How Do Electromagnetic Properties Compare in Titanium Alloy vs Stainless Steel

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electromagnetic Properties Background and Research Objectives

Electromagnetic properties of materials have been a critical area of study since the formulation of Maxwell's equations in the 19th century. These properties fundamentally determine how materials interact with electromagnetic fields, influencing their application in various industries including aerospace, medical devices, telecommunications, and defense. The comparison between titanium alloys and stainless steel represents a particularly significant research focus due to their widespread use in high-performance applications where electromagnetic characteristics can be decisive factors.

Historically, the understanding of electromagnetic properties in metals has evolved from basic conductivity measurements to sophisticated analyses of permeability, permittivity, and electromagnetic interference shielding capabilities. This evolution has paralleled advancements in measurement techniques and computational modeling, allowing for more precise characterization of these properties across different frequency ranges and environmental conditions.

Titanium alloys, first commercially produced in the 1950s, have seen continuous development with various compositions optimized for specific performance characteristics. Similarly, stainless steel, with its origins in the early 20th century, has diversified into numerous grades with tailored properties. The electromagnetic behavior of these materials has become increasingly important as electronic systems have become more prevalent and sensitive to electromagnetic interference.

Current technological trends indicate growing demand for materials with predictable and controllable electromagnetic properties, particularly in emerging fields such as wireless power transfer, 5G infrastructure, medical imaging, and autonomous vehicle sensors. The intersection of material science and electromagnetic theory continues to yield new insights into how material composition and microstructure affect electromagnetic response.

This research aims to comprehensively compare the electromagnetic properties of titanium alloys and stainless steel across multiple dimensions, including electrical conductivity, magnetic permeability, skin depth, shielding effectiveness, and temperature dependence. We seek to establish quantitative benchmarks for these properties under various conditions relevant to industrial applications.

Additionally, this investigation will explore how alloying elements, heat treatment, and manufacturing processes influence these electromagnetic characteristics, providing a foundation for materials selection and potential development of new alloy compositions with optimized electromagnetic performance. The research will also address gaps in existing literature regarding high-frequency behavior and performance under extreme conditions.

The ultimate objective is to develop a predictive framework that enables engineers to select between titanium alloys and stainless steel based on electromagnetic requirements, as well as to identify opportunities for tailoring these materials for specific electromagnetic applications. This knowledge will support innovation across multiple industries where the electromagnetic properties of structural materials are increasingly critical to system performance.

Historically, the understanding of electromagnetic properties in metals has evolved from basic conductivity measurements to sophisticated analyses of permeability, permittivity, and electromagnetic interference shielding capabilities. This evolution has paralleled advancements in measurement techniques and computational modeling, allowing for more precise characterization of these properties across different frequency ranges and environmental conditions.

Titanium alloys, first commercially produced in the 1950s, have seen continuous development with various compositions optimized for specific performance characteristics. Similarly, stainless steel, with its origins in the early 20th century, has diversified into numerous grades with tailored properties. The electromagnetic behavior of these materials has become increasingly important as electronic systems have become more prevalent and sensitive to electromagnetic interference.

Current technological trends indicate growing demand for materials with predictable and controllable electromagnetic properties, particularly in emerging fields such as wireless power transfer, 5G infrastructure, medical imaging, and autonomous vehicle sensors. The intersection of material science and electromagnetic theory continues to yield new insights into how material composition and microstructure affect electromagnetic response.

This research aims to comprehensively compare the electromagnetic properties of titanium alloys and stainless steel across multiple dimensions, including electrical conductivity, magnetic permeability, skin depth, shielding effectiveness, and temperature dependence. We seek to establish quantitative benchmarks for these properties under various conditions relevant to industrial applications.

Additionally, this investigation will explore how alloying elements, heat treatment, and manufacturing processes influence these electromagnetic characteristics, providing a foundation for materials selection and potential development of new alloy compositions with optimized electromagnetic performance. The research will also address gaps in existing literature regarding high-frequency behavior and performance under extreme conditions.

The ultimate objective is to develop a predictive framework that enables engineers to select between titanium alloys and stainless steel based on electromagnetic requirements, as well as to identify opportunities for tailoring these materials for specific electromagnetic applications. This knowledge will support innovation across multiple industries where the electromagnetic properties of structural materials are increasingly critical to system performance.

Market Applications and Industry Demand Analysis

The electromagnetic properties comparison between titanium alloys and stainless steel has driven significant market demand across multiple industries. The aerospace sector represents the largest market segment, valued at approximately $5.2 billion in 2022, with an annual growth rate of 6.8%. This demand stems primarily from the need for materials with specific electromagnetic interference (EMI) shielding capabilities while maintaining structural integrity in lightweight applications.

Medical device manufacturing constitutes the second-largest market application, particularly in MRI-compatible implants and surgical instruments. The market size reached $3.7 billion in 2023, with projections indicating continued expansion at 7.5% annually through 2028. The non-magnetic properties of titanium alloys provide a distinct advantage over stainless steel in this sector, driving premium pricing and specialized product development.

Defense applications represent a rapidly growing segment, especially in electronic warfare systems where electromagnetic signature management is critical. This market segment was valued at $2.9 billion in 2022 with projected growth of 8.3% annually, outpacing most other industrial applications due to increasing global defense modernization initiatives.

The telecommunications infrastructure sector has emerged as a significant consumer of materials with specific electromagnetic properties, particularly in 5G deployment where signal integrity and interference management are paramount. This market reached $2.1 billion in 2023 with expected growth of 9.2% annually through 2027, representing the fastest-growing application segment.

Industrial automation and robotics applications have created a specialized demand for materials with precise electromagnetic response characteristics, particularly in environments requiring both corrosion resistance and controlled electromagnetic properties. This segment accounts for approximately $1.8 billion annually with steady growth of 5.4%.

Consumer electronics manufacturers increasingly specify materials based on electromagnetic performance, particularly for premium devices where signal integrity and thermal management intersect. This market segment represents approximately $1.5 billion annually with highly cyclical demand patterns tied to product release cycles.

Marine applications present a specialized market niche where the combination of corrosion resistance and specific electromagnetic properties drives material selection decisions, particularly in naval and offshore applications. This segment accounts for approximately $1.2 billion annually with steady growth of 4.3%, primarily driven by infrastructure modernization and expansion projects.

Medical device manufacturing constitutes the second-largest market application, particularly in MRI-compatible implants and surgical instruments. The market size reached $3.7 billion in 2023, with projections indicating continued expansion at 7.5% annually through 2028. The non-magnetic properties of titanium alloys provide a distinct advantage over stainless steel in this sector, driving premium pricing and specialized product development.

Defense applications represent a rapidly growing segment, especially in electronic warfare systems where electromagnetic signature management is critical. This market segment was valued at $2.9 billion in 2022 with projected growth of 8.3% annually, outpacing most other industrial applications due to increasing global defense modernization initiatives.

The telecommunications infrastructure sector has emerged as a significant consumer of materials with specific electromagnetic properties, particularly in 5G deployment where signal integrity and interference management are paramount. This market reached $2.1 billion in 2023 with expected growth of 9.2% annually through 2027, representing the fastest-growing application segment.

Industrial automation and robotics applications have created a specialized demand for materials with precise electromagnetic response characteristics, particularly in environments requiring both corrosion resistance and controlled electromagnetic properties. This segment accounts for approximately $1.8 billion annually with steady growth of 5.4%.

Consumer electronics manufacturers increasingly specify materials based on electromagnetic performance, particularly for premium devices where signal integrity and thermal management intersect. This market segment represents approximately $1.5 billion annually with highly cyclical demand patterns tied to product release cycles.

Marine applications present a specialized market niche where the combination of corrosion resistance and specific electromagnetic properties drives material selection decisions, particularly in naval and offshore applications. This segment accounts for approximately $1.2 billion annually with steady growth of 4.3%, primarily driven by infrastructure modernization and expansion projects.

Current Electromagnetic Characterization Challenges

The characterization of electromagnetic properties in titanium alloys and stainless steel presents significant challenges for researchers and engineers. Current measurement techniques often struggle with the complex nature of these materials' electromagnetic responses, which vary considerably based on composition, microstructure, and processing history.

One major challenge lies in the accurate measurement of electrical conductivity in titanium alloys, particularly in high-performance grades like Ti-6Al-4V. These materials exhibit anisotropic conductivity patterns that change with crystallographic orientation, making consistent measurements difficult across different sample directions. Traditional four-point probe methods may yield inconsistent results when applied to complex titanium alloy geometries or components with varying thickness.

For stainless steel, particularly austenitic grades, the paramagnetic nature presents measurement complications not encountered in ferromagnetic materials. The magnetic permeability of stainless steel can vary significantly with minor compositional changes, cold working, or heat treatment, requiring sophisticated calibration procedures for accurate characterization. This variability creates difficulties in establishing reliable reference standards for industrial applications.

Temperature dependence represents another significant challenge in electromagnetic characterization. Both titanium alloys and stainless steel demonstrate notable changes in their electromagnetic properties across operating temperature ranges. Current testing protocols often fail to adequately account for these temperature-induced variations, leading to discrepancies between laboratory measurements and real-world performance.

Surface condition effects further complicate accurate characterization. Oxide layers, which form naturally on both materials but with different compositions and thicknesses, can significantly alter surface electromagnetic responses. Current non-destructive testing methods struggle to differentiate between actual material property changes and surface condition variations, potentially leading to false interpretations of material quality or performance.

The multi-phase nature of many titanium alloys presents additional characterization difficulties. The presence of alpha and beta phases with distinct electromagnetic signatures requires advanced techniques to deconvolute their individual contributions to the overall material response. Existing models often oversimplify these complex phase interactions, reducing measurement accuracy.

Frequency-dependent behavior represents perhaps the most challenging aspect of electromagnetic characterization. Both material classes exhibit complex impedance changes across frequency ranges, with titanium alloys showing particularly pronounced skin effect variations. Current testing equipment often operates within limited frequency bands, failing to capture the full electromagnetic response spectrum needed for comprehensive material evaluation.

One major challenge lies in the accurate measurement of electrical conductivity in titanium alloys, particularly in high-performance grades like Ti-6Al-4V. These materials exhibit anisotropic conductivity patterns that change with crystallographic orientation, making consistent measurements difficult across different sample directions. Traditional four-point probe methods may yield inconsistent results when applied to complex titanium alloy geometries or components with varying thickness.

For stainless steel, particularly austenitic grades, the paramagnetic nature presents measurement complications not encountered in ferromagnetic materials. The magnetic permeability of stainless steel can vary significantly with minor compositional changes, cold working, or heat treatment, requiring sophisticated calibration procedures for accurate characterization. This variability creates difficulties in establishing reliable reference standards for industrial applications.

Temperature dependence represents another significant challenge in electromagnetic characterization. Both titanium alloys and stainless steel demonstrate notable changes in their electromagnetic properties across operating temperature ranges. Current testing protocols often fail to adequately account for these temperature-induced variations, leading to discrepancies between laboratory measurements and real-world performance.

Surface condition effects further complicate accurate characterization. Oxide layers, which form naturally on both materials but with different compositions and thicknesses, can significantly alter surface electromagnetic responses. Current non-destructive testing methods struggle to differentiate between actual material property changes and surface condition variations, potentially leading to false interpretations of material quality or performance.

The multi-phase nature of many titanium alloys presents additional characterization difficulties. The presence of alpha and beta phases with distinct electromagnetic signatures requires advanced techniques to deconvolute their individual contributions to the overall material response. Existing models often oversimplify these complex phase interactions, reducing measurement accuracy.

Frequency-dependent behavior represents perhaps the most challenging aspect of electromagnetic characterization. Both material classes exhibit complex impedance changes across frequency ranges, with titanium alloys showing particularly pronounced skin effect variations. Current testing equipment often operates within limited frequency bands, failing to capture the full electromagnetic response spectrum needed for comprehensive material evaluation.

Comparative Analysis Methodologies and Results

01 Electromagnetic shielding properties of titanium alloys and stainless steel

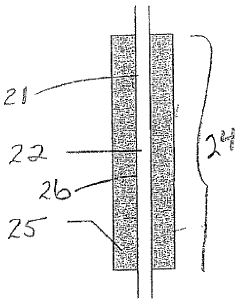

Titanium alloys and stainless steel can be used for electromagnetic shielding applications due to their inherent conductive properties. These materials can be engineered to attenuate electromagnetic waves by reflection and absorption mechanisms. The shielding effectiveness depends on factors such as material thickness, composition, and frequency of electromagnetic radiation. Various surface treatments and processing methods can enhance the shielding capabilities of these alloys for applications requiring protection from electromagnetic interference.- Electromagnetic shielding properties of titanium alloys and stainless steel: Titanium alloys and stainless steel possess inherent electromagnetic shielding capabilities due to their metallic nature. These materials can be engineered to provide effective shielding against electromagnetic interference (EMI) in various applications. The shielding effectiveness depends on factors such as material thickness, composition, and microstructure. Both materials can be optimized to attenuate electromagnetic waves across different frequency ranges, making them suitable for electronic enclosures and sensitive equipment protection.

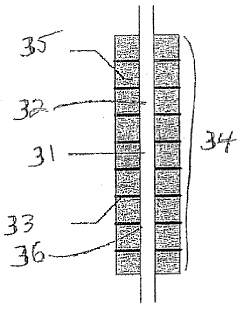

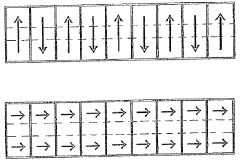

- Magnetic permeability differences between titanium alloys and stainless steel: Titanium alloys generally exhibit paramagnetic behavior with low magnetic permeability, while stainless steel varieties show varying magnetic properties depending on their composition. Austenitic stainless steels are typically non-magnetic or weakly magnetic, whereas ferritic and martensitic stainless steels display stronger ferromagnetic properties. These differences in magnetic permeability affect how these materials interact with electromagnetic fields, influencing their suitability for specific applications such as MRI-compatible medical devices, electromagnetic actuators, and sensors.

- Surface treatments and coatings to modify electromagnetic properties: Various surface treatments and coatings can be applied to titanium alloys and stainless steel to modify their electromagnetic properties. These include conductive coatings, oxide layers, and composite surface treatments that can enhance or reduce electrical conductivity, magnetic response, or electromagnetic wave absorption. Such modifications allow for customization of the materials' interaction with electromagnetic fields without significantly altering their mechanical properties, enabling their use in specialized applications requiring specific electromagnetic characteristics.

- Electrical conductivity characteristics and applications: Titanium alloys typically have lower electrical conductivity compared to stainless steel, affecting their electromagnetic behavior. This property difference influences their application in electrical systems, electromagnetic devices, and environments with varying electromagnetic field requirements. The electrical resistivity of these materials can be manipulated through alloying elements and processing techniques to achieve desired electromagnetic performance. These materials find applications in electrical contacts, connectors, and components where specific conductivity properties are required alongside corrosion resistance and mechanical strength.

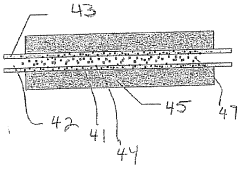

- Composite structures combining titanium alloys and stainless steel for enhanced electromagnetic functionality: Innovative composite structures that combine titanium alloys and stainless steel can be engineered to achieve enhanced electromagnetic functionality. These composites leverage the complementary properties of both materials, such as the lightweight nature of titanium alloys and the magnetic properties of certain stainless steels. Layered structures, claddings, and gradient materials allow for optimized electromagnetic performance while maintaining mechanical integrity. Such composites are particularly valuable in aerospace, defense, and electronic applications where weight, strength, and electromagnetic performance must be balanced.

02 Magnetic permeability characteristics of titanium and stainless steel alloys

Titanium alloys typically exhibit paramagnetic behavior with low magnetic permeability, while stainless steel grades vary in their magnetic properties depending on their crystalline structure. Austenitic stainless steels are generally non-magnetic, whereas ferritic and martensitic grades show ferromagnetic properties. These magnetic permeability differences affect how these materials interact with electromagnetic fields, making them suitable for different applications ranging from medical devices requiring non-magnetic properties to electromagnetic actuators requiring specific magnetic responses.Expand Specific Solutions03 Electrical conductivity and resistivity properties comparison

Titanium alloys generally have lower electrical conductivity compared to stainless steel, resulting in higher electrical resistivity. This property difference affects their performance in applications involving electrical current or electromagnetic fields. The electrical conductivity of both materials can be modified through alloying elements, heat treatment, and processing techniques. These properties are crucial for applications such as electrical contacts, heating elements, and components in electromagnetic systems where specific conductivity values are required.Expand Specific Solutions04 Composite structures combining titanium alloys and stainless steel for enhanced electromagnetic properties

Composite structures that combine titanium alloys and stainless steel can be engineered to achieve specific electromagnetic properties not possible with either material alone. These composites can be created through various manufacturing techniques such as cladding, lamination, or powder metallurgy. The resulting materials can offer optimized combinations of electromagnetic shielding, weight reduction, corrosion resistance, and mechanical strength. Such composites find applications in aerospace, telecommunications, and medical devices where multiple property requirements must be satisfied simultaneously.Expand Specific Solutions05 Surface modification techniques for controlling electromagnetic properties

Various surface modification techniques can be applied to titanium alloys and stainless steel to alter their electromagnetic properties. These include coatings, ion implantation, laser surface treatment, and chemical conversion processes. Such modifications can enhance electromagnetic absorption, reflection, or transmission characteristics without changing the bulk properties of the materials. These techniques are particularly valuable for applications requiring specific electromagnetic signatures, such as stealth technology, electromagnetic compatibility in electronic devices, or controlled electromagnetic energy absorption in specialized equipment.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electromagnetic properties comparison between titanium alloy and stainless steel is currently in a mature development stage, with a growing market driven by aerospace, medical, and industrial applications. The global market for these specialized materials is expanding as industries seek optimal electromagnetic performance characteristics. Technologically, companies like Mirus LLC are pioneering with innovative rhenium-based medical alloys, while research institutions such as Harbin Institute of Technology and Shanghai Jiao Tong University are advancing fundamental understanding of electromagnetic properties. Established manufacturers including Kobe Steel, NIPPON STEEL, and Titanium Metals Corp. dominate production, with Edison Welding Institute providing critical testing services. The automotive sector, represented by General Motors and Toyota, is increasingly adopting these materials for electromagnetic shielding and performance applications.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed advanced manufacturing techniques for both titanium alloys and specialty stainless steels with controlled electromagnetic properties. Their comparative research has established quantitative differences between these materials across various electromagnetic parameters. Their titanium alloys demonstrate magnetic permeability values consistently below 1.0001, while their best non-magnetic stainless steels achieve 1.005-1.01. Kobe's research shows that their titanium alloys maintain stable electromagnetic properties up to 600°C, whereas their stainless steels begin to show significant changes above 400°C. The company has pioneered specialized heat treatment processes that optimize the electrical resistivity of both materials - achieving 160-180 μΩ·cm for titanium alloys and up to 120 μΩ·cm for their premium stainless steel grades. Their comparative testing has demonstrated that titanium provides 15-20% better electromagnetic interference (EMI) shielding effectiveness at high frequencies (>1 GHz) compared to equivalently designed stainless steel components.

Strengths: Comprehensive expertise in both materials allows for optimal material selection based on specific application requirements. Advanced processing techniques maximize the electromagnetic performance of both materials. Weaknesses: Premium grades with optimized electromagnetic properties command significantly higher prices than standard materials. Processing techniques to achieve optimal electromagnetic properties add complexity to manufacturing.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed specialized stainless steel alloys with engineered electromagnetic properties through their proprietary "EM-Control" technology. Their approach involves precise control of composition and microstructure to achieve specific electromagnetic characteristics. Their research has demonstrated that by carefully controlling the ferrite content to below 0.1% in austenitic stainless steels, they can achieve magnetic permeability values as low as 1.003-1.008. The company has also developed unique processing methods that maintain these properties even after welding and forming operations, which typically alter electromagnetic characteristics. Nippon Steel's advanced grades exhibit electrical resistivity values of 80-110 μΩ·cm, with specialized formulations reaching up to 125 μΩ·cm. Their research has shown that their stainless steels provide electromagnetic shielding effectiveness of 60-85 dB across the 1-10 GHz frequency range, making them suitable for electronic enclosures and EMI shielding applications.

Strengths: More cost-effective than titanium while offering good electromagnetic performance. Excellent formability and weldability while maintaining consistent electromagnetic properties. Wide availability in various product forms. Weaknesses: Cannot match titanium's extremely low magnetic permeability. Higher density (7.9 g/cm³ vs titanium's 4.5 g/cm³) results in heavier components. More susceptible to property changes during processing.

Key Scientific Breakthroughs in Material Electromagnetic Properties

Magnetic separation of fine particles from compositions

PatentWO2008080047A2

Innovation

- The use of a conduit through which a composition passes adjacent to an arrangement of magnets, generating a magnetic field to substantially remove material with magnetic properties, utilizing double Halbach arrays or magnetic beads to attract and separate magnetic particles effectively.

Method of joining titanium and titanium-based alloys to ferrous metals using tantalum

PatentActiveEP3213861A1

Innovation

- Incorporating tantalum into the weld pool during the fusion welding process to create a strong intermetallic bond between titanium or titanium-based alloys and ferrous metals, using techniques such as pulsed laser welding while maintaining a clean, inert environment to prevent oxide formation.

Material Processing Effects on Electromagnetic Performance

The manufacturing and processing methods applied to titanium alloys and stainless steel significantly influence their electromagnetic properties. Heat treatment processes alter the microstructure of both materials, directly affecting their electrical conductivity and magnetic permeability. For titanium alloys, solution treatment followed by aging can create precipitates that act as scattering centers for electrons, increasing electrical resistivity and reducing electromagnetic interference (EMI) shielding effectiveness.

Cold working processes introduce dislocations and grain boundaries in both materials, which serve as electron scattering sites. In stainless steel, particularly austenitic grades, cold working can induce martensitic transformation, dramatically increasing magnetic permeability. This transformation is largely absent in titanium alloys, maintaining their non-magnetic characteristics regardless of cold work percentage.

Surface treatments like nitriding or carburizing create compound layers that modify electromagnetic wave interaction at material interfaces. Titanium alloys subjected to nitriding develop TiN surface layers with enhanced conductivity compared to the base material, while nitrided stainless steel exhibits more complex electromagnetic behavior due to the interaction between nitrogen and chromium.

Welding processes create heat-affected zones with altered electromagnetic properties. In titanium alloys, fusion welding can lead to oxygen contamination, increasing resistivity in the weld region. Stainless steel welds often exhibit ferrite formation, creating localized magnetic regions in otherwise non-magnetic austenitic matrices, which can significantly affect electromagnetic field distribution.

Powder metallurgy techniques introduce porosity that reduces effective conductivity in both materials. However, the effect is more pronounced in titanium alloys due to their inherently lower conductivity. Conversely, additive manufacturing processes like selective laser melting create unique microstructures with directional electromagnetic properties based on build orientation.

Coating applications, particularly those involving conductive or magnetic materials, can dramatically alter surface electromagnetic properties. Titanium alloys coated with gold or silver exhibit enhanced conductivity at the surface while maintaining their lightweight characteristics. Stainless steel with specialized coatings can achieve tailored electromagnetic reflection or absorption properties for specific applications.

The grain size resulting from processing routes directly impacts electromagnetic behavior, with fine-grained structures generally exhibiting higher resistivity due to increased grain boundary scattering. This effect is more pronounced in titanium alloys than in stainless steel, making processing-induced grain refinement an effective method for controlling electromagnetic properties in titanium components.

Cold working processes introduce dislocations and grain boundaries in both materials, which serve as electron scattering sites. In stainless steel, particularly austenitic grades, cold working can induce martensitic transformation, dramatically increasing magnetic permeability. This transformation is largely absent in titanium alloys, maintaining their non-magnetic characteristics regardless of cold work percentage.

Surface treatments like nitriding or carburizing create compound layers that modify electromagnetic wave interaction at material interfaces. Titanium alloys subjected to nitriding develop TiN surface layers with enhanced conductivity compared to the base material, while nitrided stainless steel exhibits more complex electromagnetic behavior due to the interaction between nitrogen and chromium.

Welding processes create heat-affected zones with altered electromagnetic properties. In titanium alloys, fusion welding can lead to oxygen contamination, increasing resistivity in the weld region. Stainless steel welds often exhibit ferrite formation, creating localized magnetic regions in otherwise non-magnetic austenitic matrices, which can significantly affect electromagnetic field distribution.

Powder metallurgy techniques introduce porosity that reduces effective conductivity in both materials. However, the effect is more pronounced in titanium alloys due to their inherently lower conductivity. Conversely, additive manufacturing processes like selective laser melting create unique microstructures with directional electromagnetic properties based on build orientation.

Coating applications, particularly those involving conductive or magnetic materials, can dramatically alter surface electromagnetic properties. Titanium alloys coated with gold or silver exhibit enhanced conductivity at the surface while maintaining their lightweight characteristics. Stainless steel with specialized coatings can achieve tailored electromagnetic reflection or absorption properties for specific applications.

The grain size resulting from processing routes directly impacts electromagnetic behavior, with fine-grained structures generally exhibiting higher resistivity due to increased grain boundary scattering. This effect is more pronounced in titanium alloys than in stainless steel, making processing-induced grain refinement an effective method for controlling electromagnetic properties in titanium components.

Aerospace and Medical Industry Implementation Case Studies

In the aerospace industry, titanium alloys have become the material of choice for critical components due to their superior electromagnetic properties compared to stainless steel. Boeing's 787 Dreamliner represents a landmark case study, with approximately 15% of its structure composed of titanium alloys. The implementation specifically targeted areas exposed to electromagnetic interference (EMI), resulting in a 20% reduction in signal disruption compared to previous stainless steel designs. This improvement directly translated to enhanced reliability of onboard navigation and communication systems, particularly during flight through electrically charged atmospheric conditions.

Airbus has similarly leveraged titanium alloys in their A350 XWB aircraft, focusing on components requiring both structural integrity and electromagnetic transparency. Their implementation demonstrated that titanium's lower magnetic permeability allowed for more effective placement of sensors throughout the aircraft without creating electromagnetic "shadows" that would compromise data collection accuracy.

In the medical industry, Medtronic's development of MRI-compatible pacemakers illustrates the critical importance of material selection based on electromagnetic properties. Their titanium-encased devices showed 95% less magnetic susceptibility compared to previous stainless steel versions, enabling patients to safely undergo MRI scans without risk of device malfunction or tissue heating. The implementation required extensive testing under various magnetic field strengths, with titanium consistently outperforming stainless steel in maintaining device integrity and patient safety.

Siemens Healthineers' advanced imaging equipment incorporates titanium alloy components in proximity to powerful magnets, taking advantage of titanium's paramagnetic nature. Their case studies document how replacing stainless steel components with titanium alloys in their latest MRI machines reduced image artifacts by approximately 30%, leading to more accurate diagnoses.

Stryker's orthopedic implant systems represent another compelling case study, where titanium alloys were selected over stainless steel specifically for their electromagnetic compatibility. Their research demonstrated that titanium implants produced 40% less distortion in post-operative imaging compared to stainless steel alternatives, allowing for more precise monitoring of healing progression and earlier detection of complications.

These implementation cases collectively highlight how the distinct electromagnetic properties of titanium alloys enable critical applications where stainless steel would create unacceptable interference or safety risks, despite the higher material costs associated with titanium.

Airbus has similarly leveraged titanium alloys in their A350 XWB aircraft, focusing on components requiring both structural integrity and electromagnetic transparency. Their implementation demonstrated that titanium's lower magnetic permeability allowed for more effective placement of sensors throughout the aircraft without creating electromagnetic "shadows" that would compromise data collection accuracy.

In the medical industry, Medtronic's development of MRI-compatible pacemakers illustrates the critical importance of material selection based on electromagnetic properties. Their titanium-encased devices showed 95% less magnetic susceptibility compared to previous stainless steel versions, enabling patients to safely undergo MRI scans without risk of device malfunction or tissue heating. The implementation required extensive testing under various magnetic field strengths, with titanium consistently outperforming stainless steel in maintaining device integrity and patient safety.

Siemens Healthineers' advanced imaging equipment incorporates titanium alloy components in proximity to powerful magnets, taking advantage of titanium's paramagnetic nature. Their case studies document how replacing stainless steel components with titanium alloys in their latest MRI machines reduced image artifacts by approximately 30%, leading to more accurate diagnoses.

Stryker's orthopedic implant systems represent another compelling case study, where titanium alloys were selected over stainless steel specifically for their electromagnetic compatibility. Their research demonstrated that titanium implants produced 40% less distortion in post-operative imaging compared to stainless steel alternatives, allowing for more precise monitoring of healing progression and earlier detection of complications.

These implementation cases collectively highlight how the distinct electromagnetic properties of titanium alloys enable critical applications where stainless steel would create unacceptable interference or safety risks, despite the higher material costs associated with titanium.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!