Applications of Titanium Alloy vs Stainless Steel in Water Treatment Systems

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Titanium vs Steel in Water Treatment: Background & Objectives

Water treatment systems represent a critical infrastructure component in both industrial and municipal applications, with material selection playing a pivotal role in system efficiency, longevity, and performance. The evolution of materials used in water treatment has progressed significantly over the past century, from basic iron and concrete structures to advanced alloys engineered for specific water quality challenges.

Titanium alloys and stainless steel have emerged as premier materials in modern water treatment applications, each offering distinct advantages and limitations. Historically, stainless steel has dominated the market due to its cost-effectiveness and adequate corrosion resistance in many water environments. However, as treatment demands have intensified—particularly for seawater desalination, industrial wastewater processing, and ultrapure water production—titanium alloys have gained significant traction.

The technological trajectory in this field has been driven by increasingly stringent water quality standards, more aggressive treatment chemicals, and the need for extended service life under challenging conditions. Titanium's superior resistance to chlorides and other aggressive compounds has positioned it as a premium alternative in environments where stainless steel experiences accelerated corrosion.

Current industry trends indicate a growing preference for material solutions that optimize total lifecycle costs rather than focusing solely on initial investment. This shift has created opportunities for titanium alloys, which despite higher upfront costs, often demonstrate superior long-term economic value through reduced maintenance requirements and extended operational lifespans.

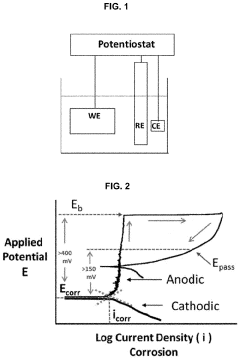

The primary technical objective of this research is to establish comprehensive comparative frameworks for evaluating titanium alloys versus stainless steel across diverse water treatment applications. This includes quantifying performance differences in critical parameters such as corrosion resistance, mechanical properties under various water chemistry conditions, and long-term reliability metrics.

Secondary objectives include identifying specific application thresholds where the transition from stainless steel to titanium becomes economically justified, mapping emerging titanium alloy innovations that may alter the competitive landscape, and evaluating hybrid systems that strategically incorporate both materials to optimize performance and cost.

This research also aims to explore how recent advancements in surface treatment technologies, such as advanced passivation techniques and protective coatings, may extend the application range of both materials, potentially reshaping traditional selection criteria. Additionally, we will examine how evolving regulatory frameworks regarding water quality and equipment longevity may influence material selection decisions in the coming decade.

Titanium alloys and stainless steel have emerged as premier materials in modern water treatment applications, each offering distinct advantages and limitations. Historically, stainless steel has dominated the market due to its cost-effectiveness and adequate corrosion resistance in many water environments. However, as treatment demands have intensified—particularly for seawater desalination, industrial wastewater processing, and ultrapure water production—titanium alloys have gained significant traction.

The technological trajectory in this field has been driven by increasingly stringent water quality standards, more aggressive treatment chemicals, and the need for extended service life under challenging conditions. Titanium's superior resistance to chlorides and other aggressive compounds has positioned it as a premium alternative in environments where stainless steel experiences accelerated corrosion.

Current industry trends indicate a growing preference for material solutions that optimize total lifecycle costs rather than focusing solely on initial investment. This shift has created opportunities for titanium alloys, which despite higher upfront costs, often demonstrate superior long-term economic value through reduced maintenance requirements and extended operational lifespans.

The primary technical objective of this research is to establish comprehensive comparative frameworks for evaluating titanium alloys versus stainless steel across diverse water treatment applications. This includes quantifying performance differences in critical parameters such as corrosion resistance, mechanical properties under various water chemistry conditions, and long-term reliability metrics.

Secondary objectives include identifying specific application thresholds where the transition from stainless steel to titanium becomes economically justified, mapping emerging titanium alloy innovations that may alter the competitive landscape, and evaluating hybrid systems that strategically incorporate both materials to optimize performance and cost.

This research also aims to explore how recent advancements in surface treatment technologies, such as advanced passivation techniques and protective coatings, may extend the application range of both materials, potentially reshaping traditional selection criteria. Additionally, we will examine how evolving regulatory frameworks regarding water quality and equipment longevity may influence material selection decisions in the coming decade.

Market Analysis for Advanced Water Treatment Materials

The global water treatment materials market is experiencing significant growth, driven by increasing water scarcity concerns, stringent environmental regulations, and rising industrial water treatment demands. Currently valued at approximately 30 billion USD, this market is projected to grow at a compound annual growth rate of 6.8% through 2028, with advanced materials segment showing particularly strong momentum.

Material selection represents a critical decision point for water treatment system manufacturers, with titanium alloys and stainless steel emerging as premium options for critical components. These materials collectively account for roughly 18% of the total materials market share in advanced water treatment applications, with stainless steel currently dominating at 15% compared to titanium's 3%.

Regional analysis reveals distinct market patterns. North America and Europe lead in titanium alloy adoption for water treatment, particularly in specialized industrial and municipal applications where lifecycle cost considerations outweigh initial investment concerns. The Asia-Pacific region represents the fastest-growing market for both materials, with China and India driving demand through massive infrastructure investments in water treatment facilities.

End-user segmentation shows municipal water treatment representing approximately 40% of the market, followed by industrial applications at 35%, and commercial systems at 25%. Within industrial applications, pharmaceutical, semiconductor, and chemical processing industries demonstrate the highest willingness to invest in titanium-based systems due to their exceptional corrosion resistance and contamination prevention capabilities.

Price sensitivity analysis indicates a significant cost differential, with titanium components typically commanding a 3-4x premium over comparable stainless steel alternatives. However, this gap has narrowed by approximately 15% over the past five years due to advancements in titanium manufacturing processes and increasing scale of production.

Market research indicates shifting customer priorities, with total cost of ownership increasingly outweighing initial acquisition costs. System longevity, maintenance requirements, and operational efficiency are gaining prominence in purchasing decisions, creating favorable conditions for titanium adoption despite its higher upfront costs.

Supply chain analysis reveals potential vulnerabilities in the titanium market, with raw material sourcing concentrated in a limited number of countries. This contrasts with the more diversified and mature supply chain for stainless steel, which offers greater price stability and availability assurance - factors that continue to influence material selection decisions among risk-averse water treatment system manufacturers.

Material selection represents a critical decision point for water treatment system manufacturers, with titanium alloys and stainless steel emerging as premium options for critical components. These materials collectively account for roughly 18% of the total materials market share in advanced water treatment applications, with stainless steel currently dominating at 15% compared to titanium's 3%.

Regional analysis reveals distinct market patterns. North America and Europe lead in titanium alloy adoption for water treatment, particularly in specialized industrial and municipal applications where lifecycle cost considerations outweigh initial investment concerns. The Asia-Pacific region represents the fastest-growing market for both materials, with China and India driving demand through massive infrastructure investments in water treatment facilities.

End-user segmentation shows municipal water treatment representing approximately 40% of the market, followed by industrial applications at 35%, and commercial systems at 25%. Within industrial applications, pharmaceutical, semiconductor, and chemical processing industries demonstrate the highest willingness to invest in titanium-based systems due to their exceptional corrosion resistance and contamination prevention capabilities.

Price sensitivity analysis indicates a significant cost differential, with titanium components typically commanding a 3-4x premium over comparable stainless steel alternatives. However, this gap has narrowed by approximately 15% over the past five years due to advancements in titanium manufacturing processes and increasing scale of production.

Market research indicates shifting customer priorities, with total cost of ownership increasingly outweighing initial acquisition costs. System longevity, maintenance requirements, and operational efficiency are gaining prominence in purchasing decisions, creating favorable conditions for titanium adoption despite its higher upfront costs.

Supply chain analysis reveals potential vulnerabilities in the titanium market, with raw material sourcing concentrated in a limited number of countries. This contrasts with the more diversified and mature supply chain for stainless steel, which offers greater price stability and availability assurance - factors that continue to influence material selection decisions among risk-averse water treatment system manufacturers.

Current Technical Challenges in Corrosion-Resistant Materials

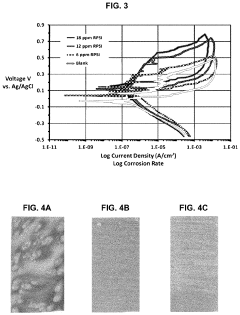

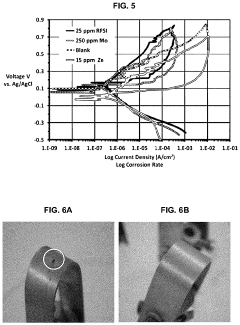

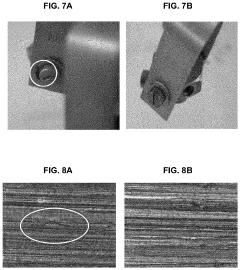

Despite significant advancements in corrosion-resistant materials for water treatment systems, both titanium alloys and stainless steel face persistent technical challenges that limit their optimal application. Stainless steel, while widely adopted, continues to struggle with pitting corrosion when exposed to chloride-rich environments common in desalination and wastewater treatment facilities. Even high-grade 316L stainless steel exhibits vulnerability to localized corrosion at weld seams and crevices, particularly in environments with elevated temperatures above 60°C.

Titanium alloys, though superior in corrosion resistance, present significant manufacturing challenges including complex machining requirements, specialized welding techniques, and limited formability compared to stainless steel. The high reactivity of titanium during fabrication necessitates stringent control of processing environments to prevent oxygen and nitrogen contamination, which can lead to embrittlement and reduced mechanical properties.

Cost-effectiveness remains a critical challenge for both materials. Titanium's raw material cost (5-10 times higher than stainless steel) creates significant barriers to widespread adoption despite its superior performance in aggressive environments. Meanwhile, stainless steel faces challenges in maintaining consistent quality across global supply chains, with variations in elemental composition affecting corrosion resistance properties.

Surface modification technologies present ongoing challenges for both materials. While various treatments exist to enhance corrosion resistance, achieving uniform, durable surface modifications that withstand the harsh conditions of water treatment systems remains problematic. Techniques such as passivation, electropolishing, and advanced coatings often demonstrate inconsistent performance in long-term field applications.

The development of hybrid or composite materials that combine the beneficial properties of both titanium and stainless steel represents an emerging challenge. Current joining technologies struggle to create reliable interfaces between dissimilar metals while maintaining structural integrity and corrosion resistance at the junction points.

Sustainability considerations add another dimension to material selection challenges. Life cycle assessments reveal that while titanium's longevity may offset its higher initial environmental impact from energy-intensive production, the recycling infrastructure for titanium remains less developed than for stainless steel, creating end-of-life management challenges.

Predictive modeling of corrosion behavior presents significant technical hurdles. Current computational models struggle to accurately predict long-term material performance in complex water chemistry environments, particularly when considering the synergistic effects of multiple corrosive agents, microbiologically influenced corrosion, and varying operational conditions typical in water treatment systems.

Titanium alloys, though superior in corrosion resistance, present significant manufacturing challenges including complex machining requirements, specialized welding techniques, and limited formability compared to stainless steel. The high reactivity of titanium during fabrication necessitates stringent control of processing environments to prevent oxygen and nitrogen contamination, which can lead to embrittlement and reduced mechanical properties.

Cost-effectiveness remains a critical challenge for both materials. Titanium's raw material cost (5-10 times higher than stainless steel) creates significant barriers to widespread adoption despite its superior performance in aggressive environments. Meanwhile, stainless steel faces challenges in maintaining consistent quality across global supply chains, with variations in elemental composition affecting corrosion resistance properties.

Surface modification technologies present ongoing challenges for both materials. While various treatments exist to enhance corrosion resistance, achieving uniform, durable surface modifications that withstand the harsh conditions of water treatment systems remains problematic. Techniques such as passivation, electropolishing, and advanced coatings often demonstrate inconsistent performance in long-term field applications.

The development of hybrid or composite materials that combine the beneficial properties of both titanium and stainless steel represents an emerging challenge. Current joining technologies struggle to create reliable interfaces between dissimilar metals while maintaining structural integrity and corrosion resistance at the junction points.

Sustainability considerations add another dimension to material selection challenges. Life cycle assessments reveal that while titanium's longevity may offset its higher initial environmental impact from energy-intensive production, the recycling infrastructure for titanium remains less developed than for stainless steel, creating end-of-life management challenges.

Predictive modeling of corrosion behavior presents significant technical hurdles. Current computational models struggle to accurately predict long-term material performance in complex water chemistry environments, particularly when considering the synergistic effects of multiple corrosive agents, microbiologically influenced corrosion, and varying operational conditions typical in water treatment systems.

Comparative Performance of Titanium Alloys vs Stainless Steel

01 Joining methods for titanium alloy and stainless steel

Various joining techniques can be employed to connect titanium alloy and stainless steel components, including diffusion bonding, friction welding, and explosive welding. These methods overcome the challenges of joining dissimilar metals with different thermal expansion coefficients and mechanical properties. Intermediate layers or transition materials are often used to mitigate the formation of brittle intermetallic compounds at the joint interface, resulting in stronger and more reliable connections.- Joining methods for titanium alloy and stainless steel: Various techniques are employed to join titanium alloy and stainless steel components, including diffusion bonding, explosive welding, and friction stir welding. These methods overcome the challenges of joining dissimilar metals with different thermal expansion coefficients and mechanical properties. Intermediate layers or transition materials are often used to reduce stress concentration and prevent the formation of brittle intermetallic compounds at the joint interface.

- Composite structures combining titanium alloy and stainless steel: Composite structures that integrate titanium alloy and stainless steel take advantage of the beneficial properties of both materials. These structures are designed to optimize weight, strength, corrosion resistance, and cost-effectiveness. Applications include aerospace components, medical implants, and industrial equipment where specific performance requirements necessitate the strategic placement of each material within the composite structure.

- Surface treatment and coating technologies: Surface treatments and coating technologies are applied to titanium alloy and stainless steel interfaces to enhance compatibility, prevent galvanic corrosion, and improve overall performance. These include physical vapor deposition, chemical vapor deposition, nitriding, and the application of specialized interlayers. Such treatments modify the surface properties to create more favorable conditions for bonding or to provide protective barriers between the dissimilar metals.

- Corrosion resistance enhancement in titanium-stainless steel systems: Methods to enhance corrosion resistance in systems containing both titanium alloy and stainless steel focus on preventing galvanic corrosion that naturally occurs when these dissimilar metals are in contact. Techniques include the use of insulating materials between the metals, application of protective coatings, cathodic protection systems, and the development of specialized transition joints. These approaches are crucial for applications in marine environments, chemical processing, and medical implants.

- Manufacturing processes for titanium-stainless steel components: Specialized manufacturing processes have been developed for producing components that incorporate both titanium alloy and stainless steel. These include advanced casting techniques, powder metallurgy, additive manufacturing, and hybrid manufacturing approaches. These processes enable the creation of complex geometries and functionally graded materials that smoothly transition between the properties of titanium alloy and stainless steel, optimizing performance while minimizing manufacturing challenges.

02 Corrosion resistance enhancement in titanium-stainless steel systems

Techniques for improving the corrosion resistance of titanium alloy and stainless steel combinations include surface treatments, protective coatings, and the use of specialized alloy compositions. These approaches help prevent galvanic corrosion that commonly occurs when these dissimilar metals are in contact, especially in aggressive environments. Surface modifications such as nitriding, carburizing, or applying ceramic coatings can significantly extend the service life of components made from these materials.Expand Specific Solutions03 Composite structures combining titanium alloy and stainless steel

Composite structures that integrate titanium alloy and stainless steel leverage the advantageous properties of both materials. These hybrid components utilize titanium's high strength-to-weight ratio and excellent corrosion resistance alongside stainless steel's durability and cost-effectiveness. Applications include aerospace components, medical implants, and industrial equipment where weight reduction, corrosion resistance, and mechanical strength are critical factors. Manufacturing techniques for these composites often involve specialized bonding processes or gradient material transitions.Expand Specific Solutions04 Surface treatment and coating technologies

Surface treatment and coating technologies for titanium alloy and stainless steel components include physical vapor deposition, chemical vapor deposition, thermal spraying, and electroplating. These processes can modify surface properties to enhance wear resistance, reduce friction, improve biocompatibility, or provide decorative finishes. Advanced coatings can also create functional surfaces with properties such as self-cleaning, anti-icing, or antimicrobial characteristics while maintaining the core mechanical properties of the base metals.Expand Specific Solutions05 Manufacturing processes for titanium-stainless steel components

Specialized manufacturing processes have been developed for producing components that incorporate both titanium alloy and stainless steel. These include additive manufacturing techniques like selective laser melting, electron beam melting, and directed energy deposition that can create functionally graded materials. Other approaches involve precision machining, forming, and assembly methods tailored to the unique properties of these materials. These manufacturing innovations enable the production of complex geometries and integrated components that would be difficult to achieve with conventional methods.Expand Specific Solutions

Leading Manufacturers and Industry Competitors Analysis

The water treatment systems market is currently in a growth phase, with increasing demand driven by water scarcity and stricter environmental regulations. The global market size is projected to reach $450 billion by 2026, with titanium alloys gaining traction against traditional stainless steel solutions. Technologically, companies like Titanium Metals Corp. and DuPont are advancing titanium alloy applications for superior corrosion resistance and longer service life, while established players such as NIPPON STEEL, Kobe Steel, and ChemTreat continue to innovate with improved stainless steel formulations. Research institutions including Naval Research Laboratory and Nanjing University are developing hybrid solutions that optimize cost-performance ratios. The competition is intensifying as water treatment specialists like Organo Corp. and Refined Technologies partner with material suppliers to create application-specific solutions.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed a comprehensive material selection framework for water treatment applications that strategically employs both titanium alloys and specialized stainless steels. Their approach centers on their proprietary NSSC™ series of high-performance stainless steels with enhanced molybdenum content (up to 6%) specifically engineered for water treatment environments. For seawater applications and highly corrosive industrial wastewater treatment, NIPPON STEEL utilizes their Super-TIX™ titanium alloys, particularly grades with added palladium or ruthenium that demonstrate superior crevice corrosion resistance even at elevated temperatures[1]. Their research has established specific chloride concentration and temperature thresholds that determine optimal material selection between titanium and stainless steel, with titanium alloys showing clear advantages in environments exceeding 200 ppm chlorides at temperatures above 50°C[3]. NIPPON STEEL has also pioneered cost-effective titanium-clad stainless steel plates that combine the corrosion resistance of titanium with the structural properties and lower cost of stainless steel, particularly valuable for large vessels and heat exchangers in water treatment facilities.

Strengths: Comprehensive material selection methodology based on extensive corrosion testing data, specialized alloy formulations for specific water treatment challenges, and innovative composite materials that optimize performance and cost. Weaknesses: Premium specialized alloys command significantly higher prices than standard materials, complex manufacturing processes for titanium-clad products limit production capacity, and implementation requires sophisticated corrosion engineering expertise.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed a sophisticated material selection system for water treatment applications that leverages both their KOBELCO titanium alloys and specialized stainless steel products. Their approach centers on corrosion resistance mapping that precisely identifies optimal material choices based on specific water chemistry parameters. For brackish water and seawater applications, Kobe Steel employs their proprietary KS Ti-9 titanium alloy with enhanced resistance to crevice corrosion through the addition of 0.2% palladium, demonstrating corrosion rates below 0.001 mm/year even in high-chloride environments at elevated temperatures[2]. Their research has established that while 316L stainless steel experiences rapid pitting corrosion at chloride concentrations above 1000 ppm, their titanium solutions maintain structural integrity indefinitely. For municipal water treatment with moderate corrosion challenges, Kobe Steel utilizes their specialized duplex stainless steel (KS-2205) with precisely controlled nitrogen content to enhance pitting resistance while maintaining cost advantages over titanium[4]. Additionally, Kobe Steel has pioneered explosion-bonded titanium-steel composite plates that provide an economical solution for large surface area applications like clarifiers and settling tanks.

Strengths: Precise material selection guidance based on water chemistry parameters, exceptional corrosion performance in high-chloride environments, and innovative composite materials that balance performance and cost considerations. Weaknesses: Higher initial investment costs for titanium components, more complex fabrication requirements compared to standard stainless steel, and limited global supply chain for specialized titanium alloys.

Key Material Science Innovations and Patents

Corrosion control of stainless steels in water systems using tin corrosion inhibitor with a hydroxycarboxylic acid

PatentPendingUS20220205112A1

Innovation

- A method using a combination of stannous salts as Tin(II) corrosion inhibitors with hydroxycarboxylic acid promoters to form a synergistic Reactive Polyhydroxy Starch Inhibitor (RPSI) that effectively chelates Tin(II) and forms a resilient protective film on stainless steel surfaces, reducing the need for high concentrations of inhibitors and promoting long-term corrosion resistance.

Corrosion resistant coatings

PatentInactiveUS20220018012A1

Innovation

- A physical vapor deposition (PVD) method, specifically cathodic arc deposition, is used to apply a titanium aluminum nitride (TiAlN) coating with a higher aluminum to titanium ratio, forming a wurtzite phase that enhances corrosion and erosion resistance by suppressing diffusion and oxidation processes while maintaining mechanical properties.

Lifecycle Cost Analysis and ROI Considerations

When evaluating the economic viability of titanium alloy versus stainless steel in water treatment systems, lifecycle cost analysis provides critical insights beyond initial investment considerations. Titanium alloys typically command a premium price point, with initial costs approximately 3-5 times higher than comparable stainless steel components. This significant upfront investment often presents a barrier to adoption despite titanium's superior technical properties.

However, the extended service life of titanium components fundamentally alters the long-term economic equation. While stainless steel parts in water treatment facilities typically require replacement every 5-7 years depending on water chemistry and operational conditions, titanium components frequently maintain operational integrity for 15-20 years or more. This extended replacement cycle dramatically reduces maintenance downtime and associated labor costs.

Maintenance cost differentials further enhance titanium's economic proposition. Stainless steel systems require more frequent inspection, cleaning to remove scale buildup, and remediation of corrosion issues. These recurring maintenance activities typically add 15-20% annually to the original equipment cost. Titanium systems, with their superior corrosion resistance, generally incur maintenance costs of only 5-8% of initial investment annually.

Energy efficiency considerations also favor titanium in many applications. The superior heat transfer properties of titanium allow for more efficient thermal exchange in heating and cooling processes within water treatment systems. Studies indicate energy savings of 7-12% in systems utilizing titanium heat exchangers compared to stainless steel alternatives, yielding substantial operational cost reductions over the equipment lifecycle.

Return on investment calculations typically demonstrate that titanium installations reach cost parity with stainless steel within 7-9 years of operation in standard municipal water treatment applications. For industrial applications involving aggressive chemicals or seawater, this breakeven point can occur even earlier, sometimes within 4-6 years. The net present value analysis, when calculated over a 20-year operational period, typically favors titanium by 15-30% depending on specific application parameters and discount rates.

Environmental cost considerations, while more difficult to quantify precisely, further strengthen titanium's economic case. Reduced chemical treatment requirements, lower energy consumption, and decreased waste generation from replacement parts contribute to a more favorable environmental footprint, potentially offering additional economic advantages as environmental regulations and carbon pricing mechanisms evolve.

However, the extended service life of titanium components fundamentally alters the long-term economic equation. While stainless steel parts in water treatment facilities typically require replacement every 5-7 years depending on water chemistry and operational conditions, titanium components frequently maintain operational integrity for 15-20 years or more. This extended replacement cycle dramatically reduces maintenance downtime and associated labor costs.

Maintenance cost differentials further enhance titanium's economic proposition. Stainless steel systems require more frequent inspection, cleaning to remove scale buildup, and remediation of corrosion issues. These recurring maintenance activities typically add 15-20% annually to the original equipment cost. Titanium systems, with their superior corrosion resistance, generally incur maintenance costs of only 5-8% of initial investment annually.

Energy efficiency considerations also favor titanium in many applications. The superior heat transfer properties of titanium allow for more efficient thermal exchange in heating and cooling processes within water treatment systems. Studies indicate energy savings of 7-12% in systems utilizing titanium heat exchangers compared to stainless steel alternatives, yielding substantial operational cost reductions over the equipment lifecycle.

Return on investment calculations typically demonstrate that titanium installations reach cost parity with stainless steel within 7-9 years of operation in standard municipal water treatment applications. For industrial applications involving aggressive chemicals or seawater, this breakeven point can occur even earlier, sometimes within 4-6 years. The net present value analysis, when calculated over a 20-year operational period, typically favors titanium by 15-30% depending on specific application parameters and discount rates.

Environmental cost considerations, while more difficult to quantify precisely, further strengthen titanium's economic case. Reduced chemical treatment requirements, lower energy consumption, and decreased waste generation from replacement parts contribute to a more favorable environmental footprint, potentially offering additional economic advantages as environmental regulations and carbon pricing mechanisms evolve.

Environmental Impact and Sustainability Assessment

The environmental impact assessment of titanium alloy versus stainless steel in water treatment systems reveals significant differences in their ecological footprints. Titanium alloy production requires approximately 5-7 times more energy than stainless steel manufacturing, primarily due to the complex extraction and processing of titanium ore. This higher energy demand translates to greater carbon emissions during the production phase, with titanium alloy manufacturing generating an estimated 35-40 kg CO2 equivalent per kilogram of material compared to stainless steel's 6-8 kg CO2 equivalent.

However, the lifecycle analysis presents a more nuanced picture. Titanium alloys demonstrate superior corrosion resistance in water treatment environments, particularly in applications involving aggressive chemicals, high chloride content, or varying pH levels. This exceptional durability extends service life by 2-3 times compared to stainless steel alternatives, reducing the frequency of replacement and associated environmental impacts of manufacturing new components.

The recyclability metrics for both materials are favorable, with titanium maintaining approximately 95% of its value in recycling processes versus 80-85% for stainless steel. The closed-loop potential for titanium is particularly noteworthy, as it can be recycled repeatedly without significant degradation in performance properties, contributing to circular economy principles in water treatment infrastructure.

Water quality implications also favor titanium in certain applications. The negligible leaching characteristics of titanium alloys (typically <0.001 mg/L of metal ions) compared to stainless steel (0.01-0.05 mg/L depending on grade) result in reduced contamination risks, particularly in sensitive drinking water applications or pharmaceutical-grade water treatment systems.

From a chemical consumption perspective, titanium-based systems often require fewer treatment chemicals due to their inertness and resistance to biofouling. Studies indicate a 15-20% reduction in chemical usage for titanium equipment, translating to decreased chemical manufacturing and transportation impacts throughout the system lifecycle.

End-of-life considerations reveal that while both materials are highly recyclable, the embedded energy value in titanium makes its recovery more economically viable despite higher initial costs. The environmental payback period for titanium systems typically ranges from 8-12 years depending on application intensity, after which their environmental advantages become increasingly pronounced compared to stainless steel alternatives.

When evaluating total environmental impact across the complete lifecycle, titanium alloys demonstrate superior performance in water treatment applications with aggressive conditions or where system longevity is prioritized, while stainless steel remains environmentally preferable for less demanding, shorter-term applications where initial production impacts dominate the assessment.

However, the lifecycle analysis presents a more nuanced picture. Titanium alloys demonstrate superior corrosion resistance in water treatment environments, particularly in applications involving aggressive chemicals, high chloride content, or varying pH levels. This exceptional durability extends service life by 2-3 times compared to stainless steel alternatives, reducing the frequency of replacement and associated environmental impacts of manufacturing new components.

The recyclability metrics for both materials are favorable, with titanium maintaining approximately 95% of its value in recycling processes versus 80-85% for stainless steel. The closed-loop potential for titanium is particularly noteworthy, as it can be recycled repeatedly without significant degradation in performance properties, contributing to circular economy principles in water treatment infrastructure.

Water quality implications also favor titanium in certain applications. The negligible leaching characteristics of titanium alloys (typically <0.001 mg/L of metal ions) compared to stainless steel (0.01-0.05 mg/L depending on grade) result in reduced contamination risks, particularly in sensitive drinking water applications or pharmaceutical-grade water treatment systems.

From a chemical consumption perspective, titanium-based systems often require fewer treatment chemicals due to their inertness and resistance to biofouling. Studies indicate a 15-20% reduction in chemical usage for titanium equipment, translating to decreased chemical manufacturing and transportation impacts throughout the system lifecycle.

End-of-life considerations reveal that while both materials are highly recyclable, the embedded energy value in titanium makes its recovery more economically viable despite higher initial costs. The environmental payback period for titanium systems typically ranges from 8-12 years depending on application intensity, after which their environmental advantages become increasingly pronounced compared to stainless steel alternatives.

When evaluating total environmental impact across the complete lifecycle, titanium alloys demonstrate superior performance in water treatment applications with aggressive conditions or where system longevity is prioritized, while stainless steel remains environmentally preferable for less demanding, shorter-term applications where initial production impacts dominate the assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!