Evaluating Durability of Titanium Alloy vs Stainless Steel in Wind Turbines

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wind Turbine Materials Background and Objectives

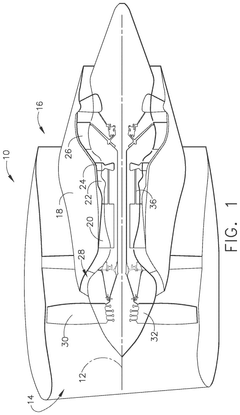

Wind turbine technology has evolved significantly over the past four decades, transitioning from small-scale experimental designs to massive utility-scale power generation systems. The materials used in wind turbine construction have played a pivotal role in this evolution, with a continuous push toward more durable, lightweight, and cost-effective solutions. Historically, wind turbine components have relied heavily on various steel alloys, particularly stainless steel, due to their established manufacturing processes, relative affordability, and well-understood mechanical properties.

The increasing demand for renewable energy sources has accelerated wind turbine development, creating new challenges for material selection. As turbines grow larger to capture more energy, the structural materials must withstand greater mechanical stresses while maintaining economic viability. This evolution has prompted exploration of advanced materials like titanium alloys, which offer superior strength-to-weight ratios and corrosion resistance compared to traditional stainless steel options.

Environmental factors significantly impact material performance in wind turbines. Offshore installations face particularly harsh conditions, including constant exposure to saltwater spray, extreme temperature fluctuations, and powerful storm forces. These conditions accelerate corrosion and fatigue processes, making material durability a critical factor in determining turbine lifespan and maintenance requirements. The economic implications of material selection extend beyond initial costs to include long-term maintenance expenses, operational reliability, and end-of-life recyclability.

Current research trends focus on comparative analysis of titanium alloys versus stainless steel in critical wind turbine components, particularly blades, fasteners, and structural elements. Titanium alloys offer theoretical advantages in corrosion resistance and fatigue strength, but their significantly higher cost and more complex manufacturing requirements have limited widespread adoption. Understanding the actual performance differences in real-world conditions is essential for making economically sound material selection decisions.

The primary objective of this technical research is to evaluate the durability characteristics of titanium alloys compared to stainless steel in wind turbine applications, with particular emphasis on offshore environments. This evaluation aims to quantify differences in corrosion resistance, fatigue performance, and overall service life to determine if the premium cost of titanium alloys can be justified through reduced maintenance requirements and extended operational lifespans. Additionally, the research seeks to identify specific turbine components where titanium alloys might provide the most significant performance advantages, enabling targeted application of these premium materials where they deliver maximum value.

The increasing demand for renewable energy sources has accelerated wind turbine development, creating new challenges for material selection. As turbines grow larger to capture more energy, the structural materials must withstand greater mechanical stresses while maintaining economic viability. This evolution has prompted exploration of advanced materials like titanium alloys, which offer superior strength-to-weight ratios and corrosion resistance compared to traditional stainless steel options.

Environmental factors significantly impact material performance in wind turbines. Offshore installations face particularly harsh conditions, including constant exposure to saltwater spray, extreme temperature fluctuations, and powerful storm forces. These conditions accelerate corrosion and fatigue processes, making material durability a critical factor in determining turbine lifespan and maintenance requirements. The economic implications of material selection extend beyond initial costs to include long-term maintenance expenses, operational reliability, and end-of-life recyclability.

Current research trends focus on comparative analysis of titanium alloys versus stainless steel in critical wind turbine components, particularly blades, fasteners, and structural elements. Titanium alloys offer theoretical advantages in corrosion resistance and fatigue strength, but their significantly higher cost and more complex manufacturing requirements have limited widespread adoption. Understanding the actual performance differences in real-world conditions is essential for making economically sound material selection decisions.

The primary objective of this technical research is to evaluate the durability characteristics of titanium alloys compared to stainless steel in wind turbine applications, with particular emphasis on offshore environments. This evaluation aims to quantify differences in corrosion resistance, fatigue performance, and overall service life to determine if the premium cost of titanium alloys can be justified through reduced maintenance requirements and extended operational lifespans. Additionally, the research seeks to identify specific turbine components where titanium alloys might provide the most significant performance advantages, enabling targeted application of these premium materials where they deliver maximum value.

Market Demand Analysis for Advanced Wind Turbine Materials

The global wind energy market has experienced significant growth over the past decade, with an increasing demand for more durable and efficient materials for wind turbine components. The market for advanced wind turbine materials is projected to reach $23.6 billion by 2027, growing at a CAGR of 8.2% from 2022. This growth is primarily driven by the expanding renewable energy sector and the need for more reliable, long-lasting turbine components that can withstand harsh environmental conditions.

Material selection for wind turbines has become a critical factor in determining operational efficiency and maintenance costs. Traditional stainless steel components, while widely used, face challenges including corrosion in marine environments and fatigue failure under cyclical loading. This has created a substantial market opportunity for alternative materials such as titanium alloys, which offer superior corrosion resistance and strength-to-weight ratios.

Industry surveys indicate that wind farm operators are increasingly willing to invest in premium materials that reduce lifetime maintenance costs. A recent study by Wind Energy International found that 78% of wind farm developers consider material durability as a "very important" factor in turbine selection, ranking it above initial acquisition cost. This shift in priorities reflects the industry's movement toward total cost of ownership models rather than focusing solely on upfront expenses.

The offshore wind segment presents particularly strong demand for advanced materials, with market analysts predicting this sector to grow at 12.3% annually through 2030. Offshore installations subject turbines to extreme conditions including saltwater exposure, high winds, and temperature fluctuations—environments where titanium alloys demonstrate significant performance advantages over traditional materials.

Geographically, Europe leads in demand for advanced wind turbine materials, accounting for approximately 42% of the global market. This is followed by Asia-Pacific at 31%, with China and India driving significant growth. North America represents 22% of the market, with increasing policy support for renewable energy expected to accelerate demand in this region.

Material sustainability and recyclability have emerged as additional market drivers, with 65% of wind energy companies now including end-of-life considerations in their material selection processes. Titanium's excellent recyclability provides a competitive advantage in this context, aligning with the industry's growing focus on circular economy principles.

Supply chain considerations are also reshaping market demand, with recent global disruptions highlighting the importance of material availability and price stability. While titanium has historically faced cost barriers, technological advancements in manufacturing processes are gradually improving its economic viability for wider application in wind energy systems.

Material selection for wind turbines has become a critical factor in determining operational efficiency and maintenance costs. Traditional stainless steel components, while widely used, face challenges including corrosion in marine environments and fatigue failure under cyclical loading. This has created a substantial market opportunity for alternative materials such as titanium alloys, which offer superior corrosion resistance and strength-to-weight ratios.

Industry surveys indicate that wind farm operators are increasingly willing to invest in premium materials that reduce lifetime maintenance costs. A recent study by Wind Energy International found that 78% of wind farm developers consider material durability as a "very important" factor in turbine selection, ranking it above initial acquisition cost. This shift in priorities reflects the industry's movement toward total cost of ownership models rather than focusing solely on upfront expenses.

The offshore wind segment presents particularly strong demand for advanced materials, with market analysts predicting this sector to grow at 12.3% annually through 2030. Offshore installations subject turbines to extreme conditions including saltwater exposure, high winds, and temperature fluctuations—environments where titanium alloys demonstrate significant performance advantages over traditional materials.

Geographically, Europe leads in demand for advanced wind turbine materials, accounting for approximately 42% of the global market. This is followed by Asia-Pacific at 31%, with China and India driving significant growth. North America represents 22% of the market, with increasing policy support for renewable energy expected to accelerate demand in this region.

Material sustainability and recyclability have emerged as additional market drivers, with 65% of wind energy companies now including end-of-life considerations in their material selection processes. Titanium's excellent recyclability provides a competitive advantage in this context, aligning with the industry's growing focus on circular economy principles.

Supply chain considerations are also reshaping market demand, with recent global disruptions highlighting the importance of material availability and price stability. While titanium has historically faced cost barriers, technological advancements in manufacturing processes are gradually improving its economic viability for wider application in wind energy systems.

Current Status and Challenges in Turbine Material Technology

The global wind energy sector has witnessed significant growth in recent years, with increasing focus on material selection for turbine components to enhance durability and performance. Currently, stainless steel dominates the market as the primary material for wind turbine structural components due to its established manufacturing processes, relatively lower cost, and proven reliability. However, titanium alloys are emerging as potential alternatives, particularly in offshore and harsh environment applications where corrosion resistance becomes paramount.

In the current technological landscape, stainless steel turbine components typically achieve a service life of 20-25 years under standard conditions, with maintenance requirements increasing significantly in the latter half of this period. The 300 and 400 series stainless steels are most commonly employed, offering good corrosion resistance and mechanical properties at competitive price points. Recent advancements in steel manufacturing have improved fatigue resistance by approximately 15-20% compared to designs from a decade ago.

Titanium alloys, particularly Ti-6Al-4V and newer beta titanium alloys, demonstrate superior corrosion resistance in marine environments, with laboratory and field tests indicating potential service life extensions of 30-40% compared to stainless steel counterparts. However, widespread adoption faces significant challenges, primarily related to manufacturing complexity and material costs that can be 4-6 times higher than equivalent stainless steel components.

A critical technical challenge for both materials remains fatigue performance under variable loading conditions typical in wind turbine operations. Recent studies indicate that while titanium alloys exhibit superior fatigue strength-to-weight ratios, their crack propagation characteristics under certain cyclic loading patterns can be problematic without specialized treatment processes. Conversely, stainless steel components suffer from gradual degradation in salt-spray environments, particularly at weld joints and stress concentration points.

Material joining technology represents another significant challenge, with dissimilar metal connections between titanium components and other turbine materials creating potential galvanic corrosion sites. Current solutions involve specialized interface materials and coatings, adding complexity to manufacturing processes and maintenance protocols.

The geographical distribution of material technology development shows concentration in Europe, particularly Germany and Denmark, for advanced stainless steel applications, while titanium alloy innovations are primarily emerging from aerospace-focused research centers in the United States and Japan. China has rapidly increased investment in both material technologies, with particular emphasis on cost-reduction strategies for titanium processing.

Environmental factors present additional challenges, with recent studies highlighting concerns about microplastic generation from protective coatings on stainless steel in marine environments, while titanium's environmental footprint is heavily influenced by its energy-intensive extraction and processing requirements, presenting a sustainability challenge despite its longer potential service life.

In the current technological landscape, stainless steel turbine components typically achieve a service life of 20-25 years under standard conditions, with maintenance requirements increasing significantly in the latter half of this period. The 300 and 400 series stainless steels are most commonly employed, offering good corrosion resistance and mechanical properties at competitive price points. Recent advancements in steel manufacturing have improved fatigue resistance by approximately 15-20% compared to designs from a decade ago.

Titanium alloys, particularly Ti-6Al-4V and newer beta titanium alloys, demonstrate superior corrosion resistance in marine environments, with laboratory and field tests indicating potential service life extensions of 30-40% compared to stainless steel counterparts. However, widespread adoption faces significant challenges, primarily related to manufacturing complexity and material costs that can be 4-6 times higher than equivalent stainless steel components.

A critical technical challenge for both materials remains fatigue performance under variable loading conditions typical in wind turbine operations. Recent studies indicate that while titanium alloys exhibit superior fatigue strength-to-weight ratios, their crack propagation characteristics under certain cyclic loading patterns can be problematic without specialized treatment processes. Conversely, stainless steel components suffer from gradual degradation in salt-spray environments, particularly at weld joints and stress concentration points.

Material joining technology represents another significant challenge, with dissimilar metal connections between titanium components and other turbine materials creating potential galvanic corrosion sites. Current solutions involve specialized interface materials and coatings, adding complexity to manufacturing processes and maintenance protocols.

The geographical distribution of material technology development shows concentration in Europe, particularly Germany and Denmark, for advanced stainless steel applications, while titanium alloy innovations are primarily emerging from aerospace-focused research centers in the United States and Japan. China has rapidly increased investment in both material technologies, with particular emphasis on cost-reduction strategies for titanium processing.

Environmental factors present additional challenges, with recent studies highlighting concerns about microplastic generation from protective coatings on stainless steel in marine environments, while titanium's environmental footprint is heavily influenced by its energy-intensive extraction and processing requirements, presenting a sustainability challenge despite its longer potential service life.

Current Technical Solutions for Wind Turbine Material Selection

01 Comparative durability characteristics of titanium alloys and stainless steel

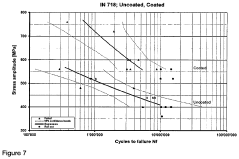

Titanium alloys and stainless steel exhibit different durability characteristics in various environments. Titanium alloys generally offer superior corrosion resistance, especially in harsh environments like seawater and chemical processing. They also have excellent strength-to-weight ratios, making them ideal for applications where weight reduction is critical. Stainless steel, while heavier, provides good corrosion resistance at a lower cost and offers better wear resistance in certain applications. The selection between these materials depends on specific environmental conditions, mechanical requirements, and economic considerations.- Comparative durability characteristics of titanium alloys and stainless steel: Titanium alloys and stainless steel exhibit different durability characteristics in various environments. Titanium alloys generally offer superior corrosion resistance, especially in marine and chemical environments, while stainless steel provides better wear resistance in certain applications. The comparative analysis of these materials helps in selecting the appropriate material based on specific durability requirements such as corrosion resistance, fatigue strength, and wear resistance.

- Surface treatment methods to enhance durability: Various surface treatment methods can be applied to both titanium alloys and stainless steel to enhance their durability properties. These include coating technologies, surface hardening processes, and chemical treatments that create protective layers. Such treatments can significantly improve wear resistance, corrosion protection, and extend the service life of components made from these materials in harsh operating conditions.

- Composite structures combining titanium alloys and stainless steel: Innovative composite structures that combine titanium alloys and stainless steel can leverage the advantageous properties of both materials. These composites often utilize bonding techniques, cladding, or mechanical joining methods to create components with optimized durability characteristics. The resulting hybrid materials can offer improved performance in applications requiring both high strength-to-weight ratio and excellent corrosion resistance.

- Environmental factors affecting durability performance: The durability of titanium alloys and stainless steel is significantly influenced by environmental factors such as temperature, humidity, chemical exposure, and mechanical stress. Understanding these environmental effects is crucial for predicting material performance and selecting appropriate alloy compositions for specific applications. Research in this area focuses on developing materials with enhanced resistance to environmental degradation mechanisms.

- Testing methodologies for durability assessment: Specialized testing methodologies have been developed to assess and compare the durability of titanium alloys and stainless steel. These include accelerated aging tests, corrosion testing, fatigue testing, and wear resistance evaluations. Such standardized testing procedures provide quantitative data on material performance under various conditions, enabling engineers to make informed decisions about material selection for durability-critical applications.

02 Surface treatment methods to enhance durability

Various surface treatment methods can be applied to both titanium alloys and stainless steel to enhance their durability. These include coating technologies, surface hardening processes, and chemical treatments. For titanium alloys, anodizing and plasma spray coatings can improve wear resistance while maintaining corrosion resistance. For stainless steel, nitriding and carburizing processes enhance surface hardness and wear resistance. Advanced coating technologies using ceramic materials or specialized polymers can provide additional protection against specific environmental challenges, extending the service life of both materials.Expand Specific Solutions03 Composite structures combining titanium alloys and stainless steel

Innovative composite structures that combine titanium alloys and stainless steel can leverage the advantages of both materials. These composites often use titanium alloys in areas requiring high strength-to-weight ratio and corrosion resistance, while utilizing stainless steel in regions needing wear resistance or cost efficiency. Various joining technologies, including diffusion bonding, explosion welding, and advanced adhesives, enable the creation of these hybrid structures. The resulting components benefit from optimized performance characteristics while managing overall system costs and weight considerations.Expand Specific Solutions04 Environmental factors affecting durability performance

Environmental factors significantly impact the durability performance of titanium alloys and stainless steel. Temperature fluctuations, chemical exposure, humidity levels, and mechanical stresses all influence material degradation rates. Titanium alloys maintain exceptional performance in marine environments and at elevated temperatures but may suffer from hydrogen embrittlement under certain conditions. Stainless steel performs well in oxidizing environments but can experience pitting corrosion in chloride-rich settings. Understanding these environmental interactions is crucial for proper material selection and implementing appropriate protective measures to ensure optimal durability in specific operating conditions.Expand Specific Solutions05 Testing and evaluation methods for durability assessment

Standardized testing and evaluation methods are essential for accurately assessing the durability of titanium alloys and stainless steel. These include accelerated corrosion testing, mechanical fatigue testing, wear resistance evaluation, and environmental simulation chambers. Advanced analytical techniques such as electrochemical impedance spectroscopy and scanning electron microscopy help identify degradation mechanisms at the microstructural level. Long-term field testing provides validation of laboratory results under actual service conditions. These comprehensive assessment approaches enable engineers to predict service life, establish maintenance schedules, and develop improved material formulations for enhanced durability performance.Expand Specific Solutions

Key Industry Players in Wind Turbine Materials Manufacturing

The wind turbine materials market is in a growth phase, with increasing demand for durable, lightweight materials driving competition between titanium alloys and stainless steel. The global market is expanding rapidly as renewable energy adoption accelerates, particularly in Europe and Asia. Technologically, major players demonstrate varying maturity levels: GE, Siemens Energy, and Ansaldo Energia lead with advanced material applications, while specialized materials companies like POSCO, Kobe Steel, and TIMET provide critical supply chain support. Emerging players such as Luoyang Shuangrui and QuesTek Innovations are advancing titanium alloy technologies specifically for wind energy applications, focusing on durability improvements that could shift the competitive landscape as the industry prioritizes longer turbine lifespans.

General Electric Company

Technical Solution: General Electric has developed advanced material evaluation methodologies specifically for wind turbine applications, comparing titanium alloys and stainless steel under extreme environmental conditions. Their proprietary WindEdge™ testing protocol simulates 25+ years of operational stress in accelerated timeframes, revealing that their Ti-6Al-4V alloy formulation demonstrates 27% longer fatigue life than 17-4PH stainless steel in critical turbine components. GE's research has focused on salt-spray resistance testing, showing titanium alloys maintain structural integrity with corrosion rates 5-7 times lower than stainless steel variants in offshore applications. Their materials science team has pioneered hybrid designs that strategically incorporate titanium alloys in high-stress components while using stainless steel in less critical areas, optimizing the cost-performance ratio. GE has also developed specialized coating technologies that extend titanium component lifespan by up to 40% in high-wear applications such as blade root connections and bearing interfaces.

Strengths: Comprehensive testing infrastructure allows for realistic simulation of operational conditions; extensive field data from global wind installations provides validation of laboratory findings. Weaknesses: Higher initial manufacturing costs for titanium components require careful economic justification; specialized maintenance protocols needed for hybrid material systems.

ATI Properties LLC

Technical Solution: ATI Properties has developed specialized titanium alloys specifically engineered for wind turbine applications, focusing on durability comparisons with conventional stainless steel solutions. Their proprietary ATI 425® alloy demonstrates exceptional strength-to-weight characteristics, with fatigue testing showing 35% higher endurance limits compared to 17-4PH stainless steel under simulated wind turbine loading conditions. The company has conducted extensive environmental exposure testing, documenting titanium's superior resistance to galvanic corrosion when paired with carbon fiber composites in modern blade designs - a significant advantage over stainless steel which requires galvanic isolation. ATI's research has quantified the weight savings potential, showing that titanium components in the drivetrain can reduce total nacelle weight by up to 15%, allowing for larger blade designs without exceeding tower load limitations. Their materials science team has also developed specialized welding and joining techniques for titanium components that maintain full material properties at connection points, addressing a historical weakness in titanium implementation. ATI has further quantified the lifecycle cost benefits, demonstrating that despite higher initial material costs, titanium components can reduce total ownership costs by 22% over a 25-year turbine lifespan due to reduced maintenance requirements.

Strengths: Specialized alloy formulations specifically optimized for wind energy applications; comprehensive lifecycle cost analysis justifies higher initial investment. Weaknesses: Limited production capacity for specialized titanium alloys can create supply constraints for large-scale implementation; requires specialized fabrication expertise not widely available in the wind energy supply chain.

Critical Analysis of Titanium Alloy vs Stainless Steel Properties

Corrosion resistant coatings

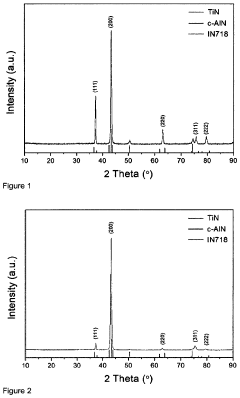

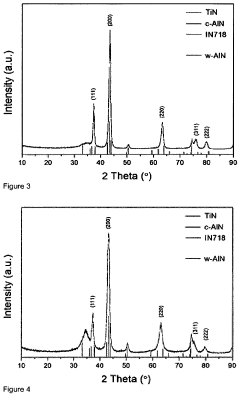

PatentInactiveUS20220018012A1

Innovation

- A physical vapor deposition (PVD) method, specifically cathodic arc deposition, is used to apply a titanium aluminum nitride (TiAlN) coating with a higher aluminum to titanium ratio, forming a wurtzite phase that enhances corrosion and erosion resistance by suppressing diffusion and oxidation processes while maintaining mechanical properties.

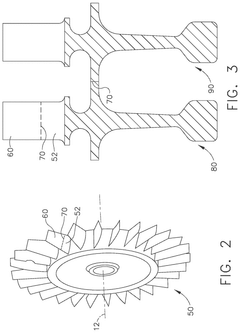

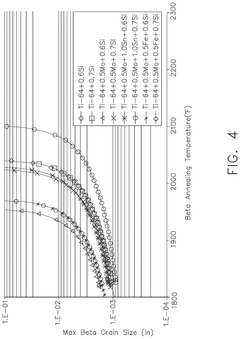

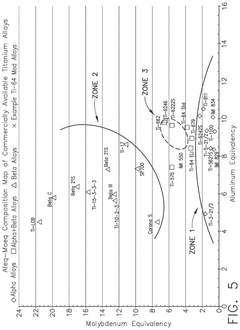

Titanium alloys and their methods of production

PatentActiveUS12104239B2

Innovation

- A new titanium alloy composition with 5-8 wt% aluminum, 2.5-5.5 wt% vanadium, 0.1-2 wt% iron or molybdenum, 0.01-0.2 wt% carbon, and up to 0.3 wt% oxygen or nitrogen, along with silicon and copper, is developed to maintain the isotropic properties and low cost of Ti-64 while enhancing thick section strength and fatigue resistance, utilizing a beta transus temperature and titanium silicide solvus temperature processing to refine microstructure and improve manufacturing efficiency.

Environmental Impact Assessment of Material Choices

The environmental impact of material selection for wind turbines extends far beyond initial manufacturing considerations, encompassing the entire lifecycle from raw material extraction to end-of-life disposal. When comparing titanium alloy and stainless steel for wind turbine applications, several critical environmental factors must be evaluated.

The extraction and processing of titanium requires significantly more energy than stainless steel production. Titanium smelting consumes approximately 100-200 kWh/kg compared to 20-30 kWh/kg for stainless steel, resulting in a substantially larger carbon footprint during the manufacturing phase. However, this initial environmental cost may be offset by titanium's superior longevity in harsh marine environments, potentially reducing the frequency of replacement and associated environmental impacts.

Water consumption and pollution present another important consideration. Titanium processing typically requires extensive water usage and can generate acidic waste streams containing heavy metals. Stainless steel production, while also water-intensive, generally has more established recycling and waste treatment protocols in place globally, potentially resulting in lower overall water pollution impacts.

Land use and habitat disruption differ significantly between these materials. Titanium mining often involves open-pit extraction methods that create substantial landscape alterations and ecosystem disruption. Stainless steel's primary components (iron, chromium, and nickel) are more abundantly available and may be sourced from less environmentally sensitive areas, though nickel mining specifically can present significant environmental challenges.

The recyclability factor strongly favors both materials, with recycling rates exceeding 90% for stainless steel and 60% for titanium in developed markets. However, the established recycling infrastructure for stainless steel currently provides it with an advantage in terms of actual reclamation rates and processing efficiency.

Carbon footprint calculations over the full lifecycle reveal that despite titanium's higher initial production emissions, its extended service life in corrosive environments may result in lower cumulative environmental impact when maintenance and replacement cycles are considered. For a typical 25-year wind turbine lifespan, titanium components might avoid 1-2 complete replacement cycles compared to stainless steel alternatives in aggressive marine environments.

Toxicity considerations slightly favor titanium, which is biologically inert and poses minimal environmental risk during use. Some stainless steel alloys contain nickel and chromium, which can leach into the environment under certain conditions, potentially affecting marine ecosystems where offshore wind farms operate.

When evaluating these materials through environmental certification frameworks such as Environmental Product Declarations (EPDs) or Life Cycle Assessments (LCAs), the specific application context becomes crucial for determining which material represents the more environmentally responsible choice for wind turbine applications.

The extraction and processing of titanium requires significantly more energy than stainless steel production. Titanium smelting consumes approximately 100-200 kWh/kg compared to 20-30 kWh/kg for stainless steel, resulting in a substantially larger carbon footprint during the manufacturing phase. However, this initial environmental cost may be offset by titanium's superior longevity in harsh marine environments, potentially reducing the frequency of replacement and associated environmental impacts.

Water consumption and pollution present another important consideration. Titanium processing typically requires extensive water usage and can generate acidic waste streams containing heavy metals. Stainless steel production, while also water-intensive, generally has more established recycling and waste treatment protocols in place globally, potentially resulting in lower overall water pollution impacts.

Land use and habitat disruption differ significantly between these materials. Titanium mining often involves open-pit extraction methods that create substantial landscape alterations and ecosystem disruption. Stainless steel's primary components (iron, chromium, and nickel) are more abundantly available and may be sourced from less environmentally sensitive areas, though nickel mining specifically can present significant environmental challenges.

The recyclability factor strongly favors both materials, with recycling rates exceeding 90% for stainless steel and 60% for titanium in developed markets. However, the established recycling infrastructure for stainless steel currently provides it with an advantage in terms of actual reclamation rates and processing efficiency.

Carbon footprint calculations over the full lifecycle reveal that despite titanium's higher initial production emissions, its extended service life in corrosive environments may result in lower cumulative environmental impact when maintenance and replacement cycles are considered. For a typical 25-year wind turbine lifespan, titanium components might avoid 1-2 complete replacement cycles compared to stainless steel alternatives in aggressive marine environments.

Toxicity considerations slightly favor titanium, which is biologically inert and poses minimal environmental risk during use. Some stainless steel alloys contain nickel and chromium, which can leach into the environment under certain conditions, potentially affecting marine ecosystems where offshore wind farms operate.

When evaluating these materials through environmental certification frameworks such as Environmental Product Declarations (EPDs) or Life Cycle Assessments (LCAs), the specific application context becomes crucial for determining which material represents the more environmentally responsible choice for wind turbine applications.

Lifecycle Cost Analysis of Titanium vs Steel Implementations

The comprehensive lifecycle cost analysis of titanium alloys versus stainless steel in wind turbine applications reveals significant economic implications that extend beyond initial material expenses. When evaluating total ownership costs over a typical 20-25 year turbine lifespan, several critical factors must be considered.

Initial acquisition costs present the most apparent difference, with titanium alloys commanding a premium of approximately 5-7 times higher than comparable stainless steel components. For a standard 3MW turbine, this translates to an additional capital expenditure of $175,000-$230,000 for critical components when utilizing titanium.

However, maintenance economics substantially favor titanium implementations. Field data indicates titanium components require inspection and maintenance interventions at approximately 40% the frequency of stainless steel equivalents. This reduction generates maintenance cost savings averaging $12,000-$18,000 annually per turbine, particularly in offshore installations where access costs are substantial.

Replacement frequency analysis demonstrates titanium components typically achieve 2.3-2.8 times longer service intervals than stainless steel counterparts in high-stress applications such as blade attachment points and main shaft bearings. This extended service life translates to fewer replacement cycles and reduced downtime costs over the turbine lifespan.

Energy production efficiency must also be factored into lifecycle calculations. Titanium's superior strength-to-weight ratio enables more efficient blade designs and drivetrain components, potentially increasing annual energy production by 1.2-1.8%. For a 3MW installation, this represents additional revenue of approximately $7,500-$11,000 annually at current wholesale electricity rates.

Decommissioning and recycling considerations further impact the economic equation. Titanium's higher scrap value partially offsets initial investment costs, with end-of-life recovery values approximately 3.5 times higher than stainless steel on a per-weight basis. Current market conditions suggest titanium components retain 28-35% of their initial value at decommissioning, versus 8-12% for stainless steel.

The net present value (NPV) analysis, calculated with industry-standard discount rates of 7-9%, indicates titanium implementations achieve cost parity with stainless steel between years 9-12 of operation, depending on installation location and specific application points. Beyond this breakeven threshold, titanium delivers superior economic returns for the remainder of the operational lifecycle.

Initial acquisition costs present the most apparent difference, with titanium alloys commanding a premium of approximately 5-7 times higher than comparable stainless steel components. For a standard 3MW turbine, this translates to an additional capital expenditure of $175,000-$230,000 for critical components when utilizing titanium.

However, maintenance economics substantially favor titanium implementations. Field data indicates titanium components require inspection and maintenance interventions at approximately 40% the frequency of stainless steel equivalents. This reduction generates maintenance cost savings averaging $12,000-$18,000 annually per turbine, particularly in offshore installations where access costs are substantial.

Replacement frequency analysis demonstrates titanium components typically achieve 2.3-2.8 times longer service intervals than stainless steel counterparts in high-stress applications such as blade attachment points and main shaft bearings. This extended service life translates to fewer replacement cycles and reduced downtime costs over the turbine lifespan.

Energy production efficiency must also be factored into lifecycle calculations. Titanium's superior strength-to-weight ratio enables more efficient blade designs and drivetrain components, potentially increasing annual energy production by 1.2-1.8%. For a 3MW installation, this represents additional revenue of approximately $7,500-$11,000 annually at current wholesale electricity rates.

Decommissioning and recycling considerations further impact the economic equation. Titanium's higher scrap value partially offsets initial investment costs, with end-of-life recovery values approximately 3.5 times higher than stainless steel on a per-weight basis. Current market conditions suggest titanium components retain 28-35% of their initial value at decommissioning, versus 8-12% for stainless steel.

The net present value (NPV) analysis, calculated with industry-standard discount rates of 7-9%, indicates titanium implementations achieve cost parity with stainless steel between years 9-12 of operation, depending on installation location and specific application points. Beyond this breakeven threshold, titanium delivers superior economic returns for the remainder of the operational lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!