The role of ammonium hydroxide in the baking industry

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Baking: Background and Objectives

Ammonium hydroxide, a compound of nitrogen and hydrogen, has played a significant role in the baking industry for decades. Its use can be traced back to the early 20th century when bakers began exploring chemical leavening agents to improve the texture and appearance of baked goods. The evolution of this technology has been driven by the constant pursuit of better quality, consistency, and efficiency in commercial baking processes.

The primary objective of using ammonium hydroxide in baking is to enhance the overall quality of baked products. It serves as a leavening agent, contributing to the rise and texture of various baked goods, particularly cookies and crackers. Additionally, it acts as a pH regulator, helping to control the acidity levels in dough and batter, which is crucial for optimal flavor development and browning reactions during baking.

Another key goal in utilizing ammonium hydroxide is to improve the shelf life of baked products. By creating an alkaline environment, it helps inhibit the growth of certain microorganisms, thus extending the freshness and safety of baked goods. This property has become increasingly important as the demand for longer-lasting packaged bakery items has grown in the modern food industry.

The technical evolution of ammonium hydroxide in baking has been marked by continuous refinement in its application methods and dosage control. Early uses were often imprecise, leading to inconsistent results. However, advancements in food science and baking technology have led to more sophisticated understanding and precise application of this ingredient, allowing for better control over its effects on the final product.

In recent years, the baking industry has faced new challenges and opportunities related to the use of ammonium hydroxide. There is a growing consumer demand for "clean label" products, which has prompted research into natural alternatives or reduced usage of chemical additives. Simultaneously, there is an increasing focus on developing low-sodium baked goods, where ammonium hydroxide's leavening properties can be particularly valuable.

The future direction of ammonium hydroxide use in baking is likely to be influenced by several factors, including regulatory changes, consumer preferences, and technological advancements. Research is ongoing to optimize its use in conjunction with other ingredients and to explore potential new applications in novel baked products. The industry is also investigating ways to minimize any potential off-flavors or odors associated with its use, aiming to maintain its functional benefits while addressing sensory concerns.

The primary objective of using ammonium hydroxide in baking is to enhance the overall quality of baked products. It serves as a leavening agent, contributing to the rise and texture of various baked goods, particularly cookies and crackers. Additionally, it acts as a pH regulator, helping to control the acidity levels in dough and batter, which is crucial for optimal flavor development and browning reactions during baking.

Another key goal in utilizing ammonium hydroxide is to improve the shelf life of baked products. By creating an alkaline environment, it helps inhibit the growth of certain microorganisms, thus extending the freshness and safety of baked goods. This property has become increasingly important as the demand for longer-lasting packaged bakery items has grown in the modern food industry.

The technical evolution of ammonium hydroxide in baking has been marked by continuous refinement in its application methods and dosage control. Early uses were often imprecise, leading to inconsistent results. However, advancements in food science and baking technology have led to more sophisticated understanding and precise application of this ingredient, allowing for better control over its effects on the final product.

In recent years, the baking industry has faced new challenges and opportunities related to the use of ammonium hydroxide. There is a growing consumer demand for "clean label" products, which has prompted research into natural alternatives or reduced usage of chemical additives. Simultaneously, there is an increasing focus on developing low-sodium baked goods, where ammonium hydroxide's leavening properties can be particularly valuable.

The future direction of ammonium hydroxide use in baking is likely to be influenced by several factors, including regulatory changes, consumer preferences, and technological advancements. Research is ongoing to optimize its use in conjunction with other ingredients and to explore potential new applications in novel baked products. The industry is also investigating ways to minimize any potential off-flavors or odors associated with its use, aiming to maintain its functional benefits while addressing sensory concerns.

Market Analysis of Ammonium Hydroxide in Baking

The market for ammonium hydroxide in the baking industry has experienced significant growth in recent years, driven by its versatile applications and functional benefits. As a key ingredient in various baking processes, ammonium hydroxide plays a crucial role in enhancing the quality and characteristics of baked goods.

The global baking industry has been expanding steadily, with a compound annual growth rate (CAGR) of around 6% over the past five years. This growth has directly impacted the demand for ammonium hydroxide, as it is widely used as a leavening agent and pH regulator in baked products. The market size for ammonium hydroxide in baking applications is estimated to be in the range of several hundred million dollars annually.

One of the primary drivers of market growth is the increasing consumer demand for bakery products with improved texture, appearance, and shelf life. Ammonium hydroxide contributes to these qualities by promoting browning reactions, controlling acidity, and enhancing the overall structure of baked goods. As a result, manufacturers are incorporating it into a wide range of products, including cookies, crackers, and bread.

The market for ammonium hydroxide in baking is also influenced by regional preferences and regulations. In North America and Europe, where stringent food safety regulations are in place, the use of ammonium hydroxide is closely monitored and controlled. However, these regions still represent significant market shares due to their large-scale baking industries and consumer demand for high-quality products.

Emerging markets in Asia-Pacific and Latin America are showing promising growth potential for ammonium hydroxide in baking applications. The rapid urbanization, changing dietary habits, and increasing disposable incomes in these regions are driving the demand for processed and packaged bakery products, subsequently boosting the use of ammonium hydroxide.

The competitive landscape of the ammonium hydroxide market for baking is characterized by a mix of large chemical manufacturers and specialized food ingredient suppliers. Key players are focusing on product innovation, quality improvements, and strategic partnerships to maintain their market positions and cater to evolving customer needs.

Despite its benefits, the market faces challenges related to consumer perception and health concerns. Some consumers are seeking "clean label" products with fewer chemical additives, which may impact the growth of ammonium hydroxide usage in certain segments. However, manufacturers are addressing these concerns through education and by highlighting the safety and functional advantages of ammonium hydroxide when used in appropriate quantities.

Looking ahead, the market for ammonium hydroxide in baking is expected to continue its growth trajectory, albeit at a more moderate pace. Factors such as technological advancements in food processing, the development of new bakery products, and the expansion of the global baking industry are likely to sustain demand for ammonium hydroxide in the coming years.

The global baking industry has been expanding steadily, with a compound annual growth rate (CAGR) of around 6% over the past five years. This growth has directly impacted the demand for ammonium hydroxide, as it is widely used as a leavening agent and pH regulator in baked products. The market size for ammonium hydroxide in baking applications is estimated to be in the range of several hundred million dollars annually.

One of the primary drivers of market growth is the increasing consumer demand for bakery products with improved texture, appearance, and shelf life. Ammonium hydroxide contributes to these qualities by promoting browning reactions, controlling acidity, and enhancing the overall structure of baked goods. As a result, manufacturers are incorporating it into a wide range of products, including cookies, crackers, and bread.

The market for ammonium hydroxide in baking is also influenced by regional preferences and regulations. In North America and Europe, where stringent food safety regulations are in place, the use of ammonium hydroxide is closely monitored and controlled. However, these regions still represent significant market shares due to their large-scale baking industries and consumer demand for high-quality products.

Emerging markets in Asia-Pacific and Latin America are showing promising growth potential for ammonium hydroxide in baking applications. The rapid urbanization, changing dietary habits, and increasing disposable incomes in these regions are driving the demand for processed and packaged bakery products, subsequently boosting the use of ammonium hydroxide.

The competitive landscape of the ammonium hydroxide market for baking is characterized by a mix of large chemical manufacturers and specialized food ingredient suppliers. Key players are focusing on product innovation, quality improvements, and strategic partnerships to maintain their market positions and cater to evolving customer needs.

Despite its benefits, the market faces challenges related to consumer perception and health concerns. Some consumers are seeking "clean label" products with fewer chemical additives, which may impact the growth of ammonium hydroxide usage in certain segments. However, manufacturers are addressing these concerns through education and by highlighting the safety and functional advantages of ammonium hydroxide when used in appropriate quantities.

Looking ahead, the market for ammonium hydroxide in baking is expected to continue its growth trajectory, albeit at a more moderate pace. Factors such as technological advancements in food processing, the development of new bakery products, and the expansion of the global baking industry are likely to sustain demand for ammonium hydroxide in the coming years.

Current Applications and Challenges in Baking Industry

Ammonium hydroxide plays a significant role in the baking industry, serving multiple purposes that contribute to the quality and characteristics of baked goods. Its primary applications include acting as a leavening agent, pH regulator, and dough conditioner.

As a leavening agent, ammonium hydroxide releases ammonia gas during the baking process, which helps create a light and airy texture in certain baked products. This property is particularly valuable in the production of crisp cookies, crackers, and wafers. The rapid release of gas during baking contributes to the formation of small, uniform air pockets, resulting in a desirable crunch and snap in the final product.

In its role as a pH regulator, ammonium hydroxide helps to control the acidity levels in dough and batter. This pH adjustment can influence various aspects of the baking process, including gluten development, enzyme activity, and browning reactions. By maintaining an optimal pH range, bakers can achieve consistent results in terms of texture, flavor, and appearance across different batches of products.

Ammonium hydroxide also functions as a dough conditioner, improving the handling properties of dough during processing. It can enhance dough elasticity and extensibility, making it easier to shape and form into various products. This property is particularly beneficial in large-scale industrial baking operations where consistent dough performance is crucial for efficient production.

Despite its usefulness, the application of ammonium hydroxide in baking faces several challenges. One primary concern is the potential for residual ammonia in the final product. While most of the ammonia evaporates during baking, improper use or inadequate baking conditions can lead to detectable ammonia odors or flavors, which are undesirable to consumers.

Another challenge lies in the regulatory landscape surrounding ammonium hydroxide usage. Different countries and regions have varying regulations regarding its application in food products, necessitating careful consideration and compliance for international baking operations.

The increasing consumer demand for clean label products presents an additional challenge. As ammonium hydroxide is perceived as a chemical additive, some consumers and food manufacturers are seeking alternative natural leavening agents and dough conditioners. This trend is driving research into plant-based or fermentation-derived alternatives that can provide similar functional benefits without the use of synthetic compounds.

Lastly, the handling and storage of ammonium hydroxide pose safety considerations for bakery workers. Its corrosive nature and potential for releasing harmful vapors require proper training, protective equipment, and storage facilities to ensure workplace safety.

As a leavening agent, ammonium hydroxide releases ammonia gas during the baking process, which helps create a light and airy texture in certain baked products. This property is particularly valuable in the production of crisp cookies, crackers, and wafers. The rapid release of gas during baking contributes to the formation of small, uniform air pockets, resulting in a desirable crunch and snap in the final product.

In its role as a pH regulator, ammonium hydroxide helps to control the acidity levels in dough and batter. This pH adjustment can influence various aspects of the baking process, including gluten development, enzyme activity, and browning reactions. By maintaining an optimal pH range, bakers can achieve consistent results in terms of texture, flavor, and appearance across different batches of products.

Ammonium hydroxide also functions as a dough conditioner, improving the handling properties of dough during processing. It can enhance dough elasticity and extensibility, making it easier to shape and form into various products. This property is particularly beneficial in large-scale industrial baking operations where consistent dough performance is crucial for efficient production.

Despite its usefulness, the application of ammonium hydroxide in baking faces several challenges. One primary concern is the potential for residual ammonia in the final product. While most of the ammonia evaporates during baking, improper use or inadequate baking conditions can lead to detectable ammonia odors or flavors, which are undesirable to consumers.

Another challenge lies in the regulatory landscape surrounding ammonium hydroxide usage. Different countries and regions have varying regulations regarding its application in food products, necessitating careful consideration and compliance for international baking operations.

The increasing consumer demand for clean label products presents an additional challenge. As ammonium hydroxide is perceived as a chemical additive, some consumers and food manufacturers are seeking alternative natural leavening agents and dough conditioners. This trend is driving research into plant-based or fermentation-derived alternatives that can provide similar functional benefits without the use of synthetic compounds.

Lastly, the handling and storage of ammonium hydroxide pose safety considerations for bakery workers. Its corrosive nature and potential for releasing harmful vapors require proper training, protective equipment, and storage facilities to ensure workplace safety.

Existing Formulations Using Ammonium Hydroxide

01 Use of ammonium hydroxide in chemical processes

Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH adjuster. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it suitable for neutralizing acidic solutions and controlling pH levels in different applications.- Use of ammonium hydroxide in chemical processes: Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH regulator. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it suitable for neutralizing acidic solutions and controlling pH levels in different applications.

- Application in cleaning and surface treatment: Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Additionally, it finds applications in the textile industry for fabric treatment and in the leather industry for dehairing hides.

- Role in environmental and waste management: Ammonium hydroxide plays a significant role in environmental and waste management processes. It is used in flue gas treatment to reduce nitrogen oxide emissions, in wastewater treatment for pH adjustment and nitrogen removal, and in soil remediation to neutralize acidic soils. Its ability to react with and neutralize various pollutants makes it valuable in pollution control applications.

- Use in personal care and cosmetic products: Ammonium hydroxide is employed in the formulation of personal care and cosmetic products. It is used as a pH adjuster in hair dyes, perming solutions, and skin care products. In hair coloring applications, it helps to open the hair cuticle, allowing the dye to penetrate more effectively. Its alkaline nature also assists in the development of certain fragrances in perfumery.

- Application in agricultural and food industries: Ammonium hydroxide finds applications in the agricultural and food industries. It is used as a source of nitrogen in fertilizers, contributing to plant growth and crop yield. In food processing, it serves as a leavening agent in baked goods and as a pH regulator in various food products. It is also used in the production of certain cheeses and in the treatment of drinking water.

02 Application in hair coloring and bleaching

Ammonium hydroxide is commonly used in hair coloring and bleaching products. It helps to open the hair cuticle, allowing the dye or bleaching agent to penetrate the hair shaft more effectively. The alkaline nature of ammonium hydroxide also assists in the oxidation process of hair dyes, resulting in longer-lasting color.Expand Specific Solutions03 Role in cleaning and household products

Ammonium hydroxide is a key ingredient in many cleaning and household products. Its strong alkaline properties make it effective in removing grease, grime, and stubborn stains. It is commonly found in glass cleaners, floor cleaners, and all-purpose cleaning solutions. The compound's ability to break down organic matter also makes it useful in removing odors.Expand Specific Solutions04 Use in textile processing

Ammonium hydroxide is utilized in various stages of textile processing. It is used in the mercerization of cotton fabrics to improve their luster and strength. The compound also plays a role in dyeing processes, helping to fix dyes to fabrics and improve color fastness. Additionally, it is used in the treatment of wool to enhance its properties.Expand Specific Solutions05 Environmental and agricultural applications

Ammonium hydroxide has important applications in environmental and agricultural sectors. It is used in air pollution control systems to neutralize acidic gases. In agriculture, it serves as a source of nitrogen for fertilizers and can be directly applied to soil to adjust pH levels. The compound is also used in the treatment of wastewater and in composting processes.Expand Specific Solutions

Key Manufacturers and Suppliers in Baking Industry

The ammonium hydroxide market in the baking industry is in a mature stage, with a stable global market size. The technology is well-established, with key players like DSM IP Assets BV, Nippon Soda Co., Ltd., and CSM Bakery Solutions Europe Holding BV having significant market presence. These companies have developed advanced formulations and applications for ammonium hydroxide in baking processes. The market is characterized by ongoing research and development efforts to improve product efficiency and address environmental concerns. Emerging players like Novozymes A/S and Chr. Hansen A/S are focusing on innovative bio-based alternatives, potentially disrupting the traditional ammonium hydroxide market in the baking industry.

DSM IP Assets BV

Technical Solution: DSM has developed a comprehensive baking ingredients portfolio that incorporates ammonium hydroxide in conjunction with other functional ingredients. Their approach focuses on creating clean label solutions that leverage the benefits of ammonium hydroxide while addressing consumer demands for more natural products. DSM's technology involves microencapsulation of ammonium hydroxide, allowing for controlled release during the baking process[5]. This method ensures optimal pH regulation and improves the effectiveness of other ingredients such as emulsifiers and enzymes. Additionally, DSM has conducted extensive research on the interaction between ammonium hydroxide and various flour types, enabling tailored solutions for different bakery applications[6].

Strengths: Clean label potential, versatile application across various bakery products, improved ingredient synergy. Weaknesses: Complex formulation process, potential higher production costs.

CSM Bakery Solutions Europe Holding BV

Technical Solution: CSM Bakery Solutions has developed an integrated approach to utilizing ammonium hydroxide in industrial baking processes. Their technology focuses on optimizing the use of ammonium hydroxide across various bakery applications, from bread to pastries. CSM's solution involves a precise dosing system that adjusts ammonium hydroxide levels based on real-time dough pH measurements and other process parameters[9]. This adaptive approach ensures consistent product quality while minimizing excess usage. Additionally, CSM has developed specialized baking mixes and improvers that are formulated to work synergistically with ammonium hydroxide, enhancing its effects on dough conditioning, crumb structure, and shelf life[10]. The company also offers training and support to help bakeries implement and optimize their ammonium hydroxide usage.

Strengths: Precision control of ammonium hydroxide usage, comprehensive solution for industrial bakeries, potential for cost savings through optimized ingredient use. Weaknesses: Requires significant investment in equipment and training, may be less suitable for small-scale operations.

Scientific Principles of Ammonium Hydroxide in Baking

Baked composition

PatentActiveAU2018203079A1

Innovation

- Adding non-pre-reacted amino acids and reducing sugars directly to ingredients before baking allows for the formation of flavor active molecules during the baking process, leveraging high temperatures and pressures to accelerate flavor generation and trap these molecules within the food matrix, resulting in improved flavor and texture.

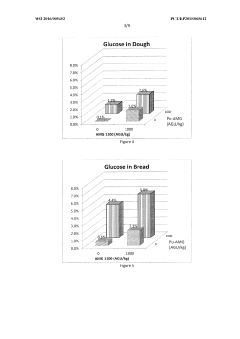

Sugar-producing and texture-improving bakery methods and products formed therefrom

PatentWO2016005452A1

Innovation

- A method involving a dough formulation with yeast, a source of starch, and specific enzymes like thermally-stable amyloglucosidase and raw starch degrading amyloglucosidases that generate sugar during baking, reducing fructose content and improving texture by increasing glucose and maltose production.

Food Safety Regulations for Ammonium Hydroxide Use

The use of ammonium hydroxide in the baking industry is subject to strict food safety regulations to ensure consumer protection. In the United States, the Food and Drug Administration (FDA) classifies ammonium hydroxide as Generally Recognized as Safe (GRAS) when used as a leavening agent, pH control agent, or surface-finishing agent in baked goods. However, its use is limited to specific concentrations and applications.

The European Food Safety Authority (EFSA) has also evaluated the safety of ammonium hydroxide as a food additive. In the European Union, it is approved for use in certain food categories, including bakery wares, under the E number E527. The EFSA has established an Acceptable Daily Intake (ADI) for ammonium ions, which applies to all ammonium-containing food additives, including ammonium hydroxide.

Regulatory bodies require manufacturers to adhere to Good Manufacturing Practices (GMP) when using ammonium hydroxide in baking processes. This includes proper handling, storage, and application of the substance to prevent contamination and ensure consistent quality. Bakeries must maintain detailed records of ammonium hydroxide usage and implement quality control measures to comply with food safety standards.

Labeling regulations also play a crucial role in the use of ammonium hydroxide. In many jurisdictions, manufacturers are required to list ammonium hydroxide as an ingredient on product labels when it is used in baked goods. This transparency allows consumers to make informed choices about the products they purchase and consume.

Food safety authorities conduct regular inspections of bakeries and food manufacturing facilities to ensure compliance with regulations regarding ammonium hydroxide use. These inspections may include checks on storage conditions, handling procedures, and documentation of usage levels. Non-compliance can result in penalties, product recalls, or suspension of operations.

International trade of baked goods containing ammonium hydroxide must comply with both the exporting and importing countries' regulations. This often requires manufacturers to meet the most stringent standards to ensure global market access. The Codex Alimentarius, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that serve as a reference for many countries' regulations on ammonium hydroxide use in food production.

As scientific understanding evolves, regulatory bodies continuously review and update their guidelines on ammonium hydroxide use in the baking industry. This ongoing process ensures that food safety regulations remain current with the latest research findings and technological advancements in food production.

The European Food Safety Authority (EFSA) has also evaluated the safety of ammonium hydroxide as a food additive. In the European Union, it is approved for use in certain food categories, including bakery wares, under the E number E527. The EFSA has established an Acceptable Daily Intake (ADI) for ammonium ions, which applies to all ammonium-containing food additives, including ammonium hydroxide.

Regulatory bodies require manufacturers to adhere to Good Manufacturing Practices (GMP) when using ammonium hydroxide in baking processes. This includes proper handling, storage, and application of the substance to prevent contamination and ensure consistent quality. Bakeries must maintain detailed records of ammonium hydroxide usage and implement quality control measures to comply with food safety standards.

Labeling regulations also play a crucial role in the use of ammonium hydroxide. In many jurisdictions, manufacturers are required to list ammonium hydroxide as an ingredient on product labels when it is used in baked goods. This transparency allows consumers to make informed choices about the products they purchase and consume.

Food safety authorities conduct regular inspections of bakeries and food manufacturing facilities to ensure compliance with regulations regarding ammonium hydroxide use. These inspections may include checks on storage conditions, handling procedures, and documentation of usage levels. Non-compliance can result in penalties, product recalls, or suspension of operations.

International trade of baked goods containing ammonium hydroxide must comply with both the exporting and importing countries' regulations. This often requires manufacturers to meet the most stringent standards to ensure global market access. The Codex Alimentarius, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that serve as a reference for many countries' regulations on ammonium hydroxide use in food production.

As scientific understanding evolves, regulatory bodies continuously review and update their guidelines on ammonium hydroxide use in the baking industry. This ongoing process ensures that food safety regulations remain current with the latest research findings and technological advancements in food production.

Environmental Impact of Ammonium Hydroxide Production

The production of ammonium hydroxide for use in the baking industry has significant environmental implications that warrant careful consideration. The manufacturing process primarily involves the Haber-Bosch process, which combines nitrogen from the air with hydrogen derived from natural gas to produce ammonia. This ammonia is then dissolved in water to create ammonium hydroxide. While this process has revolutionized industrial ammonia production, it is energy-intensive and contributes to greenhouse gas emissions.

The Haber-Bosch process consumes approximately 1-2% of the world's annual energy supply and is responsible for about 1.4% of global CO2 emissions. The high energy demand stems from the need for high temperatures and pressures to facilitate the reaction between nitrogen and hydrogen. Natural gas, the primary feedstock for hydrogen production, is a fossil fuel, and its extraction and processing contribute to methane emissions, a potent greenhouse gas.

Water consumption is another environmental concern in ammonium hydroxide production. The process requires substantial amounts of water for cooling and as a reactant. In water-stressed regions, this can exacerbate local water scarcity issues and potentially impact aquatic ecosystems.

The transportation and storage of ammonium hydroxide also present environmental risks. Accidental spills or leaks can lead to soil and water contamination, affecting local flora and fauna. Ammonia is highly soluble in water and can cause eutrophication in aquatic environments, leading to algal blooms and oxygen depletion.

However, it's important to note that the baking industry's use of ammonium hydroxide is relatively small compared to its application in fertilizers. Nevertheless, the cumulative impact across various industries contributes to the overall environmental footprint of ammonium hydroxide production.

Efforts to mitigate these environmental impacts are ongoing. Research into more sustainable hydrogen production methods, such as electrolysis powered by renewable energy, could significantly reduce the carbon footprint of ammonium hydroxide production. Additionally, improving energy efficiency in the Haber-Bosch process and implementing better waste heat recovery systems can help minimize energy consumption.

The baking industry, as a consumer of ammonium hydroxide, can contribute to environmental sustainability by optimizing its use, exploring alternative leavening agents where possible, and supporting suppliers who implement more environmentally friendly production methods. As environmental regulations become more stringent, the industry may need to adapt to potential restrictions on ammonium hydroxide use or increased costs associated with its production.

The Haber-Bosch process consumes approximately 1-2% of the world's annual energy supply and is responsible for about 1.4% of global CO2 emissions. The high energy demand stems from the need for high temperatures and pressures to facilitate the reaction between nitrogen and hydrogen. Natural gas, the primary feedstock for hydrogen production, is a fossil fuel, and its extraction and processing contribute to methane emissions, a potent greenhouse gas.

Water consumption is another environmental concern in ammonium hydroxide production. The process requires substantial amounts of water for cooling and as a reactant. In water-stressed regions, this can exacerbate local water scarcity issues and potentially impact aquatic ecosystems.

The transportation and storage of ammonium hydroxide also present environmental risks. Accidental spills or leaks can lead to soil and water contamination, affecting local flora and fauna. Ammonia is highly soluble in water and can cause eutrophication in aquatic environments, leading to algal blooms and oxygen depletion.

However, it's important to note that the baking industry's use of ammonium hydroxide is relatively small compared to its application in fertilizers. Nevertheless, the cumulative impact across various industries contributes to the overall environmental footprint of ammonium hydroxide production.

Efforts to mitigate these environmental impacts are ongoing. Research into more sustainable hydrogen production methods, such as electrolysis powered by renewable energy, could significantly reduce the carbon footprint of ammonium hydroxide production. Additionally, improving energy efficiency in the Haber-Bosch process and implementing better waste heat recovery systems can help minimize energy consumption.

The baking industry, as a consumer of ammonium hydroxide, can contribute to environmental sustainability by optimizing its use, exploring alternative leavening agents where possible, and supporting suppliers who implement more environmentally friendly production methods. As environmental regulations become more stringent, the industry may need to adapt to potential restrictions on ammonium hydroxide use or increased costs associated with its production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!