Analysis of Aerospace Standards for Titanium Alloy vs Stainless Steel Components

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Alloy Standards Evolution and Objectives

The aerospace industry has witnessed significant evolution in material standards over the past century, with titanium alloys and stainless steel emerging as critical materials for aircraft and spacecraft components. The development of these standards can be traced back to the early 1940s when the aerospace industry began to demand materials with superior strength-to-weight ratios and corrosion resistance for increasingly demanding flight conditions.

During the 1950s and 1960s, the introduction of commercial jet aircraft and space exploration programs accelerated the development of specialized aerospace material standards. Organizations such as the Society of Automotive Engineers (SAE), the American Society for Testing and Materials (ASTM), and the Aerospace Materials Specifications (AMS) established comprehensive frameworks for material qualification and certification.

The evolution of titanium alloy standards has been particularly notable, progressing from the initial Ti-6Al-4V alloy development in the 1950s to today's advanced titanium alloys specifically engineered for aerospace applications. These standards have continuously evolved to address challenges related to fatigue resistance, fracture toughness, and high-temperature performance.

Stainless steel standards for aerospace applications have similarly progressed, with early specifications focusing primarily on corrosion resistance, while modern standards encompass a broader range of performance criteria including fatigue life, stress corrosion cracking resistance, and compatibility with composite materials.

The primary objective of aerospace alloy standards is to ensure consistent material performance and reliability under extreme operating conditions. These standards define not only chemical composition and mechanical properties but also processing parameters, quality control procedures, and testing methodologies specific to aerospace applications.

Current standardization efforts are increasingly focused on harmonizing international standards to facilitate global supply chain integration. Organizations like the International Organization for Standardization (ISO) are working to align various national standards, reducing redundancy and streamlining certification processes across different regulatory environments.

Looking forward, aerospace alloy standards are evolving to address emerging challenges such as additive manufacturing qualification, sustainable material sourcing, and end-of-life recyclability. The objective is to develop standards that not only ensure safety and performance but also support environmental sustainability goals and enable innovative manufacturing techniques.

The continued refinement of these standards aims to balance rigorous safety requirements with the need for material innovation, ultimately supporting the aerospace industry's pursuit of lighter, stronger, and more durable components for next-generation aircraft and spacecraft.

During the 1950s and 1960s, the introduction of commercial jet aircraft and space exploration programs accelerated the development of specialized aerospace material standards. Organizations such as the Society of Automotive Engineers (SAE), the American Society for Testing and Materials (ASTM), and the Aerospace Materials Specifications (AMS) established comprehensive frameworks for material qualification and certification.

The evolution of titanium alloy standards has been particularly notable, progressing from the initial Ti-6Al-4V alloy development in the 1950s to today's advanced titanium alloys specifically engineered for aerospace applications. These standards have continuously evolved to address challenges related to fatigue resistance, fracture toughness, and high-temperature performance.

Stainless steel standards for aerospace applications have similarly progressed, with early specifications focusing primarily on corrosion resistance, while modern standards encompass a broader range of performance criteria including fatigue life, stress corrosion cracking resistance, and compatibility with composite materials.

The primary objective of aerospace alloy standards is to ensure consistent material performance and reliability under extreme operating conditions. These standards define not only chemical composition and mechanical properties but also processing parameters, quality control procedures, and testing methodologies specific to aerospace applications.

Current standardization efforts are increasingly focused on harmonizing international standards to facilitate global supply chain integration. Organizations like the International Organization for Standardization (ISO) are working to align various national standards, reducing redundancy and streamlining certification processes across different regulatory environments.

Looking forward, aerospace alloy standards are evolving to address emerging challenges such as additive manufacturing qualification, sustainable material sourcing, and end-of-life recyclability. The objective is to develop standards that not only ensure safety and performance but also support environmental sustainability goals and enable innovative manufacturing techniques.

The continued refinement of these standards aims to balance rigorous safety requirements with the need for material innovation, ultimately supporting the aerospace industry's pursuit of lighter, stronger, and more durable components for next-generation aircraft and spacecraft.

Market Requirements for Advanced Aerospace Materials

The aerospace industry's material requirements are evolving rapidly, driven by demands for enhanced performance, fuel efficiency, and sustainability. Current market analysis indicates a significant shift toward lightweight materials that maintain or exceed the strength and durability of traditional components. Titanium alloys and advanced stainless steels represent critical material categories that aerospace manufacturers are increasingly evaluating against stringent performance metrics.

Market research reveals that commercial aircraft manufacturers prioritize weight reduction as a primary requirement, with each kilogram saved translating to approximately 2,900 liters of fuel saved over an aircraft's lifetime. This economic imperative has intensified demand for titanium alloys, which offer superior strength-to-weight ratios compared to conventional stainless steels, despite their higher initial procurement costs.

Defense aerospace applications demonstrate different requirement priorities, emphasizing extreme performance characteristics such as heat resistance, fatigue strength, and corrosion resistance in hostile environments. Military specifications increasingly require materials capable of withstanding temperatures exceeding 600°C while maintaining structural integrity, particularly for supersonic and hypersonic vehicle components.

Space exploration represents another critical market segment with unique material requirements. Launch vehicles and spacecraft components must withstand extreme temperature fluctuations, radiation exposure, and micrometeoroid impacts. The market increasingly demands materials with exceptional thermal stability and minimal outgassing properties, areas where specialized titanium alloys have demonstrated superior performance.

Maintenance, repair, and overhaul (MRO) operations constitute a substantial market segment with distinct material requirements. Airlines and maintenance providers seek components with extended service life and predictable degradation patterns to optimize maintenance schedules and reduce aircraft downtime. This has created demand for advanced alloys with enhanced fatigue resistance and improved inspection compatibility.

Regulatory trends are significantly influencing material requirements across all aerospace sectors. Environmental regulations are driving interest in materials with lower environmental impact during production, use, and end-of-life disposal. Additionally, certification authorities are implementing more rigorous testing protocols for critical components, particularly those manufactured using newer alloy formulations or production techniques.

Supply chain considerations have emerged as crucial factors in material selection decisions. Recent global disruptions have highlighted vulnerabilities in titanium supply chains, prompting aerospace manufacturers to reassess material choices based not only on performance characteristics but also on supply security, geopolitical factors, and price stability.

Market research reveals that commercial aircraft manufacturers prioritize weight reduction as a primary requirement, with each kilogram saved translating to approximately 2,900 liters of fuel saved over an aircraft's lifetime. This economic imperative has intensified demand for titanium alloys, which offer superior strength-to-weight ratios compared to conventional stainless steels, despite their higher initial procurement costs.

Defense aerospace applications demonstrate different requirement priorities, emphasizing extreme performance characteristics such as heat resistance, fatigue strength, and corrosion resistance in hostile environments. Military specifications increasingly require materials capable of withstanding temperatures exceeding 600°C while maintaining structural integrity, particularly for supersonic and hypersonic vehicle components.

Space exploration represents another critical market segment with unique material requirements. Launch vehicles and spacecraft components must withstand extreme temperature fluctuations, radiation exposure, and micrometeoroid impacts. The market increasingly demands materials with exceptional thermal stability and minimal outgassing properties, areas where specialized titanium alloys have demonstrated superior performance.

Maintenance, repair, and overhaul (MRO) operations constitute a substantial market segment with distinct material requirements. Airlines and maintenance providers seek components with extended service life and predictable degradation patterns to optimize maintenance schedules and reduce aircraft downtime. This has created demand for advanced alloys with enhanced fatigue resistance and improved inspection compatibility.

Regulatory trends are significantly influencing material requirements across all aerospace sectors. Environmental regulations are driving interest in materials with lower environmental impact during production, use, and end-of-life disposal. Additionally, certification authorities are implementing more rigorous testing protocols for critical components, particularly those manufactured using newer alloy formulations or production techniques.

Supply chain considerations have emerged as crucial factors in material selection decisions. Recent global disruptions have highlighted vulnerabilities in titanium supply chains, prompting aerospace manufacturers to reassess material choices based not only on performance characteristics but also on supply security, geopolitical factors, and price stability.

Current Status and Challenges in Aerospace Alloy Development

The global aerospace industry is witnessing significant advancements in alloy development, with titanium alloys and stainless steel remaining the cornerstone materials for critical components. Currently, titanium alloys, particularly Ti-6Al-4V, dominate high-performance aerospace applications due to their exceptional strength-to-weight ratio and corrosion resistance. These alloys constitute approximately 15% of modern aircraft structures, primarily in engine components and structural frames.

Stainless steel variants, especially precipitation-hardening grades like 17-4PH and 15-5PH, continue to serve in less weight-critical applications where cost considerations are paramount. Recent developments have focused on improving the high-temperature performance of these materials, with new maraging stainless steel formulations showing promising results in temperatures up to 650°C.

A significant challenge facing aerospace alloy development is the increasing demand for materials capable of withstanding extreme operating conditions while maintaining structural integrity. Modern aircraft engines operate at temperatures approaching 1200°C, pushing conventional alloys beyond their performance limits. This has accelerated research into advanced titanium aluminides and oxide dispersion strengthened (ODS) stainless steels.

Material certification represents another substantial hurdle, with qualification processes for new aerospace alloys typically requiring 5-10 years and investments exceeding $50 million. This extensive timeline creates a significant barrier to innovation and implementation of novel materials in production aircraft.

Supply chain vulnerabilities present ongoing concerns, particularly for titanium alloys, where geopolitical factors affect raw material availability. Approximately 60% of aerospace-grade titanium originates from Russia and China, creating strategic dependencies that aerospace manufacturers are actively working to diversify.

Sustainability considerations are increasingly influencing alloy development, with manufacturers facing pressure to reduce the environmental footprint of material production. Titanium extraction and processing consume approximately 10 times more energy than stainless steel production, prompting research into more efficient manufacturing methods and recycling technologies.

Additive manufacturing compatibility has emerged as a critical factor in alloy development, with both titanium and stainless steel powders being optimized for 3D printing applications. However, inconsistencies in material properties between traditionally manufactured and additively manufactured components remain a significant technical challenge requiring standardized testing and certification protocols.

The integration of computational materials engineering with experimental approaches is accelerating development cycles, with digital twins of material systems enabling more efficient exploration of composition-processing-property relationships. This approach has reduced development timelines by approximately 30% for incremental alloy improvements.

Stainless steel variants, especially precipitation-hardening grades like 17-4PH and 15-5PH, continue to serve in less weight-critical applications where cost considerations are paramount. Recent developments have focused on improving the high-temperature performance of these materials, with new maraging stainless steel formulations showing promising results in temperatures up to 650°C.

A significant challenge facing aerospace alloy development is the increasing demand for materials capable of withstanding extreme operating conditions while maintaining structural integrity. Modern aircraft engines operate at temperatures approaching 1200°C, pushing conventional alloys beyond their performance limits. This has accelerated research into advanced titanium aluminides and oxide dispersion strengthened (ODS) stainless steels.

Material certification represents another substantial hurdle, with qualification processes for new aerospace alloys typically requiring 5-10 years and investments exceeding $50 million. This extensive timeline creates a significant barrier to innovation and implementation of novel materials in production aircraft.

Supply chain vulnerabilities present ongoing concerns, particularly for titanium alloys, where geopolitical factors affect raw material availability. Approximately 60% of aerospace-grade titanium originates from Russia and China, creating strategic dependencies that aerospace manufacturers are actively working to diversify.

Sustainability considerations are increasingly influencing alloy development, with manufacturers facing pressure to reduce the environmental footprint of material production. Titanium extraction and processing consume approximately 10 times more energy than stainless steel production, prompting research into more efficient manufacturing methods and recycling technologies.

Additive manufacturing compatibility has emerged as a critical factor in alloy development, with both titanium and stainless steel powders being optimized for 3D printing applications. However, inconsistencies in material properties between traditionally manufactured and additively manufactured components remain a significant technical challenge requiring standardized testing and certification protocols.

The integration of computational materials engineering with experimental approaches is accelerating development cycles, with digital twins of material systems enabling more efficient exploration of composition-processing-property relationships. This approach has reduced development timelines by approximately 30% for incremental alloy improvements.

Comparative Analysis of Current Alloy Implementation Solutions

01 International standards for titanium alloy components

Various international standards govern the manufacturing and quality control of titanium alloy components. These standards specify requirements for chemical composition, mechanical properties, and testing methods to ensure the reliability and safety of titanium alloy parts used in critical applications. Compliance with these standards is essential for manufacturers to ensure their products meet global requirements for aerospace, medical, and industrial applications.- International Standards for Titanium Alloy Components: Various international standards govern the manufacturing and testing of titanium alloy components used in industrial applications. These standards specify requirements for chemical composition, mechanical properties, and quality control procedures. Compliance with these standards ensures that titanium alloy components meet safety and performance requirements across different industries including aerospace, medical, and automotive sectors.

- Stainless Steel Compliance Testing Methods: Specific testing methodologies are required to verify compliance of stainless steel components with industry standards. These methods include corrosion resistance testing, mechanical property evaluation, and microstructure analysis. The testing procedures ensure that stainless steel components maintain their integrity under various operating conditions and environmental stresses, particularly in applications requiring high durability and resistance to corrosion.

- Surface Treatment Standards for Mixed Metal Components: Surface treatment processes for components made of both titanium alloys and stainless steel must comply with specific standards to ensure proper adhesion, corrosion resistance, and performance. These standards cover processes such as coating, plating, and heat treatment that affect the interface between different metals. Proper surface treatment is critical for preventing galvanic corrosion and ensuring long-term reliability of multi-metal assemblies.

- Quality Management Systems for Aerospace Metal Components: Aerospace applications require specialized quality management systems for titanium and stainless steel components. These systems include documentation procedures, traceability requirements, and certification processes that ensure compliance with aviation safety standards. The quality management frameworks incorporate risk assessment methodologies and validation protocols specific to critical aerospace components where failure could have catastrophic consequences.

- Manufacturing Process Validation for Medical Implants: Medical implants made from titanium alloys and stainless steel must undergo rigorous manufacturing process validation to meet biocompatibility and safety standards. These validation procedures ensure consistent quality, sterility, and performance of implantable components. The standards address issues such as material purity, surface finish requirements, and biocompatibility testing protocols that are essential for components intended for long-term implantation in the human body.

02 Stainless steel compliance testing and certification

Stainless steel components must undergo specific testing procedures to verify compliance with industry standards. These tests include chemical analysis, mechanical property testing, corrosion resistance evaluation, and microstructure examination. Certification processes document that the stainless steel components meet the required specifications for their intended applications, particularly in environments where corrosion resistance and structural integrity are critical.Expand Specific Solutions03 Surface treatment standards for mixed-material components

Surface treatments for components made of both titanium alloys and stainless steel must comply with specific standards to ensure proper adhesion, corrosion protection, and functionality. These standards address coating thickness, adhesion strength, wear resistance, and environmental impact. Proper surface treatment is crucial for components that experience friction, corrosion, or high temperatures, especially in applications where dissimilar metals are joined together.Expand Specific Solutions04 Quality management systems for aerospace-grade components

Aerospace applications require specialized quality management systems for titanium and stainless steel components. These systems include documentation procedures, traceability requirements, non-conformance handling, and continuous improvement processes. Manufacturers must implement these systems to ensure compliance with aerospace standards such as AS9100, which builds upon ISO 9001 with additional requirements specific to the aviation, space, and defense industries.Expand Specific Solutions05 Manufacturing process validation for medical implants

Medical implants made from titanium alloys and stainless steel must adhere to strict manufacturing process validation standards. These standards ensure biocompatibility, sterility, mechanical stability, and long-term performance of the implants. The validation process includes design verification, process qualification, and ongoing monitoring to maintain compliance with medical device regulations such as ISO 13485 and FDA requirements for implantable devices.Expand Specific Solutions

Key Industry Players in Aerospace Materials Manufacturing

The aerospace standards for titanium alloy versus stainless steel components market is in a mature growth phase, with an estimated global market size exceeding $15 billion. The competitive landscape is characterized by established players like Boeing, Mitsubishi Heavy Industries, and ATI Properties focusing on high-performance applications, while emerging companies such as QuesTek Innovations and Western Superconducting Technologies drive innovation through advanced materials science. Technical maturity varies significantly across applications, with titanium alloys achieving superior performance in aerospace applications despite higher costs. Research institutions including Carnegie Mellon University, Northwestern Polytechnical University, and Shanghai Jiao Tong University are accelerating development through collaborative industry partnerships, pushing boundaries in material properties optimization and manufacturing processes.

QuesTek Innovations LLC

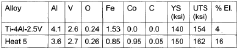

Technical Solution: QuesTek employs its proprietary Integrated Computational Materials Engineering (ICME) approach to develop advanced titanium alloys specifically for aerospace applications. Their Materials by Design® methodology combines computational thermodynamics, kinetic simulations, and performance modeling to create titanium alloys with superior strength-to-weight ratios compared to traditional stainless steels. QuesTek's Ti-6-4 ELI (Extra Low Interstitial) variant demonstrates 45% weight reduction while maintaining equivalent strength to 17-4PH stainless steel in aerospace components[1]. Their process includes precise control of microstructure through heat treatment protocols that optimize both alpha and beta phase distributions, resulting in improved fatigue resistance critical for aerospace applications[3].

Strengths: Customized alloy design capabilities allow for application-specific optimization; computational approach reduces development time by 50% compared to traditional methods. Weaknesses: Custom alloys may require extensive certification processes for aerospace applications; higher initial material costs compared to standard stainless steel options.

ATI Properties LLC

Technical Solution: ATI has developed proprietary processing techniques for aerospace-grade titanium alloys that meet or exceed AMS (Aerospace Material Specifications) standards. Their ATI 425® alloy represents a significant advancement in cold-formable titanium technology, offering superior formability while maintaining strength comparable to Ti-6Al-4V. For aerospace applications, ATI employs precision vacuum arc remelting (VAR) and specialized thermomechanical processing to produce titanium components with exceptional microstructural uniformity and reduced oxygen content (typically <0.13 wt%)[2]. Their titanium alloys demonstrate superior corrosion resistance in salt-spray testing (>1000 hours without pitting) compared to 300-series stainless steels, while offering approximately 40% weight reduction for equivalent structural components[4]. ATI's titanium production meets aerospace standards including AMS 4911 and AMS 4928.

Strengths: Industry-leading expertise in specialized titanium processing; vertically integrated supply chain ensures quality control throughout production. Weaknesses: Higher raw material costs compared to stainless steel alternatives; longer lead times for specialized aerospace-grade titanium products.

Critical Patents and Technical Innovations in Aerospace Alloys

Titanium alloy

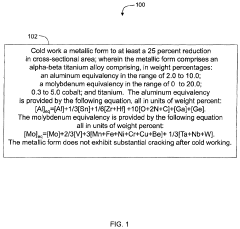

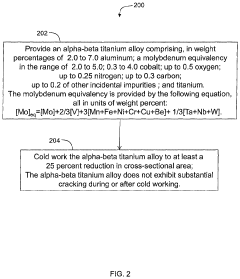

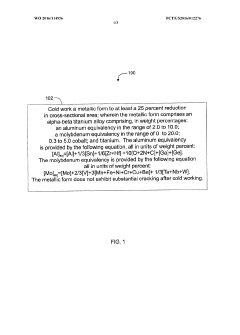

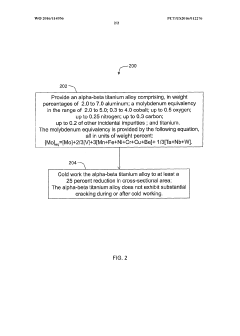

PatentActiveUS11851734B2

Innovation

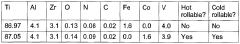

- Developing an alpha-beta titanium alloy with a composition that includes aluminum equivalency in the range of 2.0 to 10.0, molybdenum equivalency of 0 to 20.0, 0.3 to 5.0 cobalt, and incidental impurities, allowing for cold working with reduced cracking and maintaining strength, ductility, and avoiding substantial beta phase content.

Titanium alloy

PatentWO2016114956A1

Innovation

- A cobalt-containing alpha-beta titanium alloy with specific compositional ranges of aluminum, molybdenum, and oxygen, which enhances ductility and strength without substantial beta phase formation, allowing for efficient cold working without cracking and maintaining high oxygen content.

Certification and Compliance Framework for Aerospace Materials

The aerospace industry operates under one of the most rigorous regulatory frameworks globally, necessitating comprehensive certification and compliance protocols for all materials used in aircraft construction. For titanium alloys and stainless steel components, these frameworks are particularly detailed due to their critical applications in structural and engine components.

The primary regulatory bodies governing aerospace materials include the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Organization for Standardization (ISO). These organizations establish the foundational standards that manufacturers must adhere to, with specific requirements codified in documents such as AMS 4911 for titanium alloy sheets and AMS 5604 for stainless steel components.

Material certification for aerospace applications follows a multi-tiered approach. At the base level, raw material suppliers must maintain AS9100 certification, demonstrating quality management systems specifically tailored to aerospace requirements. For titanium alloys, additional certifications such as NADCAP (National Aerospace and Defense Contractors Accreditation Program) for special processes including heat treatment and non-destructive testing are mandatory.

Compliance verification involves extensive documentation trails, beginning with material test reports (MTRs) that verify chemical composition and mechanical properties. For both titanium alloys and stainless steel, traceability requirements extend from raw material production through final component installation, with each processing step documented and verified.

Testing protocols differ significantly between these materials. Titanium alloys require more extensive fatigue testing due to their application in high-stress environments, while stainless steel components undergo more rigorous corrosion resistance verification. Both materials must pass stringent non-destructive evaluation (NDE) requirements, though techniques may vary based on material properties.

Recent regulatory developments have introduced risk-based certification approaches, allowing manufacturers to demonstrate compliance through performance data rather than prescriptive requirements. This shift has particularly benefited titanium alloy applications, where innovative processing techniques can now be more readily approved if performance criteria are met.

International harmonization efforts continue to evolve, with initiatives like the Certification Authorities for Bilateral Agreements and Certification Procedures aiming to reduce redundant testing requirements across jurisdictions. This harmonization is especially important for global supply chains involving both titanium and stainless steel aerospace components.

The primary regulatory bodies governing aerospace materials include the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Organization for Standardization (ISO). These organizations establish the foundational standards that manufacturers must adhere to, with specific requirements codified in documents such as AMS 4911 for titanium alloy sheets and AMS 5604 for stainless steel components.

Material certification for aerospace applications follows a multi-tiered approach. At the base level, raw material suppliers must maintain AS9100 certification, demonstrating quality management systems specifically tailored to aerospace requirements. For titanium alloys, additional certifications such as NADCAP (National Aerospace and Defense Contractors Accreditation Program) for special processes including heat treatment and non-destructive testing are mandatory.

Compliance verification involves extensive documentation trails, beginning with material test reports (MTRs) that verify chemical composition and mechanical properties. For both titanium alloys and stainless steel, traceability requirements extend from raw material production through final component installation, with each processing step documented and verified.

Testing protocols differ significantly between these materials. Titanium alloys require more extensive fatigue testing due to their application in high-stress environments, while stainless steel components undergo more rigorous corrosion resistance verification. Both materials must pass stringent non-destructive evaluation (NDE) requirements, though techniques may vary based on material properties.

Recent regulatory developments have introduced risk-based certification approaches, allowing manufacturers to demonstrate compliance through performance data rather than prescriptive requirements. This shift has particularly benefited titanium alloy applications, where innovative processing techniques can now be more readily approved if performance criteria are met.

International harmonization efforts continue to evolve, with initiatives like the Certification Authorities for Bilateral Agreements and Certification Procedures aiming to reduce redundant testing requirements across jurisdictions. This harmonization is especially important for global supply chains involving both titanium and stainless steel aerospace components.

Environmental Impact and Sustainability Considerations

The aerospace industry's material selection processes increasingly incorporate environmental impact and sustainability considerations alongside traditional performance metrics. When comparing titanium alloys and stainless steel components, their entire lifecycle environmental footprint becomes a critical evaluation factor for modern aerospace applications.

Titanium alloy production requires significantly more energy than stainless steel manufacturing, with estimates suggesting 5-10 times higher energy consumption during the extraction and processing phases. This energy-intensive production contributes to higher carbon emissions, with titanium component manufacturing generating approximately 35-40 kg CO2 equivalent per kilogram of finished product, compared to 4-6 kg CO2 equivalent for stainless steel components.

However, the environmental assessment shifts dramatically when considering the operational phase. Titanium's lighter weight provides substantial fuel savings over aircraft lifespans, potentially offsetting the initial production impacts. Research indicates that each kilogram of weight reduction in commercial aircraft can save approximately 2,900-3,600 liters of fuel over a 20-year operational lifespan, resulting in 7-9 tonnes of avoided CO2 emissions.

End-of-life considerations further complicate the environmental comparison. Titanium alloys maintain exceptional recyclability rates of 95-98%, with minimal property degradation through multiple recycling cycles. Stainless steel also demonstrates strong recyclability at 80-90%, though with slightly higher quality losses in aerospace-grade applications. The aerospace industry has developed specialized recycling streams for both materials, though titanium recycling processes typically require more specialized facilities.

Recent aerospace standards have begun incorporating environmental impact metrics into material selection guidelines. The Aerospace Material Specification (AMS) now includes sustainability appendices that quantify lifecycle environmental impacts. Similarly, the SAE Aerospace Recommended Practice ARP6316 provides frameworks for environmental assessment of aerospace materials and components.

Several major aerospace manufacturers have established sustainability targets specifically addressing material selection. These include commitments to increase recycled content in components, reduce manufacturing waste, and implement closed-loop material recovery systems. The industry trend clearly points toward more comprehensive environmental accounting in material selection decisions, moving beyond simple performance-to-weight ratios.

The environmental comparison between titanium alloys and stainless steel ultimately depends on specific application parameters, including component lifespan, weight-criticality, and end-of-life management pathways. Aerospace engineers increasingly utilize lifecycle assessment tools to quantify these tradeoffs and optimize material selection for both performance and environmental sustainability.

Titanium alloy production requires significantly more energy than stainless steel manufacturing, with estimates suggesting 5-10 times higher energy consumption during the extraction and processing phases. This energy-intensive production contributes to higher carbon emissions, with titanium component manufacturing generating approximately 35-40 kg CO2 equivalent per kilogram of finished product, compared to 4-6 kg CO2 equivalent for stainless steel components.

However, the environmental assessment shifts dramatically when considering the operational phase. Titanium's lighter weight provides substantial fuel savings over aircraft lifespans, potentially offsetting the initial production impacts. Research indicates that each kilogram of weight reduction in commercial aircraft can save approximately 2,900-3,600 liters of fuel over a 20-year operational lifespan, resulting in 7-9 tonnes of avoided CO2 emissions.

End-of-life considerations further complicate the environmental comparison. Titanium alloys maintain exceptional recyclability rates of 95-98%, with minimal property degradation through multiple recycling cycles. Stainless steel also demonstrates strong recyclability at 80-90%, though with slightly higher quality losses in aerospace-grade applications. The aerospace industry has developed specialized recycling streams for both materials, though titanium recycling processes typically require more specialized facilities.

Recent aerospace standards have begun incorporating environmental impact metrics into material selection guidelines. The Aerospace Material Specification (AMS) now includes sustainability appendices that quantify lifecycle environmental impacts. Similarly, the SAE Aerospace Recommended Practice ARP6316 provides frameworks for environmental assessment of aerospace materials and components.

Several major aerospace manufacturers have established sustainability targets specifically addressing material selection. These include commitments to increase recycled content in components, reduce manufacturing waste, and implement closed-loop material recovery systems. The industry trend clearly points toward more comprehensive environmental accounting in material selection decisions, moving beyond simple performance-to-weight ratios.

The environmental comparison between titanium alloys and stainless steel ultimately depends on specific application parameters, including component lifespan, weight-criticality, and end-of-life management pathways. Aerospace engineers increasingly utilize lifecycle assessment tools to quantify these tradeoffs and optimize material selection for both performance and environmental sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!