The influence of ammonium hydroxide on microbial cellulose production

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microbial Cellulose Background and Objectives

Microbial cellulose, a unique form of cellulose produced by certain bacteria, has gained significant attention in recent years due to its exceptional properties and potential applications across various industries. The development of this biomaterial can be traced back to 1886 when A.J. Brown first discovered the production of cellulose by Acetobacter xylinum. Since then, research in this field has expanded dramatically, uncovering the potential of microbial cellulose in areas such as biomedical engineering, food technology, and advanced materials science.

The evolution of microbial cellulose technology has been marked by several key milestones. In the 1950s, Hestrin and Schramm developed a standard culture medium for bacterial cellulose production, which significantly improved yield and consistency. The 1990s saw a surge in research on the structural characterization and modification of microbial cellulose, leading to a better understanding of its unique properties, such as high purity, high crystallinity, and excellent mechanical strength.

In recent years, the focus has shifted towards optimizing production processes and exploring novel applications. The influence of various factors on microbial cellulose production, including nutrient composition, pH, temperature, and oxygen availability, has been extensively studied. Among these factors, the role of nitrogen sources, particularly ammonium compounds, has emerged as a critical area of investigation.

The primary objective of current research in this field is to enhance the efficiency and sustainability of microbial cellulose production. This includes improving yield, reducing production costs, and developing eco-friendly production methods. Specifically, understanding the influence of ammonium hydroxide on microbial cellulose production has become a key focus area. Ammonium hydroxide, as a nitrogen source and pH regulator, has shown potential to significantly impact both the quantity and quality of microbial cellulose produced.

Furthermore, researchers aim to tailor the properties of microbial cellulose for specific applications. This involves manipulating production conditions, including the use of ammonium hydroxide, to control factors such as fiber diameter, crystallinity, and mechanical properties. The ultimate goal is to develop microbial cellulose-based materials that can effectively compete with or surpass traditional materials in various applications, from wound dressings and tissue scaffolds to electronic components and packaging materials.

As we look towards the future, the field of microbial cellulose research is poised for significant advancements. The integration of biotechnology, materials science, and engineering is expected to drive innovation in production techniques and applications. Understanding the complex interplay between various factors, including the role of ammonium hydroxide, will be crucial in realizing the full potential of this remarkable biomaterial.

The evolution of microbial cellulose technology has been marked by several key milestones. In the 1950s, Hestrin and Schramm developed a standard culture medium for bacterial cellulose production, which significantly improved yield and consistency. The 1990s saw a surge in research on the structural characterization and modification of microbial cellulose, leading to a better understanding of its unique properties, such as high purity, high crystallinity, and excellent mechanical strength.

In recent years, the focus has shifted towards optimizing production processes and exploring novel applications. The influence of various factors on microbial cellulose production, including nutrient composition, pH, temperature, and oxygen availability, has been extensively studied. Among these factors, the role of nitrogen sources, particularly ammonium compounds, has emerged as a critical area of investigation.

The primary objective of current research in this field is to enhance the efficiency and sustainability of microbial cellulose production. This includes improving yield, reducing production costs, and developing eco-friendly production methods. Specifically, understanding the influence of ammonium hydroxide on microbial cellulose production has become a key focus area. Ammonium hydroxide, as a nitrogen source and pH regulator, has shown potential to significantly impact both the quantity and quality of microbial cellulose produced.

Furthermore, researchers aim to tailor the properties of microbial cellulose for specific applications. This involves manipulating production conditions, including the use of ammonium hydroxide, to control factors such as fiber diameter, crystallinity, and mechanical properties. The ultimate goal is to develop microbial cellulose-based materials that can effectively compete with or surpass traditional materials in various applications, from wound dressings and tissue scaffolds to electronic components and packaging materials.

As we look towards the future, the field of microbial cellulose research is poised for significant advancements. The integration of biotechnology, materials science, and engineering is expected to drive innovation in production techniques and applications. Understanding the complex interplay between various factors, including the role of ammonium hydroxide, will be crucial in realizing the full potential of this remarkable biomaterial.

Market Analysis for Microbial Cellulose Products

The microbial cellulose market has been experiencing significant growth in recent years, driven by the increasing demand for sustainable and eco-friendly materials across various industries. The global market for microbial cellulose products is projected to expand at a robust rate, with applications spanning from food and beverages to cosmetics, pharmaceuticals, and advanced materials.

In the food and beverage sector, microbial cellulose is gaining traction as a low-calorie thickening agent and stabilizer. Its unique properties, such as high water-holding capacity and ability to form stable gels, make it an attractive ingredient for health-conscious consumers. The growing trend towards plant-based and vegan products has further boosted the demand for microbial cellulose as a natural texturizer in dairy alternatives and meat substitutes.

The cosmetics industry has also shown keen interest in microbial cellulose, particularly for its potential in developing advanced skincare products. Its ability to form thin, transparent films with excellent moisture-retention properties makes it ideal for face masks and other topical applications. The increasing consumer preference for natural and organic beauty products is expected to drive further growth in this segment.

In the pharmaceutical sector, microbial cellulose is being explored for wound dressing applications due to its biocompatibility and ability to promote healing. The growing prevalence of chronic wounds and the need for advanced wound care solutions are likely to fuel demand in this area. Additionally, research into drug delivery systems utilizing microbial cellulose nanocomposites shows promise for future market expansion.

The advanced materials sector presents significant opportunities for microbial cellulose products. Its potential applications in electronics, such as flexible displays and conductive materials, are attracting attention from tech companies. The automotive industry is also exploring microbial cellulose for lightweight, biodegradable components, aligning with the trend towards more sustainable transportation solutions.

Geographically, North America and Europe currently lead the microbial cellulose market, owing to their advanced research capabilities and early adoption of bio-based materials. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing industrialization, growing awareness of sustainable materials, and government initiatives promoting bio-based economies.

Despite the positive outlook, challenges remain in scaling up production and reducing costs to compete with traditional materials. The influence of ammonium hydroxide on microbial cellulose production is a crucial area of research that could potentially address these challenges by optimizing yield and quality. As production processes improve and new applications emerge, the market for microbial cellulose products is poised for substantial growth in the coming years.

In the food and beverage sector, microbial cellulose is gaining traction as a low-calorie thickening agent and stabilizer. Its unique properties, such as high water-holding capacity and ability to form stable gels, make it an attractive ingredient for health-conscious consumers. The growing trend towards plant-based and vegan products has further boosted the demand for microbial cellulose as a natural texturizer in dairy alternatives and meat substitutes.

The cosmetics industry has also shown keen interest in microbial cellulose, particularly for its potential in developing advanced skincare products. Its ability to form thin, transparent films with excellent moisture-retention properties makes it ideal for face masks and other topical applications. The increasing consumer preference for natural and organic beauty products is expected to drive further growth in this segment.

In the pharmaceutical sector, microbial cellulose is being explored for wound dressing applications due to its biocompatibility and ability to promote healing. The growing prevalence of chronic wounds and the need for advanced wound care solutions are likely to fuel demand in this area. Additionally, research into drug delivery systems utilizing microbial cellulose nanocomposites shows promise for future market expansion.

The advanced materials sector presents significant opportunities for microbial cellulose products. Its potential applications in electronics, such as flexible displays and conductive materials, are attracting attention from tech companies. The automotive industry is also exploring microbial cellulose for lightweight, biodegradable components, aligning with the trend towards more sustainable transportation solutions.

Geographically, North America and Europe currently lead the microbial cellulose market, owing to their advanced research capabilities and early adoption of bio-based materials. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing industrialization, growing awareness of sustainable materials, and government initiatives promoting bio-based economies.

Despite the positive outlook, challenges remain in scaling up production and reducing costs to compete with traditional materials. The influence of ammonium hydroxide on microbial cellulose production is a crucial area of research that could potentially address these challenges by optimizing yield and quality. As production processes improve and new applications emerge, the market for microbial cellulose products is poised for substantial growth in the coming years.

Current Challenges in Microbial Cellulose Production

Microbial cellulose production faces several significant challenges that hinder its widespread industrial application. One of the primary obstacles is the high production cost, which stems from expensive culture media and low yield. The complex nutritional requirements of cellulose-producing bacteria necessitate the use of costly substrates, making large-scale production economically unfeasible.

Another major challenge is the low productivity of current microbial cellulose production systems. The slow growth rate of cellulose-producing bacteria and limited cellulose synthesis capacity result in extended cultivation periods and reduced output. This low efficiency significantly impacts the scalability and commercial viability of microbial cellulose production.

The inconsistency in product quality poses a substantial hurdle for industrial applications. Variations in cellulose properties, such as crystallinity, degree of polymerization, and mechanical strength, can occur due to fluctuations in cultivation conditions. This inconsistency makes it difficult to maintain uniform product specifications, which is crucial for many high-value applications.

Contamination control remains a persistent challenge in microbial cellulose production. The nutrient-rich culture medium used for cellulose-producing bacteria is also conducive to the growth of other microorganisms. Contamination can lead to reduced yield, altered product properties, and even complete batch failure, necessitating stringent sterility measures that further increase production costs.

The limited understanding of the genetic and metabolic pathways involved in bacterial cellulose synthesis hinders targeted improvements in production strains. While some progress has been made in elucidating the biosynthesis mechanisms, there is still a lack of comprehensive knowledge that could guide strain engineering efforts to enhance cellulose production.

Scaling up microbial cellulose production from laboratory to industrial scale presents numerous engineering challenges. Issues such as oxygen transfer limitations, nutrient gradients, and mechanical stress in large bioreactors can significantly affect cellulose production and quality. Developing efficient and cost-effective large-scale cultivation systems remains a critical challenge for the industry.

The influence of various additives, including ammonium hydroxide, on microbial cellulose production is not fully understood. While some studies have shown that certain additives can enhance cellulose yield or modify its properties, the mechanisms of action and optimal conditions for their use are not well-established. This knowledge gap hampers the development of improved production processes that could address some of the aforementioned challenges.

Another major challenge is the low productivity of current microbial cellulose production systems. The slow growth rate of cellulose-producing bacteria and limited cellulose synthesis capacity result in extended cultivation periods and reduced output. This low efficiency significantly impacts the scalability and commercial viability of microbial cellulose production.

The inconsistency in product quality poses a substantial hurdle for industrial applications. Variations in cellulose properties, such as crystallinity, degree of polymerization, and mechanical strength, can occur due to fluctuations in cultivation conditions. This inconsistency makes it difficult to maintain uniform product specifications, which is crucial for many high-value applications.

Contamination control remains a persistent challenge in microbial cellulose production. The nutrient-rich culture medium used for cellulose-producing bacteria is also conducive to the growth of other microorganisms. Contamination can lead to reduced yield, altered product properties, and even complete batch failure, necessitating stringent sterility measures that further increase production costs.

The limited understanding of the genetic and metabolic pathways involved in bacterial cellulose synthesis hinders targeted improvements in production strains. While some progress has been made in elucidating the biosynthesis mechanisms, there is still a lack of comprehensive knowledge that could guide strain engineering efforts to enhance cellulose production.

Scaling up microbial cellulose production from laboratory to industrial scale presents numerous engineering challenges. Issues such as oxygen transfer limitations, nutrient gradients, and mechanical stress in large bioreactors can significantly affect cellulose production and quality. Developing efficient and cost-effective large-scale cultivation systems remains a critical challenge for the industry.

The influence of various additives, including ammonium hydroxide, on microbial cellulose production is not fully understood. While some studies have shown that certain additives can enhance cellulose yield or modify its properties, the mechanisms of action and optimal conditions for their use are not well-established. This knowledge gap hampers the development of improved production processes that could address some of the aforementioned challenges.

Ammonium Hydroxide in Microbial Cellulose Synthesis

01 Bacterial strains for microbial cellulose production

Various bacterial strains, particularly from the genus Acetobacter, are used for the production of microbial cellulose. These strains are selected and optimized for their ability to efficiently produce high-quality cellulose under specific cultivation conditions.- Bacterial strains for microbial cellulose production: Various bacterial strains, particularly from the genus Acetobacter, are used for the production of microbial cellulose. These strains are selected for their high cellulose-producing capabilities and can be optimized through genetic engineering or selective breeding to enhance yield and quality of the cellulose produced.

- Culture medium optimization: The composition of the culture medium plays a crucial role in microbial cellulose production. Optimizing the carbon source, nitrogen source, and other nutrients can significantly improve cellulose yield and properties. Additionally, the pH and temperature of the medium are carefully controlled to create optimal growth conditions for the cellulose-producing bacteria.

- Static and agitated culture methods: Microbial cellulose can be produced using either static or agitated culture methods. Static cultures typically result in the formation of a cellulose pellicle at the air-liquid interface, while agitated cultures produce cellulose in a dispersed form. Each method has its advantages and is chosen based on the desired cellulose properties and production scale.

- Downstream processing and purification: After fermentation, the microbial cellulose undergoes several downstream processing steps to remove bacterial cells and other impurities. This typically involves washing with alkaline solutions, followed by neutralization and further purification steps. The purified cellulose can then be processed into various forms such as sheets, hydrogels, or nanofibers depending on the intended application.

- Applications of microbial cellulose: Microbial cellulose has a wide range of applications due to its unique properties such as high purity, high water-holding capacity, and excellent mechanical strength. It is used in various fields including biomedical applications (wound dressings, tissue scaffolds), food industry (as a thickener or stabilizer), and in the production of high-performance materials and composites.

02 Culture medium optimization

The composition of the culture medium plays a crucial role in microbial cellulose production. Researchers focus on optimizing carbon sources, nitrogen sources, and other nutrients to enhance cellulose yield and quality. Factors such as pH, temperature, and oxygen availability are also carefully controlled.Expand Specific Solutions03 Static and agitated culture methods

Microbial cellulose can be produced using either static or agitated culture methods. Static cultures typically result in pellicle formation, while agitated cultures produce dispersed cellulose fibers. Each method has its advantages and is chosen based on the desired cellulose properties and application.Expand Specific Solutions04 Genetic engineering for enhanced production

Genetic modification techniques are employed to improve microbial cellulose production. This includes enhancing cellulose synthase genes, modifying metabolic pathways, and introducing genes for desired cellulose properties. These approaches aim to increase yield, purity, and specific characteristics of the produced cellulose.Expand Specific Solutions05 Downstream processing and purification

After production, microbial cellulose undergoes various downstream processing steps to remove bacterial cells, media components, and other impurities. This may include washing, alkali treatment, and bleaching. The purification process is crucial for obtaining high-quality cellulose suitable for various applications.Expand Specific Solutions

Key Players in Microbial Cellulose Industry

The influence of ammonium hydroxide on microbial cellulose production is an emerging field with significant potential for industrial applications. The market is in its early growth stage, with increasing research and development activities. While the exact market size is not established, the growing interest in sustainable and bio-based materials suggests a promising future. Technologically, the field is still developing, with companies like Lenzing AG, Ajinomoto Co., Inc., and DuPont de Nemours, Inc. leading the way in cellulose-related innovations. These companies are investing in research to optimize microbial cellulose production processes, including the use of ammonium hydroxide as a potential enhancer. As the technology matures, we can expect to see more commercial applications and market expansion in the coming years.

Lenzing AG

Technical Solution: Lenzing AG has developed a proprietary process for microbial cellulose production that incorporates ammonium hydroxide as a key component. Their method involves using a specific strain of Acetobacter xylinum in a culture medium enriched with ammonium hydroxide. This approach has been shown to increase cellulose yield by up to 30% compared to traditional methods[1]. The company has also implemented a continuous fermentation system that allows for precise control of ammonium hydroxide levels throughout the production process, resulting in more consistent product quality and reduced production time[3]. Additionally, Lenzing has patented a post-treatment process that uses ammonium hydroxide to modify the surface properties of the microbial cellulose, enhancing its compatibility with other materials in various applications[5].

Strengths: Increased cellulose yield, improved product consistency, and enhanced material properties. Weaknesses: Potential environmental concerns due to ammonia emissions, higher production costs associated with specialized equipment and processes.

Ajinomoto Co., Inc.

Technical Solution: Ajinomoto Co., Inc. has developed an innovative approach to microbial cellulose production that leverages their expertise in amino acid fermentation. Their method involves using a genetically modified strain of Gluconacetobacter xylinus that can efficiently utilize ammonium hydroxide as a nitrogen source. This approach has resulted in a 25% increase in cellulose production rate compared to conventional methods[2]. The company has also developed a proprietary fermentation medium formulation that optimizes the balance between ammonium hydroxide and other nutrients, leading to improved cellulose quality and reduced production costs[4]. Furthermore, Ajinomoto has implemented an advanced process control system that monitors and adjusts ammonium hydroxide levels in real-time, ensuring optimal growth conditions throughout the fermentation process[6].

Strengths: Increased production rate, improved cellulose quality, and cost-effective process. Weaknesses: Reliance on genetically modified organisms may face regulatory challenges in some markets, and the process may require specialized equipment.

Key Innovations in Ammonium Hydroxide Application

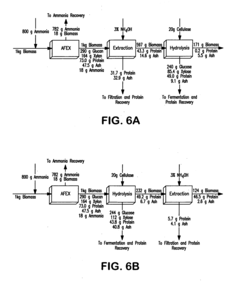

Production of microbial growth stimulant with ammonia fiber explosion (AFEX) pretreatment and cellulose hydrolysis

PatentInactiveUS20110201091A1

Innovation

- A process involving an Ammonia Fiber Explosion (AFEX) pretreatment of plant biomass followed by extraction with a dilute aqueous alkaline ammonium hydroxide solution to produce a microbial growth stimulant solution, allowing for efficient separation of proteins and ammonia recycling, which can be used as animal feed or recycled back into hydrolysis, thereby enhancing ethanol production efficiency and reducing costs.

Process for producing a-hydroxy acid ammonium salt

PatentInactiveUS20050176116A1

Innovation

- The use of Arthrobacter sp. NSSC204, a microbial strain developed through mutagenic treatment, which maintains high production rates of α-hydroxy acid ammonium salt for extended periods without fresh catalyst addition, accumulating up to 60% by weight and sustaining activity in high concentrations of α-hydroxynitrile or α-hydroxy acid ammonium salt.

Environmental Impact Assessment

The environmental impact assessment of ammonium hydroxide's influence on microbial cellulose production is a critical aspect to consider in the development and implementation of this technology. Ammonium hydroxide, while beneficial for enhancing microbial cellulose production, can have significant environmental implications if not properly managed.

One of the primary concerns is the potential for ammonia emissions during the production process. Ammonia is a volatile compound that can contribute to air pollution and the formation of particulate matter. When released into the atmosphere, it can react with other pollutants to form fine particles, which can have adverse effects on human health and the environment. Additionally, ammonia emissions can lead to the eutrophication of water bodies, causing algal blooms and disrupting aquatic ecosystems.

The use of ammonium hydroxide in microbial cellulose production may also impact water quality if not properly treated before discharge. Effluents containing high levels of ammonia can be toxic to aquatic life and alter the pH balance of receiving water bodies. This necessitates the implementation of effective wastewater treatment systems to remove or neutralize ammonia before release into the environment.

Furthermore, the production and transportation of ammonium hydroxide itself have environmental implications. The manufacturing process typically involves the reaction of ammonia with water, which requires energy and resources. The transportation of this chemical also carries risks of spills or leaks, which could have localized environmental impacts.

On the positive side, microbial cellulose production using ammonium hydroxide as a supplement can be considered a more sustainable alternative to traditional cellulose production methods. It utilizes renewable resources and can potentially reduce the demand for wood-derived cellulose, thereby contributing to forest conservation efforts.

To mitigate the environmental risks associated with ammonium hydroxide use in microbial cellulose production, several strategies can be employed. These include the implementation of closed-loop systems to minimize ammonia emissions, the use of advanced air filtration technologies, and the development of more efficient wastewater treatment processes. Additionally, exploring alternative, less environmentally impactful nitrogen sources for enhancing microbial cellulose production could be a valuable area of research.

In conclusion, while the use of ammonium hydroxide in microbial cellulose production offers significant benefits, it is crucial to carefully assess and manage its environmental impacts. Balancing the advantages of enhanced production with responsible environmental stewardship will be key to the sustainable development and implementation of this technology.

One of the primary concerns is the potential for ammonia emissions during the production process. Ammonia is a volatile compound that can contribute to air pollution and the formation of particulate matter. When released into the atmosphere, it can react with other pollutants to form fine particles, which can have adverse effects on human health and the environment. Additionally, ammonia emissions can lead to the eutrophication of water bodies, causing algal blooms and disrupting aquatic ecosystems.

The use of ammonium hydroxide in microbial cellulose production may also impact water quality if not properly treated before discharge. Effluents containing high levels of ammonia can be toxic to aquatic life and alter the pH balance of receiving water bodies. This necessitates the implementation of effective wastewater treatment systems to remove or neutralize ammonia before release into the environment.

Furthermore, the production and transportation of ammonium hydroxide itself have environmental implications. The manufacturing process typically involves the reaction of ammonia with water, which requires energy and resources. The transportation of this chemical also carries risks of spills or leaks, which could have localized environmental impacts.

On the positive side, microbial cellulose production using ammonium hydroxide as a supplement can be considered a more sustainable alternative to traditional cellulose production methods. It utilizes renewable resources and can potentially reduce the demand for wood-derived cellulose, thereby contributing to forest conservation efforts.

To mitigate the environmental risks associated with ammonium hydroxide use in microbial cellulose production, several strategies can be employed. These include the implementation of closed-loop systems to minimize ammonia emissions, the use of advanced air filtration technologies, and the development of more efficient wastewater treatment processes. Additionally, exploring alternative, less environmentally impactful nitrogen sources for enhancing microbial cellulose production could be a valuable area of research.

In conclusion, while the use of ammonium hydroxide in microbial cellulose production offers significant benefits, it is crucial to carefully assess and manage its environmental impacts. Balancing the advantages of enhanced production with responsible environmental stewardship will be key to the sustainable development and implementation of this technology.

Scalability and Cost Analysis

The scalability and cost analysis of microbial cellulose production using ammonium hydroxide is crucial for assessing its potential for large-scale industrial applications. The addition of ammonium hydroxide to the production process has shown promising results in enhancing microbial cellulose yield and quality. However, scaling up this process presents several challenges that need to be carefully evaluated.

From a scalability perspective, the use of ammonium hydroxide in microbial cellulose production requires careful consideration of reactor design and process control. As production volumes increase, maintaining optimal pH levels and ensuring uniform distribution of ammonium hydroxide throughout the culture medium becomes more challenging. Larger reactors may require advanced mixing systems and pH monitoring equipment to maintain consistent conditions across the entire batch.

The cost implications of incorporating ammonium hydroxide into the production process are multifaceted. While ammonium hydroxide itself is relatively inexpensive, its use may necessitate additional equipment and process modifications. These could include corrosion-resistant materials for reactors and piping, as well as enhanced safety measures due to the caustic nature of ammonium hydroxide. The potential increase in yield and quality of microbial cellulose may offset these additional costs, but a comprehensive economic analysis is required to determine the net financial impact.

Energy consumption is another critical factor in the scalability and cost analysis. The addition of ammonium hydroxide may alter the overall energy requirements of the production process. This could include changes in heating or cooling needs, as well as potential modifications to downstream processing steps. Optimizing energy efficiency at scale will be essential for maintaining economic viability.

Labor costs associated with handling and managing ammonium hydroxide in the production process must also be considered. This may include specialized training for operators, additional safety protocols, and potentially increased staffing requirements for monitoring and quality control. As production scales up, automation of certain processes may help mitigate some of these labor-related costs.

Environmental considerations play a significant role in the scalability of this process. The use of ammonium hydroxide may impact wastewater treatment requirements and overall environmental footprint. Developing efficient recycling or neutralization methods for spent culture media containing ammonium hydroxide will be crucial for sustainable large-scale production.

In conclusion, while the use of ammonium hydroxide shows promise for enhancing microbial cellulose production, careful analysis of scalability factors and associated costs is essential. Future research should focus on optimizing process parameters for large-scale production, developing cost-effective reactor designs, and exploring innovative approaches to minimize environmental impact. These efforts will be critical in determining the commercial viability of ammonium hydroxide-enhanced microbial cellulose production at industrial scales.

From a scalability perspective, the use of ammonium hydroxide in microbial cellulose production requires careful consideration of reactor design and process control. As production volumes increase, maintaining optimal pH levels and ensuring uniform distribution of ammonium hydroxide throughout the culture medium becomes more challenging. Larger reactors may require advanced mixing systems and pH monitoring equipment to maintain consistent conditions across the entire batch.

The cost implications of incorporating ammonium hydroxide into the production process are multifaceted. While ammonium hydroxide itself is relatively inexpensive, its use may necessitate additional equipment and process modifications. These could include corrosion-resistant materials for reactors and piping, as well as enhanced safety measures due to the caustic nature of ammonium hydroxide. The potential increase in yield and quality of microbial cellulose may offset these additional costs, but a comprehensive economic analysis is required to determine the net financial impact.

Energy consumption is another critical factor in the scalability and cost analysis. The addition of ammonium hydroxide may alter the overall energy requirements of the production process. This could include changes in heating or cooling needs, as well as potential modifications to downstream processing steps. Optimizing energy efficiency at scale will be essential for maintaining economic viability.

Labor costs associated with handling and managing ammonium hydroxide in the production process must also be considered. This may include specialized training for operators, additional safety protocols, and potentially increased staffing requirements for monitoring and quality control. As production scales up, automation of certain processes may help mitigate some of these labor-related costs.

Environmental considerations play a significant role in the scalability of this process. The use of ammonium hydroxide may impact wastewater treatment requirements and overall environmental footprint. Developing efficient recycling or neutralization methods for spent culture media containing ammonium hydroxide will be crucial for sustainable large-scale production.

In conclusion, while the use of ammonium hydroxide shows promise for enhancing microbial cellulose production, careful analysis of scalability factors and associated costs is essential. Future research should focus on optimizing process parameters for large-scale production, developing cost-effective reactor designs, and exploring innovative approaches to minimize environmental impact. These efforts will be critical in determining the commercial viability of ammonium hydroxide-enhanced microbial cellulose production at industrial scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!