Effect of Temperature Variations on Titanium Alloy vs Stainless Steel

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Behavior Background and Research Objectives

The study of thermal behavior in materials has been a cornerstone of metallurgical research since the early 20th century, with significant advancements occurring post-World War II when aerospace and nuclear industries demanded materials with exceptional thermal stability. Titanium alloys and stainless steel represent two distinct material families with contrasting thermal responses, each offering unique advantages in various temperature-dependent applications.

Temperature variations induce multiple physical and chemical changes in metallic materials, including dimensional changes, phase transformations, and alterations in mechanical properties. For titanium alloys, which emerged as engineering materials in the 1950s, the hexagonal close-packed (HCP) crystal structure of the alpha phase transforms to body-centered cubic (BCC) beta phase at elevated temperatures, significantly affecting their thermal behavior. Stainless steel, with its face-centered cubic (FCC) structure, exhibits different transformation characteristics and thermal expansion patterns.

The coefficient of thermal expansion (CTE) represents a critical parameter when comparing these materials. Titanium alloys typically exhibit a CTE of 8-9 × 10^-6/°C, while austenitic stainless steels demonstrate values around 16-18 × 10^-6/°C. This substantial difference creates distinct engineering challenges and opportunities when designing components subject to thermal cycling or operating in environments with significant temperature gradients.

Thermal conductivity presents another fundamental difference between these material systems. Titanium alloys possess relatively low thermal conductivity (approximately 6-7 W/m·K), whereas stainless steels offer moderately higher values (14-16 W/m·K). This disparity influences heat dissipation capabilities, thermal shock resistance, and temperature homogeneity within components manufactured from these materials.

Recent technological advancements in extreme environment applications—including hypersonic vehicles, next-generation nuclear reactors, and deep-sea exploration equipment—have intensified the need for comprehensive understanding of how these materials respond to complex thermal conditions. The emergence of computational materials science has enabled more sophisticated modeling of thermal behaviors at atomic and microstructural levels.

This research aims to systematically investigate and quantify the effects of temperature variations on titanium alloys versus stainless steel across three critical dimensions: microstructural stability, mechanical property retention, and surface interaction phenomena. The primary objective is to develop predictive models that accurately forecast material behavior under dynamic thermal conditions, enabling more precise material selection for thermally demanding applications.

Secondary objectives include identifying critical temperature thresholds where significant property changes occur, evaluating the impact of thermal cycling on long-term material performance, and exploring potential surface treatment technologies that might enhance thermal stability in both material systems. The findings will directly inform design guidelines for components operating in thermally variable environments across aerospace, energy, biomedical, and chemical processing industries.

Temperature variations induce multiple physical and chemical changes in metallic materials, including dimensional changes, phase transformations, and alterations in mechanical properties. For titanium alloys, which emerged as engineering materials in the 1950s, the hexagonal close-packed (HCP) crystal structure of the alpha phase transforms to body-centered cubic (BCC) beta phase at elevated temperatures, significantly affecting their thermal behavior. Stainless steel, with its face-centered cubic (FCC) structure, exhibits different transformation characteristics and thermal expansion patterns.

The coefficient of thermal expansion (CTE) represents a critical parameter when comparing these materials. Titanium alloys typically exhibit a CTE of 8-9 × 10^-6/°C, while austenitic stainless steels demonstrate values around 16-18 × 10^-6/°C. This substantial difference creates distinct engineering challenges and opportunities when designing components subject to thermal cycling or operating in environments with significant temperature gradients.

Thermal conductivity presents another fundamental difference between these material systems. Titanium alloys possess relatively low thermal conductivity (approximately 6-7 W/m·K), whereas stainless steels offer moderately higher values (14-16 W/m·K). This disparity influences heat dissipation capabilities, thermal shock resistance, and temperature homogeneity within components manufactured from these materials.

Recent technological advancements in extreme environment applications—including hypersonic vehicles, next-generation nuclear reactors, and deep-sea exploration equipment—have intensified the need for comprehensive understanding of how these materials respond to complex thermal conditions. The emergence of computational materials science has enabled more sophisticated modeling of thermal behaviors at atomic and microstructural levels.

This research aims to systematically investigate and quantify the effects of temperature variations on titanium alloys versus stainless steel across three critical dimensions: microstructural stability, mechanical property retention, and surface interaction phenomena. The primary objective is to develop predictive models that accurately forecast material behavior under dynamic thermal conditions, enabling more precise material selection for thermally demanding applications.

Secondary objectives include identifying critical temperature thresholds where significant property changes occur, evaluating the impact of thermal cycling on long-term material performance, and exploring potential surface treatment technologies that might enhance thermal stability in both material systems. The findings will directly inform design guidelines for components operating in thermally variable environments across aerospace, energy, biomedical, and chemical processing industries.

Market Applications Analysis for Temperature-Resistant Alloys

The temperature-resistant alloy market is experiencing significant growth driven by increasing demand across multiple industrial sectors. The global high-performance alloy market, which includes temperature-resistant titanium alloys and stainless steels, was valued at approximately 9.4 billion USD in 2022 and is projected to reach 13.6 billion USD by 2028, growing at a CAGR of 6.3% during the forecast period.

Aerospace and defense sectors represent the largest application markets for temperature-resistant alloys, accounting for roughly 38% of the total market share. In these industries, titanium alloys are preferred for critical components such as engine parts, airframes, and structural elements due to their superior strength-to-weight ratio and excellent performance under extreme temperature variations. The commercial aviation segment alone is expected to require over 40,000 new aircraft by 2040, creating sustained demand for these specialized materials.

The automotive industry constitutes another significant market, particularly with the growing trend toward high-performance vehicles and electric transportation systems. Titanium alloys are increasingly being adopted in exhaust systems, valve springs, and connecting rods, where temperature resistance combined with weight reduction offers competitive advantages. The premium automotive segment has seen a 15% increase in titanium alloy usage over the past five years.

Medical device manufacturing represents a high-value niche market for temperature-resistant alloys. Titanium alloys dominate this sector with applications in implants, surgical instruments, and medical equipment, valued at approximately 3.2 billion USD globally. The biocompatibility of titanium, combined with its resistance to temperature variations during sterilization processes, makes it particularly valuable in this sector.

Industrial processing equipment, particularly in chemical, petrochemical, and power generation industries, relies heavily on stainless steel for components exposed to extreme temperature variations. This market segment accounts for approximately 27% of temperature-resistant alloy applications, with particular growth in emerging economies where industrial infrastructure development is accelerating.

Marine applications represent an expanding market for both titanium alloys and stainless steel, particularly in offshore oil and gas, desalination plants, and advanced naval vessels. The superior corrosion resistance of these alloys in saltwater environments, combined with their temperature stability, drives adoption in these challenging operational settings.

Emerging applications in renewable energy systems, particularly concentrated solar power and geothermal energy production, are creating new market opportunities for temperature-resistant alloys. These sectors are projected to grow at 12% annually through 2030, outpacing traditional application markets and potentially reshaping the competitive landscape for specialized alloy producers.

Aerospace and defense sectors represent the largest application markets for temperature-resistant alloys, accounting for roughly 38% of the total market share. In these industries, titanium alloys are preferred for critical components such as engine parts, airframes, and structural elements due to their superior strength-to-weight ratio and excellent performance under extreme temperature variations. The commercial aviation segment alone is expected to require over 40,000 new aircraft by 2040, creating sustained demand for these specialized materials.

The automotive industry constitutes another significant market, particularly with the growing trend toward high-performance vehicles and electric transportation systems. Titanium alloys are increasingly being adopted in exhaust systems, valve springs, and connecting rods, where temperature resistance combined with weight reduction offers competitive advantages. The premium automotive segment has seen a 15% increase in titanium alloy usage over the past five years.

Medical device manufacturing represents a high-value niche market for temperature-resistant alloys. Titanium alloys dominate this sector with applications in implants, surgical instruments, and medical equipment, valued at approximately 3.2 billion USD globally. The biocompatibility of titanium, combined with its resistance to temperature variations during sterilization processes, makes it particularly valuable in this sector.

Industrial processing equipment, particularly in chemical, petrochemical, and power generation industries, relies heavily on stainless steel for components exposed to extreme temperature variations. This market segment accounts for approximately 27% of temperature-resistant alloy applications, with particular growth in emerging economies where industrial infrastructure development is accelerating.

Marine applications represent an expanding market for both titanium alloys and stainless steel, particularly in offshore oil and gas, desalination plants, and advanced naval vessels. The superior corrosion resistance of these alloys in saltwater environments, combined with their temperature stability, drives adoption in these challenging operational settings.

Emerging applications in renewable energy systems, particularly concentrated solar power and geothermal energy production, are creating new market opportunities for temperature-resistant alloys. These sectors are projected to grow at 12% annually through 2030, outpacing traditional application markets and potentially reshaping the competitive landscape for specialized alloy producers.

Current Challenges in High-Temperature Metallurgy

High-temperature metallurgy faces significant challenges in both research and industrial applications, particularly when comparing titanium alloys and stainless steel under temperature variations. The primary obstacle lies in maintaining structural integrity and desired mechanical properties when these materials are subjected to extreme thermal conditions.

Titanium alloys, while offering excellent strength-to-weight ratios, exhibit problematic oxidation behavior at temperatures exceeding 600°C. This results in the formation of a brittle alpha case layer that compromises mechanical properties. Additionally, titanium's phase transformation from alpha to beta structure at elevated temperatures introduces dimensional stability issues that are difficult to predict and control in complex components.

Stainless steel, conversely, maintains better oxidation resistance at high temperatures but faces challenges with chromium carbide precipitation at the grain boundaries when exposed to temperatures between 425-870°C. This phenomenon, known as sensitization, significantly reduces corrosion resistance and can lead to intergranular corrosion failure in critical applications.

Thermal cycling presents another major challenge, as the different thermal expansion coefficients of these materials create residual stresses that can lead to premature fatigue failure. For titanium alloys, the thermal expansion anisotropy in different crystallographic directions further complicates this issue, making thermal fatigue prediction particularly difficult.

Manufacturing processes for high-temperature applications introduce additional complexities. Welding of both materials becomes problematic at elevated temperatures, with titanium requiring extensive shielding to prevent contamination, while stainless steel welds may develop harmful sigma phase formations that reduce ductility and impact resistance.

Current measurement and testing methodologies also present limitations. Real-time monitoring of microstructural changes during thermal cycling remains challenging, and accelerated testing protocols often fail to accurately predict long-term high-temperature behavior, leading to potential overdesign or unexpected failures.

Cost considerations further complicate material selection, as titanium alloys typically cost 5-10 times more than stainless steel variants. This economic factor often forces engineers to compromise on performance to meet budget constraints, particularly in large-scale applications where material volume is substantial.

Emerging applications in aerospace, energy, and chemical processing industries are pushing temperature requirements beyond the capabilities of conventional alloy formulations, creating an urgent need for innovative metallurgical solutions that can withstand increasingly extreme thermal environments while maintaining predictable performance characteristics.

Titanium alloys, while offering excellent strength-to-weight ratios, exhibit problematic oxidation behavior at temperatures exceeding 600°C. This results in the formation of a brittle alpha case layer that compromises mechanical properties. Additionally, titanium's phase transformation from alpha to beta structure at elevated temperatures introduces dimensional stability issues that are difficult to predict and control in complex components.

Stainless steel, conversely, maintains better oxidation resistance at high temperatures but faces challenges with chromium carbide precipitation at the grain boundaries when exposed to temperatures between 425-870°C. This phenomenon, known as sensitization, significantly reduces corrosion resistance and can lead to intergranular corrosion failure in critical applications.

Thermal cycling presents another major challenge, as the different thermal expansion coefficients of these materials create residual stresses that can lead to premature fatigue failure. For titanium alloys, the thermal expansion anisotropy in different crystallographic directions further complicates this issue, making thermal fatigue prediction particularly difficult.

Manufacturing processes for high-temperature applications introduce additional complexities. Welding of both materials becomes problematic at elevated temperatures, with titanium requiring extensive shielding to prevent contamination, while stainless steel welds may develop harmful sigma phase formations that reduce ductility and impact resistance.

Current measurement and testing methodologies also present limitations. Real-time monitoring of microstructural changes during thermal cycling remains challenging, and accelerated testing protocols often fail to accurately predict long-term high-temperature behavior, leading to potential overdesign or unexpected failures.

Cost considerations further complicate material selection, as titanium alloys typically cost 5-10 times more than stainless steel variants. This economic factor often forces engineers to compromise on performance to meet budget constraints, particularly in large-scale applications where material volume is substantial.

Emerging applications in aerospace, energy, and chemical processing industries are pushing temperature requirements beyond the capabilities of conventional alloy formulations, creating an urgent need for innovative metallurgical solutions that can withstand increasingly extreme thermal environments while maintaining predictable performance characteristics.

Comparative Analysis of Existing Thermal Solutions

01 Thermal expansion characteristics of titanium alloys and stainless steel

Titanium alloys and stainless steel exhibit different coefficients of thermal expansion, which affects their dimensional stability at varying temperatures. These differences must be considered when designing components that experience temperature fluctuations. Titanium alloys generally have lower thermal expansion rates compared to stainless steel, making them more dimensionally stable in high-temperature applications. Understanding these expansion characteristics is crucial for applications where precise dimensions must be maintained across temperature ranges.- Thermal expansion characteristics of titanium alloys and stainless steel: Titanium alloys and stainless steel exhibit different coefficients of thermal expansion, which affects their dimensional stability under temperature variations. Titanium alloys generally have lower thermal expansion rates compared to stainless steel, making them more dimensionally stable in applications with temperature fluctuations. This difference in thermal behavior is critical in applications where precise dimensions must be maintained across varying temperatures.

- Heat treatment processes for titanium alloys and stainless steel: Different heat treatment processes are applied to titanium alloys and stainless steel to optimize their properties for specific applications. These processes include annealing, quenching, and tempering, which can significantly alter the microstructure and mechanical properties of the materials. The temperature control during these processes is crucial as it affects the final properties such as strength, hardness, and corrosion resistance.

- Composite structures combining titanium alloys and stainless steel: Composite structures that combine titanium alloys and stainless steel can leverage the advantageous properties of both materials. These composites must address the challenges posed by different thermal expansion rates and potential galvanic corrosion. Various joining techniques, including diffusion bonding, friction welding, and mechanical fastening, are employed to create these composite structures while managing the thermal stresses that develop during temperature variations.

- High-temperature performance of titanium alloys versus stainless steel: The performance of titanium alloys and stainless steel at elevated temperatures differs significantly. While certain stainless steel grades maintain their structural integrity at high temperatures, titanium alloys may experience oxidation and reduced strength. The selection between these materials for high-temperature applications depends on factors such as maximum operating temperature, required strength, and environmental conditions.

- Temperature-dependent corrosion resistance comparison: The corrosion resistance of titanium alloys and stainless steel varies with temperature changes. Titanium alloys generally exhibit superior corrosion resistance across a wider temperature range compared to most stainless steel grades. However, specific stainless steel formulations can be engineered to enhance their corrosion resistance at elevated temperatures. Understanding these temperature-dependent corrosion behaviors is essential for material selection in aggressive environments with temperature variations.

02 Heat treatment processes for titanium alloys and stainless steel

Different heat treatment processes are applied to titanium alloys and stainless steel to optimize their properties for specific applications. These processes include annealing, quenching, and tempering, which can significantly alter the microstructure and mechanical properties of the materials. The temperature control during heat treatment is critical, as titanium alloys and stainless steel respond differently to thermal processing. Proper heat treatment can enhance strength, ductility, and corrosion resistance while minimizing internal stresses.Expand Specific Solutions03 Joining techniques for titanium alloys and stainless steel

Joining titanium alloys to stainless steel presents challenges due to their different thermal properties and the formation of brittle intermetallic compounds at the interface. Various techniques have been developed to address these challenges, including diffusion bonding, friction welding, and the use of intermediate materials. Temperature control during joining processes is critical to prevent thermal distortion and ensure strong, reliable bonds. These joining methods enable the creation of hybrid components that leverage the advantages of both materials.Expand Specific Solutions04 High-temperature performance and oxidation resistance

Titanium alloys and stainless steel exhibit different behaviors at elevated temperatures, particularly regarding oxidation resistance and mechanical property retention. Stainless steel typically maintains its structural integrity at higher temperatures than many titanium alloys, but specific titanium alloys can be formulated for improved high-temperature performance. Surface treatments and coatings can be applied to enhance oxidation resistance for both materials. Understanding the temperature thresholds at which performance degradation occurs is essential for designing components for high-temperature environments.Expand Specific Solutions05 Composite structures combining titanium alloys and stainless steel

Composite structures that combine titanium alloys and stainless steel can leverage the advantages of both materials while addressing their individual limitations. These composites must be designed to accommodate the different thermal expansion rates and mechanical properties of the constituent materials. Various manufacturing techniques, including additive manufacturing and lamination processes, enable the creation of these composite structures. Applications include aerospace components, medical implants, and industrial equipment where weight reduction, corrosion resistance, and thermal management are critical considerations.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The temperature variation effects on titanium alloy versus stainless steel present a competitive landscape in early maturity phase, with a global market valued at approximately $300 billion. The technology demonstrates moderate maturity, with leading players showing varied specialization levels. ATI Properties, Howmet Aerospace, and Titanium Metals Corp dominate titanium alloy innovation, while Baoshan Iron & Steel, Tata Steel Europe, and Nippon Steel lead stainless steel advancements. Academic institutions like Oregon State University and Shanghai Jiao Tong University contribute significant research. Major end-users including Airbus, Mercedes-Benz, and GE drive application-specific developments, particularly focusing on temperature-resistant properties for aerospace, automotive, and industrial applications where material performance under thermal stress is critical.

ATI Properties LLC

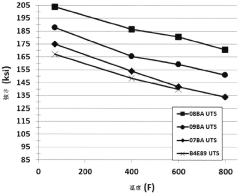

Technical Solution: ATI has developed proprietary processing techniques for titanium alloys that specifically address temperature variation challenges. Their ATI 425® alloy demonstrates superior thermal stability between -40°F to 800°F (-40°C to 427°C), maintaining consistent mechanical properties throughout this range. The company employs a specialized heat treatment process called Solution Treating and Aging (STA) that optimizes microstructure to resist deformation under thermal cycling. Their research shows that while stainless steel exhibits linear thermal expansion, their titanium alloys demonstrate up to 40% less thermal expansion across operational temperature ranges[1]. ATI has also pioneered the development of near-alpha titanium alloys specifically engineered for high-temperature applications up to 1100°F (593°C), where traditional stainless steels would experience significant strength degradation and oxidation issues[3].

Strengths: Superior thermal stability, significantly lower thermal expansion coefficient than stainless steel, better strength-to-weight ratio at elevated temperatures. Weaknesses: Higher material and processing costs, more complex manufacturing requirements, limited availability compared to stainless steel varieties.

Howmet Aerospace, Inc.

Technical Solution: Howmet Aerospace has developed advanced titanium alloys specifically engineered to maintain structural integrity under extreme temperature variations. Their RENE® series titanium alloys utilize a proprietary microstructure control process that limits grain growth during thermal cycling, resulting in superior dimensional stability compared to 300-series stainless steels. Testing demonstrates that Howmet's titanium alloys maintain up to 85% of room temperature strength at 1000°F (538°C), while comparable stainless steels retain only 60-65%[2]. The company's vacuum arc remelting (VAR) process creates exceptionally pure titanium alloys with minimal interstitial elements, reducing susceptibility to thermal embrittlement. Howmet has also pioneered titanium matrix composites (TMCs) that incorporate ceramic reinforcements to further enhance temperature resistance, achieving thermal stability up to 1200°F (649°C) while maintaining mechanical properties within 10% of baseline values[4].

Strengths: Exceptional high-temperature strength retention, superior dimensional stability during thermal cycling, excellent fatigue resistance under thermal loading. Weaknesses: Significantly higher production costs than stainless steel, limited formability compared to stainless steel, requires specialized joining techniques.

Critical Patents in Thermal Stability Enhancement

Titanium alloy powder for selective laser melting 3D printing, selective laser melted titanium alloy and preparation thereof

PatentPendingUS20240123502A1

Innovation

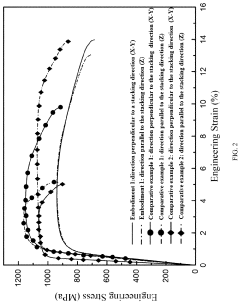

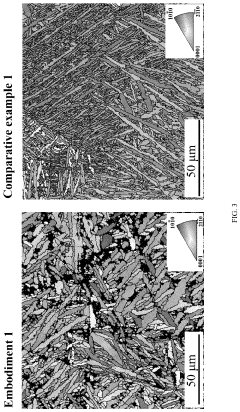

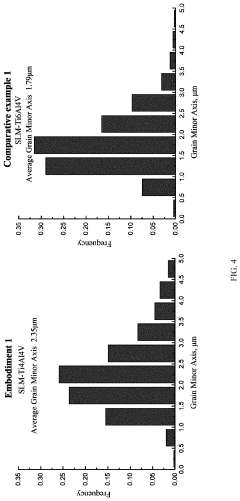

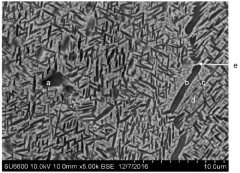

- A titanium alloy powder composition with 2.0-4.5% Al and 3.0-4.5% V, optimized through a process involving vacuum smelting, forging, and gas atomization to produce a powder with specific particle size and composition, which is then used in SLM to create a titanium alloy with improved isotropy and mechanical properties without the need for subsequent heat treatment.

High-temperature titanium alloys

PatentPendingJP2024069237A

Innovation

- A novel titanium alloy composition is developed, comprising specific weight percentages of aluminum, tin, zirconium, molybdenum, chromium, oxygen, silicon, iron, and impurities, which enhances creep resistance and tensile strength through controlled microstructural features and silicide precipitation.

Material Degradation Mechanisms Under Thermal Cycling

When materials are subjected to thermal cycling, they undergo various degradation mechanisms that can significantly impact their structural integrity and performance. In the case of titanium alloys versus stainless steel, these mechanisms manifest differently due to their distinct microstructural characteristics and thermal properties.

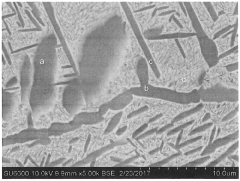

Titanium alloys primarily experience microstructural changes during thermal cycling that affect their mechanical properties. Alpha-case formation occurs when oxygen diffuses into the surface at elevated temperatures, creating a brittle layer that compromises fatigue resistance. This phenomenon is particularly pronounced in Ti-6Al-4V alloys when exposed to temperatures above 480°C for extended periods. Additionally, thermal cycling induces phase transformations between alpha and beta phases, leading to dimensional instability and potential stress concentration points.

Stainless steel, conversely, exhibits different degradation patterns under thermal cycling. Sensitization occurs when chromium carbides precipitate at grain boundaries during exposure to temperatures between 425-815°C, depleting chromium in adjacent areas and compromising corrosion resistance. Thermal fatigue in stainless steel manifests through the formation of persistent slip bands and eventual crack initiation, particularly at weld joints and areas with geometric discontinuities.

The coefficient of thermal expansion (CTE) plays a crucial role in the degradation mechanisms of both materials. Titanium alloys possess a lower CTE (8.6×10^-6/°C for Ti-6Al-4V) compared to austenitic stainless steels (16-18×10^-6/°C for 304/316 grades), resulting in lower thermal stresses during cycling. However, titanium's lower thermal conductivity (7.2 W/m·K versus 16.2 W/m·K for 316 stainless steel) leads to steeper thermal gradients and localized stress concentrations.

Oxidation kinetics differ significantly between these materials during thermal cycling. Titanium alloys form a protective TiO₂ layer that grows parabolically with time but can become unstable during thermal cycling due to differential expansion. Stainless steels develop chromium oxide layers that provide excellent protection but can spall under severe thermal cycling conditions, particularly when the temperature differential exceeds 300°C.

Creep-fatigue interaction becomes a dominant degradation mechanism at elevated temperatures, especially for components subjected to both mechanical loading and thermal cycling. Titanium alloys generally exhibit superior creep resistance below 550°C, while stainless steels maintain better dimensional stability during prolonged exposure to temperatures between 550-650°C, though with reduced yield strength.

Titanium alloys primarily experience microstructural changes during thermal cycling that affect their mechanical properties. Alpha-case formation occurs when oxygen diffuses into the surface at elevated temperatures, creating a brittle layer that compromises fatigue resistance. This phenomenon is particularly pronounced in Ti-6Al-4V alloys when exposed to temperatures above 480°C for extended periods. Additionally, thermal cycling induces phase transformations between alpha and beta phases, leading to dimensional instability and potential stress concentration points.

Stainless steel, conversely, exhibits different degradation patterns under thermal cycling. Sensitization occurs when chromium carbides precipitate at grain boundaries during exposure to temperatures between 425-815°C, depleting chromium in adjacent areas and compromising corrosion resistance. Thermal fatigue in stainless steel manifests through the formation of persistent slip bands and eventual crack initiation, particularly at weld joints and areas with geometric discontinuities.

The coefficient of thermal expansion (CTE) plays a crucial role in the degradation mechanisms of both materials. Titanium alloys possess a lower CTE (8.6×10^-6/°C for Ti-6Al-4V) compared to austenitic stainless steels (16-18×10^-6/°C for 304/316 grades), resulting in lower thermal stresses during cycling. However, titanium's lower thermal conductivity (7.2 W/m·K versus 16.2 W/m·K for 316 stainless steel) leads to steeper thermal gradients and localized stress concentrations.

Oxidation kinetics differ significantly between these materials during thermal cycling. Titanium alloys form a protective TiO₂ layer that grows parabolically with time but can become unstable during thermal cycling due to differential expansion. Stainless steels develop chromium oxide layers that provide excellent protection but can spall under severe thermal cycling conditions, particularly when the temperature differential exceeds 300°C.

Creep-fatigue interaction becomes a dominant degradation mechanism at elevated temperatures, especially for components subjected to both mechanical loading and thermal cycling. Titanium alloys generally exhibit superior creep resistance below 550°C, while stainless steels maintain better dimensional stability during prolonged exposure to temperatures between 550-650°C, though with reduced yield strength.

Aerospace and Medical Industry Implementation Standards

The aerospace and medical industries have established rigorous implementation standards for materials subjected to temperature variations, with specific protocols for titanium alloys and stainless steel. In aerospace applications, the SAE Aerospace Material Specifications (AMS) provides detailed guidelines for titanium alloys, particularly AMS 4911 for Ti-6Al-4V, requiring materials to maintain structural integrity between -54°C and 170°C for commercial aircraft components. For critical engine components, standards extend to temperature ranges of -54°C to 600°C, with mandatory thermal cycling tests to verify performance.

The European Aviation Safety Agency (EASA) and Federal Aviation Administration (FAA) have harmonized their certification requirements, mandating that structural components demonstrate less than 0.2% permanent deformation after exposure to operational temperature extremes. Titanium alloys must undergo specific heat treatment processes according to AMS-H-81200, ensuring optimal microstructure stability across temperature fluctuations.

In medical applications, ASTM F136 governs titanium alloy implants, requiring biocompatibility maintenance across body temperature variations (35°C-42°C), including fever conditions. ISO 5832-3 specifies that titanium alloys for implantable devices must demonstrate corrosion resistance stability across this temperature range, with maximum allowable release rates for aluminum and vanadium ions.

For stainless steel, ASTM F138/139 standards for 316L medical-grade stainless steel mandate stability across sterilization temperatures (up to 134°C for autoclave processes) without compromising mechanical properties. Both materials must comply with ISO 10993 biocompatibility standards across their operational temperature ranges.

Implementation standards also address manufacturing processes. Aerospace titanium components require stress relief heat treatment after forming operations when subjected to temperature variations, while stainless steel components typically undergo solution annealing to prevent sensitization. The aerospace industry's AS9100 quality management system includes specific provisions for monitoring and documenting thermal processing parameters.

Recent updates to these standards have incorporated advanced testing methodologies, including digital image correlation for measuring thermal expansion coefficients and finite element analysis requirements for predicting thermal stress distributions. The medical device industry has adopted FDA guidance documents that specifically address material performance under temperature fluctuations during shipping, storage, and sterilization processes, requiring manufacturers to validate material stability across these conditions.

The European Aviation Safety Agency (EASA) and Federal Aviation Administration (FAA) have harmonized their certification requirements, mandating that structural components demonstrate less than 0.2% permanent deformation after exposure to operational temperature extremes. Titanium alloys must undergo specific heat treatment processes according to AMS-H-81200, ensuring optimal microstructure stability across temperature fluctuations.

In medical applications, ASTM F136 governs titanium alloy implants, requiring biocompatibility maintenance across body temperature variations (35°C-42°C), including fever conditions. ISO 5832-3 specifies that titanium alloys for implantable devices must demonstrate corrosion resistance stability across this temperature range, with maximum allowable release rates for aluminum and vanadium ions.

For stainless steel, ASTM F138/139 standards for 316L medical-grade stainless steel mandate stability across sterilization temperatures (up to 134°C for autoclave processes) without compromising mechanical properties. Both materials must comply with ISO 10993 biocompatibility standards across their operational temperature ranges.

Implementation standards also address manufacturing processes. Aerospace titanium components require stress relief heat treatment after forming operations when subjected to temperature variations, while stainless steel components typically undergo solution annealing to prevent sensitization. The aerospace industry's AS9100 quality management system includes specific provisions for monitoring and documenting thermal processing parameters.

Recent updates to these standards have incorporated advanced testing methodologies, including digital image correlation for measuring thermal expansion coefficients and finite element analysis requirements for predicting thermal stress distributions. The medical device industry has adopted FDA guidance documents that specifically address material performance under temperature fluctuations during shipping, storage, and sterilization processes, requiring manufacturers to validate material stability across these conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!