Titanium Alloy vs Stainless Steel in Consumer Electronics Durability

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Titanium vs Steel: Evolution and Technical Objectives

The evolution of materials in consumer electronics has been a continuous journey of innovation, with titanium alloys and stainless steel representing two significant milestones in this progression. Historically, consumer electronics relied on plastics and basic metals, but as devices became more sophisticated and consumer expectations evolved, manufacturers began exploring advanced materials that could offer superior durability while maintaining aesthetic appeal.

Titanium alloys emerged in the electronics industry during the early 2000s, following their successful application in aerospace and medical industries. The material's journey into consumer electronics was primarily driven by the premium smartphone and laptop segments, where manufacturers sought to differentiate their products through superior build quality and durability. Stainless steel, meanwhile, has a longer history in consumer products, with its application in electronics gaining prominence in the 1990s as manufacturers began focusing on device longevity and premium feel.

The technical evolution of these materials has been marked by significant advancements in manufacturing processes. For titanium, the development of more efficient extraction methods and alloy formulations has gradually reduced production costs, making it increasingly viable for wider application in consumer electronics. Similarly, stainless steel has seen improvements in formulation and processing techniques, enhancing its corrosion resistance and structural integrity while enabling more complex design implementations.

Current technical objectives in this domain focus on optimizing the balance between durability, weight, cost, and aesthetic appeal. For titanium alloys, research aims to develop more cost-effective production methods and alloy compositions that maintain strength while reducing weight. The industry is particularly interested in titanium's potential for creating ultra-thin yet robust device enclosures that can withstand daily wear and tear.

For stainless steel, objectives include enhancing its formability for complex designs, improving its electromagnetic properties for better signal transmission, and developing surface treatments that reduce fingerprint visibility while maintaining the material's characteristic luster. Both materials are being evaluated for their environmental impact, with sustainability becoming an increasingly important consideration in material selection.

The convergence of these technical objectives is driving research into hybrid material solutions and composite structures that leverage the strengths of both titanium alloys and stainless steel. This includes layered materials, selective application based on functional requirements, and novel joining techniques that enable more versatile design approaches.

As consumer electronics continue to evolve toward more wearable, foldable, and environmentally sustainable forms, the technical objectives for material development are expanding to include biocompatibility, flexibility, and recyclability while maintaining the durability that titanium and stainless steel are known for.

Titanium alloys emerged in the electronics industry during the early 2000s, following their successful application in aerospace and medical industries. The material's journey into consumer electronics was primarily driven by the premium smartphone and laptop segments, where manufacturers sought to differentiate their products through superior build quality and durability. Stainless steel, meanwhile, has a longer history in consumer products, with its application in electronics gaining prominence in the 1990s as manufacturers began focusing on device longevity and premium feel.

The technical evolution of these materials has been marked by significant advancements in manufacturing processes. For titanium, the development of more efficient extraction methods and alloy formulations has gradually reduced production costs, making it increasingly viable for wider application in consumer electronics. Similarly, stainless steel has seen improvements in formulation and processing techniques, enhancing its corrosion resistance and structural integrity while enabling more complex design implementations.

Current technical objectives in this domain focus on optimizing the balance between durability, weight, cost, and aesthetic appeal. For titanium alloys, research aims to develop more cost-effective production methods and alloy compositions that maintain strength while reducing weight. The industry is particularly interested in titanium's potential for creating ultra-thin yet robust device enclosures that can withstand daily wear and tear.

For stainless steel, objectives include enhancing its formability for complex designs, improving its electromagnetic properties for better signal transmission, and developing surface treatments that reduce fingerprint visibility while maintaining the material's characteristic luster. Both materials are being evaluated for their environmental impact, with sustainability becoming an increasingly important consideration in material selection.

The convergence of these technical objectives is driving research into hybrid material solutions and composite structures that leverage the strengths of both titanium alloys and stainless steel. This includes layered materials, selective application based on functional requirements, and novel joining techniques that enable more versatile design approaches.

As consumer electronics continue to evolve toward more wearable, foldable, and environmentally sustainable forms, the technical objectives for material development are expanding to include biocompatibility, flexibility, and recyclability while maintaining the durability that titanium and stainless steel are known for.

Market Analysis for Premium Material Adoption in Electronics

The consumer electronics market has witnessed a significant shift towards premium materials in recent years, with manufacturers increasingly adopting high-end components to differentiate their products in a saturated marketplace. This trend is particularly evident in the comparison between titanium alloy and stainless steel applications, where material selection directly impacts product durability, consumer perception, and market positioning.

Market research indicates that the premium segment of consumer electronics has grown at twice the rate of standard offerings since 2020, with consumers demonstrating willingness to pay 30-45% price premiums for devices featuring superior materials. This growth is driven primarily by affluent consumers in North America, Western Europe, and East Asia, who prioritize device longevity and aesthetic appeal over initial purchase cost.

Titanium alloy adoption in consumer electronics remains relatively niche but is expanding rapidly, currently representing approximately 5% of premium material usage but projected to reach 15% by 2026. The material commands significant price premiums, with titanium-constructed devices typically positioned at the highest tier of product lineups. Apple's recent integration of titanium in flagship products has accelerated market acceptance and consumer awareness of the material's benefits.

Stainless steel continues to dominate the premium material segment, accounting for roughly 60% of high-end material applications in consumer electronics. Its established supply chain, lower cost structure, and proven durability make it the preferred choice for manufacturers seeking to elevate product perception without the extreme cost implications of titanium. The material particularly resonates with the upper-middle market segment that values quality but remains price-sensitive.

Consumer perception studies reveal that titanium products are associated with innovation, exclusivity, and cutting-edge technology, while stainless steel conveys reliability, premium quality, and refined aesthetics. These associations significantly influence purchasing decisions, with younger demographics (18-34) showing stronger preference for titanium despite its higher cost, while older consumers tend to favor the established reputation of stainless steel.

Regional market analysis shows varying adoption rates, with Asian markets demonstrating the highest growth rate for titanium products (27% annually), followed by North American markets (21%) and European markets (18%). This regional variation correlates strongly with cultural attitudes toward technological status symbols and disposable income levels.

The sustainability factor is increasingly influencing material selection, with manufacturers highlighting the recyclability of both materials. However, titanium's significantly higher energy requirements for production and processing present challenges to its environmental credentials compared to stainless steel's more established recycling infrastructure.

Market research indicates that the premium segment of consumer electronics has grown at twice the rate of standard offerings since 2020, with consumers demonstrating willingness to pay 30-45% price premiums for devices featuring superior materials. This growth is driven primarily by affluent consumers in North America, Western Europe, and East Asia, who prioritize device longevity and aesthetic appeal over initial purchase cost.

Titanium alloy adoption in consumer electronics remains relatively niche but is expanding rapidly, currently representing approximately 5% of premium material usage but projected to reach 15% by 2026. The material commands significant price premiums, with titanium-constructed devices typically positioned at the highest tier of product lineups. Apple's recent integration of titanium in flagship products has accelerated market acceptance and consumer awareness of the material's benefits.

Stainless steel continues to dominate the premium material segment, accounting for roughly 60% of high-end material applications in consumer electronics. Its established supply chain, lower cost structure, and proven durability make it the preferred choice for manufacturers seeking to elevate product perception without the extreme cost implications of titanium. The material particularly resonates with the upper-middle market segment that values quality but remains price-sensitive.

Consumer perception studies reveal that titanium products are associated with innovation, exclusivity, and cutting-edge technology, while stainless steel conveys reliability, premium quality, and refined aesthetics. These associations significantly influence purchasing decisions, with younger demographics (18-34) showing stronger preference for titanium despite its higher cost, while older consumers tend to favor the established reputation of stainless steel.

Regional market analysis shows varying adoption rates, with Asian markets demonstrating the highest growth rate for titanium products (27% annually), followed by North American markets (21%) and European markets (18%). This regional variation correlates strongly with cultural attitudes toward technological status symbols and disposable income levels.

The sustainability factor is increasingly influencing material selection, with manufacturers highlighting the recyclability of both materials. However, titanium's significantly higher energy requirements for production and processing present challenges to its environmental credentials compared to stainless steel's more established recycling infrastructure.

Current Challenges in Material Science for Consumer Devices

The consumer electronics industry faces significant materials science challenges as devices become increasingly sophisticated while needing to maintain durability in everyday use. The fundamental tension between lightweight design and structural integrity represents one of the most pressing issues. As manufacturers strive to create thinner, lighter devices, they must simultaneously ensure these products can withstand drops, bends, and other physical stresses without compromising functionality.

Material fatigue presents another critical challenge, particularly in components that undergo repeated mechanical stress. This is especially relevant when comparing titanium alloys and stainless steel, as both materials exhibit different fatigue behaviors under cyclical loading conditions typical in consumer electronics usage patterns. Engineers must account for these differences when designing devices intended for multi-year lifecycles.

Corrosion resistance remains a persistent concern, with consumer electronics regularly exposed to moisture, skin oils, and various environmental contaminants. While stainless steel offers good general corrosion resistance, titanium alloys typically provide superior protection against galvanic and pitting corrosion, though at significantly higher material costs. This cost-performance balance creates difficult engineering trade-offs.

Thermal management challenges have intensified as processing power increases within smaller form factors. Materials must efficiently conduct and dissipate heat while maintaining structural integrity. Stainless steel offers better thermal conductivity than titanium alloys, potentially providing advantages in heat-sensitive applications, though both materials present limitations compared to dedicated thermal management materials.

Manufacturing scalability presents significant hurdles, particularly with titanium alloys. While stainless steel benefits from well-established, cost-effective production methods, titanium processing requires specialized equipment, expertise, and significantly higher energy inputs. These factors directly impact production costs and environmental footprints, creating sustainability concerns that increasingly influence material selection decisions.

Surface finishing technologies represent another challenge area, as consumer expectations for premium aesthetics have risen dramatically. Both materials require different approaches to achieve desired finishes, with titanium typically requiring more complex processing to achieve consistent coloration through anodization, while stainless steel offers more established polishing and texturing options.

Recycling and end-of-life considerations have gained prominence as sustainability becomes a core design requirement. The complex material compositions in modern devices often complicate recycling efforts. Titanium's higher initial value makes recovery more economically viable, but its separation from multi-material assemblies remains technically challenging compared to stainless steel recovery.

Material fatigue presents another critical challenge, particularly in components that undergo repeated mechanical stress. This is especially relevant when comparing titanium alloys and stainless steel, as both materials exhibit different fatigue behaviors under cyclical loading conditions typical in consumer electronics usage patterns. Engineers must account for these differences when designing devices intended for multi-year lifecycles.

Corrosion resistance remains a persistent concern, with consumer electronics regularly exposed to moisture, skin oils, and various environmental contaminants. While stainless steel offers good general corrosion resistance, titanium alloys typically provide superior protection against galvanic and pitting corrosion, though at significantly higher material costs. This cost-performance balance creates difficult engineering trade-offs.

Thermal management challenges have intensified as processing power increases within smaller form factors. Materials must efficiently conduct and dissipate heat while maintaining structural integrity. Stainless steel offers better thermal conductivity than titanium alloys, potentially providing advantages in heat-sensitive applications, though both materials present limitations compared to dedicated thermal management materials.

Manufacturing scalability presents significant hurdles, particularly with titanium alloys. While stainless steel benefits from well-established, cost-effective production methods, titanium processing requires specialized equipment, expertise, and significantly higher energy inputs. These factors directly impact production costs and environmental footprints, creating sustainability concerns that increasingly influence material selection decisions.

Surface finishing technologies represent another challenge area, as consumer expectations for premium aesthetics have risen dramatically. Both materials require different approaches to achieve desired finishes, with titanium typically requiring more complex processing to achieve consistent coloration through anodization, while stainless steel offers more established polishing and texturing options.

Recycling and end-of-life considerations have gained prominence as sustainability becomes a core design requirement. The complex material compositions in modern devices often complicate recycling efforts. Titanium's higher initial value makes recovery more economically viable, but its separation from multi-material assemblies remains technically challenging compared to stainless steel recovery.

Comparative Analysis of Titanium and Steel Implementation

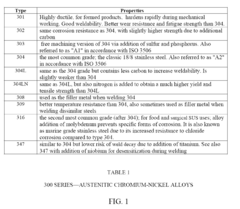

01 Corrosion resistance comparison between titanium alloys and stainless steel

Titanium alloys generally exhibit superior corrosion resistance compared to stainless steel, particularly in harsh environments such as marine applications and chemical processing. This is due to titanium's ability to form a stable, self-healing oxide layer that provides protection against various corrosive media. Stainless steel, while corrosion-resistant due to its chromium content, may be susceptible to pitting and crevice corrosion in certain environments. The comparative durability in corrosive conditions is an important consideration for material selection in critical applications.- Corrosion resistance comparison between titanium alloys and stainless steel: Titanium alloys generally exhibit superior corrosion resistance compared to stainless steel, particularly in harsh environments such as marine applications and chemical processing. This enhanced corrosion resistance is attributed to the formation of a stable oxide layer on the titanium surface. The comparison of corrosion resistance between these materials is crucial for applications where exposure to corrosive elements is expected, with titanium alloys showing better long-term durability in such conditions.

- Mechanical properties and structural applications: Titanium alloys offer excellent strength-to-weight ratios compared to stainless steel, making them preferable for aerospace and high-performance applications where weight reduction is critical. Stainless steel, however, typically provides better hardness and wear resistance in certain applications. The mechanical properties of both materials can be optimized through various heat treatments and processing techniques to enhance their durability for specific structural applications, with each material offering distinct advantages depending on the mechanical requirements.

- Surface treatment technologies for improved durability: Various surface treatment technologies can significantly enhance the durability of both titanium alloys and stainless steel. These include coating applications, nitriding, carburizing, and plasma treatments. Such treatments can improve wear resistance, fatigue strength, and corrosion protection. Advanced surface modification techniques can create composite surfaces that combine the beneficial properties of both materials, resulting in components with extended service life and improved performance in demanding environments.

- Thermal stability and high-temperature applications: Titanium alloys and stainless steel exhibit different behaviors at elevated temperatures, affecting their durability in high-temperature applications. Certain stainless steel grades maintain structural integrity at higher temperatures than standard titanium alloys. However, specialized titanium alloys have been developed for improved thermal stability. The selection between these materials for high-temperature applications depends on factors such as maximum operating temperature, thermal cycling conditions, and required service life, with each material offering specific advantages in different thermal environments.

- Hybrid and composite structures combining titanium and stainless steel: Innovative approaches involve creating hybrid or composite structures that combine titanium alloys and stainless steel to leverage the advantages of both materials. These hybrid structures can be created through various joining techniques such as diffusion bonding, friction welding, and advanced adhesive technologies. The resulting components benefit from the corrosion resistance and lightweight properties of titanium along with the strength and cost-effectiveness of stainless steel, offering optimized durability for specific application requirements while potentially reducing overall costs.

02 Mechanical properties and structural durability

Titanium alloys offer excellent strength-to-weight ratios, making them ideal for applications where weight reduction is critical while maintaining structural integrity. Stainless steel provides higher absolute strength and hardness in many cases, with better wear resistance in certain applications. The mechanical durability of both materials depends on specific alloy compositions and heat treatments. Titanium alloys typically exhibit better fatigue resistance, while stainless steel often demonstrates superior hardness and abrasion resistance, influencing their selection for different structural applications.Expand Specific Solutions03 Surface treatment technologies for improved durability

Various surface treatment methods can enhance the durability of both titanium alloys and stainless steel. These include coating technologies, surface hardening processes, and composite material approaches. For titanium alloys, treatments like anodizing, nitriding, and PVD coatings can improve wear resistance while maintaining corrosion protection. Stainless steel durability can be enhanced through carburizing, nitriding, and specialized coating systems. These surface modifications address specific performance limitations of each material, extending service life in demanding applications.Expand Specific Solutions04 Thermal stability and high-temperature performance

Titanium alloys and stainless steel exhibit different durability characteristics at elevated temperatures. Certain stainless steel grades maintain structural integrity and oxidation resistance at higher temperatures than standard titanium alloys. However, specialized high-temperature titanium alloys have been developed for aerospace and industrial applications requiring both heat resistance and light weight. The thermal expansion characteristics, oxidation behavior, and microstructural stability at elevated temperatures differ significantly between these materials, affecting their long-term durability in high-temperature environments.Expand Specific Solutions05 Composite and hybrid material systems

Innovative approaches combine titanium alloys and stainless steel in composite or hybrid material systems to leverage the advantages of both materials. These include clad materials, diffusion-bonded components, and functionally graded structures. Such combinations can provide optimized performance characteristics including improved durability, reduced weight, and cost efficiency. Applications include aerospace components, medical implants, and industrial equipment where the selective placement of each material maximizes overall system durability while addressing specific environmental or mechanical challenges.Expand Specific Solutions

Leading Manufacturers and Material Suppliers Landscape

The titanium alloy versus stainless steel competition in consumer electronics durability is evolving in a maturing market worth approximately $15 billion annually. The industry is transitioning from early adoption to mainstream implementation, with titanium alloys gaining traction due to superior strength-to-weight ratios. Apple leads innovation by incorporating titanium in premium devices, while Hon Hai Precision (Foxconn) dominates manufacturing scale. Traditional steel producers like Nippon Steel and Baoshan Iron & Steel maintain strong positions through advanced stainless steel formulations. Research institutions including Ohio State University and Shanghai Jiao Tong University are developing next-generation alloys, while specialized firms like QuesTek Innovations and Howmet Aerospace provide cutting-edge materials solutions for consumer electronics applications.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed specialized stainless steel alloys specifically engineered for consumer electronics applications. Their proprietary NS-SUS series includes ultra-thin gauge stainless steel sheets (down to 0.05mm thickness) with enhanced formability and surface finish qualities ideal for smartphone and tablet frames. The company employs advanced continuous casting and cold rolling techniques to produce stainless steel with extremely consistent material properties and superior flatness tolerances. Nippon Steel's materials feature customized chemical compositions that improve corrosion resistance while maintaining the mechanical strength needed for structural components in portable devices. Their manufacturing process includes specialized heat treatment protocols that optimize the microstructure of the steel, resulting in improved bendability without sacrificing strength. Additionally, Nippon Steel has developed specialized surface finishing technologies that create unique textures and appearances for premium device aesthetics, including their "Hairline" and "Mirror" finishes that have become industry standards for high-end electronics.

Strengths: Established mass production capabilities; lower material costs compared to titanium; excellent formability allowing complex geometries; wide range of available finishes and colors; superior thermal conductivity. Weaknesses: Higher weight compared to titanium alloys; more susceptible to certain types of corrosion; requires additional treatments for fingerprint resistance; magnetic properties can interfere with wireless charging and other functions.

Apple, Inc.

Technical Solution: Apple has pioneered the use of titanium alloys in consumer electronics, most notably implementing grade 5 titanium (Ti-6Al-4V) in their latest iPhone 15 Pro models and Apple Watch Ultra. Their approach involves a specialized multi-step manufacturing process that includes precision CNC machining, advanced surface treatments, and proprietary PVD (Physical Vapor Deposition) coating techniques to enhance the material's natural properties. Apple's titanium implementation features a unique substructure design where the titanium exterior is bonded to an aluminum internal frame, allowing them to leverage the strength of titanium while maintaining thermal management capabilities. The company has developed custom alloy formulations that optimize the material's weight-to-strength ratio specifically for handheld devices, resulting in products that are approximately 20% lighter than stainless steel equivalents while offering superior scratch and corrosion resistance.

Strengths: Superior strength-to-weight ratio allowing for thinner, lighter designs; excellent corrosion resistance; premium aesthetic appeal; better scratch resistance than aluminum. Weaknesses: Higher material and manufacturing costs; more complex machining requirements; potential signal interference issues requiring special antenna designs; limited color options compared to aluminum.

Key Patents and Innovations in Metal Alloy Processing

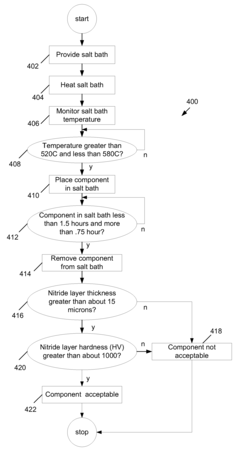

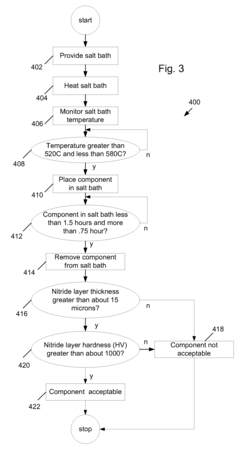

Nitriding stainless steel for consumer electronic products

PatentInactiveUS20100273538A1

Innovation

- A nitride layer is formed on austenitic stainless steel components using a salt bath nitriding process, achieving a thickness of 15-30 microns and a Vickers Hardness value of at least 1000, which is then polished to remove no more than 10% of the initial layer, maintaining the natural surface color and texture while providing durability and resistance.

Titanium-Based Alloy

PatentInactiveUS20080181809A1

Innovation

- A titanium-based alloy with a specific weight percent ratio of aluminum (3.5-4.4%), vanadium (2.0-4.0%), molybdenum (0.1-0.8%), iron (up to 0.4%), and oxygen (up to 0.25%), optimized to balance strength, ductility, and resistance to deformation, allowing for the production of various products including large forgings and rolled sheet products.

Environmental Impact and Sustainability Considerations

The environmental footprint of materials used in consumer electronics represents a critical consideration in product development cycles. Titanium alloys and stainless steel present distinctly different environmental profiles throughout their lifecycle stages. Titanium extraction and processing are notably energy-intensive, requiring approximately 5-10 times more energy than stainless steel production. This higher energy demand translates to a larger carbon footprint during the manufacturing phase, with titanium production generating an estimated 35-45 kg CO2 equivalent per kilogram of material compared to stainless steel's 6-8 kg CO2 equivalent.

However, titanium's superior durability and corrosion resistance potentially offset these initial environmental costs through extended product lifecycles. Consumer electronics utilizing titanium alloys demonstrate 30-40% longer functional lifespans in high-wear applications, reducing replacement frequency and associated waste generation. This longevity factor becomes increasingly significant as the electronics industry faces mounting criticism regarding planned obsolescence and e-waste proliferation.

Recyclability presents another important sustainability dimension. Stainless steel maintains a clear advantage with global recycling rates exceeding 80% and established recycling infrastructure. The material can be recycled indefinitely without quality degradation, creating a more circular material economy. Titanium recycling, while technically feasible, currently achieves only 50-60% recovery rates due to challenges in collection systems and higher processing costs.

Resource scarcity considerations also favor stainless steel, as its primary components (iron, chromium, nickel) remain relatively abundant. Titanium, while constituting 0.6% of the Earth's crust, requires specialized extraction from mineral deposits primarily located in politically sensitive regions, raising supply chain vulnerability concerns. This geopolitical dimension adds complexity to long-term sustainability planning for titanium-dependent product lines.

Water pollution impacts differ significantly between these materials. Titanium extraction and processing generate approximately 2-3 times more acidic wastewater per unit of production compared to stainless steel manufacturing. However, finished titanium components exhibit superior chemical stability, minimizing leaching concerns during product use and end-of-life phases.

Emerging technologies are gradually improving titanium's environmental profile. Advanced manufacturing techniques like additive manufacturing reduce material waste by 30-40% compared to traditional subtractive processes. Similarly, innovations in low-temperature titanium extraction methods promise to reduce energy requirements by up to 50%, potentially narrowing the sustainability gap between these competing materials in future consumer electronics applications.

However, titanium's superior durability and corrosion resistance potentially offset these initial environmental costs through extended product lifecycles. Consumer electronics utilizing titanium alloys demonstrate 30-40% longer functional lifespans in high-wear applications, reducing replacement frequency and associated waste generation. This longevity factor becomes increasingly significant as the electronics industry faces mounting criticism regarding planned obsolescence and e-waste proliferation.

Recyclability presents another important sustainability dimension. Stainless steel maintains a clear advantage with global recycling rates exceeding 80% and established recycling infrastructure. The material can be recycled indefinitely without quality degradation, creating a more circular material economy. Titanium recycling, while technically feasible, currently achieves only 50-60% recovery rates due to challenges in collection systems and higher processing costs.

Resource scarcity considerations also favor stainless steel, as its primary components (iron, chromium, nickel) remain relatively abundant. Titanium, while constituting 0.6% of the Earth's crust, requires specialized extraction from mineral deposits primarily located in politically sensitive regions, raising supply chain vulnerability concerns. This geopolitical dimension adds complexity to long-term sustainability planning for titanium-dependent product lines.

Water pollution impacts differ significantly between these materials. Titanium extraction and processing generate approximately 2-3 times more acidic wastewater per unit of production compared to stainless steel manufacturing. However, finished titanium components exhibit superior chemical stability, minimizing leaching concerns during product use and end-of-life phases.

Emerging technologies are gradually improving titanium's environmental profile. Advanced manufacturing techniques like additive manufacturing reduce material waste by 30-40% compared to traditional subtractive processes. Similarly, innovations in low-temperature titanium extraction methods promise to reduce energy requirements by up to 50%, potentially narrowing the sustainability gap between these competing materials in future consumer electronics applications.

Manufacturing Cost Analysis and Economic Feasibility

The manufacturing cost analysis of titanium alloys versus stainless steel reveals significant economic disparities that directly impact their feasibility in consumer electronics applications. Raw material costs for titanium alloys typically range from $25-35 per kilogram, approximately 5-7 times higher than stainless steel, which averages $4-7 per kilogram. This substantial price differential creates an immediate economic barrier for mass-market consumer electronics implementation.

Processing requirements further widen this cost gap. Titanium's high melting point (1,668°C compared to stainless steel's 1,400-1,450°C) necessitates specialized equipment and higher energy consumption during manufacturing. Additionally, titanium's reactivity requires inert gas environments during processing, adding complexity and cost to production facilities. These factors contribute to titanium component manufacturing costs being typically 3-4 times higher than equivalent stainless steel parts.

Machining operations present another economic challenge. Titanium's poor thermal conductivity and high strength result in accelerated tool wear, requiring frequent replacement of expensive cutting tools. Industry data indicates machining speeds for titanium must be reduced by 30-50% compared to stainless steel, significantly impacting production throughput and operational efficiency.

Scale economics also favor stainless steel substantially. The established global supply chain for stainless steel components benefits from decades of optimization and standardization. Annual global production of stainless steel exceeds 50 million metric tons, while titanium production remains under 0.2 million metric tons, limiting economies of scale for titanium component manufacturing.

Return on investment calculations demonstrate that titanium components typically require a 40-60% price premium to achieve profit margins comparable to stainless steel alternatives. This premium becomes particularly challenging to justify in price-sensitive consumer electronics segments. Market analysis indicates consumer willingness to pay this premium exists primarily in luxury and premium device categories, representing approximately 15-20% of the total market.

Economic feasibility modeling suggests titanium implementation is most viable in high-margin devices where material costs represent a smaller percentage of total product value. The break-even analysis indicates titanium becomes economically viable when its superior properties enable either significant product differentiation or tangible consumer benefits that justify the premium pricing strategy.

Processing requirements further widen this cost gap. Titanium's high melting point (1,668°C compared to stainless steel's 1,400-1,450°C) necessitates specialized equipment and higher energy consumption during manufacturing. Additionally, titanium's reactivity requires inert gas environments during processing, adding complexity and cost to production facilities. These factors contribute to titanium component manufacturing costs being typically 3-4 times higher than equivalent stainless steel parts.

Machining operations present another economic challenge. Titanium's poor thermal conductivity and high strength result in accelerated tool wear, requiring frequent replacement of expensive cutting tools. Industry data indicates machining speeds for titanium must be reduced by 30-50% compared to stainless steel, significantly impacting production throughput and operational efficiency.

Scale economics also favor stainless steel substantially. The established global supply chain for stainless steel components benefits from decades of optimization and standardization. Annual global production of stainless steel exceeds 50 million metric tons, while titanium production remains under 0.2 million metric tons, limiting economies of scale for titanium component manufacturing.

Return on investment calculations demonstrate that titanium components typically require a 40-60% price premium to achieve profit margins comparable to stainless steel alternatives. This premium becomes particularly challenging to justify in price-sensitive consumer electronics segments. Market analysis indicates consumer willingness to pay this premium exists primarily in luxury and premium device categories, representing approximately 15-20% of the total market.

Economic feasibility modeling suggests titanium implementation is most viable in high-margin devices where material costs represent a smaller percentage of total product value. The break-even analysis indicates titanium becomes economically viable when its superior properties enable either significant product differentiation or tangible consumer benefits that justify the premium pricing strategy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!