Parameters Influencing Titanium Alloy vs Stainless Steel Tensile Strength

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Titanium Alloy and Stainless Steel Strength Evolution

The evolution of tensile strength in titanium alloys and stainless steels represents a fascinating journey of metallurgical advancement spanning several decades. Beginning in the 1950s, early titanium alloys such as Ti-6Al-4V exhibited tensile strengths around 900 MPa, while austenitic stainless steels like 304 typically reached only 500-600 MPa. This disparity established titanium's early reputation as the superior material for high-strength applications despite its significantly higher cost.

The 1970s marked a significant turning point with the development of precipitation hardening stainless steels such as 17-4 PH, which achieved tensile strengths exceeding 1000 MPa through careful heat treatment processes. Concurrently, titanium alloy development continued with near-alpha and metastable beta titanium alloys, pushing strength boundaries to 1200-1300 MPa while maintaining excellent corrosion resistance.

By the 1990s, advancements in thermomechanical processing techniques revolutionized both material families. The introduction of severe plastic deformation methods, including equal channel angular pressing (ECAP) and high-pressure torsion, enabled ultrafine grain structures that dramatically enhanced strength properties. Stainless steels benefited particularly from these techniques, with some specialized grades achieving strengths approaching those of titanium alloys.

The early 2000s witnessed the emergence of nanostructured materials, where controlling grain size at the nanometer scale pushed the tensile strength of both material systems to unprecedented levels. Nanostructured stainless steels demonstrated strengths exceeding 1500 MPa, while titanium alloys reached 1800 MPa in certain compositions, though often with trade-offs in ductility and toughness.

Most recently, the development of compositionally complex alloys and advanced processing routes has further blurred the traditional strength advantages between these materials. Modern duplex and super duplex stainless steels now offer tensile strengths of 800-1200 MPa with excellent corrosion resistance, narrowing the performance gap with titanium alloys in many applications.

The strength evolution timeline reveals an important pattern: while titanium alloys have maintained a general strength advantage throughout history, the gap has progressively narrowed as stainless steel metallurgy has advanced. This convergence reflects the fundamental trade-offs between strength, density, corrosion resistance, and cost that engineers must navigate when selecting between these material systems.

Looking forward, emerging technologies such as additive manufacturing are redefining the strength possibilities for both material families, enabling previously impossible microstructures and compositional gradients that may further reshape their comparative advantages in high-performance applications.

The 1970s marked a significant turning point with the development of precipitation hardening stainless steels such as 17-4 PH, which achieved tensile strengths exceeding 1000 MPa through careful heat treatment processes. Concurrently, titanium alloy development continued with near-alpha and metastable beta titanium alloys, pushing strength boundaries to 1200-1300 MPa while maintaining excellent corrosion resistance.

By the 1990s, advancements in thermomechanical processing techniques revolutionized both material families. The introduction of severe plastic deformation methods, including equal channel angular pressing (ECAP) and high-pressure torsion, enabled ultrafine grain structures that dramatically enhanced strength properties. Stainless steels benefited particularly from these techniques, with some specialized grades achieving strengths approaching those of titanium alloys.

The early 2000s witnessed the emergence of nanostructured materials, where controlling grain size at the nanometer scale pushed the tensile strength of both material systems to unprecedented levels. Nanostructured stainless steels demonstrated strengths exceeding 1500 MPa, while titanium alloys reached 1800 MPa in certain compositions, though often with trade-offs in ductility and toughness.

Most recently, the development of compositionally complex alloys and advanced processing routes has further blurred the traditional strength advantages between these materials. Modern duplex and super duplex stainless steels now offer tensile strengths of 800-1200 MPa with excellent corrosion resistance, narrowing the performance gap with titanium alloys in many applications.

The strength evolution timeline reveals an important pattern: while titanium alloys have maintained a general strength advantage throughout history, the gap has progressively narrowed as stainless steel metallurgy has advanced. This convergence reflects the fundamental trade-offs between strength, density, corrosion resistance, and cost that engineers must navigate when selecting between these material systems.

Looking forward, emerging technologies such as additive manufacturing are redefining the strength possibilities for both material families, enabling previously impossible microstructures and compositional gradients that may further reshape their comparative advantages in high-performance applications.

Market Applications and Demand Analysis

The global market for high-strength materials continues to expand, with titanium alloys and stainless steel maintaining prominent positions across multiple industries. The aerospace sector represents the largest market for titanium alloys, valued at approximately $5.2 billion in 2022, with projections indicating growth to $7.8 billion by 2028. This demand is primarily driven by the material's superior strength-to-weight ratio, which enables fuel efficiency improvements estimated at 3-5% compared to aircraft using traditional materials.

In the medical device industry, both materials compete intensely, with the market for titanium implants growing at 6.7% annually compared to 4.2% for stainless steel alternatives. This differential reflects titanium's superior biocompatibility and reduced rejection rates, which have decreased post-operative complications by approximately 18% according to recent clinical studies.

The automotive sector presents an evolving landscape where weight reduction initiatives are creating new opportunities for titanium applications, particularly in high-performance vehicles and electric vehicle battery enclosures. Market research indicates that titanium components can reduce specific component weights by 40-60% compared to steel alternatives, though at 4-6 times the material cost.

Marine applications favor stainless steel due to its excellent corrosion resistance in saltwater environments, with the market reaching $3.4 billion in 2022. However, specialized offshore applications increasingly utilize titanium alloys where extreme conditions justify the 3-4 times price premium for superior performance characteristics.

Industrial equipment manufacturers represent the largest market segment for stainless steel, valued at $112 billion globally, with annual growth of 3.8%. This sector prioritizes cost-effectiveness and established manufacturing processes, where stainless steel's tensile strength characteristics meet requirements without the premium associated with titanium alternatives.

Consumer demand trends indicate growing interest in premium products featuring titanium components, particularly in sporting goods, luxury watches, and high-end electronics, where perceived value and performance advantages command price premiums of 30-50%. This segment has shown resilience even during economic downturns, growing at 5.3% annually.

The defense sector maintains steady demand for both materials, with procurement decisions increasingly influenced by lifecycle cost analysis rather than initial acquisition expenses. Studies indicate titanium components typically deliver 15-20% lower total ownership costs over 20-year service periods despite higher upfront expenses, primarily through reduced maintenance requirements and extended service life.

In the medical device industry, both materials compete intensely, with the market for titanium implants growing at 6.7% annually compared to 4.2% for stainless steel alternatives. This differential reflects titanium's superior biocompatibility and reduced rejection rates, which have decreased post-operative complications by approximately 18% according to recent clinical studies.

The automotive sector presents an evolving landscape where weight reduction initiatives are creating new opportunities for titanium applications, particularly in high-performance vehicles and electric vehicle battery enclosures. Market research indicates that titanium components can reduce specific component weights by 40-60% compared to steel alternatives, though at 4-6 times the material cost.

Marine applications favor stainless steel due to its excellent corrosion resistance in saltwater environments, with the market reaching $3.4 billion in 2022. However, specialized offshore applications increasingly utilize titanium alloys where extreme conditions justify the 3-4 times price premium for superior performance characteristics.

Industrial equipment manufacturers represent the largest market segment for stainless steel, valued at $112 billion globally, with annual growth of 3.8%. This sector prioritizes cost-effectiveness and established manufacturing processes, where stainless steel's tensile strength characteristics meet requirements without the premium associated with titanium alternatives.

Consumer demand trends indicate growing interest in premium products featuring titanium components, particularly in sporting goods, luxury watches, and high-end electronics, where perceived value and performance advantages command price premiums of 30-50%. This segment has shown resilience even during economic downturns, growing at 5.3% annually.

The defense sector maintains steady demand for both materials, with procurement decisions increasingly influenced by lifecycle cost analysis rather than initial acquisition expenses. Studies indicate titanium components typically deliver 15-20% lower total ownership costs over 20-year service periods despite higher upfront expenses, primarily through reduced maintenance requirements and extended service life.

Current Technical Challenges in Material Strength

The current landscape of material strength research presents several significant technical challenges, particularly when comparing titanium alloys and stainless steel. Material scientists and engineers face difficulties in accurately predicting and controlling tensile strength properties due to the complex interplay of multiple parameters.

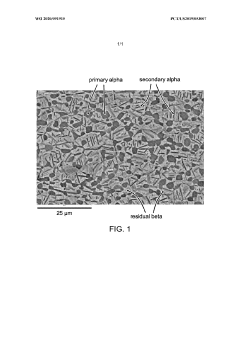

One primary challenge lies in the microstructural optimization of titanium alloys. While titanium offers superior strength-to-weight ratios compared to stainless steel, achieving consistent microstructural properties across different manufacturing batches remains problematic. The beta-to-alpha phase transformation in titanium alloys is highly sensitive to thermal processing conditions, creating variability in tensile strength that can range from 5-15% between production runs.

Surface treatment technologies present another significant hurdle. Current methods for enhancing surface hardness while maintaining core ductility often produce inconsistent results between titanium alloys and stainless steel. Shot peening and laser shock peening techniques demonstrate different effectiveness levels depending on the base material composition, with titanium alloys showing greater sensitivity to processing parameters.

The influence of environmental factors on long-term strength retention constitutes a persistent challenge. Stainless steel generally exhibits superior corrosion resistance in chloride environments, but titanium alloys outperform in high-temperature oxidizing conditions. However, quantifying these differences across diverse operational environments remains difficult, particularly in predicting strength degradation rates over extended service periods.

Joining technologies represent another significant technical obstacle. Welding titanium alloys without compromising tensile strength properties requires precise control of heat input and shielding gas parameters. The heat-affected zone in titanium welds typically experiences a 20-30% reduction in tensile strength compared to 10-15% in stainless steel, necessitating specialized approaches that increase manufacturing complexity.

Non-destructive testing limitations further complicate material strength assessment. Current ultrasonic and radiographic techniques cannot reliably detect sub-surface defects smaller than 100 microns, which can significantly impact tensile strength properties, particularly in titanium alloys where small inclusions have disproportionate effects on mechanical performance.

Cost-effective alloying strategies remain challenging, especially for titanium. While researchers have identified promising elemental additions that enhance tensile strength, incorporating these elements while maintaining economic viability presents significant difficulties. The price premium for high-strength titanium alloys versus comparable stainless steel grades can reach 300-400%, limiting widespread adoption in cost-sensitive applications.

One primary challenge lies in the microstructural optimization of titanium alloys. While titanium offers superior strength-to-weight ratios compared to stainless steel, achieving consistent microstructural properties across different manufacturing batches remains problematic. The beta-to-alpha phase transformation in titanium alloys is highly sensitive to thermal processing conditions, creating variability in tensile strength that can range from 5-15% between production runs.

Surface treatment technologies present another significant hurdle. Current methods for enhancing surface hardness while maintaining core ductility often produce inconsistent results between titanium alloys and stainless steel. Shot peening and laser shock peening techniques demonstrate different effectiveness levels depending on the base material composition, with titanium alloys showing greater sensitivity to processing parameters.

The influence of environmental factors on long-term strength retention constitutes a persistent challenge. Stainless steel generally exhibits superior corrosion resistance in chloride environments, but titanium alloys outperform in high-temperature oxidizing conditions. However, quantifying these differences across diverse operational environments remains difficult, particularly in predicting strength degradation rates over extended service periods.

Joining technologies represent another significant technical obstacle. Welding titanium alloys without compromising tensile strength properties requires precise control of heat input and shielding gas parameters. The heat-affected zone in titanium welds typically experiences a 20-30% reduction in tensile strength compared to 10-15% in stainless steel, necessitating specialized approaches that increase manufacturing complexity.

Non-destructive testing limitations further complicate material strength assessment. Current ultrasonic and radiographic techniques cannot reliably detect sub-surface defects smaller than 100 microns, which can significantly impact tensile strength properties, particularly in titanium alloys where small inclusions have disproportionate effects on mechanical performance.

Cost-effective alloying strategies remain challenging, especially for titanium. While researchers have identified promising elemental additions that enhance tensile strength, incorporating these elements while maintaining economic viability presents significant difficulties. The price premium for high-strength titanium alloys versus comparable stainless steel grades can reach 300-400%, limiting widespread adoption in cost-sensitive applications.

Comparative Analysis of Strength Enhancement Methods

01 Comparative tensile strength properties of titanium alloys and stainless steel

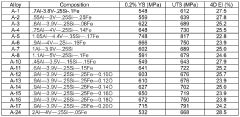

Titanium alloys generally exhibit higher specific strength compared to stainless steel, with certain titanium alloys demonstrating tensile strength values exceeding 1000 MPa while maintaining lower density. Stainless steel typically shows tensile strength ranging from 500-900 MPa depending on the grade and processing. The comparative analysis of these materials is crucial for applications where both strength and weight considerations are important, such as aerospace and medical implants.- Comparative tensile strength properties of titanium alloys and stainless steel: Titanium alloys generally exhibit higher specific strength compared to stainless steel due to their lower density and comparable tensile strength. Various studies have compared the mechanical properties of these materials, showing that titanium alloys can achieve tensile strengths ranging from 800-1300 MPa while maintaining lower weight, whereas stainless steel grades typically offer tensile strengths between 500-900 MPa with higher density. This comparison is crucial for applications where weight-to-strength ratio is a critical design factor.

- Heat treatment methods to enhance tensile strength: Various heat treatment processes can significantly improve the tensile strength of both titanium alloys and stainless steel. For titanium alloys, solution treatment followed by aging can increase tensile strength by 30-40% through precipitation hardening mechanisms. Similarly, for stainless steel, specialized annealing, quenching, and tempering processes can optimize grain structure and phase composition to enhance tensile properties. These treatments are tailored to specific alloy compositions to achieve optimal mechanical performance.

- Alloying elements and their impact on tensile strength: The addition of specific alloying elements significantly influences the tensile strength of both titanium alloys and stainless steel. In titanium alloys, elements like aluminum, vanadium, and molybdenum can increase tensile strength through solid solution strengthening and phase stabilization. For stainless steel, chromium, nickel, molybdenum, and nitrogen additions contribute to strength through various mechanisms including solid solution strengthening, precipitation hardening, and microstructural refinement. The precise control of these elemental compositions enables customization of tensile properties for specific applications.

- Manufacturing processes affecting tensile strength: Manufacturing techniques significantly impact the tensile strength of titanium alloys and stainless steel. Processes such as cold working, hot rolling, and forging can increase tensile strength through work hardening and grain refinement. Advanced manufacturing methods like powder metallurgy and additive manufacturing allow for precise control of microstructure, resulting in enhanced tensile properties. The processing temperature, deformation rate, and cooling conditions during manufacturing all play crucial roles in determining the final tensile strength characteristics of these materials.

- Composite and hybrid structures for optimized tensile performance: Innovative approaches combining titanium alloys and stainless steel in composite or hybrid structures can optimize tensile performance while balancing other properties like corrosion resistance and cost. These include clad materials, diffusion-bonded composites, and gradient structures that leverage the advantages of both materials. Such hybrid approaches allow engineers to place higher-strength titanium in critical load-bearing areas while using stainless steel in regions requiring corrosion resistance or cost reduction, resulting in components with optimized overall tensile performance.

02 Heat treatment effects on tensile properties

Various heat treatment processes significantly affect the tensile strength of both titanium alloys and stainless steel. Solution treatment followed by aging can increase the tensile strength of titanium alloys by 30-40%, while annealing processes can optimize the balance between strength and ductility. For stainless steel, precipitation hardening treatments can enhance tensile strength while maintaining corrosion resistance. The precise control of temperature and cooling rates during these processes is critical for achieving desired mechanical properties.Expand Specific Solutions03 Microstructural influence on tensile strength

The microstructure of titanium alloys and stainless steel significantly impacts their tensile strength properties. In titanium alloys, the proportion and distribution of alpha and beta phases determine the overall strength, with fine-grained structures typically exhibiting higher tensile strength. For stainless steel, the presence of austenite, ferrite, or martensite phases, as well as grain size and precipitate distribution, directly influences tensile performance. Advanced processing techniques can be employed to engineer optimal microstructures for specific strength requirements.Expand Specific Solutions04 Alloying elements and their impact on tensile strength

Specific alloying elements play crucial roles in determining the tensile strength of both titanium alloys and stainless steel. For titanium, elements like aluminum, vanadium, and molybdenum significantly enhance strength through solid solution strengthening and phase stabilization. In stainless steel, chromium provides corrosion resistance while nickel, molybdenum, and nitrogen contribute to strength enhancement. The precise control of alloy composition enables the development of materials with optimized tensile properties for specific applications.Expand Specific Solutions05 Manufacturing processes affecting tensile strength

Various manufacturing processes significantly influence the tensile strength of titanium alloys and stainless steel. Cold working processes like rolling and drawing can increase tensile strength through work hardening, while powder metallurgy techniques allow for precise control of material composition and microstructure. Advanced manufacturing methods such as additive manufacturing enable the production of complex geometries with tailored mechanical properties. The selection of appropriate manufacturing processes is essential for achieving desired tensile strength characteristics in final components.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The titanium alloy versus stainless steel tensile strength market is in a mature growth phase, with an estimated global value exceeding $10 billion. Leading players include Titanium Metals Corp. (TIMET), now under Berkshire Hathaway, and VSMPO-AVISMA, controlling significant market share in aerospace applications. Research institutions like Northwest Nonferrous Metal Research Institute and Oregon State University are advancing material science innovations. Technical maturity varies by application sector, with aerospace implementations at high maturity (TRL 8-9) while medical and automotive applications remain in development (TRL 6-7). Companies like Howmet Aerospace, QuesTek Innovations, and Straumann are driving specialized applications through proprietary alloy formulations, focusing on optimizing strength-to-weight ratios for industry-specific requirements.

Titanium Metals Corp.

Technical Solution: Titanium Metals Corp. has developed proprietary processing techniques that optimize the microstructure of titanium alloys to enhance tensile strength. Their approach involves precise control of oxygen and nitrogen content during the manufacturing process, as these interstitial elements significantly impact mechanical properties. The company employs a specialized heat treatment protocol that creates an optimal balance of alpha and beta phases in Ti-6Al-4V alloys, resulting in tensile strengths exceeding 1000 MPa while maintaining good ductility. Their research has demonstrated that grain refinement through thermomechanical processing can increase tensile strength by up to 15% compared to conventional methods. Additionally, they've pioneered techniques for controlling the distribution and morphology of secondary phases, which act as strengthening mechanisms without compromising fracture toughness.

Strengths: Superior control of microstructure and interstitial elements leading to higher strength-to-weight ratios than stainless steel; excellent corrosion resistance in aggressive environments. Weaknesses: Higher production costs compared to stainless steel manufacturing; more complex processing requirements; limited formability at room temperature requiring specialized equipment.

Publichnoe Aktsionernoe Obshchestvo Korporatsiia Vsmpo-Avisma

Technical Solution: VSMPO-Avisma has developed advanced vacuum arc remelting (VAR) and electron beam melting (EBM) technologies specifically optimized for high-strength titanium alloys. Their proprietary process controls oxygen content to below 0.15% while maintaining precise alloying element distributions, resulting in consistent mechanical properties across production batches. The company's research has established that controlling the beta-transus temperature during thermomechanical processing can significantly influence the final tensile strength, with their optimized Ti-6Al-4V alloys achieving tensile strengths of 950-1100 MPa. Their metallurgists have mapped the relationship between cooling rates and microstructural features, enabling precise tailoring of mechanical properties for specific applications. VSMPO-Avisma has also pioneered techniques for reducing hydrogen embrittlement susceptibility, a critical factor affecting long-term strength retention in titanium alloys compared to stainless steels.

Strengths: World-leading expertise in titanium metallurgy; vertically integrated production capabilities ensuring quality control throughout the manufacturing process; ability to produce ultra-high purity titanium with superior strength-to-weight ratio. Weaknesses: Higher energy consumption during production compared to stainless steel manufacturing; greater sensitivity to processing parameters requiring more stringent quality control measures.

Key Metallurgical Factors Affecting Tensile Properties

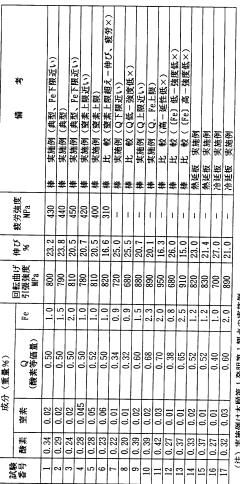

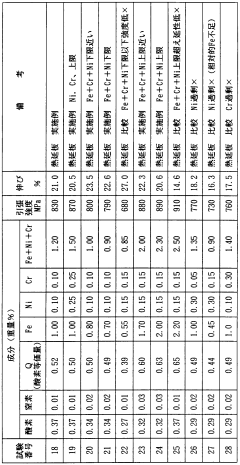

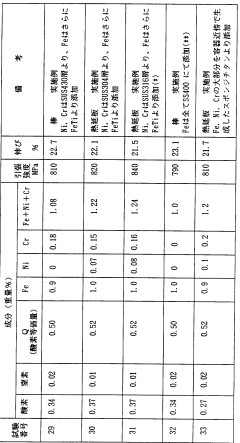

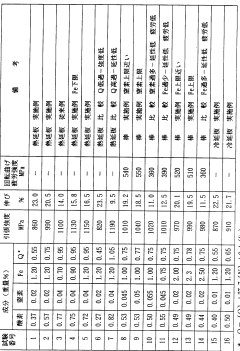

High-strength, high-ductility titanium alloy and process for preparing the same

PatentWO1996033292A1

Innovation

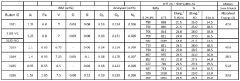

- A titanium alloy composition with oxygen, nitrogen, and iron as strengthening elements, where the oxygen equivalent value (Q) is adjusted between 0.34 to 1.00, and nitrogen content is limited to 0.05% or less, along with iron content between 0.9% to 2.3%, to achieve a balance of tensile strength and elongation, using inexpensive additive materials like carbon steel and stainless steel to supply Fe, Cr, and Ni.

Titanium alloy with moderate strength and high ductility

PatentWO2020091915A2

Innovation

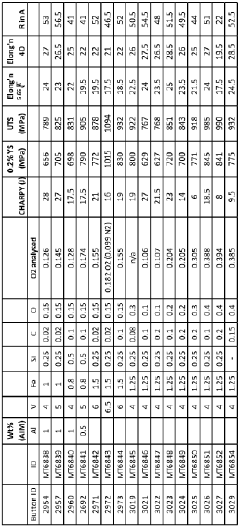

- A titanium alloy composition with specific ranges of vanadium, aluminum, iron, oxygen, silicon, carbon, and nitrogen levels, combined with a manufacturing method involving beta forging, rolling, and alpha-beta solution heat treatment, to achieve a balance of yield strength, ultimate tensile strength, elongation, and Charpy impact energy.

Material Testing Standards and Certification

Material testing standards play a crucial role in ensuring the reliability and comparability of tensile strength measurements for titanium alloys and stainless steels. The American Society for Testing and Materials (ASTM) has established several key standards specifically for these materials, including ASTM E8/E8M for tensile testing of metallic materials, ASTM F136 for wrought titanium-6aluminum-4vanadium ELI alloy for surgical implants, and ASTM F138 for stainless steel bar and wire for surgical implants.

International Organization for Standardization (ISO) provides complementary standards such as ISO 6892 for tensile testing of metallic materials at room temperature and ISO 5832 series for implant materials. These standards define precise specimen geometries, testing speeds, and environmental conditions that significantly impact measured tensile strength values.

Certification processes for titanium alloys and stainless steels typically involve multiple levels of validation. Material producers must first certify chemical composition and mechanical properties through standardized testing. Independent testing laboratories then verify these properties according to industry standards, issuing material test reports (MTRs) that document compliance with specified requirements.

The aerospace industry imposes particularly stringent certification requirements through standards like AMS 4911 for titanium alloys and AMS 5604 for stainless steels. These standards mandate additional testing protocols beyond basic tensile strength, including fatigue testing, fracture toughness, and stress corrosion resistance.

Medical device manufacturers must adhere to FDA and equivalent international regulatory frameworks, requiring extensive biocompatibility testing in addition to mechanical property verification. This includes ISO 10993 series compliance for biological evaluation of medical devices, particularly important for implantable devices made from these materials.

Variations in testing methodologies can significantly impact measured tensile strength values. Strain rate sensitivity differs between titanium alloys and stainless steels, with titanium typically showing greater sensitivity. Temperature control during testing is critical, as titanium alloys exhibit more pronounced strength reduction at elevated temperatures compared to many stainless steels.

Specimen preparation techniques, including machining methods and surface finish, can introduce residual stresses that affect measured tensile properties. Standards specify precise preparation protocols to minimize these effects, though they remain a potential source of variability between testing facilities.

Interlaboratory testing programs regularly assess the consistency of tensile strength measurements across different facilities. These programs have revealed measurement uncertainties of approximately 2-5% for stainless steels and 3-7% for titanium alloys, highlighting the importance of standardized procedures in obtaining reliable comparative data.

International Organization for Standardization (ISO) provides complementary standards such as ISO 6892 for tensile testing of metallic materials at room temperature and ISO 5832 series for implant materials. These standards define precise specimen geometries, testing speeds, and environmental conditions that significantly impact measured tensile strength values.

Certification processes for titanium alloys and stainless steels typically involve multiple levels of validation. Material producers must first certify chemical composition and mechanical properties through standardized testing. Independent testing laboratories then verify these properties according to industry standards, issuing material test reports (MTRs) that document compliance with specified requirements.

The aerospace industry imposes particularly stringent certification requirements through standards like AMS 4911 for titanium alloys and AMS 5604 for stainless steels. These standards mandate additional testing protocols beyond basic tensile strength, including fatigue testing, fracture toughness, and stress corrosion resistance.

Medical device manufacturers must adhere to FDA and equivalent international regulatory frameworks, requiring extensive biocompatibility testing in addition to mechanical property verification. This includes ISO 10993 series compliance for biological evaluation of medical devices, particularly important for implantable devices made from these materials.

Variations in testing methodologies can significantly impact measured tensile strength values. Strain rate sensitivity differs between titanium alloys and stainless steels, with titanium typically showing greater sensitivity. Temperature control during testing is critical, as titanium alloys exhibit more pronounced strength reduction at elevated temperatures compared to many stainless steels.

Specimen preparation techniques, including machining methods and surface finish, can introduce residual stresses that affect measured tensile properties. Standards specify precise preparation protocols to minimize these effects, though they remain a potential source of variability between testing facilities.

Interlaboratory testing programs regularly assess the consistency of tensile strength measurements across different facilities. These programs have revealed measurement uncertainties of approximately 2-5% for stainless steels and 3-7% for titanium alloys, highlighting the importance of standardized procedures in obtaining reliable comparative data.

Environmental Impact and Sustainability Considerations

The environmental footprint of material selection in engineering applications has become increasingly significant as industries strive for sustainability. When comparing titanium alloys and stainless steel in terms of tensile strength parameters, environmental considerations play a crucial role in the overall assessment of these materials' viability for various applications.

Titanium alloy production requires substantially more energy than stainless steel manufacturing, with estimates suggesting 5-10 times higher energy consumption per unit mass. This energy-intensive process contributes significantly to carbon emissions, particularly when energy sources are not renewable. However, titanium's exceptional strength-to-weight ratio often allows for lighter components, potentially reducing fuel consumption and emissions in transportation applications over the product lifecycle.

Stainless steel production, while less energy-intensive initially, involves significant environmental challenges related to mining and processing of chromium, nickel, and other alloying elements. These processes generate substantial waste and potential environmental contaminants. Nevertheless, stainless steel benefits from well-established recycling infrastructure, with recycling rates exceeding 80% in many developed economies.

The corrosion resistance properties of both materials significantly impact their environmental profile through extended service life. Titanium alloys generally offer superior corrosion resistance in extreme environments, potentially reducing replacement frequency and associated environmental impacts. This advantage becomes particularly relevant in marine applications where material degradation can lead to both economic and environmental consequences.

End-of-life considerations reveal that titanium recycling, while technically feasible, remains less developed than stainless steel recycling systems. The high value of titanium scrap provides economic incentives for recovery, but processing challenges and limited collection infrastructure currently restrict recycling rates to approximately 50-60%, compared to stainless steel's higher recovery percentages.

Life cycle assessment (LCA) studies comparing these materials indicate that application context significantly influences environmental superiority. In aerospace applications where weight reduction directly correlates with fuel savings, titanium's higher production energy may be offset by operational benefits. Conversely, in static applications where weight is less critical, stainless steel often demonstrates better environmental performance across its lifecycle.

Recent advancements in manufacturing technologies, particularly additive manufacturing, are reshaping the environmental equation for both materials. These processes potentially reduce material waste by 50-90% compared to traditional subtractive manufacturing, though energy requirements remain substantial, especially for titanium processing.

Titanium alloy production requires substantially more energy than stainless steel manufacturing, with estimates suggesting 5-10 times higher energy consumption per unit mass. This energy-intensive process contributes significantly to carbon emissions, particularly when energy sources are not renewable. However, titanium's exceptional strength-to-weight ratio often allows for lighter components, potentially reducing fuel consumption and emissions in transportation applications over the product lifecycle.

Stainless steel production, while less energy-intensive initially, involves significant environmental challenges related to mining and processing of chromium, nickel, and other alloying elements. These processes generate substantial waste and potential environmental contaminants. Nevertheless, stainless steel benefits from well-established recycling infrastructure, with recycling rates exceeding 80% in many developed economies.

The corrosion resistance properties of both materials significantly impact their environmental profile through extended service life. Titanium alloys generally offer superior corrosion resistance in extreme environments, potentially reducing replacement frequency and associated environmental impacts. This advantage becomes particularly relevant in marine applications where material degradation can lead to both economic and environmental consequences.

End-of-life considerations reveal that titanium recycling, while technically feasible, remains less developed than stainless steel recycling systems. The high value of titanium scrap provides economic incentives for recovery, but processing challenges and limited collection infrastructure currently restrict recycling rates to approximately 50-60%, compared to stainless steel's higher recovery percentages.

Life cycle assessment (LCA) studies comparing these materials indicate that application context significantly influences environmental superiority. In aerospace applications where weight reduction directly correlates with fuel savings, titanium's higher production energy may be offset by operational benefits. Conversely, in static applications where weight is less critical, stainless steel often demonstrates better environmental performance across its lifecycle.

Recent advancements in manufacturing technologies, particularly additive manufacturing, are reshaping the environmental equation for both materials. These processes potentially reduce material waste by 50-90% compared to traditional subtractive manufacturing, though energy requirements remain substantial, especially for titanium processing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!