Analysis of Lightweight Structures: Titanium Alloy vs Stainless Steel

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lightweight Materials Evolution and Objectives

The evolution of lightweight materials in structural engineering has undergone significant transformation over the past century. Initially dominated by traditional metals like steel and aluminum, the field has progressively embraced more advanced alloys and composites to meet increasing demands for weight reduction while maintaining structural integrity. The 1950s marked a pivotal shift with the aerospace industry driving titanium alloy development, while stainless steel continued to evolve from its early 20th century origins into various specialized grades.

The trajectory of lightweight material development has been characterized by continuous refinement of manufacturing processes, including precision casting, advanced machining techniques, and more recently, additive manufacturing. These innovations have enabled more complex geometries and optimized material distribution, further enhancing the weight-to-strength ratio of structural components.

In the context of titanium alloys versus stainless steel, both materials have experienced parallel but distinct evolutionary paths. Titanium alloys have progressed from simple alpha and beta phases to complex multi-phase compositions, with each generation offering improved specific strength and temperature resistance. Simultaneously, stainless steel has evolved from basic austenitic compositions to sophisticated duplex, precipitation-hardened, and nitrogen-enhanced variants with improved strength-to-weight characteristics.

The primary objective in comparing titanium alloys and stainless steel for lightweight structures is to establish a comprehensive framework for material selection based on performance metrics beyond mere density considerations. This includes evaluating specific strength (strength-to-weight ratio), fatigue resistance, corrosion behavior, and temperature performance across various environmental conditions.

Additional objectives include quantifying the long-term economic implications of material selection, considering not only initial material costs but also fabrication complexity, maintenance requirements, and service life expectations. The analysis aims to develop predictive models for structural performance that account for material-specific behaviors under dynamic loading conditions.

Furthermore, this technical exploration seeks to identify optimal application domains for each material class, recognizing that neither titanium alloys nor stainless steel represents a universal solution for all lightweight structural challenges. By establishing clear performance boundaries and application-specific selection criteria, this research aims to provide engineers with decision-making tools that balance technical performance with practical implementation considerations.

The trajectory of lightweight material development has been characterized by continuous refinement of manufacturing processes, including precision casting, advanced machining techniques, and more recently, additive manufacturing. These innovations have enabled more complex geometries and optimized material distribution, further enhancing the weight-to-strength ratio of structural components.

In the context of titanium alloys versus stainless steel, both materials have experienced parallel but distinct evolutionary paths. Titanium alloys have progressed from simple alpha and beta phases to complex multi-phase compositions, with each generation offering improved specific strength and temperature resistance. Simultaneously, stainless steel has evolved from basic austenitic compositions to sophisticated duplex, precipitation-hardened, and nitrogen-enhanced variants with improved strength-to-weight characteristics.

The primary objective in comparing titanium alloys and stainless steel for lightweight structures is to establish a comprehensive framework for material selection based on performance metrics beyond mere density considerations. This includes evaluating specific strength (strength-to-weight ratio), fatigue resistance, corrosion behavior, and temperature performance across various environmental conditions.

Additional objectives include quantifying the long-term economic implications of material selection, considering not only initial material costs but also fabrication complexity, maintenance requirements, and service life expectations. The analysis aims to develop predictive models for structural performance that account for material-specific behaviors under dynamic loading conditions.

Furthermore, this technical exploration seeks to identify optimal application domains for each material class, recognizing that neither titanium alloys nor stainless steel represents a universal solution for all lightweight structural challenges. By establishing clear performance boundaries and application-specific selection criteria, this research aims to provide engineers with decision-making tools that balance technical performance with practical implementation considerations.

Market Demand for Lightweight Structural Solutions

The global market for lightweight structural solutions has experienced significant growth over the past decade, driven primarily by industries seeking to improve fuel efficiency, reduce environmental impact, and enhance performance characteristics. The aerospace sector represents the largest market segment, valued at approximately $45 billion in 2022, with projected annual growth rates of 6.8% through 2030. This demand stems from commercial aircraft manufacturers' push to reduce operating costs and meet increasingly stringent emissions regulations.

Automotive manufacturers constitute the second-largest market segment, particularly as electric vehicle production accelerates. Weight reduction directly correlates with extended battery range, making lightweight materials a critical competitive advantage. Market research indicates that for every 10% reduction in vehicle weight, fuel economy improves by 6-8%, translating to substantial operational savings over a vehicle's lifetime.

The medical device industry has emerged as a rapidly expanding market for lightweight structural materials, particularly titanium alloys, due to their biocompatibility and strength-to-weight advantages. Surgical instruments, implantable devices, and mobility equipment manufacturers increasingly specify these materials to improve patient outcomes and provider usability.

Defense applications represent another significant market driver, with military equipment manufacturers prioritizing mobility and transportability while maintaining structural integrity under extreme conditions. Government contracts for lightweight armor systems and portable equipment exceeded $12 billion globally in 2022.

Consumer electronics and sporting goods industries have also contributed to market growth, with premium products leveraging the aesthetic and performance benefits of lightweight materials to command higher price points and brand differentiation. The marine industry similarly seeks weight reduction to improve vessel speed, fuel efficiency, and handling characteristics.

Market analysis reveals regional variations in demand patterns. North America and Europe currently lead in adoption rates, primarily due to established aerospace and automotive manufacturing bases. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China's industrial policy specifically targeting lightweight materials development as a strategic priority.

Economic factors influencing market demand include raw material price volatility, manufacturing process complexity, and total lifecycle costs. While initial material costs for titanium alloys exceed those of stainless steel by 300-400%, the long-term operational benefits often justify this premium in applications where weight reduction delivers measurable performance advantages.

Automotive manufacturers constitute the second-largest market segment, particularly as electric vehicle production accelerates. Weight reduction directly correlates with extended battery range, making lightweight materials a critical competitive advantage. Market research indicates that for every 10% reduction in vehicle weight, fuel economy improves by 6-8%, translating to substantial operational savings over a vehicle's lifetime.

The medical device industry has emerged as a rapidly expanding market for lightweight structural materials, particularly titanium alloys, due to their biocompatibility and strength-to-weight advantages. Surgical instruments, implantable devices, and mobility equipment manufacturers increasingly specify these materials to improve patient outcomes and provider usability.

Defense applications represent another significant market driver, with military equipment manufacturers prioritizing mobility and transportability while maintaining structural integrity under extreme conditions. Government contracts for lightweight armor systems and portable equipment exceeded $12 billion globally in 2022.

Consumer electronics and sporting goods industries have also contributed to market growth, with premium products leveraging the aesthetic and performance benefits of lightweight materials to command higher price points and brand differentiation. The marine industry similarly seeks weight reduction to improve vessel speed, fuel efficiency, and handling characteristics.

Market analysis reveals regional variations in demand patterns. North America and Europe currently lead in adoption rates, primarily due to established aerospace and automotive manufacturing bases. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China's industrial policy specifically targeting lightweight materials development as a strategic priority.

Economic factors influencing market demand include raw material price volatility, manufacturing process complexity, and total lifecycle costs. While initial material costs for titanium alloys exceed those of stainless steel by 300-400%, the long-term operational benefits often justify this premium in applications where weight reduction delivers measurable performance advantages.

Current Status and Challenges in Titanium and Steel Technologies

The global landscape of lightweight structural materials is witnessing significant advancements, with titanium alloys and stainless steel remaining at the forefront of engineering applications. Currently, titanium alloys dominate aerospace and high-performance applications due to their exceptional strength-to-weight ratio, with Ti-6Al-4V being the most widely utilized grade, accounting for approximately 50% of all titanium alloy usage worldwide. However, production capacity constraints persist, with global titanium sponge production hovering around 230,000 metric tons annually, creating supply chain vulnerabilities.

In contrast, stainless steel production has reached over 50 million tons annually, offering significantly greater availability and established supply chains. Recent advancements in precipitation-hardened stainless steels have narrowed the performance gap with titanium alloys, particularly in moderate temperature applications below 500°C. The development of ultra-high-strength stainless steel grades with yield strengths exceeding 1400 MPa represents a notable technological breakthrough in this space.

A critical challenge facing titanium technology is the energy-intensive Kroll process, which accounts for approximately 55% of titanium's high production costs. Alternative extraction methods, including the FFC Cambridge process and Armstrong process, show promise but remain commercially limited. Similarly, advanced manufacturing techniques like additive manufacturing are revolutionizing titanium component production, though challenges in powder quality consistency and post-processing requirements persist.

For stainless steel, the primary technical challenges include improving high-temperature performance beyond 800°C and enhancing corrosion resistance in extreme environments. Recent innovations in nitrogen-enhanced duplex stainless steels have demonstrated improved strength and corrosion resistance, but their widespread adoption faces processing difficulties and higher production costs.

Geographically, titanium technology leadership remains concentrated in the United States, Russia, Japan, and increasingly China, which now produces over 30% of global titanium materials. Stainless steel technology, while more globally distributed, sees significant innovation clusters in Europe, Japan, South Korea, and China, with specialized high-performance grades predominantly developed in Germany, Sweden, and Japan.

Environmental considerations present additional challenges, with titanium production generating 5-7 times more CO₂ emissions per ton than stainless steel. However, lifecycle assessments often favor titanium in long-term applications due to extended service life and reduced maintenance requirements. Both materials face increasing pressure to develop more sustainable production methods, with hydrogen-based reduction processes showing particular promise for stainless steel manufacturing.

In contrast, stainless steel production has reached over 50 million tons annually, offering significantly greater availability and established supply chains. Recent advancements in precipitation-hardened stainless steels have narrowed the performance gap with titanium alloys, particularly in moderate temperature applications below 500°C. The development of ultra-high-strength stainless steel grades with yield strengths exceeding 1400 MPa represents a notable technological breakthrough in this space.

A critical challenge facing titanium technology is the energy-intensive Kroll process, which accounts for approximately 55% of titanium's high production costs. Alternative extraction methods, including the FFC Cambridge process and Armstrong process, show promise but remain commercially limited. Similarly, advanced manufacturing techniques like additive manufacturing are revolutionizing titanium component production, though challenges in powder quality consistency and post-processing requirements persist.

For stainless steel, the primary technical challenges include improving high-temperature performance beyond 800°C and enhancing corrosion resistance in extreme environments. Recent innovations in nitrogen-enhanced duplex stainless steels have demonstrated improved strength and corrosion resistance, but their widespread adoption faces processing difficulties and higher production costs.

Geographically, titanium technology leadership remains concentrated in the United States, Russia, Japan, and increasingly China, which now produces over 30% of global titanium materials. Stainless steel technology, while more globally distributed, sees significant innovation clusters in Europe, Japan, South Korea, and China, with specialized high-performance grades predominantly developed in Germany, Sweden, and Japan.

Environmental considerations present additional challenges, with titanium production generating 5-7 times more CO₂ emissions per ton than stainless steel. However, lifecycle assessments often favor titanium in long-term applications due to extended service life and reduced maintenance requirements. Both materials face increasing pressure to develop more sustainable production methods, with hydrogen-based reduction processes showing particular promise for stainless steel manufacturing.

Comparative Technical Solutions: Ti Alloys vs Stainless Steel

01 Titanium alloy compositions for improved strength-to-weight ratio

Specific titanium alloy compositions are developed to optimize the strength-to-weight ratio for lightweight structural applications. These alloys typically contain carefully balanced amounts of elements such as aluminum, vanadium, molybdenum, and other stabilizing elements to achieve superior mechanical properties while maintaining low density. The microstructure of these alloys can be further optimized through heat treatment processes to enhance strength without significantly increasing weight.- Titanium alloy compositions for improved strength-to-weight ratio: Specific titanium alloy compositions have been developed to optimize the strength-to-weight ratio for lightweight structural applications. These alloys typically contain carefully balanced proportions of elements such as aluminum, vanadium, molybdenum, and other transition metals to enhance mechanical properties while maintaining low density. The microstructure of these alloys can be further optimized through heat treatment processes to achieve the desired combination of strength, ductility, and weight efficiency for aerospace, automotive, and other high-performance applications.

- Advanced stainless steel formulations for lightweight structures: Innovative stainless steel formulations have been developed specifically for lightweight structural applications where corrosion resistance is also required. These steels typically feature modified compositions with precise control of carbon, chromium, nickel, and other alloying elements to achieve higher strength-to-weight ratios than conventional stainless steels. Manufacturing techniques such as controlled rolling and specialized heat treatments are employed to optimize the microstructure, resulting in materials that combine excellent mechanical properties with the inherent corrosion resistance of stainless steel, making them suitable for applications in marine environments, chemical processing, and architectural structures.

- Composite and hybrid structures combining titanium alloys and stainless steel: Hybrid structural designs that strategically combine titanium alloys and stainless steel components can optimize the overall weight-to-strength ratio of a system. These designs typically place each material where its specific properties provide the most benefit, with titanium alloys used in high strength-to-weight critical areas and stainless steel in regions requiring corrosion resistance or specific mechanical properties. Advanced joining techniques such as friction welding, diffusion bonding, or mechanical fastening systems are employed to create these hybrid structures, resulting in components that achieve better performance metrics than would be possible with either material alone.

- Manufacturing processes to enhance strength-to-weight ratio: Specialized manufacturing processes have been developed to enhance the strength-to-weight ratio of both titanium alloys and stainless steels. These include advanced forming techniques such as superplastic forming, precision forging, and powder metallurgy, which can create near-net-shape components with optimized microstructures. Post-processing treatments such as shot peening, surface hardening, and controlled heat treatments further improve mechanical properties. Additionally, precision machining techniques remove material only where necessary, creating optimized geometries that maintain structural integrity while minimizing weight, resulting in components with exceptional strength-to-weight performance.

- Structural design optimization for titanium and stainless steel components: Advanced structural design methodologies have been developed specifically for titanium alloys and stainless steels to maximize strength-to-weight efficiency. These approaches include topology optimization, lattice structures, variable thickness designs, and biomimetic principles that distribute material only where needed for load-bearing. Computational methods such as finite element analysis and machine learning algorithms help identify optimal geometries that maintain structural integrity with minimal material usage. These design techniques, when combined with the inherent properties of titanium alloys and stainless steels, result in lightweight structures that achieve superior performance in applications ranging from aerospace components to medical implants.

02 Advanced stainless steel formulations for lightweight applications

Novel stainless steel formulations are designed specifically for applications requiring high strength-to-weight ratios. These steels incorporate precise amounts of chromium, nickel, and other alloying elements to achieve enhanced mechanical properties while reducing overall weight. Manufacturing techniques such as controlled rolling and specialized heat treatments are employed to develop fine-grained microstructures that contribute to improved strength without density penalties.Expand Specific Solutions03 Composite structures combining titanium alloys and stainless steel

Hybrid structural components that strategically combine titanium alloys and stainless steel take advantage of the beneficial properties of both materials. These composite structures are designed to optimize the weight-to-strength ratio by placing each material where its properties are most advantageous. Various joining techniques including welding, mechanical fastening, and adhesive bonding are employed to create these hybrid structures while maintaining structural integrity and preventing galvanic corrosion.Expand Specific Solutions04 Surface treatment and coating technologies for lightweight metal structures

Various surface treatment and coating technologies are applied to titanium alloys and stainless steel to enhance their performance characteristics without adding significant weight. These treatments include nitriding, carburizing, and the application of specialized coatings that improve wear resistance, corrosion protection, and fatigue strength. Such surface modifications allow for the use of lighter base materials while still meeting performance requirements for specific applications.Expand Specific Solutions05 Manufacturing processes for optimizing weight-to-strength ratio

Advanced manufacturing processes are developed specifically to optimize the weight-to-strength ratio of titanium alloy and stainless steel components. These include precision forming techniques, additive manufacturing, powder metallurgy, and specialized heat treatment protocols. Such processes enable the production of components with complex geometries, variable wall thicknesses, and engineered porosity that maximize strength while minimizing weight for aerospace, automotive, and other lightweight applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The lightweight structures market is currently in a growth phase, with titanium alloys gaining significant traction over stainless steel due to superior strength-to-weight ratios. The global market for lightweight materials is expanding rapidly, projected to reach approximately $250 billion by 2026. Technologically, titanium alloys have reached commercial maturity but continue to evolve through innovations from key players. QuesTek Innovations leads in computational materials design, while NIPPON STEEL and VSMPO-AVISMA dominate production volume. Research institutions like Harbin Institute of Technology and Shanghai Jiao Tong University are advancing next-generation alloys. In aerospace applications, Boeing, MTU Aero Engines, and Rolls-Royce are driving adoption, while medical applications see innovation from OSSTEM IMPLANT and Lake Region Manufacturing, creating a competitive landscape balanced between established producers and emerging technology developers.

QuesTek Innovations LLC

Technical Solution: QuesTek Innovations has pioneered computational materials design to develop next-generation titanium alloys specifically optimized for lightweight structural applications. Their Integrated Computational Materials Engineering (ICME) approach enables precise tailoring of microstructure and properties. QuesTek's Ti-185 alloy demonstrates 15% higher specific strength than conventional Ti-6Al-4V while maintaining excellent fatigue resistance. Their comparative analysis with advanced stainless steels shows weight savings of 45-50% for equivalent structural performance. QuesTek has also developed specialized heat treatment protocols that enhance the mechanical properties of their titanium alloys, achieving tensile strengths above 1300 MPa while maintaining good ductility. Their research includes comprehensive lifecycle analysis comparing titanium alloys to stainless steel, demonstrating that despite higher initial material costs, titanium solutions often provide better long-term value through extended service life and reduced maintenance requirements in corrosive environments.

Strengths: Cutting-edge computational design capabilities, highly optimized alloy compositions, and comprehensive performance validation. Weaknesses: Higher initial material costs and limited production scale compared to established titanium and steel manufacturers.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed innovative lightweight stainless steel solutions that directly compete with titanium alloys in structural applications. Their high-nitrogen austenitic stainless steels demonstrate tensile strengths exceeding 1000 MPa while maintaining excellent corrosion resistance. Through advanced processing techniques including controlled rolling and specialized heat treatments, Nippon Steel has created ultra-thin gauge stainless steel sheets (down to 0.1mm thickness) that provide weight reductions approaching those of titanium alloys at significantly lower cost. Their comparative analysis shows that their advanced stainless steel grades achieve 80-85% of titanium's weight reduction benefits while costing only 30-40% as much. For automotive and industrial applications, Nippon Steel has developed precipitation-hardened stainless steel grades that combine high strength (up to 1800 MPa) with good formability, enabling complex lightweight components that were previously only possible with titanium alloys.

Strengths: Excellent cost-performance ratio, established manufacturing infrastructure, and superior formability compared to titanium. Weaknesses: Still heavier than titanium alloys for equivalent strength applications and more susceptible to certain types of corrosion in extreme environments.

Key Patents and Innovations in Lightweight Metallurgy

Light-weight, high-strength, and high-elasticity titanium alloy and implementation method thereof

PatentInactiveUS20200071807A1

Innovation

- The development of a titanium alloy, SJ1100, with a composition of Ti-8Al-2V-1Cr-0.75Zr, where Al, V, and Cr are added to improve strength, stability, and plasticity, and Zr is used to refine grains and enhance processability, reducing density and manufacturing costs without using precious metals like Mo.

Titanium alloy powder for selective laser melting 3D printing, selective laser melted titanium alloy and preparation thereof

PatentPendingUS20240123502A1

Innovation

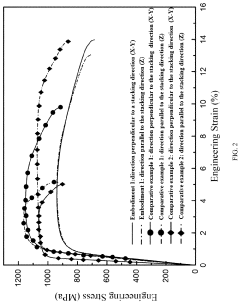

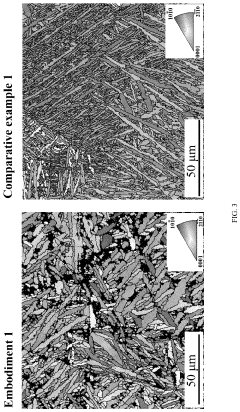

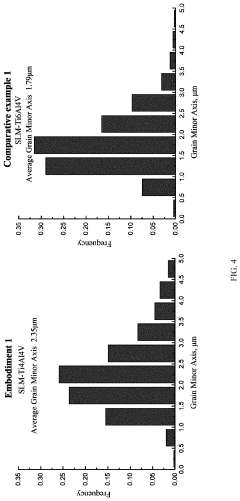

- A titanium alloy powder composition with 2.0-4.5% Al and 3.0-4.5% V, optimized through a process involving vacuum smelting, forging, and gas atomization to produce a powder with specific particle size and composition, which is then used in SLM to create a titanium alloy with improved isotropy and mechanical properties without the need for subsequent heat treatment.

Cost-Benefit Analysis of Material Selection

When evaluating material selection for lightweight structures, the cost-benefit analysis between titanium alloy and stainless steel reveals significant economic considerations that extend beyond initial material costs. The acquisition cost of titanium alloy typically ranges from 3 to 5 times higher than stainless steel, presenting a substantial upfront investment barrier for many applications.

However, the lifecycle cost analysis demonstrates that titanium's superior properties may offset this initial disadvantage. The exceptional strength-to-weight ratio of titanium alloys (approximately 60% the density of steel with comparable strength) translates into fuel savings for transportation applications. For aerospace implementations, each kilogram of weight reduction can yield $1,000-$3,000 in lifetime fuel savings, creating a compelling economic case despite higher initial costs.

Maintenance economics further favor titanium in corrosive environments. While stainless steel offers good corrosion resistance, titanium's near-immunity to corrosion in most environments results in maintenance cost reductions of 30-50% over a 20-year service life. This advantage becomes particularly pronounced in marine, chemical processing, and offshore applications where maintenance access is difficult and expensive.

Manufacturing complexity introduces additional cost considerations. Titanium's higher melting point (1,668°C versus 1,400-1,450°C for stainless steel) and reactivity with oxygen necessitate specialized processing equipment and techniques, increasing production costs by 40-60% compared to stainless steel fabrication. These manufacturing challenges can significantly impact project economics, especially for complex geometries or large-scale production.

The environmental cost-benefit analysis reveals titanium's advantages in energy consumption over the product lifecycle. While titanium production is energy-intensive (approximately 361,000 MJ/ton compared to stainless steel's 79,800 MJ/ton), the operational energy savings from weight reduction and extended service life often create a favorable environmental balance for transportation and long-term infrastructure applications.

Market volatility presents another economic consideration. Titanium pricing has historically shown greater fluctuation than stainless steel, with price variations of up to 30% annually compared to stainless steel's more stable 10-15% fluctuations. This volatility introduces financial risk that must be factored into long-term project planning and material selection decisions.

However, the lifecycle cost analysis demonstrates that titanium's superior properties may offset this initial disadvantage. The exceptional strength-to-weight ratio of titanium alloys (approximately 60% the density of steel with comparable strength) translates into fuel savings for transportation applications. For aerospace implementations, each kilogram of weight reduction can yield $1,000-$3,000 in lifetime fuel savings, creating a compelling economic case despite higher initial costs.

Maintenance economics further favor titanium in corrosive environments. While stainless steel offers good corrosion resistance, titanium's near-immunity to corrosion in most environments results in maintenance cost reductions of 30-50% over a 20-year service life. This advantage becomes particularly pronounced in marine, chemical processing, and offshore applications where maintenance access is difficult and expensive.

Manufacturing complexity introduces additional cost considerations. Titanium's higher melting point (1,668°C versus 1,400-1,450°C for stainless steel) and reactivity with oxygen necessitate specialized processing equipment and techniques, increasing production costs by 40-60% compared to stainless steel fabrication. These manufacturing challenges can significantly impact project economics, especially for complex geometries or large-scale production.

The environmental cost-benefit analysis reveals titanium's advantages in energy consumption over the product lifecycle. While titanium production is energy-intensive (approximately 361,000 MJ/ton compared to stainless steel's 79,800 MJ/ton), the operational energy savings from weight reduction and extended service life often create a favorable environmental balance for transportation and long-term infrastructure applications.

Market volatility presents another economic consideration. Titanium pricing has historically shown greater fluctuation than stainless steel, with price variations of up to 30% annually compared to stainless steel's more stable 10-15% fluctuations. This volatility introduces financial risk that must be factored into long-term project planning and material selection decisions.

Environmental Impact and Sustainability Considerations

The environmental impact of material selection in lightweight structures represents a critical consideration in modern engineering design. When comparing titanium alloys with stainless steel, lifecycle assessment reveals significant differences in their ecological footprints. Titanium extraction and processing are notably energy-intensive, requiring approximately 5-10 times more energy than stainless steel production. This higher energy demand translates to greater carbon emissions during the manufacturing phase, with titanium production generating an estimated 35-45 kg CO2 equivalent per kilogram of material compared to 6-8 kg CO2 equivalent for stainless steel.

However, the environmental equation shifts dramatically when considering the use phase of these materials. Titanium's superior strength-to-weight ratio delivers substantial fuel savings in transportation applications. For aerospace implementations, each kilogram of weight reduction can save approximately 2,900 liters of fuel over a commercial aircraft's lifetime. This operational advantage often compensates for titanium's higher initial environmental cost within 3-5 years of service in transportation applications.

End-of-life considerations further differentiate these materials. Titanium offers excellent recyclability with minimal property degradation, maintaining approximately 95% of its value through recycling processes. The current recycling rate for titanium stands at 50-60%, compared to 80-90% for stainless steel, presenting an opportunity for improved circular economy practices in titanium lifecycle management.

Water usage and pollution profiles also differ significantly between these materials. Titanium processing typically consumes 125-175 cubic meters of water per ton of material produced, while stainless steel requires 80-100 cubic meters. Additionally, titanium extraction and processing may release specific heavy metals including vanadium compounds that require specialized treatment in wastewater management systems.

From a resource depletion perspective, titanium represents a more abundant element in Earth's crust (0.6%) compared to key stainless steel alloying elements like nickel (0.008%) and chromium (0.014%). This abundance suggests potentially greater long-term sustainability for titanium, though current extraction technologies access only a fraction of theoretical reserves.

Emerging sustainable manufacturing techniques are narrowing the environmental gap between these materials. Advanced titanium production methods like the FFC Cambridge process demonstrate potential energy requirement reductions of 30-50% compared to conventional Kroll process extraction. Similarly, innovations in electric arc furnace technology for stainless steel production have reduced carbon emissions by approximately 60% compared to traditional blast furnace methods.

However, the environmental equation shifts dramatically when considering the use phase of these materials. Titanium's superior strength-to-weight ratio delivers substantial fuel savings in transportation applications. For aerospace implementations, each kilogram of weight reduction can save approximately 2,900 liters of fuel over a commercial aircraft's lifetime. This operational advantage often compensates for titanium's higher initial environmental cost within 3-5 years of service in transportation applications.

End-of-life considerations further differentiate these materials. Titanium offers excellent recyclability with minimal property degradation, maintaining approximately 95% of its value through recycling processes. The current recycling rate for titanium stands at 50-60%, compared to 80-90% for stainless steel, presenting an opportunity for improved circular economy practices in titanium lifecycle management.

Water usage and pollution profiles also differ significantly between these materials. Titanium processing typically consumes 125-175 cubic meters of water per ton of material produced, while stainless steel requires 80-100 cubic meters. Additionally, titanium extraction and processing may release specific heavy metals including vanadium compounds that require specialized treatment in wastewater management systems.

From a resource depletion perspective, titanium represents a more abundant element in Earth's crust (0.6%) compared to key stainless steel alloying elements like nickel (0.008%) and chromium (0.014%). This abundance suggests potentially greater long-term sustainability for titanium, though current extraction technologies access only a fraction of theoretical reserves.

Emerging sustainable manufacturing techniques are narrowing the environmental gap between these materials. Advanced titanium production methods like the FFC Cambridge process demonstrate potential energy requirement reductions of 30-50% compared to conventional Kroll process extraction. Similarly, innovations in electric arc furnace technology for stainless steel production have reduced carbon emissions by approximately 60% compared to traditional blast furnace methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!