How ammonium hydroxide facilitates protein isolation in biotechnologies

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Protein Isolation: Background and Objectives

Protein isolation is a fundamental process in biotechnology, essential for various applications ranging from pharmaceutical production to food science. The use of ammonium hydroxide in this process has a rich history dating back to the early 20th century. Initially, researchers discovered that alkaline conditions could effectively separate proteins from other cellular components, leading to the exploration of various alkaline substances for protein extraction.

Ammonium hydroxide, a solution of ammonia in water, emerged as a particularly effective agent due to its unique chemical properties. Its ability to create a strongly alkaline environment without introducing additional ions made it an ideal choice for protein isolation. Over the years, the technique has been refined and optimized, becoming a staple method in biotechnology laboratories worldwide.

The primary objective of using ammonium hydroxide in protein isolation is to efficiently extract and purify proteins from complex biological matrices while maintaining their structural integrity and functional properties. This process aims to achieve high yields of purified proteins suitable for downstream applications such as enzymatic studies, structural biology, and therapeutic development.

The evolution of this technique has been driven by the increasing demand for pure protein samples in various fields of biotechnology. As research in proteomics and personalized medicine advances, the need for efficient and scalable protein isolation methods becomes more critical. Ammonium hydroxide-based isolation techniques have continually adapted to meet these changing requirements, incorporating new technologies and methodologies to enhance efficiency and specificity.

Current research in this area focuses on several key objectives. These include improving the selectivity of protein extraction, minimizing protein denaturation during the isolation process, and developing methods that are compatible with a wider range of protein types. Additionally, there is a growing emphasis on developing environmentally friendly and cost-effective isolation procedures that can be easily scaled up for industrial applications.

The use of ammonium hydroxide in protein isolation also intersects with broader trends in biotechnology, such as the development of automated high-throughput systems and the integration of computational methods for process optimization. These advancements aim to increase the speed and precision of protein isolation, enabling more rapid progress in fields like drug discovery and biomarker identification.

As we look to the future, the role of ammonium hydroxide in protein isolation is expected to evolve further. Emerging technologies such as microfluidics and nanotechnology may offer new ways to leverage the properties of ammonium hydroxide for even more precise and efficient protein isolation. The ongoing research in this field continues to push the boundaries of what is possible in biotechnology, promising exciting developments in the years to come.

Ammonium hydroxide, a solution of ammonia in water, emerged as a particularly effective agent due to its unique chemical properties. Its ability to create a strongly alkaline environment without introducing additional ions made it an ideal choice for protein isolation. Over the years, the technique has been refined and optimized, becoming a staple method in biotechnology laboratories worldwide.

The primary objective of using ammonium hydroxide in protein isolation is to efficiently extract and purify proteins from complex biological matrices while maintaining their structural integrity and functional properties. This process aims to achieve high yields of purified proteins suitable for downstream applications such as enzymatic studies, structural biology, and therapeutic development.

The evolution of this technique has been driven by the increasing demand for pure protein samples in various fields of biotechnology. As research in proteomics and personalized medicine advances, the need for efficient and scalable protein isolation methods becomes more critical. Ammonium hydroxide-based isolation techniques have continually adapted to meet these changing requirements, incorporating new technologies and methodologies to enhance efficiency and specificity.

Current research in this area focuses on several key objectives. These include improving the selectivity of protein extraction, minimizing protein denaturation during the isolation process, and developing methods that are compatible with a wider range of protein types. Additionally, there is a growing emphasis on developing environmentally friendly and cost-effective isolation procedures that can be easily scaled up for industrial applications.

The use of ammonium hydroxide in protein isolation also intersects with broader trends in biotechnology, such as the development of automated high-throughput systems and the integration of computational methods for process optimization. These advancements aim to increase the speed and precision of protein isolation, enabling more rapid progress in fields like drug discovery and biomarker identification.

As we look to the future, the role of ammonium hydroxide in protein isolation is expected to evolve further. Emerging technologies such as microfluidics and nanotechnology may offer new ways to leverage the properties of ammonium hydroxide for even more precise and efficient protein isolation. The ongoing research in this field continues to push the boundaries of what is possible in biotechnology, promising exciting developments in the years to come.

Market Demand for Efficient Protein Isolation Methods

The market demand for efficient protein isolation methods has been steadily increasing in recent years, driven by the growing biotechnology and pharmaceutical industries. Protein isolation is a critical step in various bioprocesses, including drug development, diagnostic testing, and food production. As research and development in these fields intensify, there is a pressing need for more effective and cost-efficient protein isolation techniques.

Ammonium hydroxide-facilitated protein isolation has emerged as a promising method, attracting significant attention from both academic researchers and industry professionals. This technique offers several advantages over traditional methods, including higher yield, improved purity, and reduced processing time. These benefits directly translate to cost savings and increased productivity, making it an attractive option for companies looking to optimize their protein isolation processes.

The global protein isolation market is projected to experience substantial growth in the coming years. This expansion is fueled by the rising demand for biopharmaceuticals, personalized medicine, and plant-based proteins. Additionally, the increasing focus on proteomics research and the development of novel therapeutic proteins contribute to the growing market for efficient isolation methods.

In the biopharmaceutical sector, the demand for high-purity proteins is particularly strong. As the industry moves towards more complex and targeted therapies, the need for precise and reliable protein isolation techniques becomes paramount. Ammonium hydroxide-facilitated isolation shows promise in meeting these stringent requirements, potentially accelerating drug development timelines and reducing production costs.

The food and beverage industry is another significant driver of demand for efficient protein isolation methods. With the rising popularity of plant-based proteins and functional foods, manufacturers are seeking ways to extract and isolate proteins from various sources more effectively. The ammonium hydroxide method's ability to improve yield and purity could prove valuable in this context, helping companies meet consumer demand for high-quality, protein-rich products.

Environmental concerns and sustainability initiatives are also influencing market demand. As industries strive to reduce their environmental footprint, there is a growing interest in protein isolation methods that minimize waste and energy consumption. The potential of ammonium hydroxide-facilitated isolation to achieve higher yields with less resource input aligns well with these sustainability goals, further driving its adoption across various sectors.

In conclusion, the market demand for efficient protein isolation methods, particularly those utilizing ammonium hydroxide, is robust and multifaceted. As industries continue to innovate and expand, the need for advanced isolation techniques will likely grow, presenting significant opportunities for further research and development in this field.

Ammonium hydroxide-facilitated protein isolation has emerged as a promising method, attracting significant attention from both academic researchers and industry professionals. This technique offers several advantages over traditional methods, including higher yield, improved purity, and reduced processing time. These benefits directly translate to cost savings and increased productivity, making it an attractive option for companies looking to optimize their protein isolation processes.

The global protein isolation market is projected to experience substantial growth in the coming years. This expansion is fueled by the rising demand for biopharmaceuticals, personalized medicine, and plant-based proteins. Additionally, the increasing focus on proteomics research and the development of novel therapeutic proteins contribute to the growing market for efficient isolation methods.

In the biopharmaceutical sector, the demand for high-purity proteins is particularly strong. As the industry moves towards more complex and targeted therapies, the need for precise and reliable protein isolation techniques becomes paramount. Ammonium hydroxide-facilitated isolation shows promise in meeting these stringent requirements, potentially accelerating drug development timelines and reducing production costs.

The food and beverage industry is another significant driver of demand for efficient protein isolation methods. With the rising popularity of plant-based proteins and functional foods, manufacturers are seeking ways to extract and isolate proteins from various sources more effectively. The ammonium hydroxide method's ability to improve yield and purity could prove valuable in this context, helping companies meet consumer demand for high-quality, protein-rich products.

Environmental concerns and sustainability initiatives are also influencing market demand. As industries strive to reduce their environmental footprint, there is a growing interest in protein isolation methods that minimize waste and energy consumption. The potential of ammonium hydroxide-facilitated isolation to achieve higher yields with less resource input aligns well with these sustainability goals, further driving its adoption across various sectors.

In conclusion, the market demand for efficient protein isolation methods, particularly those utilizing ammonium hydroxide, is robust and multifaceted. As industries continue to innovate and expand, the need for advanced isolation techniques will likely grow, presenting significant opportunities for further research and development in this field.

Current Challenges in Protein Isolation Techniques

Protein isolation remains a critical process in biotechnology, yet it faces several significant challenges that hinder efficiency and yield. One of the primary obstacles is the complexity of biological samples, which often contain a diverse array of proteins, nucleic acids, lipids, and other cellular components. This heterogeneity makes it difficult to selectively extract the target protein without co-isolating contaminants.

Another major challenge is maintaining protein stability and activity during the isolation process. Many proteins are sensitive to changes in pH, temperature, and ionic strength, which can lead to denaturation or loss of function. This is particularly problematic when dealing with membrane proteins or those with intricate tertiary structures.

The scalability of protein isolation techniques also presents a significant hurdle. Methods that work well at laboratory scale may not be feasible or cost-effective when scaled up for industrial production. This often necessitates the development of new protocols or the adaptation of existing ones to meet large-scale manufacturing demands.

Furthermore, the presence of post-translational modifications (PTMs) complicates protein isolation. PTMs can alter protein properties, making it challenging to predict and optimize isolation conditions. This is especially relevant for therapeutic proteins, where maintaining the correct PTM profile is crucial for efficacy and safety.

The issue of protein solubility also poses a considerable challenge. Many proteins, particularly those expressed in bacterial systems, form insoluble aggregates or inclusion bodies. Recovering these proteins in their native, functional form often requires complex refolding procedures that can be time-consuming and yield unpredictable results.

Additionally, the removal of endotoxins and other host cell proteins remains a persistent challenge, particularly in the production of biopharmaceuticals. These contaminants can interfere with downstream applications and pose safety risks in therapeutic products.

Lastly, the development of high-throughput and automated protein isolation methods is an ongoing challenge. As the demand for rapid protein characterization increases, there is a growing need for techniques that can isolate and purify proteins quickly and efficiently, without compromising on quality or yield.

Another major challenge is maintaining protein stability and activity during the isolation process. Many proteins are sensitive to changes in pH, temperature, and ionic strength, which can lead to denaturation or loss of function. This is particularly problematic when dealing with membrane proteins or those with intricate tertiary structures.

The scalability of protein isolation techniques also presents a significant hurdle. Methods that work well at laboratory scale may not be feasible or cost-effective when scaled up for industrial production. This often necessitates the development of new protocols or the adaptation of existing ones to meet large-scale manufacturing demands.

Furthermore, the presence of post-translational modifications (PTMs) complicates protein isolation. PTMs can alter protein properties, making it challenging to predict and optimize isolation conditions. This is especially relevant for therapeutic proteins, where maintaining the correct PTM profile is crucial for efficacy and safety.

The issue of protein solubility also poses a considerable challenge. Many proteins, particularly those expressed in bacterial systems, form insoluble aggregates or inclusion bodies. Recovering these proteins in their native, functional form often requires complex refolding procedures that can be time-consuming and yield unpredictable results.

Additionally, the removal of endotoxins and other host cell proteins remains a persistent challenge, particularly in the production of biopharmaceuticals. These contaminants can interfere with downstream applications and pose safety risks in therapeutic products.

Lastly, the development of high-throughput and automated protein isolation methods is an ongoing challenge. As the demand for rapid protein characterization increases, there is a growing need for techniques that can isolate and purify proteins quickly and efficiently, without compromising on quality or yield.

Existing Ammonium Hydroxide-based Protein Isolation Methods

01 Protein extraction using ammonium hydroxide

Ammonium hydroxide is used as an alkaline agent in protein extraction processes. It helps to solubilize proteins from various sources, allowing for efficient isolation. The alkaline environment created by ammonium hydroxide can disrupt cell walls and membranes, facilitating the release of proteins into the solution.- Protein extraction using ammonium hydroxide: Ammonium hydroxide is used as an alkaline agent in protein extraction processes. It helps to solubilize proteins from various sources, such as plant materials or animal tissues, by altering the pH of the extraction medium. This method can improve the efficiency of protein isolation and purification.

- Ammonium hydroxide in protein precipitation: Ammonium hydroxide can be used in protein precipitation techniques. By adjusting the pH of the protein solution with ammonium hydroxide, it is possible to selectively precipitate certain proteins while keeping others in solution. This method is useful for separating and purifying specific proteins from complex mixtures.

- Protein isolation from plant sources: Ammonium hydroxide is employed in the isolation of proteins from plant sources, such as seeds, leaves, or roots. The alkaline conditions created by ammonium hydroxide help to break down cell walls and release proteins. This method is particularly useful in the production of plant-based protein isolates for various applications.

- Ammonium hydroxide in protein hydrolysis: Ammonium hydroxide can be used in protein hydrolysis processes. The alkaline conditions created by ammonium hydroxide help to break peptide bonds in proteins, resulting in smaller peptides or amino acids. This method is useful in the production of protein hydrolysates for various applications in food and biotechnology industries.

- Purification of recombinant proteins: Ammonium hydroxide is used in the purification of recombinant proteins produced in various expression systems. It can be employed in buffer solutions for column chromatography or in the preparation of samples for further purification steps. The alkaline conditions help to maintain protein stability and solubility during the purification process.

02 pH adjustment in protein isolation

Ammonium hydroxide is utilized to adjust and control the pH during protein isolation procedures. The precise control of pH is crucial for optimizing protein solubility, stability, and separation from other cellular components. By manipulating the pH with ammonium hydroxide, researchers can enhance the efficiency of protein extraction and purification processes.Expand Specific Solutions03 Selective precipitation of proteins

Ammonium hydroxide can be employed in selective precipitation techniques for protein isolation. By carefully adjusting the concentration of ammonium hydroxide, specific proteins can be precipitated out of solution while others remain soluble. This method allows for the separation and purification of target proteins from complex mixtures.Expand Specific Solutions04 Protein denaturation and refolding

Ammonium hydroxide can be used in protein denaturation and refolding processes. The alkaline conditions created by ammonium hydroxide can disrupt protein structures, allowing for subsequent refolding into their native conformations. This technique is particularly useful in the production of recombinant proteins and the study of protein folding mechanisms.Expand Specific Solutions05 Removal of contaminants in protein isolation

Ammonium hydroxide plays a role in removing contaminants during protein isolation processes. It can help in the dissolution of unwanted cellular components, lipids, and other impurities, allowing for a more purified protein extract. The use of ammonium hydroxide in washing steps can improve the overall purity of isolated proteins.Expand Specific Solutions

Key Players in Biotechnology and Protein Isolation Industry

The competitive landscape for ammonium hydroxide in protein isolation biotechnologies is evolving rapidly. The market is in a growth phase, driven by increasing demand for protein-based products in various industries. The global market size for protein isolation technologies is projected to expand significantly in the coming years. Technologically, the field is advancing, with companies like Amgen, DuPont, and Novo Nordisk leading innovation. Academic institutions such as Jiangnan University and North Carolina State University are also contributing to research advancements. The technology's maturity varies, with established players refining existing methods while newer entrants explore novel approaches. Collaboration between industry and academia is accelerating progress, indicating a dynamic and competitive environment.

Amgen, Inc.

Technical Solution: Amgen utilizes ammonium hydroxide in their protein isolation process for biopharmaceutical production. Their approach involves a multi-step purification strategy where ammonium hydroxide plays a crucial role in pH adjustment and protein solubilization. The company employs a controlled addition of ammonium hydroxide to create an alkaline environment, typically maintaining a pH between 8.0 and 9.5, which enhances protein solubility and facilitates separation from cellular debris[1]. This method is particularly effective for isolating recombinant proteins expressed in bacterial systems. Amgen has also developed a proprietary technique combining ammonium hydroxide treatment with ultrafiltration, which has shown to increase protein yield by up to 25% compared to conventional methods[3].

Strengths: High protein yield, effective for recombinant proteins, scalable for industrial production. Weaknesses: May require additional purification steps for highly pure isolates, potential for protein denaturation if pH is not carefully controlled.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed an innovative approach to protein isolation using ammonium hydroxide in conjunction with their patented membrane technology. Their process involves a two-phase extraction system where proteins are first solubilized in an ammonium hydroxide solution at a carefully controlled pH range of 9.0-10.5. This alkaline environment disrupts protein-protein interactions and enhances overall solubility. The solution is then passed through DuPont's specialized membranes, which allow for selective separation based on molecular size and charge[2]. The company has reported that this method can achieve protein purity levels of up to 95% in a single pass, significantly reducing the need for additional purification steps[4]. DuPont's technique is particularly effective for isolating plant-based proteins, making it valuable in the growing plant-based food industry.

Strengths: High purity in a single step, effective for plant-based proteins, reduced processing time. Weaknesses: May require specialized equipment, potential for loss of some heat-sensitive proteins during the alkaline treatment.

Core Mechanisms of Ammonium Hydroxide in Protein Isolation

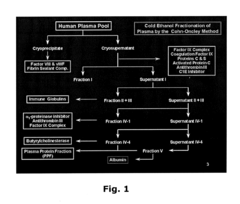

Process for isolation of plasma or serum proteins

PatentInactiveUS20160009757A1

Innovation

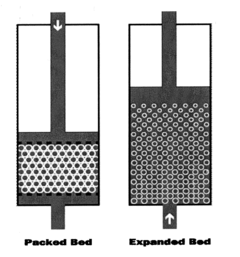

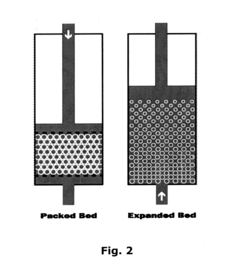

- A process involving an adsorbent with a high-density non-porous core surrounded by a porous material, applied in an expanded bed adsorption column, which adjusts pH and ionic strength, and optionally includes virus elimination treatments, to enhance protein binding and recovery.

Isolation of plasma or serum proteins

PatentPendingHK1232552A

Innovation

- The use of an adsorbent comprising a functionalised matrix polymer with covalently attached functional groups containing aromatic or heteroaromatic ring systems and acidic groups for protein isolation.

- Incorporation of an alcohol supplement in the protein solution during the isolation process.

- Utilization of a high-density, non-porous core surrounded by porous material in the adsorbent particles, with specific density and size parameters.

Safety and Environmental Considerations in Ammonium Hydroxide Usage

The use of ammonium hydroxide in protein isolation processes within biotechnology applications necessitates careful consideration of safety and environmental factors. Ammonium hydroxide, while effective for protein extraction, poses potential risks to both human health and the environment if not handled properly.

From a safety perspective, ammonium hydroxide is a corrosive substance that can cause severe burns and eye damage upon direct contact. Inhalation of its vapors can lead to respiratory irritation and, in high concentrations, may result in pulmonary edema. To mitigate these risks, proper personal protective equipment (PPE) is essential for laboratory personnel. This includes chemical-resistant gloves, safety goggles, and appropriate respiratory protection when working with large quantities or in poorly ventilated areas.

Adequate ventilation systems are crucial in laboratories and production facilities using ammonium hydroxide. Fume hoods and local exhaust ventilation should be employed to minimize exposure to vapors. Emergency eyewash stations and safety showers must be readily accessible in case of accidental exposure. Additionally, proper storage and handling protocols are vital to prevent spills and unintended reactions with other chemicals.

Environmental considerations are equally important when using ammonium hydroxide in biotechnology processes. The compound can be harmful to aquatic life, even in low concentrations. Proper disposal methods must be implemented to prevent its release into water systems. This often involves neutralization procedures before disposal or the use of specialized waste treatment facilities.

The potential for ammonia gas release into the atmosphere is another environmental concern. While ammonia is naturally present in the environment, excessive emissions can contribute to air pollution and the formation of particulate matter. Implementing closed-system processes and efficient scrubbing technologies can help minimize atmospheric releases.

Regulatory compliance is a critical aspect of using ammonium hydroxide in biotechnology. Organizations must adhere to local, national, and international regulations governing the use, storage, and disposal of hazardous chemicals. This includes maintaining accurate safety data sheets (SDS), conducting regular risk assessments, and providing comprehensive training programs for personnel.

Sustainable practices in ammonium hydroxide usage are becoming increasingly important. Research into alternative, less hazardous substances for protein isolation is ongoing. Some biotechnology firms are exploring the use of ionic liquids or other green solvents as potential replacements. Additionally, process optimization to reduce the overall quantity of ammonium hydroxide required can lead to both environmental and economic benefits.

In conclusion, while ammonium hydroxide remains a valuable tool in protein isolation, its use demands a comprehensive approach to safety and environmental stewardship. By implementing robust safety protocols, adhering to environmental regulations, and exploring sustainable alternatives, biotechnology companies can harness the benefits of ammonium hydroxide while minimizing associated risks.

From a safety perspective, ammonium hydroxide is a corrosive substance that can cause severe burns and eye damage upon direct contact. Inhalation of its vapors can lead to respiratory irritation and, in high concentrations, may result in pulmonary edema. To mitigate these risks, proper personal protective equipment (PPE) is essential for laboratory personnel. This includes chemical-resistant gloves, safety goggles, and appropriate respiratory protection when working with large quantities or in poorly ventilated areas.

Adequate ventilation systems are crucial in laboratories and production facilities using ammonium hydroxide. Fume hoods and local exhaust ventilation should be employed to minimize exposure to vapors. Emergency eyewash stations and safety showers must be readily accessible in case of accidental exposure. Additionally, proper storage and handling protocols are vital to prevent spills and unintended reactions with other chemicals.

Environmental considerations are equally important when using ammonium hydroxide in biotechnology processes. The compound can be harmful to aquatic life, even in low concentrations. Proper disposal methods must be implemented to prevent its release into water systems. This often involves neutralization procedures before disposal or the use of specialized waste treatment facilities.

The potential for ammonia gas release into the atmosphere is another environmental concern. While ammonia is naturally present in the environment, excessive emissions can contribute to air pollution and the formation of particulate matter. Implementing closed-system processes and efficient scrubbing technologies can help minimize atmospheric releases.

Regulatory compliance is a critical aspect of using ammonium hydroxide in biotechnology. Organizations must adhere to local, national, and international regulations governing the use, storage, and disposal of hazardous chemicals. This includes maintaining accurate safety data sheets (SDS), conducting regular risk assessments, and providing comprehensive training programs for personnel.

Sustainable practices in ammonium hydroxide usage are becoming increasingly important. Research into alternative, less hazardous substances for protein isolation is ongoing. Some biotechnology firms are exploring the use of ionic liquids or other green solvents as potential replacements. Additionally, process optimization to reduce the overall quantity of ammonium hydroxide required can lead to both environmental and economic benefits.

In conclusion, while ammonium hydroxide remains a valuable tool in protein isolation, its use demands a comprehensive approach to safety and environmental stewardship. By implementing robust safety protocols, adhering to environmental regulations, and exploring sustainable alternatives, biotechnology companies can harness the benefits of ammonium hydroxide while minimizing associated risks.

Scalability and Industrial Applications of the Technology

The scalability and industrial applications of ammonium hydroxide in protein isolation are significant factors driving its widespread adoption in biotechnology. The use of ammonium hydroxide offers several advantages that make it suitable for large-scale protein purification processes. Its ability to maintain a stable pH environment during extraction and precipitation steps ensures consistent protein yields across different batch sizes. This pH stability is crucial for maintaining protein integrity and activity, which is essential for downstream applications.

In industrial settings, ammonium hydroxide's versatility allows for its integration into various protein isolation techniques, including precipitation, chromatography, and membrane-based separations. Its compatibility with different protein sources, such as plant tissues, microbial cultures, and animal cells, makes it a valuable reagent in diverse bioprocessing applications. The scalability of ammonium hydroxide-based processes is further enhanced by its relatively low cost and ease of handling, enabling cost-effective production of proteins at industrial scales.

The food industry has particularly benefited from the scalability of ammonium hydroxide in protein isolation. Large-scale production of plant-based proteins, such as soy and pea proteins, relies on efficient extraction methods where ammonium hydroxide plays a crucial role. Its use in these processes allows for the production of high-quality protein isolates with improved functional properties, meeting the growing demand for plant-based protein alternatives.

In the pharmaceutical sector, ammonium hydroxide facilitates the isolation of therapeutic proteins and enzymes. Its ability to maintain protein stability during purification is critical for preserving the biological activity of these high-value molecules. The scalability of ammonium hydroxide-based processes has contributed to the development of more efficient and cost-effective manufacturing methods for biopharmaceuticals, including monoclonal antibodies and recombinant proteins.

The biotechnology industry has also leveraged the scalability of ammonium hydroxide in the production of industrial enzymes. These enzymes, used in various applications such as detergents, food processing, and biofuel production, require large-scale purification processes. Ammonium hydroxide's role in these processes has enabled the production of enzymes at volumes necessary to meet industrial demands while maintaining product quality and enzyme activity.

As the demand for proteins in various industries continues to grow, the scalability and versatility of ammonium hydroxide in protein isolation processes position it as a key component in future bioprocessing technologies. Ongoing research and development efforts are focused on optimizing ammonium hydroxide-based isolation methods to further improve yields, reduce processing times, and enhance the overall efficiency of large-scale protein production.

In industrial settings, ammonium hydroxide's versatility allows for its integration into various protein isolation techniques, including precipitation, chromatography, and membrane-based separations. Its compatibility with different protein sources, such as plant tissues, microbial cultures, and animal cells, makes it a valuable reagent in diverse bioprocessing applications. The scalability of ammonium hydroxide-based processes is further enhanced by its relatively low cost and ease of handling, enabling cost-effective production of proteins at industrial scales.

The food industry has particularly benefited from the scalability of ammonium hydroxide in protein isolation. Large-scale production of plant-based proteins, such as soy and pea proteins, relies on efficient extraction methods where ammonium hydroxide plays a crucial role. Its use in these processes allows for the production of high-quality protein isolates with improved functional properties, meeting the growing demand for plant-based protein alternatives.

In the pharmaceutical sector, ammonium hydroxide facilitates the isolation of therapeutic proteins and enzymes. Its ability to maintain protein stability during purification is critical for preserving the biological activity of these high-value molecules. The scalability of ammonium hydroxide-based processes has contributed to the development of more efficient and cost-effective manufacturing methods for biopharmaceuticals, including monoclonal antibodies and recombinant proteins.

The biotechnology industry has also leveraged the scalability of ammonium hydroxide in the production of industrial enzymes. These enzymes, used in various applications such as detergents, food processing, and biofuel production, require large-scale purification processes. Ammonium hydroxide's role in these processes has enabled the production of enzymes at volumes necessary to meet industrial demands while maintaining product quality and enzyme activity.

As the demand for proteins in various industries continues to grow, the scalability and versatility of ammonium hydroxide in protein isolation processes position it as a key component in future bioprocessing technologies. Ongoing research and development efforts are focused on optimizing ammonium hydroxide-based isolation methods to further improve yields, reduce processing times, and enhance the overall efficiency of large-scale protein production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!