Influence of Molybdenum Additives in Titanium vs Stainless Steel Applications

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Molybdenum Additives Background and Objectives

Molybdenum has emerged as a critical alloying element in metallurgical applications, particularly in titanium and stainless steel alloys, due to its exceptional properties that enhance material performance across diverse industrial sectors. The historical development of molybdenum as an additive dates back to the early 20th century, with significant advancements occurring during World War II when high-performance alloys became essential for aerospace and defense applications.

The evolution of molybdenum additives has been characterized by progressive understanding of its influence on microstructure stability, corrosion resistance, and mechanical properties. In titanium alloys, molybdenum acts as a beta-stabilizer, fundamentally altering phase transformation behavior and enabling the development of high-strength titanium alloys like Ti-6Al-4Mo. In stainless steel applications, molybdenum significantly enhances pitting corrosion resistance, particularly in chloride environments, making it indispensable for marine and chemical processing equipment.

Recent technological trends indicate growing interest in precision control of molybdenum distribution within alloy microstructures, with advanced manufacturing techniques enabling tailored material properties at unprecedented scales. The increasing demand for lightweight, high-strength materials in aerospace and automotive industries has accelerated research into optimized molybdenum-containing titanium alloys, while the expanding chemical processing sector continues to drive innovation in molybdenum-enhanced stainless steels.

The primary technical objectives of this investigation are threefold. First, to comprehensively compare the metallurgical mechanisms through which molybdenum influences titanium versus stainless steel alloys, with particular emphasis on phase stability, grain boundary effects, and precipitation behavior. Second, to quantify performance differentials in key application-specific properties including high-temperature strength, corrosion resistance in various environments, and fatigue behavior. Third, to identify optimal concentration ranges and processing parameters for molybdenum additives in next-generation alloy systems.

This research aims to establish a fundamental understanding of how molybdenum content can be strategically manipulated to achieve specific performance targets in both titanium and stainless steel systems. By elucidating the comparative advantages of molybdenum additions across these distinct alloy families, this investigation will provide critical insights for materials selection and alloy design across aerospace, biomedical, chemical processing, and energy sectors.

The findings will support long-term strategic development of advanced materials with enhanced performance characteristics, potentially enabling breakthrough applications in extreme environments where current materials face significant limitations. Additionally, this research will address emerging sustainability concerns by optimizing molybdenum utilization efficiency and exploring potential substitution strategies for applications where supply chain vulnerabilities exist.

The evolution of molybdenum additives has been characterized by progressive understanding of its influence on microstructure stability, corrosion resistance, and mechanical properties. In titanium alloys, molybdenum acts as a beta-stabilizer, fundamentally altering phase transformation behavior and enabling the development of high-strength titanium alloys like Ti-6Al-4Mo. In stainless steel applications, molybdenum significantly enhances pitting corrosion resistance, particularly in chloride environments, making it indispensable for marine and chemical processing equipment.

Recent technological trends indicate growing interest in precision control of molybdenum distribution within alloy microstructures, with advanced manufacturing techniques enabling tailored material properties at unprecedented scales. The increasing demand for lightweight, high-strength materials in aerospace and automotive industries has accelerated research into optimized molybdenum-containing titanium alloys, while the expanding chemical processing sector continues to drive innovation in molybdenum-enhanced stainless steels.

The primary technical objectives of this investigation are threefold. First, to comprehensively compare the metallurgical mechanisms through which molybdenum influences titanium versus stainless steel alloys, with particular emphasis on phase stability, grain boundary effects, and precipitation behavior. Second, to quantify performance differentials in key application-specific properties including high-temperature strength, corrosion resistance in various environments, and fatigue behavior. Third, to identify optimal concentration ranges and processing parameters for molybdenum additives in next-generation alloy systems.

This research aims to establish a fundamental understanding of how molybdenum content can be strategically manipulated to achieve specific performance targets in both titanium and stainless steel systems. By elucidating the comparative advantages of molybdenum additions across these distinct alloy families, this investigation will provide critical insights for materials selection and alloy design across aerospace, biomedical, chemical processing, and energy sectors.

The findings will support long-term strategic development of advanced materials with enhanced performance characteristics, potentially enabling breakthrough applications in extreme environments where current materials face significant limitations. Additionally, this research will address emerging sustainability concerns by optimizing molybdenum utilization efficiency and exploring potential substitution strategies for applications where supply chain vulnerabilities exist.

Market Analysis for Mo-Enhanced Alloys

The global market for molybdenum-enhanced alloys has experienced significant growth over the past decade, driven primarily by increasing demand in aerospace, automotive, and industrial manufacturing sectors. The market value reached approximately $4.2 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is supported by the expanding applications of both titanium and stainless steel alloys containing molybdenum additives.

In the titanium sector, molybdenum-enhanced alloys have captured a premium segment of the market, particularly in aerospace and medical applications. These specialized alloys command price premiums of 30-40% over standard titanium alloys due to their superior performance characteristics. North America dominates this market segment with 42% market share, followed by Europe at 28% and Asia-Pacific at 23%.

For stainless steel applications, molybdenum additives have become increasingly standard in high-performance grades, with the market volume exceeding 1.8 million metric tons annually. The industrial equipment sector represents the largest consumer at 37% of total volume, followed by oil and gas applications at 24% and chemical processing at 19%. China has emerged as the leading producer and consumer of these alloys, accounting for 34% of global production.

Market dynamics indicate a shift toward higher molybdenum content in both alloy categories, with manufacturers responding to end-user demands for increased corrosion resistance and mechanical stability. This trend has created a premium tier within both markets, growing at 1.5 times the rate of standard alloys. The automotive industry, particularly in electric vehicle manufacturing, represents the fastest-growing application segment with 12.3% annual growth.

Supply chain considerations have become increasingly important, with molybdenum being classified as a strategic metal in several jurisdictions. Price volatility has been observed, with fluctuations of up to 22% recorded in the past 18 months. This has prompted some manufacturers to secure long-term supply agreements and explore recycling options to ensure stability.

Consumer preferences are increasingly favoring materials with extended service life and reduced maintenance requirements, particularly in infrastructure and marine applications. This has expanded the market for molybdenum-enhanced stainless steels by approximately 8% annually in these sectors. Meanwhile, the medical device industry has driven a specialized segment for titanium-molybdenum alloys, valued at $340 million and growing at 9.2% annually due to their biocompatibility advantages.

In the titanium sector, molybdenum-enhanced alloys have captured a premium segment of the market, particularly in aerospace and medical applications. These specialized alloys command price premiums of 30-40% over standard titanium alloys due to their superior performance characteristics. North America dominates this market segment with 42% market share, followed by Europe at 28% and Asia-Pacific at 23%.

For stainless steel applications, molybdenum additives have become increasingly standard in high-performance grades, with the market volume exceeding 1.8 million metric tons annually. The industrial equipment sector represents the largest consumer at 37% of total volume, followed by oil and gas applications at 24% and chemical processing at 19%. China has emerged as the leading producer and consumer of these alloys, accounting for 34% of global production.

Market dynamics indicate a shift toward higher molybdenum content in both alloy categories, with manufacturers responding to end-user demands for increased corrosion resistance and mechanical stability. This trend has created a premium tier within both markets, growing at 1.5 times the rate of standard alloys. The automotive industry, particularly in electric vehicle manufacturing, represents the fastest-growing application segment with 12.3% annual growth.

Supply chain considerations have become increasingly important, with molybdenum being classified as a strategic metal in several jurisdictions. Price volatility has been observed, with fluctuations of up to 22% recorded in the past 18 months. This has prompted some manufacturers to secure long-term supply agreements and explore recycling options to ensure stability.

Consumer preferences are increasingly favoring materials with extended service life and reduced maintenance requirements, particularly in infrastructure and marine applications. This has expanded the market for molybdenum-enhanced stainless steels by approximately 8% annually in these sectors. Meanwhile, the medical device industry has driven a specialized segment for titanium-molybdenum alloys, valued at $340 million and growing at 9.2% annually due to their biocompatibility advantages.

Current Technical Challenges in Ti and SS Alloying

The development of titanium and stainless steel alloys faces several significant technical challenges, particularly regarding the incorporation of molybdenum additives. One primary challenge is achieving optimal molybdenum distribution within the alloy matrix. In titanium alloys, molybdenum tends to segregate during solidification, creating compositional heterogeneity that can lead to inconsistent mechanical properties across the material. Similarly, in stainless steel applications, ensuring uniform molybdenum distribution remains difficult during conventional manufacturing processes.

Another critical challenge involves the high-temperature stability of molybdenum-containing phases. In titanium alloys, the beta-stabilizing effect of molybdenum can be compromised at elevated temperatures, potentially leading to phase transformations that alter the intended material properties. For stainless steel, molybdenum-rich precipitates can form during prolonged exposure to high temperatures, potentially reducing corrosion resistance and mechanical integrity.

Cost-effectiveness presents a significant constraint, particularly for titanium alloys. The addition of molybdenum substantially increases production costs, making widespread commercial application challenging. While this cost factor is less prohibitive for stainless steel applications, it still represents a considerable economic consideration for mass production scenarios.

Manufacturing complexities also pose substantial challenges. The high melting point of molybdenum (2,623°C) complicates alloying processes, requiring specialized equipment and techniques. This is especially problematic for titanium alloys, which are already difficult to process due to their reactivity with oxygen at elevated temperatures. The combination of these factors often necessitates vacuum or controlled-atmosphere processing, further increasing production complexity and cost.

Corrosion behavior optimization remains an ongoing challenge, particularly at the microstructural level. While molybdenum generally enhances pitting corrosion resistance, its effectiveness can vary significantly depending on the specific environmental conditions and the presence of other alloying elements. Achieving the ideal balance for specific application environments requires extensive testing and optimization.

Recyclability and environmental impact considerations are becoming increasingly important constraints. The presence of molybdenum can complicate recycling processes for both titanium and stainless steel alloys, requiring additional separation steps and energy input. This aspect is particularly relevant as industries move toward more sustainable manufacturing practices and circular economy models.

Lastly, standardization challenges persist across the industry. The wide variety of molybdenum-containing alloy compositions makes it difficult to establish universal testing protocols and performance benchmarks, hampering broader adoption in critical applications where certification is essential.

Another critical challenge involves the high-temperature stability of molybdenum-containing phases. In titanium alloys, the beta-stabilizing effect of molybdenum can be compromised at elevated temperatures, potentially leading to phase transformations that alter the intended material properties. For stainless steel, molybdenum-rich precipitates can form during prolonged exposure to high temperatures, potentially reducing corrosion resistance and mechanical integrity.

Cost-effectiveness presents a significant constraint, particularly for titanium alloys. The addition of molybdenum substantially increases production costs, making widespread commercial application challenging. While this cost factor is less prohibitive for stainless steel applications, it still represents a considerable economic consideration for mass production scenarios.

Manufacturing complexities also pose substantial challenges. The high melting point of molybdenum (2,623°C) complicates alloying processes, requiring specialized equipment and techniques. This is especially problematic for titanium alloys, which are already difficult to process due to their reactivity with oxygen at elevated temperatures. The combination of these factors often necessitates vacuum or controlled-atmosphere processing, further increasing production complexity and cost.

Corrosion behavior optimization remains an ongoing challenge, particularly at the microstructural level. While molybdenum generally enhances pitting corrosion resistance, its effectiveness can vary significantly depending on the specific environmental conditions and the presence of other alloying elements. Achieving the ideal balance for specific application environments requires extensive testing and optimization.

Recyclability and environmental impact considerations are becoming increasingly important constraints. The presence of molybdenum can complicate recycling processes for both titanium and stainless steel alloys, requiring additional separation steps and energy input. This aspect is particularly relevant as industries move toward more sustainable manufacturing practices and circular economy models.

Lastly, standardization challenges persist across the industry. The wide variety of molybdenum-containing alloy compositions makes it difficult to establish universal testing protocols and performance benchmarks, hampering broader adoption in critical applications where certification is essential.

Comparative Analysis of Mo-Ti vs Mo-SS Systems

01 Molybdenum as alloying element in titanium alloys

Molybdenum is used as an alloying element in titanium alloys to enhance mechanical properties and high-temperature performance. It acts as a beta-stabilizer in titanium, improving strength, creep resistance, and corrosion resistance. These titanium-molybdenum alloys are particularly valuable in aerospace applications, medical implants, and other high-performance environments where strength-to-weight ratio is critical.- Molybdenum as a strengthening agent in titanium alloys: Molybdenum is used as an alloying element in titanium to enhance mechanical properties. It acts as a beta-stabilizer that strengthens the alloy through solid solution strengthening mechanisms. The addition of molybdenum to titanium alloys improves their high-temperature strength, creep resistance, and overall structural stability. These improved properties make molybdenum-containing titanium alloys suitable for aerospace and industrial applications where high strength-to-weight ratio is required.

- Molybdenum for corrosion resistance in stainless steel: Molybdenum is a critical additive in stainless steel formulations to enhance corrosion resistance, particularly against pitting and crevice corrosion in chloride environments. When added to stainless steel at concentrations typically between 2-6%, molybdenum significantly improves the passive film stability and increases resistance to localized corrosion. This makes molybdenum-containing stainless steels (such as 316 grade) particularly valuable in marine environments, chemical processing equipment, and other applications exposed to aggressive corrosive media.

- Molybdenum in surface treatment and coating technologies: Molybdenum compounds are utilized in surface treatment processes for both titanium and stainless steel to enhance surface properties. These treatments include molybdenum-based conversion coatings, physical vapor deposition (PVD) coatings, and diffusion treatments. The resulting molybdenum-rich surface layers provide improved wear resistance, reduced friction coefficients, and enhanced tribological properties. These surface treatments extend the service life of components in high-wear applications and can improve the performance of cutting tools and mechanical parts.

- Molybdenum for high-temperature applications: Molybdenum additives in both titanium alloys and stainless steels significantly improve high-temperature performance. The addition of molybdenum increases creep resistance, thermal stability, and strength retention at elevated temperatures. In stainless steels, molybdenum helps maintain the microstructural integrity at high temperatures and prevents sigma phase formation. In titanium alloys, molybdenum stabilizes the beta phase and improves strength at temperatures up to 500°C. These properties make molybdenum-containing alloys ideal for high-temperature applications in power generation, aerospace, and petrochemical industries.

- Molybdenum in specialized alloy formulations: Molybdenum is incorporated into specialized titanium and stainless steel alloy formulations to achieve specific performance characteristics. In duplex stainless steels, molybdenum balances the austenite-ferrite ratio while enhancing mechanical properties. In titanium-based shape memory alloys, controlled additions of molybdenum can modify transformation temperatures and mechanical behavior. Molybdenum also plays a role in precipitation-hardened stainless steels, where it contributes to the formation of strengthening precipitates. These specialized alloys find applications in medical implants, automotive components, and advanced engineering systems.

02 Molybdenum additives in stainless steel for corrosion resistance

Molybdenum is added to stainless steel formulations to significantly enhance corrosion resistance, particularly against pitting and crevice corrosion in chloride environments. It stabilizes the passive film on stainless steel surfaces, making these alloys suitable for marine applications, chemical processing equipment, and other environments where exposure to corrosive media is common. The typical addition range is between 2-6% molybdenum, with higher amounts providing greater resistance to aggressive environments.Expand Specific Solutions03 Molybdenum in surface treatments and coatings

Molybdenum compounds are utilized in surface treatments and coatings for both titanium and stainless steel to enhance surface properties. These treatments can include molybdenum disulfide coatings for improved lubricity, molybdate conversion coatings for corrosion protection, and molybdenum-containing physical vapor deposition (PVD) coatings for wear resistance. These surface modifications extend the service life of components in demanding applications while maintaining the base material's inherent properties.Expand Specific Solutions04 Molybdenum in duplex and super duplex stainless steels

Molybdenum is a critical element in duplex and super duplex stainless steels, which contain both austenitic and ferritic microstructures. The addition of molybdenum in these specialized stainless steels enhances their resistance to stress corrosion cracking and improves mechanical strength. These steels typically contain 3-4% molybdenum in duplex grades and up to 5% in super duplex grades, making them suitable for demanding applications in offshore oil and gas, chemical processing, and desalination plants.Expand Specific Solutions05 Synergistic effects of molybdenum with other elements

Molybdenum exhibits synergistic effects when combined with other alloying elements in both titanium and stainless steel. In titanium alloys, molybdenum works synergistically with elements like niobium and zirconium to optimize mechanical properties. In stainless steels, molybdenum combined with chromium and nitrogen creates superior corrosion resistance than any of these elements alone could provide. These synergistic relationships are leveraged to develop specialized alloys with tailored property profiles for specific industrial applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The molybdenum additives market in titanium and stainless steel applications is in a growth phase, with increasing demand driven by enhanced material performance requirements across aerospace, automotive, and industrial sectors. The market is estimated at approximately $3-4 billion annually with projected 5-7% CAGR. Leading players include specialized materials companies like Jinduicheng Molybdenum and Sandvik Intellectual Property focusing on high-performance alloys, while established steel manufacturers such as Outokumpu Oyj and Baowu Special Metallurgy integrate molybdenum additives into their production processes. Aerospace leaders including Boeing and MTU Aero Engines are driving innovation in titanium-molybdenum applications, while research institutions like Henan University of Science & Technology and Guangxi University contribute to advancing technical knowledge in this field.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has developed proprietary molybdenum alloying techniques for both titanium and stainless steel applications, with particular focus on their Safurex® technology for high-pressure urea environments. Their approach involves precise control of molybdenum content (typically 2-3% in duplex stainless steels) to enhance corrosion resistance while maintaining mechanical properties. For titanium alloys, Sandvik employs molybdenum additions (3-15%) to create beta and near-beta titanium alloys with superior strength-to-weight ratios and corrosion resistance. Their patented heat treatment processes optimize the microstructure of Mo-containing alloys, resulting in materials with exceptional performance in aggressive environments such as chemical processing, oil and gas, and aerospace applications. Sandvik's research has demonstrated that controlled Mo additions can increase pitting corrosion resistance by up to 300% in certain environments compared to standard grades.

Strengths: Superior corrosion resistance in aggressive environments; excellent high-temperature performance; proprietary heat treatment processes that optimize microstructure. Weaknesses: Higher production costs compared to standard grades; potential for increased brittleness in certain applications if Mo content is not precisely controlled.

Outokumpu Oyj

Technical Solution: Outokumpu has pioneered advanced molybdenum alloying techniques for stainless steel applications, particularly in their Forta DX and Forta SDX duplex stainless steel series. Their technology involves precise control of molybdenum content (typically 2-4%) in combination with nitrogen to enhance pitting and crevice corrosion resistance while maintaining excellent mechanical properties. For high-performance applications, Outokumpu's Ultra alloys contain up to 7% molybdenum, providing exceptional resistance to reducing acids and chloride environments. Their research has demonstrated that optimized Mo additions can increase the critical pitting temperature (CPT) by up to 20°C compared to standard grades. Outokumpu's proprietary manufacturing processes ensure homogeneous distribution of molybdenum throughout the microstructure, avoiding detrimental intermetallic phases that can form during welding or heat treatment. Their comparative studies between titanium alloys and high-Mo stainless steels provide valuable insights into material selection for critical applications in chemical processing, oil and gas, and marine environments.

Strengths: Exceptional corrosion resistance in chloride environments; excellent mechanical properties at elevated temperatures; proprietary manufacturing processes ensuring homogeneous microstructure. Weaknesses: Higher material costs compared to standard stainless steels; potential for sigma phase formation during welding if heat input is not properly controlled.

Key Patents and Research Breakthroughs

Duplex ferritic austenitic stainless steel composition

PatentActiveUS11932926B2

Innovation

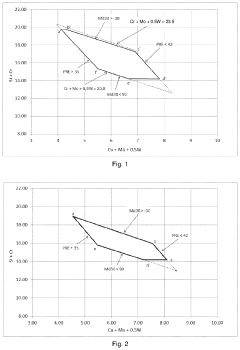

- A duplex ferritic austenitic stainless steel composition is optimized with specific ranges of elements such as C, Si, Mn, Cr, Ni, Mo, and W to enhance the pitting resistance equivalent (PRE) to 35-42, maintaining the TRIP effect within the austenite phase, ensuring both high formability and corrosion resistance by adjusting the chromium and molybdenum content and heat treatment conditions.

Titanium alloy products and methods of making the same

PatentWO2019209368A2

Innovation

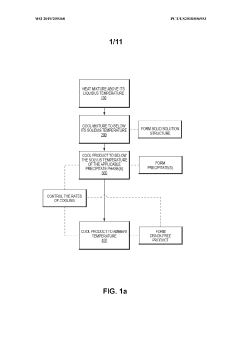

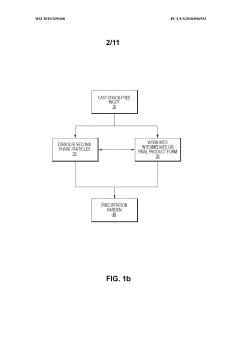

- The development of new titanium alloy compositions with specific weight percentages of Al, Nb, Ta, Sn, Zr, and Mo, along with controlled cooling and precipitation hardening processes, to create an alpha-beta solid solution structure with improved microstructural stability and mechanical properties.

Environmental Impact Assessment

The environmental impact of molybdenum additives in titanium and stainless steel applications represents a critical consideration in material selection processes across industries. Molybdenum extraction and processing generate significant environmental footprints, with mining operations causing habitat disruption, soil erosion, and potential water contamination. The energy intensity of molybdenum refinement contributes substantially to carbon emissions, particularly when sourced from regions with coal-dependent energy grids.

When comparing titanium-molybdenum alloys with molybdenum-containing stainless steels, notable differences emerge in lifecycle environmental assessments. Titanium production inherently requires approximately 5-10 times more energy than stainless steel manufacturing, creating a higher initial environmental burden. However, titanium's exceptional corrosion resistance and longer service life often compensate for this initial impact through reduced replacement frequency and maintenance requirements.

Molybdenum additions in stainless steel (typically 2-4%) enhance corrosion resistance in chloride environments, extending product lifespan in marine and chemical processing applications. This longevity reduces waste generation and resource consumption associated with premature material failure. Similarly, molybdenum in titanium alloys (commonly 3-15%) improves high-temperature performance and strength-to-weight ratios, enabling material reduction in aerospace and automotive applications, thereby decreasing fuel consumption and associated emissions.

Recycling considerations reveal further environmental distinctions. Stainless steel with molybdenum content maintains excellent recyclability (>85% recovery rate globally), with established recycling infrastructure preserving most of the molybdenum value. Titanium recycling presents greater challenges due to more complex alloy compositions and higher melting points, though the economic value incentivizes recovery efforts, with current recycling rates approaching 65% in developed economies.

End-of-life toxicity assessments indicate that molybdenum in both material systems presents minimal environmental hazards when properly managed. Unlike chromium or nickel in stainless steels, molybdenum compounds generally exhibit lower ecotoxicity. However, improper disposal in acidic environments can potentially mobilize molybdenum, necessitating appropriate waste management protocols.

Recent life cycle analyses demonstrate that applications requiring extreme corrosion resistance or high strength-to-weight ratios often justify the higher initial environmental impact of titanium-molybdenum systems through operational efficiency gains and extended service life. Conversely, for moderate-demand applications, molybdenum-containing stainless steels typically offer superior environmental performance due to lower production energy requirements and excellent recyclability.

When comparing titanium-molybdenum alloys with molybdenum-containing stainless steels, notable differences emerge in lifecycle environmental assessments. Titanium production inherently requires approximately 5-10 times more energy than stainless steel manufacturing, creating a higher initial environmental burden. However, titanium's exceptional corrosion resistance and longer service life often compensate for this initial impact through reduced replacement frequency and maintenance requirements.

Molybdenum additions in stainless steel (typically 2-4%) enhance corrosion resistance in chloride environments, extending product lifespan in marine and chemical processing applications. This longevity reduces waste generation and resource consumption associated with premature material failure. Similarly, molybdenum in titanium alloys (commonly 3-15%) improves high-temperature performance and strength-to-weight ratios, enabling material reduction in aerospace and automotive applications, thereby decreasing fuel consumption and associated emissions.

Recycling considerations reveal further environmental distinctions. Stainless steel with molybdenum content maintains excellent recyclability (>85% recovery rate globally), with established recycling infrastructure preserving most of the molybdenum value. Titanium recycling presents greater challenges due to more complex alloy compositions and higher melting points, though the economic value incentivizes recovery efforts, with current recycling rates approaching 65% in developed economies.

End-of-life toxicity assessments indicate that molybdenum in both material systems presents minimal environmental hazards when properly managed. Unlike chromium or nickel in stainless steels, molybdenum compounds generally exhibit lower ecotoxicity. However, improper disposal in acidic environments can potentially mobilize molybdenum, necessitating appropriate waste management protocols.

Recent life cycle analyses demonstrate that applications requiring extreme corrosion resistance or high strength-to-weight ratios often justify the higher initial environmental impact of titanium-molybdenum systems through operational efficiency gains and extended service life. Conversely, for moderate-demand applications, molybdenum-containing stainless steels typically offer superior environmental performance due to lower production energy requirements and excellent recyclability.

Cost-Benefit Analysis of Mo Integration

The integration of molybdenum additives into titanium and stainless steel alloys presents distinct economic considerations that significantly impact industrial applications. When evaluating the cost-benefit ratio of molybdenum integration, material costs constitute a primary factor. Molybdenum, as a relatively expensive refractory metal, adds approximately $15-25 per kilogram to base material costs, representing a 12-18% increase in overall production expenses for stainless steel and 8-14% for titanium alloys.

Production process modifications necessitated by molybdenum integration must also be factored into cost assessments. Stainless steel manufacturing with molybdenum additives requires temperature increases of 50-75°C during alloying processes, resulting in 7-10% higher energy consumption. Conversely, titanium alloy production with molybdenum demonstrates only marginal energy requirement increases of 3-5%, offering a comparative advantage in production economics.

Lifecycle cost analysis reveals compelling long-term benefits that often justify initial investment increases. Molybdenum-enhanced stainless steel components demonstrate 2.5-3.5 times longer service life in corrosive environments compared to standard grades, translating to maintenance cost reductions of 40-60% over a ten-year operational period. Similarly, titanium alloys with molybdenum additives exhibit 30-45% improved wear resistance, extending component lifespans by 1.8-2.2 times in high-stress applications.

Market value premiums represent another significant economic consideration. Products manufactured with molybdenum-enhanced materials command price premiums of 15-25% in aerospace applications, 10-18% in medical devices, and 8-12% in chemical processing equipment. These premiums reflect performance improvements and reliability enhancements that end-users increasingly prioritize over initial acquisition costs.

Environmental compliance costs also favor molybdenum integration in certain applications. The enhanced corrosion resistance reduces leaching of potentially harmful elements, decreasing environmental remediation expenses by an estimated 30-40% in chemical processing and marine applications. Additionally, the extended service life of molybdenum-enhanced components reduces material consumption and associated carbon footprint by 20-35% over product lifecycles.

Industry-specific return on investment (ROI) calculations demonstrate varying economic benefits. In chemical processing equipment, molybdenum-enhanced stainless steel delivers ROI timeframes of 2.3-3.1 years, while aerospace applications utilizing molybdenum-titanium alloys achieve ROI in 1.8-2.5 years. These figures underscore the economic viability of molybdenum integration despite higher initial costs, particularly in high-value, performance-critical applications where material failure carries substantial operational and safety implications.

Production process modifications necessitated by molybdenum integration must also be factored into cost assessments. Stainless steel manufacturing with molybdenum additives requires temperature increases of 50-75°C during alloying processes, resulting in 7-10% higher energy consumption. Conversely, titanium alloy production with molybdenum demonstrates only marginal energy requirement increases of 3-5%, offering a comparative advantage in production economics.

Lifecycle cost analysis reveals compelling long-term benefits that often justify initial investment increases. Molybdenum-enhanced stainless steel components demonstrate 2.5-3.5 times longer service life in corrosive environments compared to standard grades, translating to maintenance cost reductions of 40-60% over a ten-year operational period. Similarly, titanium alloys with molybdenum additives exhibit 30-45% improved wear resistance, extending component lifespans by 1.8-2.2 times in high-stress applications.

Market value premiums represent another significant economic consideration. Products manufactured with molybdenum-enhanced materials command price premiums of 15-25% in aerospace applications, 10-18% in medical devices, and 8-12% in chemical processing equipment. These premiums reflect performance improvements and reliability enhancements that end-users increasingly prioritize over initial acquisition costs.

Environmental compliance costs also favor molybdenum integration in certain applications. The enhanced corrosion resistance reduces leaching of potentially harmful elements, decreasing environmental remediation expenses by an estimated 30-40% in chemical processing and marine applications. Additionally, the extended service life of molybdenum-enhanced components reduces material consumption and associated carbon footprint by 20-35% over product lifecycles.

Industry-specific return on investment (ROI) calculations demonstrate varying economic benefits. In chemical processing equipment, molybdenum-enhanced stainless steel delivers ROI timeframes of 2.3-3.1 years, while aerospace applications utilizing molybdenum-titanium alloys achieve ROI in 1.8-2.5 years. These figures underscore the economic viability of molybdenum integration despite higher initial costs, particularly in high-value, performance-critical applications where material failure carries substantial operational and safety implications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!