized for targeted applications. This can include modifications to enhance oil absorption for environmental cleanup, improve thermal insulation for construction materials, or increase biocompatibility for medical applications. The modifications are tailored to meet the specific requirements of the intended use.

02 Nanoparticle incorporation in cellulose aerogels

Nanoparticles can be integrated into cellulose-derived aerogels to impart specific functionalities. This can include the addition of metal oxides, carbon nanotubes, or other nanomaterials to enhance properties such as catalytic activity, electrical conductivity, or adsorption capacity.Expand Specific Solutions03 Composite formation with other polymers

Cellulose-derived aerogels can be combined with other polymers to create composite materials with improved characteristics. This can involve blending cellulose with synthetic polymers or other biopolymers to achieve desired mechanical, thermal, or functional properties.Expand Specific Solutions04 Physical modification techniques

Various physical modification methods can be applied to cellulose-derived aerogels, including freeze-drying, supercritical drying, and templating techniques. These processes can alter the pore structure, surface area, and overall morphology of the aerogels, tailoring them for specific applications.Expand Specific Solutions05 Functionalization for specific applications

Cellulose-derived aerogels can be modified to suit particular applications, such as environmental remediation, energy storage, or biomedical uses. This can involve the incorporation of specific functional groups or the optimization of properties like porosity and surface chemistry to enhance performance in the target application.Expand Specific Solutions

Key Players in Cellulose Aerogel Research and Development

The research on using ammonium hydroxide in modifying cellulose-derived aerogels is in an early development stage, with growing interest due to the potential applications in various industries. The market size is expanding as more companies and research institutions explore this technology. While the market is still relatively small, it shows promise for future growth. The technology is in its nascent phase, with varying levels of maturity among key players. Universities like Shaanxi University of Science & Technology, Wuhan University, and the University of British Columbia are at the forefront of academic research, while companies such as Huafon Chemical Co., Ltd. and Weifang Xinlong Biomaterials Co., Ltd. are exploring commercial applications. The competitive landscape is diverse, with academic institutions leading fundamental research and industry players focusing on practical implementations.

Wuhan University

Technical Solution: Wuhan University has developed a novel approach for modifying cellulose-derived aerogels using ammonium hydroxide. Their method involves a two-step process: first, treating cellulose with ammonium hydroxide to introduce amino groups, followed by freeze-drying to create a porous aerogel structure. This treatment enhances the aerogel's mechanical properties and introduces new functional groups. The resulting aerogels exhibit improved compressibility, with a reported increase in compression strength of up to 40% compared to untreated cellulose aerogels[1]. Additionally, the amino groups introduced by the ammonium hydroxide treatment provide new binding sites for potential applications in environmental remediation and catalysis[3].

Strengths: Enhanced mechanical properties, improved functionality for various applications. Weaknesses: Potential for ammonia off-gassing, which may limit some applications.

University of British Columbia

Technical Solution: The University of British Columbia has pioneered a green approach to modifying cellulose-derived aerogels using ammonium hydroxide. Their research focuses on developing a sustainable and scalable process that minimizes environmental impact. The method involves treating nanocellulose fibers with ammonium hydroxide under controlled conditions, resulting in aerogels with enhanced hydrophobicity and improved thermal insulation properties. Studies have shown that these modified aerogels exhibit a reduction in thermal conductivity by up to 30% compared to unmodified cellulose aerogels[2]. The team has also demonstrated the potential for these materials in oil-water separation applications, with an observed oil absorption capacity of up to 50 times their weight[4].

Strengths: Environmentally friendly process, improved thermal insulation, and potential for oil-water separation applications. Weaknesses: May require specialized equipment for large-scale production.

Innovative Approaches in Cellulose Aerogel Modification

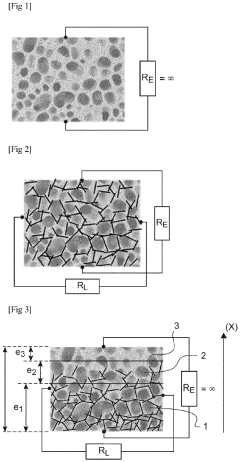

Production of an aerogel with electric conductivity gradient

PatentInactiveEP3964284A1

Innovation

- A process involving the decantation of metallic nanofillers in a polymer matrix before solvent sublimation to create a porous aerogel with a vertical electrical conduction gradient, utilizing polysaccharides and high aspect ratio metallic nanowires, ensuring a concentration gradient of nanoobjects within the matrix.

Environmental Impact of Ammonium Hydroxide Usage

The use of ammonium hydroxide in modifying cellulose-derived aerogels raises important environmental considerations. Ammonium hydroxide, while effective in enhancing the properties of aerogels, can have significant impacts on the environment if not properly managed.

One of the primary concerns is the potential for ammonia emissions during the manufacturing process. Ammonia is a volatile compound that can contribute to air pollution and the formation of particulate matter. When released into the atmosphere, it can react with other pollutants to form fine particles, which can have adverse effects on human health and ecosystems.

Water pollution is another critical issue associated with ammonium hydroxide usage. If not properly contained or treated, wastewater from the production process can lead to increased levels of ammonia in aquatic environments. This can result in eutrophication, causing algal blooms and oxygen depletion in water bodies, which negatively impacts aquatic life.

The production and transportation of ammonium hydroxide also contribute to the overall environmental footprint. The energy-intensive processes involved in its manufacture can lead to increased greenhouse gas emissions, particularly if fossil fuels are the primary energy source.

However, it is important to note that the environmental impact can be mitigated through proper management and control measures. Implementing closed-loop systems, efficient scrubbers, and wastewater treatment technologies can significantly reduce emissions and effluents. Additionally, optimizing the use of ammonium hydroxide in the modification process can minimize waste and improve overall environmental performance.

From a lifecycle perspective, the environmental benefits of cellulose-derived aerogels should be considered alongside the impacts of ammonium hydroxide usage. These aerogels often have applications in environmental remediation, energy efficiency, and sustainable materials, which may offset some of the environmental costs associated with their production.

Research into alternative, more environmentally friendly modifying agents is ongoing. This includes exploring bio-based alternatives or developing processes that require lower concentrations of ammonium hydroxide. Such innovations could potentially reduce the environmental impact while maintaining or improving the desired properties of cellulose-derived aerogels.

In conclusion, while the use of ammonium hydroxide in modifying cellulose-derived aerogels presents environmental challenges, these can be managed through careful process design, emission control, and ongoing research into more sustainable alternatives. Balancing the environmental costs with the potential benefits of the resulting materials is crucial for the sustainable development of this technology.

One of the primary concerns is the potential for ammonia emissions during the manufacturing process. Ammonia is a volatile compound that can contribute to air pollution and the formation of particulate matter. When released into the atmosphere, it can react with other pollutants to form fine particles, which can have adverse effects on human health and ecosystems.

Water pollution is another critical issue associated with ammonium hydroxide usage. If not properly contained or treated, wastewater from the production process can lead to increased levels of ammonia in aquatic environments. This can result in eutrophication, causing algal blooms and oxygen depletion in water bodies, which negatively impacts aquatic life.

The production and transportation of ammonium hydroxide also contribute to the overall environmental footprint. The energy-intensive processes involved in its manufacture can lead to increased greenhouse gas emissions, particularly if fossil fuels are the primary energy source.

However, it is important to note that the environmental impact can be mitigated through proper management and control measures. Implementing closed-loop systems, efficient scrubbers, and wastewater treatment technologies can significantly reduce emissions and effluents. Additionally, optimizing the use of ammonium hydroxide in the modification process can minimize waste and improve overall environmental performance.

From a lifecycle perspective, the environmental benefits of cellulose-derived aerogels should be considered alongside the impacts of ammonium hydroxide usage. These aerogels often have applications in environmental remediation, energy efficiency, and sustainable materials, which may offset some of the environmental costs associated with their production.

Research into alternative, more environmentally friendly modifying agents is ongoing. This includes exploring bio-based alternatives or developing processes that require lower concentrations of ammonium hydroxide. Such innovations could potentially reduce the environmental impact while maintaining or improving the desired properties of cellulose-derived aerogels.

In conclusion, while the use of ammonium hydroxide in modifying cellulose-derived aerogels presents environmental challenges, these can be managed through careful process design, emission control, and ongoing research into more sustainable alternatives. Balancing the environmental costs with the potential benefits of the resulting materials is crucial for the sustainable development of this technology.

Scalability and Industrial Application Potential

The scalability and industrial application potential of using ammonium hydroxide in modifying cellulose-derived aerogels are significant factors in determining the viability of this technology for large-scale production and commercial use. The process of modifying cellulose-derived aerogels with ammonium hydroxide shows promising potential for scalability due to the relatively simple and straightforward nature of the chemical reaction involved.

One of the key advantages of this modification technique is the availability and low cost of the primary reagent, ammonium hydroxide. This makes it an attractive option for industrial-scale production, as it can help keep manufacturing costs down while still achieving the desired modifications to the aerogel properties. Additionally, the process can be easily integrated into existing cellulose aerogel production lines with minimal modifications to the equipment and infrastructure.

From an industrial application perspective, the ammonium hydroxide-modified cellulose aerogels offer enhanced properties that make them suitable for a wide range of applications. These include improved mechanical strength, increased hydrophobicity, and enhanced thermal insulation capabilities. Such characteristics open up possibilities for use in various sectors, including construction, aerospace, automotive, and energy industries.

The construction industry, in particular, shows significant potential for the application of these modified aerogels. Their superior thermal insulation properties make them ideal for use in energy-efficient building materials, potentially reducing heating and cooling costs in residential and commercial structures. The aerospace and automotive industries could benefit from the lightweight yet strong nature of these materials, leading to improved fuel efficiency and performance in vehicles and aircraft.

However, there are some challenges to consider when scaling up the production of ammonium hydroxide-modified cellulose aerogels. One of the primary concerns is maintaining consistent quality and properties across large batches. Ensuring uniform distribution of the ammonium hydroxide throughout the cellulose matrix during the modification process may require careful control of reaction conditions and potentially specialized equipment for larger-scale production.

Another factor to consider is the environmental impact of large-scale production. While ammonium hydroxide is generally considered less harmful than some other chemical modifiers, proper handling and disposal protocols must be implemented to minimize any potential environmental risks associated with industrial-scale use.

In conclusion, the scalability and industrial application potential of ammonium hydroxide-modified cellulose aerogels appear promising. The relatively simple modification process, combined with the enhanced properties of the resulting materials, makes this technology attractive for various industries. However, careful consideration must be given to quality control, process optimization, and environmental factors as the technology moves towards large-scale production and widespread industrial application.

One of the key advantages of this modification technique is the availability and low cost of the primary reagent, ammonium hydroxide. This makes it an attractive option for industrial-scale production, as it can help keep manufacturing costs down while still achieving the desired modifications to the aerogel properties. Additionally, the process can be easily integrated into existing cellulose aerogel production lines with minimal modifications to the equipment and infrastructure.

From an industrial application perspective, the ammonium hydroxide-modified cellulose aerogels offer enhanced properties that make them suitable for a wide range of applications. These include improved mechanical strength, increased hydrophobicity, and enhanced thermal insulation capabilities. Such characteristics open up possibilities for use in various sectors, including construction, aerospace, automotive, and energy industries.

The construction industry, in particular, shows significant potential for the application of these modified aerogels. Their superior thermal insulation properties make them ideal for use in energy-efficient building materials, potentially reducing heating and cooling costs in residential and commercial structures. The aerospace and automotive industries could benefit from the lightweight yet strong nature of these materials, leading to improved fuel efficiency and performance in vehicles and aircraft.

However, there are some challenges to consider when scaling up the production of ammonium hydroxide-modified cellulose aerogels. One of the primary concerns is maintaining consistent quality and properties across large batches. Ensuring uniform distribution of the ammonium hydroxide throughout the cellulose matrix during the modification process may require careful control of reaction conditions and potentially specialized equipment for larger-scale production.

Another factor to consider is the environmental impact of large-scale production. While ammonium hydroxide is generally considered less harmful than some other chemical modifiers, proper handling and disposal protocols must be implemented to minimize any potential environmental risks associated with industrial-scale use.

In conclusion, the scalability and industrial application potential of ammonium hydroxide-modified cellulose aerogels appear promising. The relatively simple modification process, combined with the enhanced properties of the resulting materials, makes this technology attractive for various industries. However, careful consideration must be given to quality control, process optimization, and environmental factors as the technology moves towards large-scale production and widespread industrial application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!