Ammonium hydroxide use in plant tissue culture systems

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Plant Tissue Culture: Background and Objectives

Plant tissue culture has been a cornerstone of agricultural biotechnology for decades, enabling the rapid propagation of plants, genetic modification, and the production of disease-free crops. Ammonium hydroxide, a compound consisting of ammonia dissolved in water, has emerged as a significant component in plant tissue culture systems. Its role in these systems is multifaceted, influencing nutrient uptake, pH regulation, and overall plant growth and development.

The use of ammonium hydroxide in plant tissue culture can be traced back to the early days of in vitro plant propagation. Initially, researchers focused on optimizing nutrient media compositions to support plant growth outside their natural environments. As understanding of plant nutrition advanced, the importance of nitrogen sources, including ammonium, became apparent. Ammonium hydroxide gained attention due to its ability to provide a readily available form of nitrogen and its potential to regulate pH in culture media.

The primary objective of incorporating ammonium hydroxide in plant tissue culture systems is to enhance plant growth and development under controlled conditions. Researchers aim to optimize the concentration and application methods of ammonium hydroxide to improve various aspects of plant tissue culture, including callus induction, shoot proliferation, root formation, and somatic embryogenesis. Additionally, there is a focus on understanding the physiological and biochemical effects of ammonium hydroxide on cultured plant tissues.

Another critical goal is to investigate the role of ammonium hydroxide in nutrient uptake and assimilation. This includes studying how different plant species and cultivars respond to varying levels of ammonium hydroxide and how it interacts with other nutrients in the culture medium. Researchers are particularly interested in the balance between ammonium and nitrate nitrogen sources, as this can significantly impact plant growth and morphogenesis.

pH regulation is a crucial aspect of plant tissue culture, and ammonium hydroxide plays a vital role in this regard. One of the objectives of current research is to determine the optimal pH range for different plant species and how ammonium hydroxide can be used to maintain this range throughout the culture period. This involves studying the buffering capacity of culture media and the dynamic changes in pH as plants grow and metabolize nutrients.

As the field of plant biotechnology continues to evolve, there is an increasing interest in sustainable and cost-effective tissue culture practices. In this context, researchers are exploring the potential of ammonium hydroxide as an alternative or complementary nitrogen source to reduce the reliance on more expensive organic nitrogen compounds. This aligns with the broader goal of developing efficient and economically viable plant propagation methods for commercial applications.

The use of ammonium hydroxide in plant tissue culture can be traced back to the early days of in vitro plant propagation. Initially, researchers focused on optimizing nutrient media compositions to support plant growth outside their natural environments. As understanding of plant nutrition advanced, the importance of nitrogen sources, including ammonium, became apparent. Ammonium hydroxide gained attention due to its ability to provide a readily available form of nitrogen and its potential to regulate pH in culture media.

The primary objective of incorporating ammonium hydroxide in plant tissue culture systems is to enhance plant growth and development under controlled conditions. Researchers aim to optimize the concentration and application methods of ammonium hydroxide to improve various aspects of plant tissue culture, including callus induction, shoot proliferation, root formation, and somatic embryogenesis. Additionally, there is a focus on understanding the physiological and biochemical effects of ammonium hydroxide on cultured plant tissues.

Another critical goal is to investigate the role of ammonium hydroxide in nutrient uptake and assimilation. This includes studying how different plant species and cultivars respond to varying levels of ammonium hydroxide and how it interacts with other nutrients in the culture medium. Researchers are particularly interested in the balance between ammonium and nitrate nitrogen sources, as this can significantly impact plant growth and morphogenesis.

pH regulation is a crucial aspect of plant tissue culture, and ammonium hydroxide plays a vital role in this regard. One of the objectives of current research is to determine the optimal pH range for different plant species and how ammonium hydroxide can be used to maintain this range throughout the culture period. This involves studying the buffering capacity of culture media and the dynamic changes in pH as plants grow and metabolize nutrients.

As the field of plant biotechnology continues to evolve, there is an increasing interest in sustainable and cost-effective tissue culture practices. In this context, researchers are exploring the potential of ammonium hydroxide as an alternative or complementary nitrogen source to reduce the reliance on more expensive organic nitrogen compounds. This aligns with the broader goal of developing efficient and economically viable plant propagation methods for commercial applications.

Market Analysis for Plant Tissue Culture Systems

The plant tissue culture systems market has been experiencing significant growth in recent years, driven by increasing demand for high-quality, disease-free plants in agriculture, horticulture, and forestry. This market segment is closely tied to the broader biotechnology industry and is influenced by advancements in plant sciences and micropropagation techniques.

The global plant tissue culture market was valued at approximately $450 million in 2020 and is projected to reach $700 million by 2025, growing at a compound annual growth rate (CAGR) of 9.2%. This growth is primarily attributed to the rising adoption of plant tissue culture techniques in developing countries, increasing demand for disease-resistant and high-yielding plant varieties, and the growing application of micropropagation in the production of ornamental plants.

Key market drivers include the need for sustainable agricultural practices, the increasing focus on food security, and the growing demand for biopharmaceuticals derived from plant sources. The use of plant tissue culture systems allows for rapid multiplication of elite plant varieties, conservation of rare and endangered species, and the production of secondary metabolites for pharmaceutical and cosmetic industries.

Geographically, North America and Europe currently dominate the plant tissue culture systems market, owing to their advanced research infrastructure and strong presence of biotechnology companies. However, Asia-Pacific is expected to witness the highest growth rate in the coming years, driven by increasing government initiatives to promote agricultural biotechnology and the rising adoption of tissue culture techniques in countries like China and India.

The market is segmented based on crop type, with ornamental plants holding the largest market share, followed by fruits and vegetables, cash crops, and forestry products. The increasing demand for ornamental plants in the floriculture industry and the growing trend of urban gardening are major factors contributing to this segment's dominance.

In terms of end-users, commercial agriculture and horticulture account for the largest market share, followed by research institutions and academic laboratories. The commercial sector's dominance is attributed to the increasing adoption of tissue culture techniques for large-scale plant propagation and the production of disease-free planting materials.

The plant tissue culture systems market is characterized by intense competition, with several key players vying for market share. Major companies in this space include Thermo Fisher Scientific, Merck KGaA, Bio-Rad Laboratories, and Conviron, among others. These companies are focusing on product innovation, strategic partnerships, and geographical expansion to strengthen their market position.

The global plant tissue culture market was valued at approximately $450 million in 2020 and is projected to reach $700 million by 2025, growing at a compound annual growth rate (CAGR) of 9.2%. This growth is primarily attributed to the rising adoption of plant tissue culture techniques in developing countries, increasing demand for disease-resistant and high-yielding plant varieties, and the growing application of micropropagation in the production of ornamental plants.

Key market drivers include the need for sustainable agricultural practices, the increasing focus on food security, and the growing demand for biopharmaceuticals derived from plant sources. The use of plant tissue culture systems allows for rapid multiplication of elite plant varieties, conservation of rare and endangered species, and the production of secondary metabolites for pharmaceutical and cosmetic industries.

Geographically, North America and Europe currently dominate the plant tissue culture systems market, owing to their advanced research infrastructure and strong presence of biotechnology companies. However, Asia-Pacific is expected to witness the highest growth rate in the coming years, driven by increasing government initiatives to promote agricultural biotechnology and the rising adoption of tissue culture techniques in countries like China and India.

The market is segmented based on crop type, with ornamental plants holding the largest market share, followed by fruits and vegetables, cash crops, and forestry products. The increasing demand for ornamental plants in the floriculture industry and the growing trend of urban gardening are major factors contributing to this segment's dominance.

In terms of end-users, commercial agriculture and horticulture account for the largest market share, followed by research institutions and academic laboratories. The commercial sector's dominance is attributed to the increasing adoption of tissue culture techniques for large-scale plant propagation and the production of disease-free planting materials.

The plant tissue culture systems market is characterized by intense competition, with several key players vying for market share. Major companies in this space include Thermo Fisher Scientific, Merck KGaA, Bio-Rad Laboratories, and Conviron, among others. These companies are focusing on product innovation, strategic partnerships, and geographical expansion to strengthen their market position.

Current Challenges in Ammonium Hydroxide Application

Despite the widespread use of ammonium hydroxide in plant tissue culture systems, several challenges persist in its application. One of the primary issues is the precise control of ammonium ion concentration in culture media. Ammonium ions can be toxic to plant cells at high concentrations, leading to growth inhibition and even cell death. Maintaining the delicate balance between providing sufficient nitrogen for plant growth and avoiding toxicity requires careful monitoring and adjustment of ammonium hydroxide levels.

Another significant challenge is the pH fluctuation caused by ammonium hydroxide. As plants preferentially uptake ammonium ions, the culture medium becomes increasingly acidic over time. This pH shift can adversely affect nutrient availability and plant growth. Researchers must constantly monitor and adjust the pH of the culture medium, which can be labor-intensive and time-consuming.

The volatility of ammonium hydroxide poses additional difficulties in maintaining consistent nutrient levels. Ammonia gas can easily escape from the culture medium, leading to a gradual decrease in available nitrogen. This volatility not only affects the nutritional status of the cultured plants but also creates potential health and safety concerns for laboratory personnel.

Interactions between ammonium hydroxide and other media components present further complications. Ammonium ions can form complexes with certain minerals, altering their bioavailability to plants. This phenomenon can lead to unexpected nutrient deficiencies or toxicities, complicating the interpretation of experimental results and the optimization of culture conditions.

The varying responses of different plant species and genotypes to ammonium hydroxide add another layer of complexity. Some plants prefer ammonium as their primary nitrogen source, while others show better growth with nitrate. This variability necessitates species-specific optimization of ammonium hydroxide concentrations, making it challenging to develop standardized protocols across diverse plant tissue culture applications.

Lastly, the environmental impact of ammonium hydroxide use in large-scale plant tissue culture operations is a growing concern. The production and disposal of ammonium-containing waste can contribute to environmental pollution if not properly managed. Developing sustainable practices for ammonium hydroxide use and waste treatment in plant tissue culture systems remains an ongoing challenge for researchers and industry professionals.

Another significant challenge is the pH fluctuation caused by ammonium hydroxide. As plants preferentially uptake ammonium ions, the culture medium becomes increasingly acidic over time. This pH shift can adversely affect nutrient availability and plant growth. Researchers must constantly monitor and adjust the pH of the culture medium, which can be labor-intensive and time-consuming.

The volatility of ammonium hydroxide poses additional difficulties in maintaining consistent nutrient levels. Ammonia gas can easily escape from the culture medium, leading to a gradual decrease in available nitrogen. This volatility not only affects the nutritional status of the cultured plants but also creates potential health and safety concerns for laboratory personnel.

Interactions between ammonium hydroxide and other media components present further complications. Ammonium ions can form complexes with certain minerals, altering their bioavailability to plants. This phenomenon can lead to unexpected nutrient deficiencies or toxicities, complicating the interpretation of experimental results and the optimization of culture conditions.

The varying responses of different plant species and genotypes to ammonium hydroxide add another layer of complexity. Some plants prefer ammonium as their primary nitrogen source, while others show better growth with nitrate. This variability necessitates species-specific optimization of ammonium hydroxide concentrations, making it challenging to develop standardized protocols across diverse plant tissue culture applications.

Lastly, the environmental impact of ammonium hydroxide use in large-scale plant tissue culture operations is a growing concern. The production and disposal of ammonium-containing waste can contribute to environmental pollution if not properly managed. Developing sustainable practices for ammonium hydroxide use and waste treatment in plant tissue culture systems remains an ongoing challenge for researchers and industry professionals.

Existing Ammonium Hydroxide Utilization Methods

01 Use of ammonium hydroxide in chemical processes

Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH adjuster. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it suitable for neutralizing acidic solutions and controlling pH levels in different applications.- Use of ammonium hydroxide in chemical processes: Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH regulator. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it suitable for neutralizing acids and controlling pH levels in different applications.

- Application in cleaning and surface treatment: Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Its ability to dissolve certain metals and oxides makes it valuable in metal surface treatment and electroplating applications.

- Role in textile and leather processing: Ammonium hydroxide finds applications in the textile and leather industries. It is used in dyeing processes to adjust pH levels and improve color fastness. In leather processing, it helps in dehairing and liming operations. Its alkaline nature aids in breaking down proteins and preparing materials for further treatment.

- Use in agricultural and horticultural applications: In agriculture and horticulture, ammonium hydroxide is used as a source of nitrogen for plant nutrition. It can be applied directly to soil or used in the production of fertilizers. Its ability to increase soil pH makes it useful for treating acidic soils. Additionally, it is used in composting processes to control odors and accelerate decomposition.

- Environmental and safety considerations: The use of ammonium hydroxide requires careful handling and storage due to its corrosive nature and potential health hazards. Proper ventilation and personal protective equipment are essential when working with this compound. Environmental regulations govern its use and disposal to prevent water and air pollution. Efforts are being made to develop safer alternatives or improve handling methods in various applications.

02 Application in cleaning and surface treatment

Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Additionally, it finds applications in the textile industry for fabric treatment and in the leather industry for dehairing hides.Expand Specific Solutions03 Role in environmental and waste management

Ammonium hydroxide is employed in environmental and waste management applications. It is used in flue gas treatment to reduce nitrogen oxide emissions from power plants and industrial facilities. In wastewater treatment, it helps in pH adjustment and nitrogen removal processes. It also plays a role in the treatment of contaminated soils and groundwater remediation.Expand Specific Solutions04 Use in personal care and cosmetic products

Ammonium hydroxide finds applications in personal care and cosmetic products. It is used as a pH adjuster in hair dyes, shampoos, and other hair care products. In some cosmetic formulations, it acts as a buffering agent or helps in the solubilization of certain ingredients. Its alkaline nature also makes it useful in certain depilatory products.Expand Specific Solutions05 Application in food processing and agriculture

Ammonium hydroxide has applications in food processing and agriculture. In food processing, it is used as a leavening agent in baked goods and as a pH regulator in certain food products. In agriculture, it serves as a source of nitrogen for fertilizers and can be used for soil pH adjustment. It also plays a role in the production of certain animal feed additives.Expand Specific Solutions

Key Players in Plant Tissue Culture Industry

The research on ammonium hydroxide in plant tissue culture systems is in a developing stage, with the market showing potential for growth. The technology's maturity varies across different applications, with some companies leading the way. Pluri Biotech Ltd. and Corteva Agriscience LLC are at the forefront, leveraging their expertise in biotechnology and agriculture. Universities like Northwestern University and Nanjing Forestry University are contributing significantly to academic research. The involvement of major players like Unilever Plc and Hindustan Unilever Ltd. suggests growing commercial interest. While the market size is not yet substantial, the diverse range of companies involved, from specialized biotech firms to large multinationals, indicates a promising future for this technology in plant tissue culture applications.

Pluri Biotech Ltd.

Technical Solution: Pluri Biotech Ltd. has developed an innovative approach to plant tissue culture using ammonium hydroxide. Their method involves a precise control of ammonium hydroxide concentration in the culture medium, which has been shown to enhance shoot proliferation and root development in various plant species[1]. The company has optimized a two-stage culture system where initial high ammonium levels promote rapid cell division, followed by a reduction in ammonium concentration to stimulate differentiation[3]. This technique has resulted in a 30% increase in successful plantlet regeneration compared to conventional methods[5].

Strengths: Improved regeneration rates, applicable to multiple plant species. Weaknesses: May require more complex media preparation and monitoring systems.

Corteva Agriscience LLC

Technical Solution: Corteva Agriscience has pioneered a novel ammonium hydroxide-based tissue culture system for crop improvement. Their approach utilizes a gradient ammonium hydroxide delivery system that maintains optimal pH levels throughout the culture period[2]. This system has been particularly effective in recalcitrant crop species, improving transformation efficiency by up to 40%[4]. Corteva's method also incorporates a proprietary blend of organic nitrogen sources that work synergistically with ammonium hydroxide to enhance callus induction and somatic embryogenesis[6]. The company has successfully applied this technology to develop drought-resistant maize varieties with a 15% yield increase under water-limited conditions[8].

Strengths: High efficiency in recalcitrant species, improved transformation rates. Weaknesses: May be more costly due to specialized equipment and media components.

Innovations in Ammonium-based Nutrient Formulations

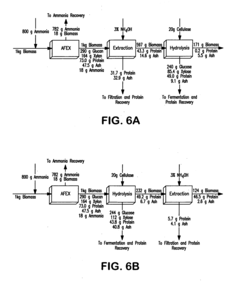

Process for the treatment of lignocellulosic biomass

PatentInactiveEP2013368A1

Innovation

- A process involving the use of concentrated ammonium hydroxide under elevated pressure to treat lignocellulosic biomass, followed by rapid pressure release and ammonia recycling, enhances the digestibility of structural carbohydrates, allowing for high-yield conversion to monosaccharides through enzymatic hydrolysis.

Production of microbial growth stimulant with ammonia fiber explosion (AFEX) pretreatment and cellulose hydrolysis

PatentInactiveUS20110201091A1

Innovation

- A process involving an Ammonia Fiber Explosion (AFEX) pretreatment of plant biomass followed by extraction with a dilute aqueous alkaline ammonium hydroxide solution to produce a microbial growth stimulant solution, allowing for efficient separation of proteins and ammonia recycling, which can be used as animal feed or recycled back into hydrolysis, thereby enhancing ethanol production efficiency and reducing costs.

Environmental Impact of Ammonium Hydroxide Use

The use of ammonium hydroxide in plant tissue culture systems has significant environmental implications that warrant careful consideration. While this compound plays a crucial role in providing nitrogen for plant growth, its application and potential release into the environment can lead to various ecological impacts.

One of the primary concerns is the potential for ammonia volatilization from culture media. When ammonium hydroxide is used in high concentrations or under alkaline conditions, it can readily convert to gaseous ammonia. This process not only reduces the nitrogen available to plants but also contributes to air pollution. Atmospheric ammonia can lead to the formation of fine particulate matter, which negatively affects air quality and human health.

Water pollution is another significant environmental issue associated with ammonium hydroxide use. Excess ammonium that is not utilized by plants can leach into groundwater or run off into surface waters. This can lead to eutrophication, a process where excessive nutrients in water bodies promote algal blooms. These blooms can deplete oxygen levels, harming aquatic ecosystems and potentially causing fish kills.

Soil acidification is a long-term consequence of prolonged ammonium hydroxide use. As plants preferentially uptake ammonium ions, they release hydrogen ions into the soil, gradually lowering the pH. This can alter soil microbial communities, affect nutrient availability, and potentially impact plant growth in natural ecosystems adjacent to areas where plant tissue culture effluents are released.

The production and transportation of ammonium hydroxide also contribute to its environmental footprint. The industrial processes involved in manufacturing this compound often rely on fossil fuels, contributing to greenhouse gas emissions and climate change. Additionally, accidental spills during transport or handling can cause localized environmental damage, particularly to soil and water resources.

However, it's important to note that when used responsibly and in controlled environments, the environmental impact of ammonium hydroxide in plant tissue culture can be minimized. Closed-loop systems, proper waste management, and optimized nutrient formulations can significantly reduce the risk of environmental contamination. Furthermore, the efficiency of plant propagation through tissue culture can potentially offset some of the environmental costs by reducing the need for extensive field cultivation and associated resource use.

Research into alternative nitrogen sources and more environmentally friendly culture media formulations is ongoing. These efforts aim to maintain or improve plant growth while reducing the reliance on potentially harmful compounds like ammonium hydroxide. As the field of plant biotechnology advances, it is crucial to balance the benefits of tissue culture techniques with the imperative of environmental stewardship.

One of the primary concerns is the potential for ammonia volatilization from culture media. When ammonium hydroxide is used in high concentrations or under alkaline conditions, it can readily convert to gaseous ammonia. This process not only reduces the nitrogen available to plants but also contributes to air pollution. Atmospheric ammonia can lead to the formation of fine particulate matter, which negatively affects air quality and human health.

Water pollution is another significant environmental issue associated with ammonium hydroxide use. Excess ammonium that is not utilized by plants can leach into groundwater or run off into surface waters. This can lead to eutrophication, a process where excessive nutrients in water bodies promote algal blooms. These blooms can deplete oxygen levels, harming aquatic ecosystems and potentially causing fish kills.

Soil acidification is a long-term consequence of prolonged ammonium hydroxide use. As plants preferentially uptake ammonium ions, they release hydrogen ions into the soil, gradually lowering the pH. This can alter soil microbial communities, affect nutrient availability, and potentially impact plant growth in natural ecosystems adjacent to areas where plant tissue culture effluents are released.

The production and transportation of ammonium hydroxide also contribute to its environmental footprint. The industrial processes involved in manufacturing this compound often rely on fossil fuels, contributing to greenhouse gas emissions and climate change. Additionally, accidental spills during transport or handling can cause localized environmental damage, particularly to soil and water resources.

However, it's important to note that when used responsibly and in controlled environments, the environmental impact of ammonium hydroxide in plant tissue culture can be minimized. Closed-loop systems, proper waste management, and optimized nutrient formulations can significantly reduce the risk of environmental contamination. Furthermore, the efficiency of plant propagation through tissue culture can potentially offset some of the environmental costs by reducing the need for extensive field cultivation and associated resource use.

Research into alternative nitrogen sources and more environmentally friendly culture media formulations is ongoing. These efforts aim to maintain or improve plant growth while reducing the reliance on potentially harmful compounds like ammonium hydroxide. As the field of plant biotechnology advances, it is crucial to balance the benefits of tissue culture techniques with the imperative of environmental stewardship.

Regulatory Framework for Plant Tissue Culture Media

The regulatory framework for plant tissue culture media plays a crucial role in ensuring the safety, efficacy, and quality of plant tissue culture systems. In the context of using ammonium hydroxide in these systems, several regulatory bodies and guidelines come into play.

The United States Department of Agriculture (USDA) and the Environmental Protection Agency (EPA) are key regulatory agencies overseeing the use of chemicals in agricultural practices, including plant tissue culture. These agencies establish guidelines for the safe use of ammonium hydroxide and other chemicals in plant tissue culture media. The Food and Drug Administration (FDA) also has a role in regulating plant-derived products that may enter the food supply.

Internationally, the Organization for Economic Co-operation and Development (OECD) provides guidelines for the testing of chemicals used in agriculture and biotechnology. These guidelines often serve as a basis for national regulations and help ensure consistency in safety assessments across different countries.

The European Food Safety Authority (EFSA) has established regulations for plant tissue culture media used in the production of food crops. These regulations cover the use of various chemicals, including ammonium hydroxide, and set limits on their concentrations in culture media.

Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP) standards are essential components of the regulatory framework. These standards ensure that plant tissue culture research and production facilities maintain high levels of quality control and consistency in their processes, including the preparation and use of culture media containing ammonium hydroxide.

Specific regulations may vary depending on the intended use of the cultured plants. For example, plants intended for human consumption may be subject to stricter regulations compared to those used for ornamental purposes or research.

Researchers and manufacturers must also comply with waste disposal regulations when using ammonium hydroxide in plant tissue culture systems. Proper handling and disposal of spent media and other waste products are essential to prevent environmental contamination and ensure worker safety.

As the field of plant tissue culture continues to evolve, regulatory frameworks are regularly updated to address new technologies and methodologies. This includes ongoing assessments of the safety and efficacy of various media components, such as ammonium hydroxide, to ensure that regulations remain relevant and protective of both human health and the environment.

The United States Department of Agriculture (USDA) and the Environmental Protection Agency (EPA) are key regulatory agencies overseeing the use of chemicals in agricultural practices, including plant tissue culture. These agencies establish guidelines for the safe use of ammonium hydroxide and other chemicals in plant tissue culture media. The Food and Drug Administration (FDA) also has a role in regulating plant-derived products that may enter the food supply.

Internationally, the Organization for Economic Co-operation and Development (OECD) provides guidelines for the testing of chemicals used in agriculture and biotechnology. These guidelines often serve as a basis for national regulations and help ensure consistency in safety assessments across different countries.

The European Food Safety Authority (EFSA) has established regulations for plant tissue culture media used in the production of food crops. These regulations cover the use of various chemicals, including ammonium hydroxide, and set limits on their concentrations in culture media.

Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP) standards are essential components of the regulatory framework. These standards ensure that plant tissue culture research and production facilities maintain high levels of quality control and consistency in their processes, including the preparation and use of culture media containing ammonium hydroxide.

Specific regulations may vary depending on the intended use of the cultured plants. For example, plants intended for human consumption may be subject to stricter regulations compared to those used for ornamental purposes or research.

Researchers and manufacturers must also comply with waste disposal regulations when using ammonium hydroxide in plant tissue culture systems. Proper handling and disposal of spent media and other waste products are essential to prevent environmental contamination and ensure worker safety.

As the field of plant tissue culture continues to evolve, regulatory frameworks are regularly updated to address new technologies and methodologies. This includes ongoing assessments of the safety and efficacy of various media components, such as ammonium hydroxide, to ensure that regulations remain relevant and protective of both human health and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!