How Do Temperature and Pressure Affect Titanium Alloy vs Stainless Steel

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Titanium and Steel Materials Background and Research Objectives

Titanium alloys and stainless steel represent two of the most significant metallic materials in modern engineering applications. The development of titanium as an industrial material began in the 1940s, primarily driven by aerospace and military requirements for high-strength, lightweight materials capable of withstanding extreme conditions. Stainless steel, with its earlier industrial adoption dating back to the early 20th century, has evolved through numerous iterations to become a versatile material across multiple sectors.

The fundamental difference between these materials lies in their atomic structure and composition. Titanium alloys typically contain elements such as aluminum, vanadium, and molybdenum, creating materials with exceptional strength-to-weight ratios. Stainless steel, characterized by a minimum of 10.5% chromium content, derives its corrosion resistance from the formation of a passive chromium oxide layer.

Temperature and pressure represent critical environmental factors that significantly influence the performance characteristics of both materials. Understanding these influences is essential for appropriate material selection in applications ranging from aerospace components to medical implants and chemical processing equipment. The thermal expansion coefficients, phase transformation temperatures, and pressure-induced deformation mechanisms differ substantially between titanium alloys and stainless steel.

Recent technological advancements have expanded the application boundaries for both materials, creating new challenges in understanding their behavior under increasingly extreme conditions. The push toward higher operating temperatures in aerospace engines, deeper subsea exploration, and more aggressive chemical processing environments necessitates a comprehensive understanding of material response under combined temperature and pressure effects.

This research aims to systematically investigate and compare the mechanical, chemical, and microstructural responses of titanium alloys and stainless steel under varying temperature and pressure conditions. Specifically, we seek to establish quantitative relationships between these environmental parameters and key performance metrics including yield strength, ultimate tensile strength, fatigue resistance, and corrosion behavior.

The objectives include developing predictive models for material behavior under combined thermal and pressure loading, identifying critical threshold points where performance characteristics significantly change, and establishing optimized selection criteria for engineering applications. Additionally, this research will explore potential synergistic effects where the combination of temperature and pressure produces behaviors not predictable from single-factor testing.

By establishing a comprehensive understanding of these relationships, this research will contribute to more efficient material selection processes, enhanced component design methodologies, and potentially identify opportunities for novel material development tailored to specific temperature-pressure profiles.

The fundamental difference between these materials lies in their atomic structure and composition. Titanium alloys typically contain elements such as aluminum, vanadium, and molybdenum, creating materials with exceptional strength-to-weight ratios. Stainless steel, characterized by a minimum of 10.5% chromium content, derives its corrosion resistance from the formation of a passive chromium oxide layer.

Temperature and pressure represent critical environmental factors that significantly influence the performance characteristics of both materials. Understanding these influences is essential for appropriate material selection in applications ranging from aerospace components to medical implants and chemical processing equipment. The thermal expansion coefficients, phase transformation temperatures, and pressure-induced deformation mechanisms differ substantially between titanium alloys and stainless steel.

Recent technological advancements have expanded the application boundaries for both materials, creating new challenges in understanding their behavior under increasingly extreme conditions. The push toward higher operating temperatures in aerospace engines, deeper subsea exploration, and more aggressive chemical processing environments necessitates a comprehensive understanding of material response under combined temperature and pressure effects.

This research aims to systematically investigate and compare the mechanical, chemical, and microstructural responses of titanium alloys and stainless steel under varying temperature and pressure conditions. Specifically, we seek to establish quantitative relationships between these environmental parameters and key performance metrics including yield strength, ultimate tensile strength, fatigue resistance, and corrosion behavior.

The objectives include developing predictive models for material behavior under combined thermal and pressure loading, identifying critical threshold points where performance characteristics significantly change, and establishing optimized selection criteria for engineering applications. Additionally, this research will explore potential synergistic effects where the combination of temperature and pressure produces behaviors not predictable from single-factor testing.

By establishing a comprehensive understanding of these relationships, this research will contribute to more efficient material selection processes, enhanced component design methodologies, and potentially identify opportunities for novel material development tailored to specific temperature-pressure profiles.

Market Applications and Industry Demand Analysis

The market for materials that can withstand extreme temperature and pressure conditions continues to expand across multiple industries. Titanium alloys and stainless steel represent two premium material choices with distinct performance characteristics under varying environmental conditions, driving specific market demands in different sectors.

In aerospace and defense, the demand for titanium alloys has seen consistent growth due to their superior strength-to-weight ratio and performance at elevated temperatures. Market analysis indicates that aircraft engine components and structural elements requiring operation in temperature ranges of 400-600°C predominantly utilize titanium alloys, particularly in next-generation commercial and military aircraft. The aerospace titanium market currently represents approximately 50% of all titanium consumption globally.

The oil and gas industry demonstrates strong demand for both materials, with distinct application profiles based on operating conditions. Deep-sea exploration equipment operating under extreme pressures (often exceeding 15,000 psi) and corrosive environments increasingly specifies super duplex stainless steel variants. Meanwhile, high-temperature downhole tools and components exposed to both pressure and temperature extremes often utilize titanium alloys, particularly in sour well environments where hydrogen sulfide is present.

Medical device manufacturing represents another significant market driver, with titanium alloys dominating in implantable devices due to their biocompatibility and mechanical properties that closely match human bone. The orthopedic implant segment alone has demonstrated consistent annual growth rates between 5-7% globally, with titanium alloys capturing the premium segment of this market.

Chemical processing industries primarily favor stainless steel for pressure vessels and reactors operating at moderate temperatures (below 550°C) due to cost considerations and established fabrication infrastructure. However, specialized chemical processes involving highly corrosive media at elevated temperatures increasingly specify titanium equipment, creating a growing niche market segment.

Power generation represents a balanced market for both materials. Traditional fossil fuel plants predominantly utilize stainless steel for steam systems and pressure components, while advanced nuclear designs and concentrated solar power systems increasingly specify titanium alloys for critical components exposed to both temperature and pressure extremes.

Market forecasts indicate continued growth in demand for both materials, with titanium experiencing faster percentage growth in high-value applications where performance justifies the premium cost. Stainless steel maintains dominant market share in moderate condition applications due to its established supply chain and cost advantages. The ongoing development of new alloy variants for both material families continues to expand their respective application envelopes and market potential.

In aerospace and defense, the demand for titanium alloys has seen consistent growth due to their superior strength-to-weight ratio and performance at elevated temperatures. Market analysis indicates that aircraft engine components and structural elements requiring operation in temperature ranges of 400-600°C predominantly utilize titanium alloys, particularly in next-generation commercial and military aircraft. The aerospace titanium market currently represents approximately 50% of all titanium consumption globally.

The oil and gas industry demonstrates strong demand for both materials, with distinct application profiles based on operating conditions. Deep-sea exploration equipment operating under extreme pressures (often exceeding 15,000 psi) and corrosive environments increasingly specifies super duplex stainless steel variants. Meanwhile, high-temperature downhole tools and components exposed to both pressure and temperature extremes often utilize titanium alloys, particularly in sour well environments where hydrogen sulfide is present.

Medical device manufacturing represents another significant market driver, with titanium alloys dominating in implantable devices due to their biocompatibility and mechanical properties that closely match human bone. The orthopedic implant segment alone has demonstrated consistent annual growth rates between 5-7% globally, with titanium alloys capturing the premium segment of this market.

Chemical processing industries primarily favor stainless steel for pressure vessels and reactors operating at moderate temperatures (below 550°C) due to cost considerations and established fabrication infrastructure. However, specialized chemical processes involving highly corrosive media at elevated temperatures increasingly specify titanium equipment, creating a growing niche market segment.

Power generation represents a balanced market for both materials. Traditional fossil fuel plants predominantly utilize stainless steel for steam systems and pressure components, while advanced nuclear designs and concentrated solar power systems increasingly specify titanium alloys for critical components exposed to both temperature and pressure extremes.

Market forecasts indicate continued growth in demand for both materials, with titanium experiencing faster percentage growth in high-value applications where performance justifies the premium cost. Stainless steel maintains dominant market share in moderate condition applications due to its established supply chain and cost advantages. The ongoing development of new alloy variants for both material families continues to expand their respective application envelopes and market potential.

Current Challenges in High-Temperature and High-Pressure Environments

The extreme conditions of high temperature and pressure present significant challenges for materials used in critical applications. Both titanium alloys and stainless steel face performance limitations when exposed to these harsh environments, though their failure mechanisms differ substantially. At temperatures exceeding 500°C, titanium alloys begin to experience accelerated oxidation, forming a brittle oxide layer that compromises structural integrity. This oxidation rate increases exponentially with temperature, creating a practical ceiling for titanium applications in high-temperature settings without specialized protective coatings.

Pressure compounds these challenges by introducing stress states that can activate deformation mechanisms not present under normal conditions. For titanium alloys, high-pressure environments can trigger phase transformations that alter mechanical properties unpredictably, particularly when combined with elevated temperatures. The α to β phase transition becomes especially problematic in these conditions, leading to microstructural instability.

Stainless steel faces different but equally significant challenges. While generally more resistant to high temperatures than titanium alloys, austenitic stainless steels suffer from sensitization between 425-870°C, where chromium carbides precipitate at grain boundaries, depleting chromium in adjacent areas and compromising corrosion resistance. This phenomenon, known as intergranular corrosion, represents a major limitation in high-temperature applications.

The synergistic effects of temperature and pressure create particularly complex failure modes. In high-pressure steam environments, for instance, both materials experience accelerated creep rates that significantly reduce service life. Hydrogen embrittlement becomes more pronounced under pressure, especially for titanium alloys, which can absorb hydrogen to form brittle hydrides that drastically reduce ductility and toughness.

Current manufacturing processes also struggle to produce components that maintain consistent properties under extreme conditions. Welded joints in both materials become particularly vulnerable points, with heat-affected zones showing altered microstructures and reduced performance under combined temperature-pressure stresses.

The aerospace and energy sectors face particularly acute challenges, as they require materials that can withstand both thermal cycling and pressure fluctuations without dimensional instability or property degradation. Conventional titanium alloys and stainless steels often fall short of these demanding requirements, necessitating expensive over-engineering or frequent replacement cycles.

Surface degradation mechanisms present another significant challenge. High-temperature oxidation combined with pressure-induced stress can accelerate surface wear through complex tribocorrosion mechanisms. This is especially problematic in applications like chemical processing equipment and aerospace components where surface integrity directly impacts functionality and safety.

Pressure compounds these challenges by introducing stress states that can activate deformation mechanisms not present under normal conditions. For titanium alloys, high-pressure environments can trigger phase transformations that alter mechanical properties unpredictably, particularly when combined with elevated temperatures. The α to β phase transition becomes especially problematic in these conditions, leading to microstructural instability.

Stainless steel faces different but equally significant challenges. While generally more resistant to high temperatures than titanium alloys, austenitic stainless steels suffer from sensitization between 425-870°C, where chromium carbides precipitate at grain boundaries, depleting chromium in adjacent areas and compromising corrosion resistance. This phenomenon, known as intergranular corrosion, represents a major limitation in high-temperature applications.

The synergistic effects of temperature and pressure create particularly complex failure modes. In high-pressure steam environments, for instance, both materials experience accelerated creep rates that significantly reduce service life. Hydrogen embrittlement becomes more pronounced under pressure, especially for titanium alloys, which can absorb hydrogen to form brittle hydrides that drastically reduce ductility and toughness.

Current manufacturing processes also struggle to produce components that maintain consistent properties under extreme conditions. Welded joints in both materials become particularly vulnerable points, with heat-affected zones showing altered microstructures and reduced performance under combined temperature-pressure stresses.

The aerospace and energy sectors face particularly acute challenges, as they require materials that can withstand both thermal cycling and pressure fluctuations without dimensional instability or property degradation. Conventional titanium alloys and stainless steels often fall short of these demanding requirements, necessitating expensive over-engineering or frequent replacement cycles.

Surface degradation mechanisms present another significant challenge. High-temperature oxidation combined with pressure-induced stress can accelerate surface wear through complex tribocorrosion mechanisms. This is especially problematic in applications like chemical processing equipment and aerospace components where surface integrity directly impacts functionality and safety.

Comparative Analysis of Current Material Solutions

01 Temperature effects on titanium alloy and stainless steel properties

Temperature significantly affects the mechanical and physical properties of titanium alloys and stainless steel. At elevated temperatures, both materials may experience changes in strength, ductility, and corrosion resistance. Titanium alloys generally maintain better strength-to-weight ratios at high temperatures compared to stainless steel, but may undergo phase transformations that alter their properties. Stainless steel exhibits good oxidation resistance at high temperatures but may suffer from reduced mechanical strength.- Temperature effects on titanium alloy and stainless steel properties: Temperature significantly affects the mechanical and physical properties of titanium alloys and stainless steel. At elevated temperatures, these materials may experience changes in strength, ductility, and corrosion resistance. Titanium alloys generally maintain their strength at higher temperatures compared to many other metals, while stainless steel may undergo phase transformations that alter its properties. Understanding these temperature effects is crucial for applications in high-temperature environments such as aerospace, power generation, and chemical processing.

- Pressure effects on titanium alloy and stainless steel performance: Pressure conditions significantly impact the performance and behavior of titanium alloys and stainless steel. Under high-pressure environments, these materials may exhibit altered mechanical properties, including changes in yield strength and fatigue resistance. The pressure effects are particularly important in applications such as deep-sea equipment, pressure vessels, and hydraulic systems. The combination of pressure with other environmental factors can also influence the long-term durability and reliability of these materials.

- Combined temperature and pressure effects on material interfaces: When titanium alloys and stainless steel are used together in composite structures or joints, the combined effects of temperature and pressure can create unique challenges. Differential thermal expansion rates between these materials can generate internal stresses at interfaces, potentially leading to deformation or failure. These effects are particularly important in applications involving thermal cycling or pressure fluctuations, such as heat exchangers, pressure vessels, and aerospace components. Proper design considerations must account for these interface behaviors under varying temperature and pressure conditions.

- Manufacturing processes influenced by temperature and pressure: Temperature and pressure are critical parameters in manufacturing processes for titanium alloys and stainless steel. These factors significantly influence forming, welding, heat treatment, and other fabrication methods. Controlled temperature and pressure conditions are essential for achieving desired microstructures, mechanical properties, and surface finishes. Advanced manufacturing techniques such as hot isostatic pressing, superplastic forming, and diffusion bonding rely on precise control of these parameters to produce high-quality components with optimal performance characteristics.

- Corrosion and oxidation behavior under temperature and pressure: Temperature and pressure significantly affect the corrosion and oxidation behavior of titanium alloys and stainless steel. While both materials are known for their corrosion resistance, extreme conditions can compromise this property. High temperatures can accelerate oxidation rates and alter protective oxide layers, while pressure can influence the kinetics of corrosion processes. In aggressive environments containing specific chemicals, the combined effects of temperature and pressure can lead to specialized forms of corrosion such as stress corrosion cracking or hydrogen embrittlement. Understanding these behaviors is crucial for applications in chemical processing, oil and gas, and marine environments.

02 Pressure effects on titanium alloy and stainless steel performance

Pressure conditions significantly impact the performance of titanium alloys and stainless steel in various applications. Under high-pressure environments, both materials may exhibit different deformation behaviors and stress responses. Titanium alloys generally show excellent resistance to pressure-induced deformation due to their high strength-to-weight ratio, while stainless steel provides good pressure resistance with appropriate alloying elements. The combination of pressure with other environmental factors can accelerate or mitigate certain failure mechanisms in both materials.Expand Specific Solutions03 Combined temperature and pressure effects on material selection

When both temperature and pressure conditions are extreme, material selection between titanium alloys and stainless steel becomes critical. The synergistic effects of temperature and pressure can accelerate degradation mechanisms that might not be significant when either factor acts alone. Titanium alloys typically offer advantages in high-temperature, high-pressure environments where weight is a concern, while stainless steel may be preferred where cost-effectiveness and formability are priorities. The specific application requirements, including exposure duration and cycling conditions, must be considered when selecting between these materials.Expand Specific Solutions04 Manufacturing processes affected by temperature and pressure

Manufacturing processes for titanium alloys and stainless steel are significantly influenced by temperature and pressure parameters. Techniques such as hot forming, cold working, and heat treatment rely on precise control of these variables to achieve desired material properties. Titanium alloys typically require more specialized processing due to their reactivity at elevated temperatures, while stainless steel processing is generally more established but still requires careful temperature control to maintain corrosion resistance. Advanced manufacturing methods like powder metallurgy and additive manufacturing introduce additional temperature and pressure considerations for both materials.Expand Specific Solutions05 Corrosion resistance under varying temperature and pressure conditions

The corrosion resistance of titanium alloys and stainless steel varies significantly under different temperature and pressure environments. Titanium alloys generally exhibit superior corrosion resistance in aggressive media and at elevated temperatures due to their stable passive oxide layer. Stainless steel's corrosion resistance depends heavily on chromium content and can be compromised at certain temperature ranges. In high-pressure environments, the integrity of protective surface films on both materials can be challenged, potentially accelerating corrosion processes. The selection between these materials often depends on the specific corrosive media and operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Advanced Alloys

The titanium alloy versus stainless steel temperature and pressure performance market is in a growth phase, with an estimated global specialty metals market exceeding $150 billion. The competitive landscape is dominated by established aerospace and industrial materials players like Howmet Aerospace and Titanium Metals Corp (TIMET), who lead in high-performance titanium alloy development. Research institutions including Oregon State University and Shanghai Jiao Tong University are advancing fundamental understanding of these materials' behavior under extreme conditions. The technology is mature for conventional applications but evolving for specialized high-temperature and high-pressure environments, with companies like Nippon Steel and Baoshan Iron & Steel focusing on stainless steel innovations, while Garrett Transportation and GE leverage both materials for transportation and energy applications requiring superior thermal and pressure resistance.

ATI Properties LLC

Technical Solution: ATI has developed advanced testing methodologies to evaluate the comparative performance of titanium alloys and stainless steel under varying temperature and pressure conditions. Their proprietary heat treatment processes optimize titanium alloys to maintain structural integrity at temperatures up to 600°C, while their stainless steel formulations resist deformation up to 800°C under high pressure environments. ATI's research has demonstrated that their titanium alloys exhibit superior strength-to-weight ratios at temperatures between 100-500°C compared to stainless steel, with approximately 40% weight reduction while maintaining comparable strength. Their testing protocols include cyclic pressure testing (up to 200 MPa) combined with temperature fluctuations to simulate extreme industrial environments, providing comprehensive data on material fatigue and structural degradation over time.

Strengths: Industry-leading expertise in specialized titanium alloys with superior corrosion resistance in high-temperature marine environments; advanced metallurgical capabilities for creating custom alloy compositions. Weaknesses: Higher production costs for specialized titanium alloys compared to standard stainless steel; longer lead times for custom formulations.

Howmet Aerospace, Inc.

Technical Solution: Howmet Aerospace has pioneered innovative manufacturing techniques for both titanium alloys and stainless steel components used in extreme temperature and pressure applications. Their research focuses on the comparative behavior of these materials in aerospace applications, where components must withstand temperatures ranging from -60°C to over 500°C and pressure differentials exceeding 100 MPa. Howmet's proprietary casting and forging processes for titanium alloys have demonstrated superior resistance to thermal fatigue compared to conventional stainless steel, with test data showing approximately 30% longer component lifespan under cyclic temperature conditions. Their research has established that while titanium alloys maintain mechanical properties better at cryogenic temperatures, specially formulated stainless steel outperforms in oxidation resistance above 550°C. Howmet has developed computational models that accurately predict material behavior under combined temperature and pressure stresses, enabling precise material selection for specific operating conditions.

Strengths: Exceptional expertise in aerospace-grade materials that must withstand extreme temperature fluctuations; advanced manufacturing capabilities for complex geometries in both material types. Weaknesses: Higher production costs for specialized aerospace components; titanium solutions typically require more complex manufacturing processes than stainless steel alternatives.

Critical Patents and Research on Thermo-Mechanical Properties

Titanium alloy powder for selective laser melting 3D printing, selective laser melted titanium alloy and preparation thereof

PatentPendingUS20240123502A1

Innovation

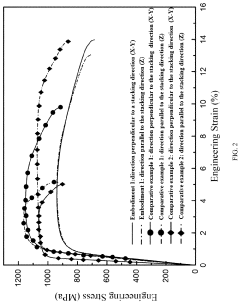

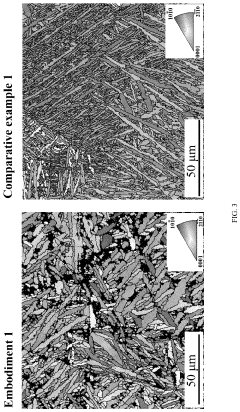

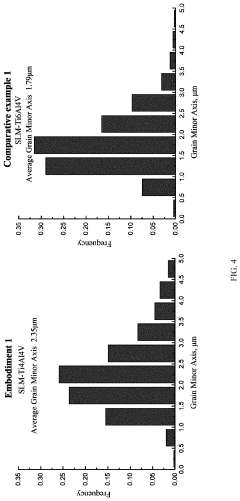

- A titanium alloy powder composition with 2.0-4.5% Al and 3.0-4.5% V, optimized through a process involving vacuum smelting, forging, and gas atomization to produce a powder with specific particle size and composition, which is then used in SLM to create a titanium alloy with improved isotropy and mechanical properties without the need for subsequent heat treatment.

Material Testing Standards and Certification Requirements

The comprehensive evaluation of titanium alloys and stainless steel under varying temperature and pressure conditions necessitates adherence to established material testing standards and certification requirements. These standards ensure reliability, reproducibility, and validity of test results across different laboratories and applications.

ASTM International provides several key standards for testing titanium alloys, including ASTM E8/E8M for tensile testing, ASTM E9 for compression testing, and ASTM E21 for elevated temperature testing. For stainless steel, ASTM A370 outlines mechanical testing requirements, while ASTM E139 governs creep and stress-rupture tests. These standards specify precise testing methodologies, specimen preparation procedures, and data analysis techniques.

ISO standards complement ASTM requirements, with ISO 6892 addressing tensile testing at ambient temperatures and ISO 783 covering elevated temperature testing. For pressure-related applications, ASME Boiler and Pressure Vessel Code Section IX and Section II provide essential guidelines for material qualification and certification, particularly relevant for high-temperature and high-pressure environments.

Aerospace applications demand more stringent certification requirements, with AMS (Aerospace Material Specifications) standards such as AMS 2631 for titanium and AMS 5639 for stainless steel dictating specific testing protocols. These standards often require additional tests like fatigue resistance under cyclic temperature and pressure conditions.

Material certification typically involves multiple documentation levels. Mill Test Reports (MTRs) provide chemical composition and basic mechanical properties. For critical applications, Certified Material Test Reports (CMTRs) offer more comprehensive data including heat treatment history and specific performance characteristics under temperature and pressure extremes.

Non-destructive testing standards also play a crucial role in material certification. ASTM E1417 for liquid penetrant inspection and ASTM E1444 for magnetic particle testing help identify surface defects that might propagate under thermal or pressure cycling. For subsurface evaluation, ASTM E1742 outlines radiographic examination methods particularly important for weld integrity assessment in pressure vessels.

Compliance with these standards is mandatory for materials used in critical applications such as nuclear facilities (ASME Section III), petrochemical equipment (API 570), and medical implants (ASTM F136 for titanium alloys). The certification process typically involves third-party verification by accredited testing laboratories, ensuring that materials meet the specified performance criteria across their intended temperature and pressure operating ranges.

ASTM International provides several key standards for testing titanium alloys, including ASTM E8/E8M for tensile testing, ASTM E9 for compression testing, and ASTM E21 for elevated temperature testing. For stainless steel, ASTM A370 outlines mechanical testing requirements, while ASTM E139 governs creep and stress-rupture tests. These standards specify precise testing methodologies, specimen preparation procedures, and data analysis techniques.

ISO standards complement ASTM requirements, with ISO 6892 addressing tensile testing at ambient temperatures and ISO 783 covering elevated temperature testing. For pressure-related applications, ASME Boiler and Pressure Vessel Code Section IX and Section II provide essential guidelines for material qualification and certification, particularly relevant for high-temperature and high-pressure environments.

Aerospace applications demand more stringent certification requirements, with AMS (Aerospace Material Specifications) standards such as AMS 2631 for titanium and AMS 5639 for stainless steel dictating specific testing protocols. These standards often require additional tests like fatigue resistance under cyclic temperature and pressure conditions.

Material certification typically involves multiple documentation levels. Mill Test Reports (MTRs) provide chemical composition and basic mechanical properties. For critical applications, Certified Material Test Reports (CMTRs) offer more comprehensive data including heat treatment history and specific performance characteristics under temperature and pressure extremes.

Non-destructive testing standards also play a crucial role in material certification. ASTM E1417 for liquid penetrant inspection and ASTM E1444 for magnetic particle testing help identify surface defects that might propagate under thermal or pressure cycling. For subsurface evaluation, ASTM E1742 outlines radiographic examination methods particularly important for weld integrity assessment in pressure vessels.

Compliance with these standards is mandatory for materials used in critical applications such as nuclear facilities (ASME Section III), petrochemical equipment (API 570), and medical implants (ASTM F136 for titanium alloys). The certification process typically involves third-party verification by accredited testing laboratories, ensuring that materials meet the specified performance criteria across their intended temperature and pressure operating ranges.

Environmental Impact and Sustainability Considerations

The environmental impact of material selection between titanium alloys and stainless steel represents a critical consideration in sustainable engineering practices. Titanium alloy production requires significantly more energy than stainless steel manufacturing, with estimates suggesting 5-10 times higher energy consumption during the extraction and processing phases. This energy-intensive production contributes to a larger carbon footprint, with titanium production generating approximately 35-45 kg CO2 equivalent per kilogram of material compared to stainless steel's 4-6 kg CO2 equivalent.

However, the lifecycle assessment reveals more nuanced sustainability profiles. Titanium's exceptional corrosion resistance in extreme temperature and pressure environments substantially extends product lifespan, potentially offsetting the initial environmental impact through reduced replacement frequency. Studies indicate titanium components in high-temperature applications can last 2-3 times longer than stainless steel alternatives, resulting in fewer replacement cycles and associated environmental costs.

Material recyclability presents another important dimension. Both materials demonstrate excellent recyclability, with stainless steel achieving recycling rates of approximately 85% globally. Titanium, while technically 100% recyclable, currently experiences lower actual recycling rates (around 50-60%) due to more complex collection and processing requirements, particularly when recovered from high-temperature or high-pressure applications where material degradation may occur.

Water consumption and pollution metrics also differ significantly between these materials. Titanium processing requires approximately 125-150 cubic meters of water per ton of finished product, while stainless steel manufacturing uses 60-80 cubic meters. Additionally, titanium production generates specific waste streams containing chlorides and other compounds requiring specialized treatment.

When considering temperature and pressure applications specifically, the environmental trade-offs become more pronounced. In high-temperature environments exceeding 500°C, titanium's superior performance reduces the need for cooling systems and thermal management infrastructure, potentially reducing overall system energy consumption by 15-25% compared to stainless steel alternatives.

Emerging sustainable manufacturing techniques are gradually improving the environmental profiles of both materials. Advanced recycling technologies, cleaner production methods, and renewable energy integration in manufacturing are reducing the environmental impact gap between these materials. Recent innovations in titanium production, such as the FFC Cambridge process, promise up to 50% reduction in energy requirements, potentially transforming titanium's sustainability profile in high-temperature and high-pressure applications.

However, the lifecycle assessment reveals more nuanced sustainability profiles. Titanium's exceptional corrosion resistance in extreme temperature and pressure environments substantially extends product lifespan, potentially offsetting the initial environmental impact through reduced replacement frequency. Studies indicate titanium components in high-temperature applications can last 2-3 times longer than stainless steel alternatives, resulting in fewer replacement cycles and associated environmental costs.

Material recyclability presents another important dimension. Both materials demonstrate excellent recyclability, with stainless steel achieving recycling rates of approximately 85% globally. Titanium, while technically 100% recyclable, currently experiences lower actual recycling rates (around 50-60%) due to more complex collection and processing requirements, particularly when recovered from high-temperature or high-pressure applications where material degradation may occur.

Water consumption and pollution metrics also differ significantly between these materials. Titanium processing requires approximately 125-150 cubic meters of water per ton of finished product, while stainless steel manufacturing uses 60-80 cubic meters. Additionally, titanium production generates specific waste streams containing chlorides and other compounds requiring specialized treatment.

When considering temperature and pressure applications specifically, the environmental trade-offs become more pronounced. In high-temperature environments exceeding 500°C, titanium's superior performance reduces the need for cooling systems and thermal management infrastructure, potentially reducing overall system energy consumption by 15-25% compared to stainless steel alternatives.

Emerging sustainable manufacturing techniques are gradually improving the environmental profiles of both materials. Advanced recycling technologies, cleaner production methods, and renewable energy integration in manufacturing are reducing the environmental impact gap between these materials. Recent innovations in titanium production, such as the FFC Cambridge process, promise up to 50% reduction in energy requirements, potentially transforming titanium's sustainability profile in high-temperature and high-pressure applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!