Review of Coating Technologies for Titanium Alloy vs Stainless Steel Protection

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Titanium & Steel Coating Evolution and Objectives

The evolution of coating technologies for metal protection has undergone significant transformation over the past century, with particularly notable advancements in the last three decades. Initially, basic galvanization and simple paint coatings dominated the field, offering minimal protection against corrosion and wear. The 1970s marked a turning point with the introduction of plasma spray technologies, enabling more sophisticated surface treatments for both titanium alloys and stainless steel.

Titanium alloys, despite their inherent corrosion resistance, face challenges in high-temperature environments and under severe mechanical stress. The evolution of titanium coatings has progressed from simple anodizing techniques to complex multi-layer systems incorporating ceramics and advanced composites. Physical Vapor Deposition (PVD) emerged in the 1980s as a breakthrough technology, allowing for nanometer-precision coatings that significantly enhanced titanium's performance in aerospace and biomedical applications.

Stainless steel coating technologies have followed a parallel but distinct evolutionary path. While stainless steel offers good baseline corrosion resistance, specialized environments such as marine applications or chemical processing demand enhanced protection. The development trajectory moved from chromate conversion coatings (now restricted due to environmental concerns) toward more sustainable alternatives including sol-gel technologies and advanced polymer systems.

The convergence of nanotechnology with coating science in the early 2000s revolutionized both titanium and steel protection strategies. Nanostructured coatings offered unprecedented combinations of hardness, wear resistance, and corrosion protection while maintaining minimal thickness. This paradigm shift enabled new applications in extreme environments previously considered unsuitable for these metals.

Current technological objectives focus on developing "smart" coatings capable of self-healing, environmental responsiveness, and in-situ monitoring capabilities. Research aims to create coating systems that can detect and respond to corrosion initiation or mechanical damage before catastrophic failure occurs. Additionally, there is growing emphasis on environmentally sustainable coating technologies that eliminate hazardous substances while maintaining or exceeding performance standards.

The industry is now targeting multi-functional coatings that simultaneously address multiple protection requirements: corrosion resistance, wear protection, thermal barriers, and even antimicrobial properties for medical applications. This holistic approach represents a significant departure from traditional single-function coatings and aligns with the broader trend toward materials with integrated functionality.

Looking forward, the field is moving toward biomimetic approaches, drawing inspiration from natural systems that have evolved sophisticated protection mechanisms. These bio-inspired coating technologies promise to deliver unprecedented performance while reducing environmental impact and energy consumption during manufacturing processes.

Titanium alloys, despite their inherent corrosion resistance, face challenges in high-temperature environments and under severe mechanical stress. The evolution of titanium coatings has progressed from simple anodizing techniques to complex multi-layer systems incorporating ceramics and advanced composites. Physical Vapor Deposition (PVD) emerged in the 1980s as a breakthrough technology, allowing for nanometer-precision coatings that significantly enhanced titanium's performance in aerospace and biomedical applications.

Stainless steel coating technologies have followed a parallel but distinct evolutionary path. While stainless steel offers good baseline corrosion resistance, specialized environments such as marine applications or chemical processing demand enhanced protection. The development trajectory moved from chromate conversion coatings (now restricted due to environmental concerns) toward more sustainable alternatives including sol-gel technologies and advanced polymer systems.

The convergence of nanotechnology with coating science in the early 2000s revolutionized both titanium and steel protection strategies. Nanostructured coatings offered unprecedented combinations of hardness, wear resistance, and corrosion protection while maintaining minimal thickness. This paradigm shift enabled new applications in extreme environments previously considered unsuitable for these metals.

Current technological objectives focus on developing "smart" coatings capable of self-healing, environmental responsiveness, and in-situ monitoring capabilities. Research aims to create coating systems that can detect and respond to corrosion initiation or mechanical damage before catastrophic failure occurs. Additionally, there is growing emphasis on environmentally sustainable coating technologies that eliminate hazardous substances while maintaining or exceeding performance standards.

The industry is now targeting multi-functional coatings that simultaneously address multiple protection requirements: corrosion resistance, wear protection, thermal barriers, and even antimicrobial properties for medical applications. This holistic approach represents a significant departure from traditional single-function coatings and aligns with the broader trend toward materials with integrated functionality.

Looking forward, the field is moving toward biomimetic approaches, drawing inspiration from natural systems that have evolved sophisticated protection mechanisms. These bio-inspired coating technologies promise to deliver unprecedented performance while reducing environmental impact and energy consumption during manufacturing processes.

Market Analysis for Advanced Metal Protection Solutions

The global market for advanced metal protection solutions has experienced significant growth in recent years, driven primarily by increasing demand across aerospace, automotive, medical, and industrial sectors. The market value for specialized coating technologies reached approximately $8.7 billion in 2022, with projections indicating a compound annual growth rate of 6.3% through 2028. This growth trajectory is particularly evident in applications requiring high-performance materials such as titanium alloys and stainless steel.

Titanium alloy protection solutions currently command a premium segment of the market, valued at $3.2 billion, due to their critical applications in aerospace and medical industries where performance requirements justify higher costs. Comparatively, the stainless steel coating market segment is substantially larger at $5.5 billion, benefiting from wider industrial adoption across multiple sectors.

Regional analysis reveals that North America and Europe currently dominate the advanced coating technologies market, collectively accounting for 58% of global market share. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at 8.7% annually, driven by rapid industrialization and increasing aerospace manufacturing capabilities.

Customer demand patterns show a clear shift toward environmentally sustainable coating solutions, with over 65% of industrial buyers now listing environmental compliance as a key purchasing criterion. This trend has accelerated development of chromium-free and VOC-compliant coating technologies, creating a specialized market segment growing at nearly twice the rate of conventional solutions.

The competitive landscape features both established industrial giants and specialized coating technology providers. Major players include PPG Industries, AkzoNobel, and Henkel dominating with combined market share of 37%, while specialized firms like Oerlikon Balzers and Bodycote have established strong positions in high-performance niches through technological differentiation.

Price sensitivity varies significantly by application sector. In aerospace and medical applications, performance characteristics typically outweigh cost considerations, with customers willing to pay premium prices for demonstrable performance advantages. Conversely, general industrial applications remain highly price-sensitive, creating distinct market segments with different competitive dynamics.

Future market growth appears concentrated in next-generation coating technologies offering multi-functional properties, such as combined corrosion resistance with antimicrobial or self-healing capabilities. This segment, though currently representing only 12% of the total market, is expanding at 14.3% annually, indicating significant future potential for innovative solution providers.

Titanium alloy protection solutions currently command a premium segment of the market, valued at $3.2 billion, due to their critical applications in aerospace and medical industries where performance requirements justify higher costs. Comparatively, the stainless steel coating market segment is substantially larger at $5.5 billion, benefiting from wider industrial adoption across multiple sectors.

Regional analysis reveals that North America and Europe currently dominate the advanced coating technologies market, collectively accounting for 58% of global market share. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at 8.7% annually, driven by rapid industrialization and increasing aerospace manufacturing capabilities.

Customer demand patterns show a clear shift toward environmentally sustainable coating solutions, with over 65% of industrial buyers now listing environmental compliance as a key purchasing criterion. This trend has accelerated development of chromium-free and VOC-compliant coating technologies, creating a specialized market segment growing at nearly twice the rate of conventional solutions.

The competitive landscape features both established industrial giants and specialized coating technology providers. Major players include PPG Industries, AkzoNobel, and Henkel dominating with combined market share of 37%, while specialized firms like Oerlikon Balzers and Bodycote have established strong positions in high-performance niches through technological differentiation.

Price sensitivity varies significantly by application sector. In aerospace and medical applications, performance characteristics typically outweigh cost considerations, with customers willing to pay premium prices for demonstrable performance advantages. Conversely, general industrial applications remain highly price-sensitive, creating distinct market segments with different competitive dynamics.

Future market growth appears concentrated in next-generation coating technologies offering multi-functional properties, such as combined corrosion resistance with antimicrobial or self-healing capabilities. This segment, though currently representing only 12% of the total market, is expanding at 14.3% annually, indicating significant future potential for innovative solution providers.

Current Coating Technologies and Technical Barriers

The current landscape of coating technologies for titanium alloys and stainless steel protection encompasses several established methods, each with specific advantages and limitations. Physical Vapor Deposition (PVD) represents one of the most widely adopted approaches, offering excellent adhesion and uniform coating thickness. However, PVD processes typically require sophisticated vacuum equipment and precise parameter control, limiting their application in certain industrial settings.

Thermal spray coating technologies, including High-Velocity Oxygen Fuel (HVOF) and plasma spraying, provide robust protection against wear and corrosion. These methods excel in depositing thick coatings with good mechanical properties but often struggle with coating porosity issues and limited bond strength, particularly on titanium substrates.

Chemical Vapor Deposition (CVD) delivers exceptional coating uniformity and can reach complex geometries, making it valuable for intricate components. The primary barriers include high processing temperatures that may alter the substrate's microstructure and the environmental concerns associated with precursor chemicals.

Electroplating and electroless plating offer cost-effective solutions for both titanium alloys and stainless steel, with relatively simple equipment requirements. These techniques face challenges in achieving uniform coating thickness on complex geometries and often involve environmentally problematic chemicals like hexavalent chromium.

Pack cementation processes provide excellent high-temperature protection but are limited by process control difficulties and environmental considerations. The coatings produced often exhibit inconsistent thickness and composition across the substrate surface.

Sol-gel coating methods represent an emerging approach with excellent chemical homogeneity and lower processing temperatures. However, they typically produce thinner coatings with inferior mechanical properties compared to traditional methods, limiting their application in high-wear environments.

A significant technical barrier across all coating technologies is the adhesion challenge between coating and substrate, particularly for titanium alloys due to their reactive surface oxide layer. This often necessitates specialized surface preparation techniques that add complexity and cost to the manufacturing process.

Coating durability remains another universal challenge, with most current technologies struggling to maintain protection under extreme service conditions such as high temperatures, cyclic loading, and aggressive chemical environments. This is particularly problematic for applications in aerospace and chemical processing industries.

Recent developments in hybrid coating systems that combine multiple technologies show promise in overcoming individual limitations, but integration complexities and cost considerations have limited widespread industrial adoption.

Thermal spray coating technologies, including High-Velocity Oxygen Fuel (HVOF) and plasma spraying, provide robust protection against wear and corrosion. These methods excel in depositing thick coatings with good mechanical properties but often struggle with coating porosity issues and limited bond strength, particularly on titanium substrates.

Chemical Vapor Deposition (CVD) delivers exceptional coating uniformity and can reach complex geometries, making it valuable for intricate components. The primary barriers include high processing temperatures that may alter the substrate's microstructure and the environmental concerns associated with precursor chemicals.

Electroplating and electroless plating offer cost-effective solutions for both titanium alloys and stainless steel, with relatively simple equipment requirements. These techniques face challenges in achieving uniform coating thickness on complex geometries and often involve environmentally problematic chemicals like hexavalent chromium.

Pack cementation processes provide excellent high-temperature protection but are limited by process control difficulties and environmental considerations. The coatings produced often exhibit inconsistent thickness and composition across the substrate surface.

Sol-gel coating methods represent an emerging approach with excellent chemical homogeneity and lower processing temperatures. However, they typically produce thinner coatings with inferior mechanical properties compared to traditional methods, limiting their application in high-wear environments.

A significant technical barrier across all coating technologies is the adhesion challenge between coating and substrate, particularly for titanium alloys due to their reactive surface oxide layer. This often necessitates specialized surface preparation techniques that add complexity and cost to the manufacturing process.

Coating durability remains another universal challenge, with most current technologies struggling to maintain protection under extreme service conditions such as high temperatures, cyclic loading, and aggressive chemical environments. This is particularly problematic for applications in aerospace and chemical processing industries.

Recent developments in hybrid coating systems that combine multiple technologies show promise in overcoming individual limitations, but integration complexities and cost considerations have limited widespread industrial adoption.

Comparative Analysis of Existing Coating Solutions

01 Physical Vapor Deposition (PVD) Coating Techniques

Physical Vapor Deposition techniques are widely used for applying protective coatings on titanium alloys and stainless steel. These methods include sputtering, evaporation, and ion plating processes that create thin films with excellent adhesion and uniformity. PVD coatings provide enhanced corrosion resistance, wear protection, and can improve the surface hardness of the metal substrates. These coatings are typically composed of nitrides, carbides, or oxides that form a protective barrier against environmental degradation.- Physical Vapor Deposition (PVD) Coating Techniques: Physical Vapor Deposition techniques are widely used for applying protective coatings on titanium alloys and stainless steel. These methods include sputtering, evaporation, and ion plating processes that create thin films with excellent adhesion and uniformity. PVD coatings provide enhanced corrosion resistance, wear protection, and can improve the surface hardness of the metal substrates while maintaining dimensional accuracy.

- Chemical Vapor Deposition (CVD) and Thermal Spray Coatings: Chemical Vapor Deposition and thermal spray techniques are effective methods for applying protective layers on titanium alloys and stainless steel. These processes involve the deposition of materials through chemical reactions or high-temperature spraying to form dense, adherent coatings. These methods can produce thick protective layers with excellent thermal stability, oxidation resistance, and mechanical properties suitable for harsh operating environments.

- Electrochemical and Conversion Coatings: Electrochemical processes and conversion coatings provide effective protection for titanium alloys and stainless steel. These include anodizing, electroplating, and chemical conversion treatments that modify the surface properties of the metals. These treatments create protective oxide layers or metallic deposits that enhance corrosion resistance, improve wear characteristics, and can provide decorative finishes while maintaining the base metal's mechanical properties.

- Composite and Multi-layer Coating Systems: Composite and multi-layer coating systems combine different materials and techniques to provide enhanced protection for titanium alloys and stainless steel. These systems typically involve sequential application of various coating layers, each serving a specific protective function. The combination of different materials creates synergistic effects that improve overall performance, including superior corrosion resistance, wear protection, thermal barrier properties, and extended service life in aggressive environments.

- Novel Surface Modification Technologies: Emerging surface modification technologies offer innovative approaches to protecting titanium alloys and stainless steel. These include laser surface treatments, plasma electrolytic oxidation, sol-gel coatings, and nanostructured surface modifications. These advanced techniques can create specialized surface properties such as superhydrophobicity, self-healing capabilities, antimicrobial properties, and enhanced tribological characteristics while maintaining or improving the base metal's corrosion resistance and mechanical integrity.

02 Chemical Vapor Deposition (CVD) and Thermal Spray Coatings

Chemical Vapor Deposition and thermal spray techniques are effective methods for protecting titanium alloys and stainless steel surfaces. CVD involves chemical reactions in a vapor phase to deposit solid materials on heated substrates, while thermal spray methods project molten or semi-molten materials onto surfaces. These processes create thick, durable coatings with excellent adhesion and can incorporate various materials including ceramics, metals, and composites. The resulting coatings provide superior protection against corrosion, oxidation, and wear in harsh environments.Expand Specific Solutions03 Electrochemical and Conversion Coatings

Electrochemical processes and conversion coatings offer effective protection for titanium alloys and stainless steel. These include anodizing, electroplating, and chemical conversion treatments that modify the surface properties of the metals. The processes create protective oxide layers or deposit metallic coatings that enhance corrosion resistance, wear protection, and aesthetic appearance. These coating methods are particularly valuable for applications requiring precise thickness control and can be tailored to provide specific functional properties such as electrical conductivity or insulation.Expand Specific Solutions04 Composite and Multi-layer Coating Systems

Advanced protection for titanium alloys and stainless steel can be achieved through composite and multi-layer coating systems. These systems combine different materials and coating techniques to create synergistic protective effects. Typically consisting of alternating layers with complementary properties, these coatings provide enhanced corrosion resistance, wear protection, and thermal stability. The multi-layer approach allows for optimization of surface properties while maintaining the beneficial mechanical characteristics of the substrate metals, making them ideal for demanding applications in aerospace, medical, and industrial sectors.Expand Specific Solutions05 Sol-gel and Polymer-based Protective Coatings

Sol-gel processes and polymer-based coatings offer versatile protection solutions for titanium alloys and stainless steel. These methods involve applying liquid precursors that transform into solid protective films through chemical reactions or curing processes. The resulting coatings provide excellent corrosion resistance, chemical stability, and can incorporate functional additives such as self-healing components or hydrophobic agents. These coating technologies are particularly valuable for applications requiring low-temperature processing, complex geometries, or environmentally friendly alternatives to traditional coating methods.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The coating technologies market for titanium alloy and stainless steel protection is currently in a growth phase, with increasing demand driven by aerospace, medical, and industrial applications. The global market is estimated to reach $15-20 billion by 2025, expanding at 5-7% CAGR. Technologically, the field shows varying maturity levels across different coating methods. Leading players include aerospace giants Boeing and Airbus, who utilize advanced protective coatings for critical components, alongside specialized coating technology providers like Oerlikon Surface Solutions. Research institutions such as CNRS and Forschungszentrum Jülich are advancing fundamental coating science, while materials companies including Kobe Steel and Titanium Metals Corp. are developing application-specific solutions. The competitive landscape features collaboration between academic institutions and industry, with companies like Safran and Rolls-Royce investing heavily in proprietary coating technologies to enhance material performance in extreme environments.

The Boeing Co.

Technical Solution: Boeing has developed proprietary coating systems for titanium alloys and stainless steel components used in aerospace applications. Their approach includes multi-layer protective systems combining different coating technologies tailored to specific environmental challenges. For titanium protection, Boeing employs specialized anodizing processes followed by application of chromium-free primers and topcoats that provide corrosion protection while minimizing galvanic coupling issues. Their research has focused on environmentally compliant coating systems that eliminate hexavalent chromium while maintaining performance requirements. For high-temperature applications, Boeing has developed thermal barrier coatings (TBCs) that protect titanium alloys from oxidation at elevated temperatures, extending component life in engine applications. Their stainless steel protection systems include specialized sol-gel based coatings that enhance corrosion resistance in marine environments while providing excellent adhesion for subsequent paint systems. Boeing has also pioneered plasma electrolytic oxidation (PEO) treatments for titanium that create ceramic-like surface layers with exceptional wear and corrosion resistance properties.

Strengths: Comprehensive multi-layer protection systems tailored for aerospace environments; environmentally compliant formulations that meet strict regulatory requirements; extensive field testing and validation in actual service conditions. Weaknesses: Proprietary systems may have higher implementation costs; some coating systems require specialized application equipment and expertise; potential weight penalties for multi-layer systems in weight-critical aerospace applications.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon Surface Solutions has developed advanced PVD (Physical Vapor Deposition) coating technologies specifically designed for titanium alloys and stainless steel protection. Their BALINIT® coating portfolio includes specialized titanium-based coatings with nano-layered structures that provide exceptional wear resistance while maintaining the corrosion resistance properties of the base materials. For titanium alloys, they've pioneered a pre-treatment process that enhances coating adhesion by removing the naturally forming oxide layer before applying their proprietary titanium nitride (TiN) and titanium aluminum nitride (TiAlN) coatings. Their BALIQ® technology combines the advantages of arc evaporation and sputtering processes to create extremely smooth, dense coatings with hardness values exceeding 3000 HV, which is particularly effective for protecting both titanium alloys and stainless steel in aggressive environments. Recent developments include their S3p® (Scalable Pulsed Power Plasma) technology that creates exceptionally dense coatings with superior adhesion properties for critical aerospace and medical applications.

Strengths: Superior coating adhesion through specialized pre-treatment processes; extremely hard (3000+ HV) coatings providing excellent wear protection; ability to maintain corrosion resistance properties of base materials. Weaknesses: Higher cost compared to conventional coating methods; requires specialized equipment and expertise; some coating processes operate at temperatures that could potentially affect the microstructure of heat-sensitive titanium alloys.

Key Patents and Innovations in Metal Surface Treatment

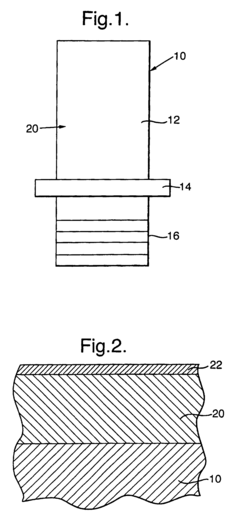

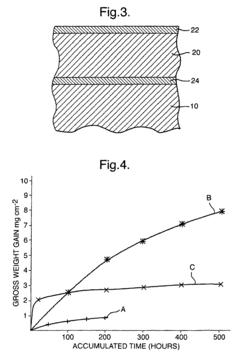

A titanium article having a protective coating and a method of applying a protective coating to a titanium article

PatentInactiveEP1054077B1

Innovation

- A protective coating comprising austenitic stainless steel with a chromia layer and optionally a silica layer, applied using physical vapour deposition or plasma spraying, which forms a dense and oxidation-resistant barrier on titanium aluminide articles, including turbine blades and vanes.

Method for obtaining an Anti-oxidative coating for a titanium alloy part

PatentWO2024018154A1

Innovation

- A protective coating is formed using a liquid composition comprising metallo-organic sol-gel precursors of aluminum or zirconium, combined with other elements like titanium, tin, or rare earths, which undergo hydrolysis and condensation to create an interconnected mixed oxide network, providing protection against oxidation up to 700°C, and can be applied without heat or with a heat treatment to accommodate thermal expansion and reduce oxygen diffusion.

Environmental Impact and Sustainability Considerations

The environmental impact of coating technologies for metal protection has become increasingly significant as industries strive for more sustainable practices. Traditional coating methods for titanium alloys and stainless steel often involve processes that release volatile organic compounds (VOCs), heavy metals, and other hazardous substances into the environment. These emissions contribute to air pollution, water contamination, and soil degradation, raising serious environmental concerns.

Recent advancements in eco-friendly coating technologies have focused on reducing or eliminating these harmful substances. Water-based coatings have emerged as viable alternatives to solvent-based systems, significantly reducing VOC emissions during application and curing processes. Additionally, powder coating technologies have gained popularity for both titanium alloys and stainless steel protection due to their near-zero VOC emissions and the ability to recycle overspray material, minimizing waste generation.

Life cycle assessment (LCA) studies comparing various coating technologies reveal substantial differences in environmental footprints. Thermal spray coatings, while effective for corrosion protection, often consume significant energy during application. In contrast, newer technologies like atomic layer deposition (ALD) and physical vapor deposition (PVD) demonstrate lower energy requirements and reduced environmental impact, particularly when applied to titanium alloys.

The durability of protective coatings also plays a crucial role in sustainability considerations. Longer-lasting coatings reduce the frequency of reapplication, thereby decreasing the overall environmental impact throughout the product lifecycle. Advanced ceramic coatings and composite materials have shown promising results in extending protection lifespans for both titanium alloys and stainless steel components, especially in aggressive environments.

Regulatory frameworks worldwide are increasingly stringent regarding the environmental impact of industrial processes. The European Union's REACH regulations and similar initiatives globally have accelerated the transition toward greener coating technologies. Manufacturers are now required to document the environmental impact of their coating processes and demonstrate compliance with sustainability standards, driving innovation in this field.

Recycling and end-of-life considerations present another dimension of environmental impact. Certain coating technologies can complicate the recycling process for titanium alloys and stainless steel by introducing contaminants that are difficult to separate during material recovery. Research is ongoing to develop coating systems that maintain protective properties while allowing for easier material recovery and recycling at the end of product life.

Recent advancements in eco-friendly coating technologies have focused on reducing or eliminating these harmful substances. Water-based coatings have emerged as viable alternatives to solvent-based systems, significantly reducing VOC emissions during application and curing processes. Additionally, powder coating technologies have gained popularity for both titanium alloys and stainless steel protection due to their near-zero VOC emissions and the ability to recycle overspray material, minimizing waste generation.

Life cycle assessment (LCA) studies comparing various coating technologies reveal substantial differences in environmental footprints. Thermal spray coatings, while effective for corrosion protection, often consume significant energy during application. In contrast, newer technologies like atomic layer deposition (ALD) and physical vapor deposition (PVD) demonstrate lower energy requirements and reduced environmental impact, particularly when applied to titanium alloys.

The durability of protective coatings also plays a crucial role in sustainability considerations. Longer-lasting coatings reduce the frequency of reapplication, thereby decreasing the overall environmental impact throughout the product lifecycle. Advanced ceramic coatings and composite materials have shown promising results in extending protection lifespans for both titanium alloys and stainless steel components, especially in aggressive environments.

Regulatory frameworks worldwide are increasingly stringent regarding the environmental impact of industrial processes. The European Union's REACH regulations and similar initiatives globally have accelerated the transition toward greener coating technologies. Manufacturers are now required to document the environmental impact of their coating processes and demonstrate compliance with sustainability standards, driving innovation in this field.

Recycling and end-of-life considerations present another dimension of environmental impact. Certain coating technologies can complicate the recycling process for titanium alloys and stainless steel by introducing contaminants that are difficult to separate during material recovery. Research is ongoing to develop coating systems that maintain protective properties while allowing for easier material recovery and recycling at the end of product life.

Cost-Benefit Analysis of Coating Technologies

When evaluating coating technologies for titanium alloy and stainless steel protection, cost-benefit analysis becomes a critical decision-making factor for industrial applications. Initial investment costs vary significantly across coating methods, with PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) technologies requiring substantial capital expenditure for equipment acquisition, ranging from $500,000 to several million dollars. Conversely, electroplating and anodizing systems present more modest initial investments, typically between $50,000 and $200,000, making them more accessible for smaller operations.

Operational expenses further differentiate these technologies. Thermal spray coatings demonstrate moderate equipment costs but higher ongoing expenses due to material consumption and energy requirements. PVD processes, while capital-intensive initially, offer lower operational costs over time with minimal waste generation and efficient material utilization rates exceeding 80% in optimized systems.

Durability metrics significantly impact long-term economic viability. Ceramic coatings applied through thermal spray techniques may cost 30-50% more than conventional treatments but can extend component lifespan by 2-3 times in corrosive environments, yielding positive return on investment within 12-18 months for high-wear applications. For titanium alloys specifically, specialized PVD coatings might increase component costs by 15-25% while providing 3-5 times greater corrosion resistance compared to uncoated parts.

Environmental compliance costs increasingly influence total ownership calculations. Traditional electroplating processes face rising regulatory expenses due to hazardous waste management requirements, adding 10-20% to operational costs annually. Newer technologies like ion implantation and plasma nitriding offer reduced environmental impact but at premium pricing points, approximately 40-60% higher than conventional methods.

Application-specific performance benefits must be quantified against these costs. In aerospace applications, where component failure can have catastrophic consequences, premium coating technologies delivering 99.9% reliability rates justify cost premiums of 200-300%. Conversely, in less critical applications like consumer goods, more economical coating options with 95% reliability rates may provide optimal cost-benefit ratios.

Maintenance requirements further differentiate coating technologies economically. Self-lubricating coatings may cost 25-35% more initially but reduce maintenance frequency by up to 70%, generating substantial operational savings. Additionally, some advanced ceramic coatings enable condition monitoring capabilities that prevent catastrophic failures, potentially saving 5-10 times their application cost through predictive maintenance opportunities.

Operational expenses further differentiate these technologies. Thermal spray coatings demonstrate moderate equipment costs but higher ongoing expenses due to material consumption and energy requirements. PVD processes, while capital-intensive initially, offer lower operational costs over time with minimal waste generation and efficient material utilization rates exceeding 80% in optimized systems.

Durability metrics significantly impact long-term economic viability. Ceramic coatings applied through thermal spray techniques may cost 30-50% more than conventional treatments but can extend component lifespan by 2-3 times in corrosive environments, yielding positive return on investment within 12-18 months for high-wear applications. For titanium alloys specifically, specialized PVD coatings might increase component costs by 15-25% while providing 3-5 times greater corrosion resistance compared to uncoated parts.

Environmental compliance costs increasingly influence total ownership calculations. Traditional electroplating processes face rising regulatory expenses due to hazardous waste management requirements, adding 10-20% to operational costs annually. Newer technologies like ion implantation and plasma nitriding offer reduced environmental impact but at premium pricing points, approximately 40-60% higher than conventional methods.

Application-specific performance benefits must be quantified against these costs. In aerospace applications, where component failure can have catastrophic consequences, premium coating technologies delivering 99.9% reliability rates justify cost premiums of 200-300%. Conversely, in less critical applications like consumer goods, more economical coating options with 95% reliability rates may provide optimal cost-benefit ratios.

Maintenance requirements further differentiate coating technologies economically. Self-lubricating coatings may cost 25-35% more initially but reduce maintenance frequency by up to 70%, generating substantial operational savings. Additionally, some advanced ceramic coatings enable condition monitoring capabilities that prevent catastrophic failures, potentially saving 5-10 times their application cost through predictive maintenance opportunities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!