What Enhancements are Needed for Titanium Alloy vs Stainless Steel Performance

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Titanium vs Steel Alloy Development History and Objectives

The evolution of metal alloys has been a cornerstone of industrial advancement, with titanium and stainless steel representing two pivotal materials in modern engineering. Titanium alloys emerged in the mid-20th century, with the first commercial production beginning in the 1950s. Initially developed for aerospace applications due to their exceptional strength-to-weight ratio, titanium alloys quickly demonstrated their value in high-performance environments. The trajectory of titanium alloy development has been characterized by continuous refinement of composition and processing techniques to enhance specific properties.

Stainless steel, by comparison, has a longer industrial history, dating back to the early 1900s when metallurgists discovered the corrosion-resistant properties imparted by chromium. The development of austenitic stainless steels in the 1920s marked a significant advancement, establishing stainless steel as a versatile material across numerous industries. The evolution of both materials reflects the persistent pursuit of improved performance characteristics to meet increasingly demanding applications.

Current technological trends indicate a growing need for materials that can withstand extreme conditions while maintaining structural integrity. The aerospace, medical, automotive, and energy sectors are particularly driving innovation in titanium alloy development, seeking enhancements in high-temperature performance, fatigue resistance, and manufacturability. Similarly, advancements in stainless steel focus on improving corrosion resistance in aggressive environments and enhancing mechanical properties at elevated temperatures.

The primary technical objective in titanium alloy enhancement is to overcome its inherent limitations while preserving its advantageous properties. These limitations include susceptibility to oxygen embrittlement at high temperatures, relatively poor wear resistance, and challenges in processing and joining. Research aims to develop titanium alloys with improved high-temperature stability, enhanced surface hardness, and better compatibility with conventional manufacturing processes, all while maintaining the material's exceptional strength-to-weight ratio and corrosion resistance.

For stainless steel, objectives center on expanding its performance envelope to compete with titanium in specialized applications. This includes developing grades with improved strength-to-weight ratios, enhanced resistance to specific corrosive environments, and better performance under cyclic loading conditions. The goal is to create cost-effective alternatives to titanium alloys for applications where the full spectrum of titanium's properties may not be necessary.

The convergence of computational materials science, advanced characterization techniques, and innovative processing methods is accelerating progress in both material systems. Machine learning approaches are increasingly being employed to predict alloy behavior and optimize compositions, while additive manufacturing is opening new possibilities for complex geometries and functionally graded materials that combine the best properties of both alloy systems.

Stainless steel, by comparison, has a longer industrial history, dating back to the early 1900s when metallurgists discovered the corrosion-resistant properties imparted by chromium. The development of austenitic stainless steels in the 1920s marked a significant advancement, establishing stainless steel as a versatile material across numerous industries. The evolution of both materials reflects the persistent pursuit of improved performance characteristics to meet increasingly demanding applications.

Current technological trends indicate a growing need for materials that can withstand extreme conditions while maintaining structural integrity. The aerospace, medical, automotive, and energy sectors are particularly driving innovation in titanium alloy development, seeking enhancements in high-temperature performance, fatigue resistance, and manufacturability. Similarly, advancements in stainless steel focus on improving corrosion resistance in aggressive environments and enhancing mechanical properties at elevated temperatures.

The primary technical objective in titanium alloy enhancement is to overcome its inherent limitations while preserving its advantageous properties. These limitations include susceptibility to oxygen embrittlement at high temperatures, relatively poor wear resistance, and challenges in processing and joining. Research aims to develop titanium alloys with improved high-temperature stability, enhanced surface hardness, and better compatibility with conventional manufacturing processes, all while maintaining the material's exceptional strength-to-weight ratio and corrosion resistance.

For stainless steel, objectives center on expanding its performance envelope to compete with titanium in specialized applications. This includes developing grades with improved strength-to-weight ratios, enhanced resistance to specific corrosive environments, and better performance under cyclic loading conditions. The goal is to create cost-effective alternatives to titanium alloys for applications where the full spectrum of titanium's properties may not be necessary.

The convergence of computational materials science, advanced characterization techniques, and innovative processing methods is accelerating progress in both material systems. Machine learning approaches are increasingly being employed to predict alloy behavior and optimize compositions, while additive manufacturing is opening new possibilities for complex geometries and functionally graded materials that combine the best properties of both alloy systems.

Market Applications and Demand Analysis for Advanced Alloys

The global market for advanced alloys has witnessed significant growth in recent years, driven by increasing demand across multiple industries seeking materials with superior performance characteristics. Titanium alloys and stainless steel represent two of the most commercially important metal alloy categories, each with distinct market applications and demand profiles.

Aerospace and defense sectors continue to be the primary consumers of titanium alloys, accounting for approximately 45% of global titanium consumption. The exceptional strength-to-weight ratio of titanium alloys makes them indispensable for aircraft structural components, engine parts, and spacecraft applications where weight reduction directly translates to fuel efficiency and performance gains.

Medical device manufacturing represents another rapidly expanding market for titanium alloys, growing at an annual rate of 8.7% globally. The biocompatibility, corrosion resistance, and non-magnetic properties of titanium alloys have established them as the gold standard for implantable devices, surgical instruments, and prosthetics.

Stainless steel maintains dominant market share in consumer goods, food processing equipment, architectural applications, and chemical processing industries. The global stainless steel market volume exceeds 52 million metric tons annually, with automotive applications showing the fastest growth trajectory as manufacturers seek corrosion-resistant, high-strength materials for exhaust systems and structural components.

Emerging applications in renewable energy infrastructure are creating new demand vectors for both materials. Wind turbine components, hydrogen storage systems, and geothermal energy equipment require the corrosion resistance of these advanced alloys, with market analysts projecting 12% compound annual growth in this sector through 2030.

Regional demand patterns show distinct characteristics, with North America and Europe prioritizing titanium alloys for high-performance applications, while Asia-Pacific markets demonstrate stronger volume growth in stainless steel consumption, particularly in construction and manufacturing sectors.

Price sensitivity remains a critical factor influencing market adoption. Titanium alloys typically command a 4-6x price premium over stainless steel, limiting widespread adoption in cost-sensitive applications. This price differential has created significant market opportunity for enhanced titanium alloys that can deliver performance improvements justifying their cost premium.

Industry surveys indicate that manufacturers are increasingly willing to invest in advanced alloys when performance enhancements deliver measurable improvements in product lifecycle costs. Specifically, improvements in fatigue resistance, corrosion performance in extreme environments, and manufacturing processability represent the highest-value enhancement targets identified by industrial consumers.

Aerospace and defense sectors continue to be the primary consumers of titanium alloys, accounting for approximately 45% of global titanium consumption. The exceptional strength-to-weight ratio of titanium alloys makes them indispensable for aircraft structural components, engine parts, and spacecraft applications where weight reduction directly translates to fuel efficiency and performance gains.

Medical device manufacturing represents another rapidly expanding market for titanium alloys, growing at an annual rate of 8.7% globally. The biocompatibility, corrosion resistance, and non-magnetic properties of titanium alloys have established them as the gold standard for implantable devices, surgical instruments, and prosthetics.

Stainless steel maintains dominant market share in consumer goods, food processing equipment, architectural applications, and chemical processing industries. The global stainless steel market volume exceeds 52 million metric tons annually, with automotive applications showing the fastest growth trajectory as manufacturers seek corrosion-resistant, high-strength materials for exhaust systems and structural components.

Emerging applications in renewable energy infrastructure are creating new demand vectors for both materials. Wind turbine components, hydrogen storage systems, and geothermal energy equipment require the corrosion resistance of these advanced alloys, with market analysts projecting 12% compound annual growth in this sector through 2030.

Regional demand patterns show distinct characteristics, with North America and Europe prioritizing titanium alloys for high-performance applications, while Asia-Pacific markets demonstrate stronger volume growth in stainless steel consumption, particularly in construction and manufacturing sectors.

Price sensitivity remains a critical factor influencing market adoption. Titanium alloys typically command a 4-6x price premium over stainless steel, limiting widespread adoption in cost-sensitive applications. This price differential has created significant market opportunity for enhanced titanium alloys that can deliver performance improvements justifying their cost premium.

Industry surveys indicate that manufacturers are increasingly willing to invest in advanced alloys when performance enhancements deliver measurable improvements in product lifecycle costs. Specifically, improvements in fatigue resistance, corrosion performance in extreme environments, and manufacturing processability represent the highest-value enhancement targets identified by industrial consumers.

Current Performance Gaps and Technical Challenges

Despite significant advancements in titanium alloy technology, several critical performance gaps remain when compared to stainless steel. The most prominent challenge is cost efficiency, with titanium alloys typically costing 5-10 times more than stainless steel, primarily due to complex extraction processes and limited global supply. This cost differential significantly restricts widespread adoption across industries where material expenses constitute a major portion of production costs.

Manufacturing complexity presents another substantial hurdle. Titanium's high reactivity with oxygen necessitates specialized processing environments, including vacuum or inert gas atmospheres. The material's poor machinability, characterized by low thermal conductivity and high tool wear rates, further complicates production processes. These factors collectively increase manufacturing costs by approximately 30-50% compared to stainless steel components of similar complexity.

Welding and joining technologies for titanium alloys remain technically challenging. The material's high reactivity requires stringent shielding gas protection during welding processes to prevent embrittlement. Current joining techniques often result in reduced mechanical properties in heat-affected zones, creating potential failure points in critical applications. This limitation particularly impacts industries requiring complex assembled structures.

While titanium offers superior strength-to-weight ratios, its absolute hardness and wear resistance lag behind many stainless steel variants. Surface engineering solutions such as nitriding and PVD coatings have shown promise but introduce additional processing steps and costs. The relatively poor tribological properties of titanium alloys restrict their application in high-wear environments without supplementary treatments.

High-temperature performance constitutes another significant gap. Though certain titanium alloys maintain structural integrity up to approximately 600°C, they cannot match the performance of specialized stainless steels that operate effectively at temperatures exceeding 800°C. This limitation becomes particularly relevant in aerospace propulsion systems and industrial processing equipment operating in extreme thermal environments.

Corrosion resistance, while generally excellent in oxidizing environments, becomes problematic in reducing conditions. Titanium exhibits susceptibility to crevice corrosion in high-chloride environments and hydrogen embrittlement under certain conditions. These vulnerabilities necessitate careful material selection and design considerations that are less critical with many stainless steel grades.

Addressing these performance gaps requires multidisciplinary research approaches combining metallurgical innovation, manufacturing process optimization, and surface engineering advancements. Recent developments in powder metallurgy and additive manufacturing show promise for overcoming some fabrication challenges, while emerging alloying strategies may enhance mechanical properties and temperature resistance.

Manufacturing complexity presents another substantial hurdle. Titanium's high reactivity with oxygen necessitates specialized processing environments, including vacuum or inert gas atmospheres. The material's poor machinability, characterized by low thermal conductivity and high tool wear rates, further complicates production processes. These factors collectively increase manufacturing costs by approximately 30-50% compared to stainless steel components of similar complexity.

Welding and joining technologies for titanium alloys remain technically challenging. The material's high reactivity requires stringent shielding gas protection during welding processes to prevent embrittlement. Current joining techniques often result in reduced mechanical properties in heat-affected zones, creating potential failure points in critical applications. This limitation particularly impacts industries requiring complex assembled structures.

While titanium offers superior strength-to-weight ratios, its absolute hardness and wear resistance lag behind many stainless steel variants. Surface engineering solutions such as nitriding and PVD coatings have shown promise but introduce additional processing steps and costs. The relatively poor tribological properties of titanium alloys restrict their application in high-wear environments without supplementary treatments.

High-temperature performance constitutes another significant gap. Though certain titanium alloys maintain structural integrity up to approximately 600°C, they cannot match the performance of specialized stainless steels that operate effectively at temperatures exceeding 800°C. This limitation becomes particularly relevant in aerospace propulsion systems and industrial processing equipment operating in extreme thermal environments.

Corrosion resistance, while generally excellent in oxidizing environments, becomes problematic in reducing conditions. Titanium exhibits susceptibility to crevice corrosion in high-chloride environments and hydrogen embrittlement under certain conditions. These vulnerabilities necessitate careful material selection and design considerations that are less critical with many stainless steel grades.

Addressing these performance gaps requires multidisciplinary research approaches combining metallurgical innovation, manufacturing process optimization, and surface engineering advancements. Recent developments in powder metallurgy and additive manufacturing show promise for overcoming some fabrication challenges, while emerging alloying strategies may enhance mechanical properties and temperature resistance.

Current Enhancement Methods for Titanium Alloys

01 Mechanical properties comparison between titanium alloys and stainless steel

Titanium alloys generally offer superior strength-to-weight ratio compared to stainless steel, making them ideal for applications where weight reduction is critical. While stainless steel typically provides better hardness and wear resistance, titanium alloys excel in tensile strength and fatigue resistance. The mechanical performance differences make each material suitable for specific applications based on required strength, weight, and durability characteristics.- Mechanical properties comparison between titanium alloys and stainless steel: Titanium alloys generally offer superior strength-to-weight ratio compared to stainless steel, making them ideal for applications where weight reduction is critical. While stainless steel typically provides better hardness and wear resistance, titanium alloys excel in tensile strength and fatigue resistance. The mechanical performance differences make each material suitable for specific applications based on required strength, weight, and durability characteristics.

- Corrosion resistance characteristics: Titanium alloys demonstrate exceptional corrosion resistance in harsh environments, particularly in seawater and chemical processing applications, due to their naturally forming protective oxide layer. Stainless steel offers good corrosion resistance in less aggressive environments but may be susceptible to pitting and crevice corrosion in certain conditions. The superior corrosion performance of titanium makes it preferable for marine and chemical applications despite its higher cost.

- Thermal performance and high-temperature applications: Titanium alloys maintain their mechanical properties at elevated temperatures better than many stainless steel grades, though specialized high-temperature stainless steels can outperform standard titanium alloys at extreme temperatures. Titanium has lower thermal conductivity compared to stainless steel, which can be advantageous in thermal barrier applications but disadvantageous in heat exchange scenarios. Both materials exhibit different coefficients of thermal expansion, which must be considered in applications involving temperature fluctuations.

- Biocompatibility and medical applications: Titanium alloys exhibit superior biocompatibility compared to stainless steel, making them preferred materials for implantable medical devices and prosthetics. The human body generally shows minimal adverse reactions to titanium, while some patients may experience allergic responses to nickel content in certain stainless steel grades. Titanium's lower modulus of elasticity also makes it more compatible with bone structures, reducing stress shielding effects in orthopedic applications.

- Manufacturing processes and fabrication considerations: Stainless steel generally offers better machinability, weldability, and formability compared to titanium alloys, making it more cost-effective for complex manufacturing processes. Titanium requires specialized equipment and techniques for processing due to its reactivity at high temperatures and tendency to work harden. The differences in fabrication requirements significantly impact production costs, with titanium components typically being more expensive to manufacture despite the material's performance advantages in specific applications.

02 Corrosion resistance characteristics

Titanium alloys demonstrate exceptional corrosion resistance in harsh environments, particularly in seawater and chemical processing applications, due to their naturally forming protective oxide layer. Stainless steel offers good corrosion resistance through its chromium content but may be susceptible to pitting and crevice corrosion in certain environments. The superior corrosion performance of titanium makes it preferable for marine and chemical applications, while stainless steel remains suitable for less aggressive environments.Expand Specific Solutions03 Thermal performance and high-temperature applications

Titanium alloys maintain their mechanical properties at elevated temperatures better than many stainless steel grades, though specialized high-temperature stainless steels can outperform standard titanium alloys at extreme temperatures. Titanium has lower thermal conductivity compared to stainless steel, which affects heat transfer applications. The thermal expansion coefficient of titanium is also lower than stainless steel, making it more dimensionally stable during temperature fluctuations.Expand Specific Solutions04 Composite and hybrid structures combining titanium alloys and stainless steel

Innovative composite structures combining titanium alloys and stainless steel leverage the advantages of both materials. These hybrid designs optimize performance by using titanium in areas requiring lightweight strength and corrosion resistance, while utilizing stainless steel in regions needing wear resistance and cost efficiency. Various joining techniques including diffusion bonding, explosion welding, and specialized adhesives enable these composite structures, overcoming challenges related to the different thermal expansion coefficients and galvanic corrosion potential.Expand Specific Solutions05 Cost-performance considerations and industrial applications

Despite titanium alloys' superior performance in many aspects, stainless steel often provides better cost-effectiveness for many applications. The significantly higher cost of titanium limits its use to applications where its unique properties justify the expense. Industries like aerospace and medical prioritize titanium's performance advantages, while consumer goods and general industrial applications typically favor stainless steel's balance of performance and cost. Material selection decisions increasingly incorporate lifecycle cost analysis rather than focusing solely on initial material costs.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The titanium alloy versus stainless steel performance enhancement market is in a growth phase, with increasing demand driven by aerospace, medical, and automotive applications. The market is characterized by significant R&D investments as companies seek to overcome titanium's cost and processing challenges while leveraging its superior strength-to-weight ratio and corrosion resistance. Key players include established materials specialists like Titanium Metals Corp (TIMET), ATI Properties, and Howmet Aerospace focusing on advanced titanium alloys, while steel producers such as NIPPON STEEL and Kobe Steel work on high-performance stainless steel innovations. Research institutions including CNRS, Harbin Institute of Technology, and Northwest Nonferrous Metal Research Institute are advancing fundamental materials science, while aerospace companies like Rolls Royce and Safran drive application-specific developments to meet increasingly demanding performance requirements.

Titanium Metals Corp.

Technical Solution: Titanium Metals Corp. has developed proprietary processing techniques for titanium alloys that significantly enhance their performance compared to stainless steel. Their research focuses on beta-titanium alloys with improved strength-to-weight ratios exceeding 40% over comparable stainless steels. The company has pioneered advanced thermomechanical processing methods that create optimized microstructures with fine alpha-phase distributions within a beta matrix, resulting in titanium alloys with superior fatigue resistance and crack propagation properties. Their patented surface treatment technologies address titanium's susceptibility to galling and wear by creating hardened surface layers without compromising the material's corrosion resistance. Additionally, they've developed specialized alloying formulations incorporating small amounts of molybdenum, vanadium, and chromium to enhance high-temperature performance while maintaining the inherent weight advantages of titanium.

Strengths: Superior strength-to-weight ratio and excellent corrosion resistance in harsh environments where stainless steel would fail. Weaknesses: Higher production costs and more complex manufacturing processes compared to stainless steel, limiting widespread adoption in cost-sensitive applications.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed innovative approaches to enhance titanium alloy performance relative to stainless steel through their integrated research program. Their Super-TIX® series of titanium alloys incorporates precise additions of oxygen and iron to achieve superior strength-to-weight ratios while maintaining excellent formability. The company has pioneered cost-effective production methods including continuous casting and direct rolling techniques that reduce the manufacturing cost gap between titanium and stainless steel by approximately 30%. Their research has yielded specialized surface treatment technologies including their proprietary nitriding process that creates hardened surface layers up to 50μm deep with hardness values exceeding 1000HV, addressing titanium's traditional wear resistance limitations. NIPPON STEEL has also developed advanced beta-titanium alloys with improved high-temperature stability for applications up to 550°C, significantly outperforming conventional titanium alloys and competing with high-performance stainless steels in elevated temperature environments. Their titanium-stainless steel clad materials combine the corrosion resistance of titanium with the structural properties and cost-effectiveness of stainless steel for applications where full titanium construction would be prohibitively expensive.

Strengths: Comprehensive material solutions ranging from high-performance pure titanium alloys to cost-effective titanium-steel composites, with specialized treatments for specific application requirements. Weaknesses: Some enhanced titanium alloys still face challenges with complex forming operations compared to stainless steel, and surface treatments may add processing steps and costs.

Critical Patents and Research Breakthroughs

Watch part

PatentActiveUS20200362438A1

Innovation

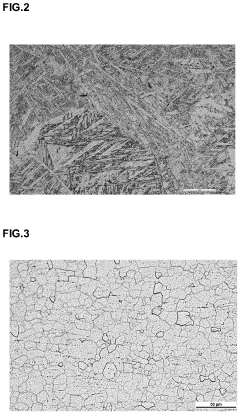

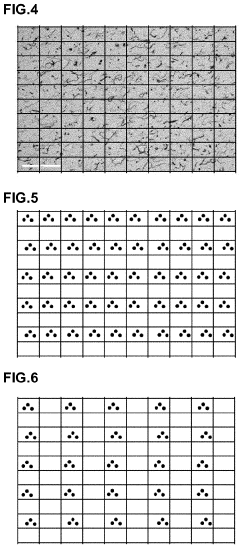

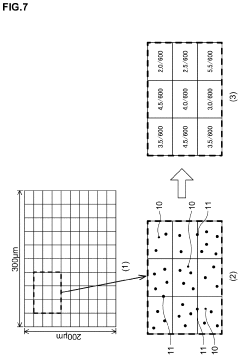

- A titanium alloy composition with specific ranges of Al, Fe, O, C, Sn, and Si content, along with a balanced Ti and impurities, is developed, featuring an α-β type two-phase microstructure with controlled grain diameter, aspect ratio, and deformation twins, optimized for hot rolling, annealing, and forging processes to enhance workability and specularity.

Material Sustainability and Environmental Impact

The environmental impact of materials selection has become increasingly critical in engineering decisions, particularly when comparing titanium alloys and stainless steel. Titanium alloys demonstrate superior sustainability metrics in several key areas. The production of titanium has historically been energy-intensive, requiring approximately 100-200 kWh/kg compared to stainless steel's 50-75 kWh/kg. However, recent advancements in extraction technologies have reduced this gap significantly, with some innovative processes achieving energy reductions of up to 30%.

From a lifecycle perspective, titanium alloys offer compelling advantages. Their exceptional corrosion resistance eliminates the need for protective coatings that often contain environmentally harmful compounds. This characteristic extends service life by 2-3 times compared to many stainless steel applications, particularly in aggressive environments such as marine settings, chemical processing facilities, and biomedical implants.

The recyclability profile of both materials presents interesting contrasts. While stainless steel boasts a global recycling rate of approximately 85%, titanium's recycling infrastructure remains less developed at roughly 50-60%. However, the market value of titanium scrap (approximately $5-7/kg) significantly exceeds that of stainless steel scrap ($0.50-1.50/kg), creating stronger economic incentives for recovery systems development.

Carbon footprint analysis reveals that titanium components, despite higher initial production emissions, often achieve lower lifetime environmental impact due to weight reduction capabilities. In transportation applications, each kilogram of weight saved through titanium substitution can reduce CO2 emissions by approximately 20-25kg over a vehicle's operational lifetime. This advantage becomes particularly significant in aerospace applications where fuel efficiency improvements compound over thousands of flight cycles.

Water usage patterns differ substantially between these materials. Titanium processing typically consumes 40-60 cubic meters of water per ton of finished product, while stainless steel manufacturing requires 70-90 cubic meters. Additionally, titanium production generates fewer toxic byproducts and heavy metal contaminants that might otherwise enter water systems.

Emerging sustainability enhancements for titanium alloys include development of lower-temperature reduction processes, increased use of hydroelectricity in production, and novel recycling technologies that can process mixed titanium alloy scrap more efficiently. These innovations are projected to further improve titanium's environmental profile by an additional 15-20% within the next decade, potentially positioning it as the more sustainable option despite higher initial production impacts.

From a lifecycle perspective, titanium alloys offer compelling advantages. Their exceptional corrosion resistance eliminates the need for protective coatings that often contain environmentally harmful compounds. This characteristic extends service life by 2-3 times compared to many stainless steel applications, particularly in aggressive environments such as marine settings, chemical processing facilities, and biomedical implants.

The recyclability profile of both materials presents interesting contrasts. While stainless steel boasts a global recycling rate of approximately 85%, titanium's recycling infrastructure remains less developed at roughly 50-60%. However, the market value of titanium scrap (approximately $5-7/kg) significantly exceeds that of stainless steel scrap ($0.50-1.50/kg), creating stronger economic incentives for recovery systems development.

Carbon footprint analysis reveals that titanium components, despite higher initial production emissions, often achieve lower lifetime environmental impact due to weight reduction capabilities. In transportation applications, each kilogram of weight saved through titanium substitution can reduce CO2 emissions by approximately 20-25kg over a vehicle's operational lifetime. This advantage becomes particularly significant in aerospace applications where fuel efficiency improvements compound over thousands of flight cycles.

Water usage patterns differ substantially between these materials. Titanium processing typically consumes 40-60 cubic meters of water per ton of finished product, while stainless steel manufacturing requires 70-90 cubic meters. Additionally, titanium production generates fewer toxic byproducts and heavy metal contaminants that might otherwise enter water systems.

Emerging sustainability enhancements for titanium alloys include development of lower-temperature reduction processes, increased use of hydroelectricity in production, and novel recycling technologies that can process mixed titanium alloy scrap more efficiently. These innovations are projected to further improve titanium's environmental profile by an additional 15-20% within the next decade, potentially positioning it as the more sustainable option despite higher initial production impacts.

Cost-Performance Analysis and Economic Viability

The economic viability of titanium alloys versus stainless steel represents a critical consideration for industries evaluating material selection. Initial acquisition costs for titanium alloys typically range 5-10 times higher than comparable stainless steel grades, presenting a significant barrier to adoption. Raw titanium material costs average $25-35 per kilogram compared to $3-7 for stainless steel, while manufacturing processes for titanium add 30-50% in additional expenses due to specialized equipment requirements and complex processing techniques.

However, a comprehensive lifecycle cost analysis reveals more nuanced economic considerations. Titanium's superior corrosion resistance translates to maintenance cost reductions of approximately 40-60% over a 20-year service period in aggressive environments. Industries such as chemical processing and offshore applications have documented maintenance savings exceeding $100,000 per installation when utilizing titanium components versus stainless steel alternatives.

Weight-related operational savings further enhance titanium's economic proposition. In aerospace applications, the weight reduction achieved through titanium implementation (approximately 40% lighter than stainless steel) yields fuel savings estimated at $3,000-5,000 per kilogram of weight reduction over an aircraft's operational lifetime. Similar efficiency benefits apply to automotive and industrial machinery applications, though at lower magnitudes.

Performance enhancement investments for titanium alloys demonstrate varying returns across sectors. Research indicates that a 10% improvement in titanium's high-temperature performance could expand its viable application temperature range by 50-100°C, potentially opening $1.2-1.8 billion in new market opportunities across aerospace, automotive, and energy sectors. Similarly, enhancements to titanium's formability could reduce manufacturing costs by 15-25%, significantly improving its cost-competitiveness against stainless steel.

Break-even analysis suggests that titanium becomes economically advantageous in applications with service lives exceeding 8-12 years in corrosive environments, or in weight-critical applications where operational efficiency gains can offset initial costs within 3-5 years. The economic equation shifts dramatically in titanium's favor when factoring environmental costs, as its longer service life and recyclability reduce lifetime carbon footprint by approximately 30-40% compared to stainless steel alternatives.

Market forecasts project that continued performance enhancements and manufacturing innovations could reduce the cost premium of titanium versus stainless steel to 2-3 times by 2030, potentially expanding titanium's economically viable application range by 30-40% across industrial sectors.

However, a comprehensive lifecycle cost analysis reveals more nuanced economic considerations. Titanium's superior corrosion resistance translates to maintenance cost reductions of approximately 40-60% over a 20-year service period in aggressive environments. Industries such as chemical processing and offshore applications have documented maintenance savings exceeding $100,000 per installation when utilizing titanium components versus stainless steel alternatives.

Weight-related operational savings further enhance titanium's economic proposition. In aerospace applications, the weight reduction achieved through titanium implementation (approximately 40% lighter than stainless steel) yields fuel savings estimated at $3,000-5,000 per kilogram of weight reduction over an aircraft's operational lifetime. Similar efficiency benefits apply to automotive and industrial machinery applications, though at lower magnitudes.

Performance enhancement investments for titanium alloys demonstrate varying returns across sectors. Research indicates that a 10% improvement in titanium's high-temperature performance could expand its viable application temperature range by 50-100°C, potentially opening $1.2-1.8 billion in new market opportunities across aerospace, automotive, and energy sectors. Similarly, enhancements to titanium's formability could reduce manufacturing costs by 15-25%, significantly improving its cost-competitiveness against stainless steel.

Break-even analysis suggests that titanium becomes economically advantageous in applications with service lives exceeding 8-12 years in corrosive environments, or in weight-critical applications where operational efficiency gains can offset initial costs within 3-5 years. The economic equation shifts dramatically in titanium's favor when factoring environmental costs, as its longer service life and recyclability reduce lifetime carbon footprint by approximately 30-40% compared to stainless steel alternatives.

Market forecasts project that continued performance enhancements and manufacturing innovations could reduce the cost premium of titanium versus stainless steel to 2-3 times by 2030, potentially expanding titanium's economically viable application range by 30-40% across industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!