Analysis of Autonomous Lab Versus Traditional Lab Efficiency in IoT

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IoT Lab Automation Background and Objectives

The Internet of Things (IoT) has revolutionized numerous industries by enabling seamless connectivity and data exchange between devices. In laboratory environments, this transformation has led to the emergence of autonomous labs, which represent a significant departure from traditional laboratory methodologies. The evolution of laboratory automation has progressed from simple mechanical automation to sophisticated systems incorporating artificial intelligence, machine learning, and IoT technologies.

Traditional laboratories have historically relied on manual processes, requiring significant human intervention for experimental setup, monitoring, and data collection. These environments, while effective for decades, face inherent limitations in terms of throughput, reproducibility, and round-the-clock operation capabilities. The progression toward automation began with basic robotic systems handling repetitive tasks but has now evolved into comprehensive autonomous systems capable of managing complex experimental workflows.

The primary objective of autonomous IoT labs is to enhance research efficiency through continuous operation, minimized human error, and optimized resource utilization. These systems aim to accelerate the pace of scientific discovery by enabling higher experimental throughput while maintaining or improving quality standards. Additionally, they seek to democratize access to advanced laboratory capabilities by reducing the expertise barrier required for complex experimental procedures.

Current technological trends in IoT lab automation include the integration of edge computing for real-time data processing, the implementation of digital twins for virtual experimentation, and the development of self-optimizing systems capable of learning from experimental outcomes. The convergence of robotics, sensor networks, and artificial intelligence has created unprecedented opportunities for laboratory innovation, particularly in fields requiring high-precision measurements or hazardous material handling.

The global research community has witnessed several milestone developments in autonomous laboratory systems, from early liquid handling robots to today's fully integrated platforms capable of designing, executing, and analyzing experiments with minimal human oversight. Companies like Emerald Cloud Lab, Strateos, and Kebotix have pioneered commercial offerings in this space, while academic institutions continue to push boundaries in specialized research domains.

Looking forward, the trajectory of IoT lab automation points toward increasingly adaptive systems capable of hypothesis generation, experimental design optimization, and autonomous scientific discovery. The ultimate vision encompasses laboratories that not only execute experiments but actively participate in the scientific method through data-driven decision making and iterative learning processes.

Traditional laboratories have historically relied on manual processes, requiring significant human intervention for experimental setup, monitoring, and data collection. These environments, while effective for decades, face inherent limitations in terms of throughput, reproducibility, and round-the-clock operation capabilities. The progression toward automation began with basic robotic systems handling repetitive tasks but has now evolved into comprehensive autonomous systems capable of managing complex experimental workflows.

The primary objective of autonomous IoT labs is to enhance research efficiency through continuous operation, minimized human error, and optimized resource utilization. These systems aim to accelerate the pace of scientific discovery by enabling higher experimental throughput while maintaining or improving quality standards. Additionally, they seek to democratize access to advanced laboratory capabilities by reducing the expertise barrier required for complex experimental procedures.

Current technological trends in IoT lab automation include the integration of edge computing for real-time data processing, the implementation of digital twins for virtual experimentation, and the development of self-optimizing systems capable of learning from experimental outcomes. The convergence of robotics, sensor networks, and artificial intelligence has created unprecedented opportunities for laboratory innovation, particularly in fields requiring high-precision measurements or hazardous material handling.

The global research community has witnessed several milestone developments in autonomous laboratory systems, from early liquid handling robots to today's fully integrated platforms capable of designing, executing, and analyzing experiments with minimal human oversight. Companies like Emerald Cloud Lab, Strateos, and Kebotix have pioneered commercial offerings in this space, while academic institutions continue to push boundaries in specialized research domains.

Looking forward, the trajectory of IoT lab automation points toward increasingly adaptive systems capable of hypothesis generation, experimental design optimization, and autonomous scientific discovery. The ultimate vision encompasses laboratories that not only execute experiments but actively participate in the scientific method through data-driven decision making and iterative learning processes.

Market Demand for Autonomous Labs in IoT Development

The Internet of Things (IoT) development market is witnessing a significant shift towards autonomous laboratory solutions, driven by increasing demands for efficiency, scalability, and innovation acceleration. Current market research indicates that the global IoT testing market is expanding at a compound annual growth rate of approximately 13% and is projected to reach $30 billion by 2025, with autonomous lab solutions representing a rapidly growing segment within this space.

Organizations across various industries are increasingly recognizing the limitations of traditional laboratory approaches in meeting the complex demands of IoT development and testing. Traditional labs require substantial human intervention, face scalability challenges, and often create bottlenecks in the development pipeline. This has created a robust market demand for autonomous laboratory solutions that can address these pain points.

The primary market drivers for autonomous labs in IoT development include the exponential growth in connected devices, which is expected to surpass 75 billion globally by 2025. This proliferation necessitates testing environments that can handle massive device ecosystems simultaneously, a capability that traditional labs struggle to provide cost-effectively.

Enterprise surveys reveal that 67% of IoT developers cite testing and validation as their most significant challenge, with 78% reporting that traditional lab processes cannot keep pace with their development cycles. This gap between development speed and testing capabilities represents a substantial market opportunity for autonomous lab solutions.

Industry verticals showing the strongest demand include smart manufacturing, where production efficiency improvements of 15-20% have been documented through autonomous testing environments; healthcare IoT, where device reliability testing is critical for patient safety; and smart city initiatives, where interoperability testing across diverse systems is essential for successful deployments.

The financial incentives for adopting autonomous labs are compelling, with organizations reporting average cost reductions of 40% in testing operations and time-to-market improvements of 35% compared to traditional laboratory approaches. These efficiency gains are particularly valuable in competitive markets where first-mover advantage can significantly impact market share.

Regional analysis shows North America currently leading in autonomous lab adoption, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in emerging markets where greenfield IoT implementations allow for direct adoption of autonomous approaches without legacy system constraints.

Customer requirements are evolving beyond basic automation to demand comprehensive autonomous solutions that incorporate artificial intelligence for predictive testing, self-healing capabilities, and continuous optimization of test environments without human intervention.

Organizations across various industries are increasingly recognizing the limitations of traditional laboratory approaches in meeting the complex demands of IoT development and testing. Traditional labs require substantial human intervention, face scalability challenges, and often create bottlenecks in the development pipeline. This has created a robust market demand for autonomous laboratory solutions that can address these pain points.

The primary market drivers for autonomous labs in IoT development include the exponential growth in connected devices, which is expected to surpass 75 billion globally by 2025. This proliferation necessitates testing environments that can handle massive device ecosystems simultaneously, a capability that traditional labs struggle to provide cost-effectively.

Enterprise surveys reveal that 67% of IoT developers cite testing and validation as their most significant challenge, with 78% reporting that traditional lab processes cannot keep pace with their development cycles. This gap between development speed and testing capabilities represents a substantial market opportunity for autonomous lab solutions.

Industry verticals showing the strongest demand include smart manufacturing, where production efficiency improvements of 15-20% have been documented through autonomous testing environments; healthcare IoT, where device reliability testing is critical for patient safety; and smart city initiatives, where interoperability testing across diverse systems is essential for successful deployments.

The financial incentives for adopting autonomous labs are compelling, with organizations reporting average cost reductions of 40% in testing operations and time-to-market improvements of 35% compared to traditional laboratory approaches. These efficiency gains are particularly valuable in competitive markets where first-mover advantage can significantly impact market share.

Regional analysis shows North America currently leading in autonomous lab adoption, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in emerging markets where greenfield IoT implementations allow for direct adoption of autonomous approaches without legacy system constraints.

Customer requirements are evolving beyond basic automation to demand comprehensive autonomous solutions that incorporate artificial intelligence for predictive testing, self-healing capabilities, and continuous optimization of test environments without human intervention.

Current State and Challenges in Lab Automation for IoT

Laboratory automation in the Internet of Things (IoT) domain has witnessed significant advancements in recent years, yet faces numerous challenges that impede widespread adoption. Currently, approximately 30% of IoT testing laboratories globally have implemented some form of automation, with only 5-10% achieving high levels of autonomous operation. This partial adoption reflects the complex transition landscape from traditional manual testing environments to fully automated systems.

The technological infrastructure supporting lab automation for IoT testing primarily consists of robotic systems, automated test equipment (ATE), and sophisticated laboratory information management systems (LIMS). These systems enable continuous testing operations, reducing human intervention and increasing throughput by an estimated 40-60% compared to traditional methods. However, integration challenges between these components often create operational bottlenecks that limit efficiency gains.

A significant challenge facing IoT lab automation is the rapid evolution of IoT standards and protocols. With over 400 IoT protocols currently in use across different applications, automated testing systems struggle to maintain compatibility and comprehensive test coverage. This diversity necessitates frequent reconfiguration and calibration of automated systems, reducing their cost-effectiveness and operational efficiency.

Data management represents another critical challenge, with automated IoT labs generating approximately 500% more test data than traditional labs. While this data abundance offers opportunities for deeper analytics and insights, it simultaneously creates storage, processing, and interpretation challenges. Many organizations lack the infrastructure and expertise to effectively leverage this data volume, resulting in underutilized analytical potential.

The financial barriers to automation remain substantial, with initial implementation costs for comprehensive lab automation systems ranging from $500,000 to several million dollars depending on scale and complexity. This investment threshold excludes many small and medium enterprises from adopting advanced automation solutions, creating a technological divide in the industry.

Workforce adaptation presents a human-centered challenge, as traditional lab technicians require significant reskilling to operate in automated environments. Industry surveys indicate that 65% of laboratory professionals express concerns about job security and role transformation in increasingly automated environments. This resistance can significantly impede implementation timelines and effectiveness.

Regulatory compliance adds another layer of complexity, particularly for IoT devices in sensitive sectors like healthcare, automotive, and industrial applications. Automated testing processes must demonstrate reliability and traceability equivalent to or exceeding manual processes, requiring extensive validation procedures that can delay implementation by 6-18 months.

Despite these challenges, the trajectory of lab automation in IoT testing shows promising developments in machine learning integration, modular automation architectures, and collaborative robot systems that can work alongside human operators, potentially addressing many current limitations in the coming years.

The technological infrastructure supporting lab automation for IoT testing primarily consists of robotic systems, automated test equipment (ATE), and sophisticated laboratory information management systems (LIMS). These systems enable continuous testing operations, reducing human intervention and increasing throughput by an estimated 40-60% compared to traditional methods. However, integration challenges between these components often create operational bottlenecks that limit efficiency gains.

A significant challenge facing IoT lab automation is the rapid evolution of IoT standards and protocols. With over 400 IoT protocols currently in use across different applications, automated testing systems struggle to maintain compatibility and comprehensive test coverage. This diversity necessitates frequent reconfiguration and calibration of automated systems, reducing their cost-effectiveness and operational efficiency.

Data management represents another critical challenge, with automated IoT labs generating approximately 500% more test data than traditional labs. While this data abundance offers opportunities for deeper analytics and insights, it simultaneously creates storage, processing, and interpretation challenges. Many organizations lack the infrastructure and expertise to effectively leverage this data volume, resulting in underutilized analytical potential.

The financial barriers to automation remain substantial, with initial implementation costs for comprehensive lab automation systems ranging from $500,000 to several million dollars depending on scale and complexity. This investment threshold excludes many small and medium enterprises from adopting advanced automation solutions, creating a technological divide in the industry.

Workforce adaptation presents a human-centered challenge, as traditional lab technicians require significant reskilling to operate in automated environments. Industry surveys indicate that 65% of laboratory professionals express concerns about job security and role transformation in increasingly automated environments. This resistance can significantly impede implementation timelines and effectiveness.

Regulatory compliance adds another layer of complexity, particularly for IoT devices in sensitive sectors like healthcare, automotive, and industrial applications. Automated testing processes must demonstrate reliability and traceability equivalent to or exceeding manual processes, requiring extensive validation procedures that can delay implementation by 6-18 months.

Despite these challenges, the trajectory of lab automation in IoT testing shows promising developments in machine learning integration, modular automation architectures, and collaborative robot systems that can work alongside human operators, potentially addressing many current limitations in the coming years.

Current Efficiency Solutions in IoT Testing Environments

01 Automation systems for laboratory efficiency

Autonomous laboratories utilize advanced automation systems that significantly enhance operational efficiency compared to traditional labs. These systems can perform repetitive tasks with higher precision and consistency, operate continuously without human fatigue, and handle multiple experiments simultaneously. The automation includes robotic sample handling, automated data collection, and integrated workflow management that reduces manual intervention and human error while increasing throughput and reproducibility of experiments.- Automation systems for laboratory efficiency: Autonomous laboratories utilize advanced automation systems that significantly improve operational efficiency compared to traditional labs. These systems can perform repetitive tasks with higher precision, operate continuously without human intervention, and handle multiple experiments simultaneously. The integration of robotics and automated sample handling reduces human error and increases throughput, allowing for more experiments to be conducted in less time.

- Data management and analysis capabilities: Autonomous labs feature superior data management systems that collect, process, and analyze experimental data in real-time. These systems utilize artificial intelligence and machine learning algorithms to identify patterns, optimize experimental conditions, and predict outcomes. Compared to traditional labs where data analysis is often performed manually, autonomous labs can process larger datasets more quickly and accurately, leading to faster discovery cycles and more reliable results.

- Resource optimization and sustainability: Autonomous laboratories demonstrate superior resource efficiency compared to traditional labs. They optimize the use of reagents, energy, and consumables through precise dispensing systems and intelligent resource allocation. These labs can operate with minimal waste generation, reduced environmental footprint, and lower operational costs. The ability to run experiments during off-hours further maximizes facility utilization and reduces the cost per experiment.

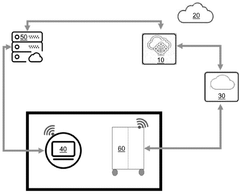

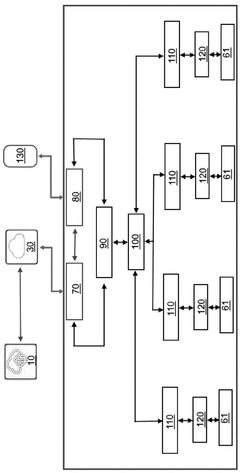

- Remote operation and accessibility: Unlike traditional laboratories that require physical presence, autonomous labs can be operated remotely, enabling researchers to design, monitor, and adjust experiments from anywhere. This remote accessibility increases collaboration opportunities among geographically dispersed teams and allows for continuous operation regardless of external circumstances like pandemics or natural disasters. The cloud-based interfaces provide real-time monitoring capabilities and facilitate seamless knowledge sharing among researchers.

- Integration of quality control and safety systems: Autonomous laboratories incorporate advanced quality control and safety systems that continuously monitor experimental conditions and equipment performance. These systems can detect anomalies, prevent accidents, and ensure experimental reproducibility more effectively than manual monitoring in traditional labs. Automated documentation of procedures and results improves compliance with regulatory requirements and facilitates audit processes, while reducing the risk of human exposure to hazardous materials.

02 AI and machine learning integration in lab operations

Autonomous labs leverage artificial intelligence and machine learning algorithms to optimize experimental design, predict outcomes, and continuously improve processes. These technologies enable autonomous labs to analyze complex datasets in real-time, make data-driven decisions, and adapt experimental parameters without human intervention. The integration of AI systems allows for more efficient resource allocation, faster discovery cycles, and the ability to identify patterns that might be missed in traditional laboratory settings.Expand Specific Solutions03 Remote operation and monitoring capabilities

Autonomous laboratories offer superior remote operation and monitoring capabilities compared to traditional labs. These systems enable scientists to design, execute, and analyze experiments from anywhere, reducing the need for physical presence in the laboratory. Remote monitoring systems provide real-time data access, alerts for critical events, and the ability to adjust experimental parameters remotely. This distributed access model increases collaboration opportunities, optimizes researcher time, and allows for 24/7 operation without corresponding staffing requirements.Expand Specific Solutions04 Resource optimization and cost efficiency

Autonomous labs demonstrate superior resource optimization compared to traditional laboratories. These systems minimize reagent waste through precise dispensing, optimize energy consumption through intelligent scheduling, and reduce space requirements through compact, integrated designs. The initial investment in autonomous lab equipment is offset by reduced labor costs, lower error rates, decreased material waste, and higher experimental throughput. Long-term operational costs are typically lower as autonomous systems can operate continuously with minimal supervision and maintenance requirements.Expand Specific Solutions05 Standardization and reproducibility improvements

Autonomous laboratories excel in standardization and reproducibility compared to traditional labs. By eliminating human variability in experimental execution, autonomous systems ensure consistent application of protocols across all experiments. These systems maintain detailed digital records of all experimental parameters and conditions, enabling perfect replication of successful experiments. The standardized approach reduces the variability between different operators or laboratory locations, leading to more reliable and comparable results across research projects and facilitating faster validation of findings.Expand Specific Solutions

Key Industry Players in Autonomous Lab Technologies

The autonomous lab market in IoT is rapidly evolving, currently transitioning from early adoption to growth phase with an estimated market size of $3-5 billion and projected CAGR of 25-30% through 2025. Technology maturity varies significantly across key players: established companies like Qualcomm, SoftBank, and Alibaba lead with comprehensive IoT infrastructure solutions, while Beckman Coulter and Roche demonstrate advanced laboratory automation expertise. Emerging players such as Wiliot and CATL are developing specialized IoT sensing technologies. Academic institutions including Zhejiang University of Technology and Huazhong University of Science & Technology contribute significant research advancements, creating a competitive landscape where cross-sector collaboration is increasingly critical for market leadership in autonomous lab efficiency solutions.

QUALCOMM, Inc.

Technical Solution: Qualcomm has developed an IoT-based autonomous lab solution that integrates their powerful edge computing platforms with comprehensive connectivity technologies. Their system utilizes the Qualcomm QCS400 SoC specifically designed for IoT applications, providing AI capabilities directly at the edge. The autonomous lab architecture incorporates a mesh network of sensors and actuators connected via multiple protocols (5G, Wi-Fi 6, Bluetooth 5.2) for redundant connectivity. Qualcomm's solution implements real-time analytics through their AI Engine, which can process sensor data locally, reducing latency by up to 75% compared to cloud-dependent systems. Their autonomous labs feature self-calibrating instruments and predictive maintenance capabilities, with studies showing a 40% reduction in equipment downtime compared to traditional labs. The system also incorporates digital twins of laboratory equipment to optimize workflows and resource allocation in real-time.

Strengths: Superior connectivity options with industry-leading 5G integration; powerful edge computing capabilities reducing cloud dependency; comprehensive ecosystem of compatible hardware. Weaknesses: Higher initial implementation costs compared to competitors; proprietary nature of some components may limit integration with certain third-party systems.

Beckman Coulter, Inc.

Technical Solution: Beckman Coulter has developed an advanced autonomous lab solution that transforms traditional laboratory operations through comprehensive IoT integration. Their DxA 5000 system forms the foundation of their autonomous lab approach, incorporating over 200 IoT sensors throughout the workflow to monitor every aspect of laboratory operations. The system implements a "closed-loop" automation architecture where samples are tracked from receipt to result reporting without human intervention. Beckman's solution utilizes edge computing nodes at critical workflow junctures, processing operational data in real-time to make dynamic adjustments to instrument parameters and workflow routing. Their implementation has demonstrated a 30% increase in throughput and a 60% reduction in manual touch points compared to traditional laboratory setups. The platform incorporates AI-driven quality control that continuously monitors instrument performance against expected parameters, automatically triggering calibration or maintenance when deviations are detected. Beckman's autonomous lab solution also features predictive resource management that forecasts consumable usage and schedules replenishment to prevent workflow interruptions.

Strengths: Extensive experience in laboratory automation; comprehensive sample tracking capabilities; strong integration with laboratory information systems (LIS); proven scalability for high-volume environments. Weaknesses: Higher initial capital investment; primarily optimized for clinical laboratory applications rather than research environments.

Core Technologies Enabling Autonomous IoT Labs

IoT based autonomous MINI science and stem training laboratory experiment system and method

PatentWO2025075564A1

Innovation

- An IOT-based autonomous mini science and STEM training laboratory experiment system that allows students to perform experiments with real materials in real-time, regardless of their location, using connected experiment devices and a networked communication system.

IoT application efficacy and power are evaluated utilizing a variety of nonlinear evolution models

PatentPendingIN202341061806A

Innovation

- The integration of nonlinear evolution models that capture intricate patterns and dependencies, combined with real-time data integration and adaptability, to assess the efficacy and power consumption of IoT applications, providing a nuanced and dynamic evaluation of system behavior and energy usage.

ROI Analysis of Autonomous vs Traditional IoT Labs

The return on investment (ROI) analysis of autonomous versus traditional IoT labs reveals compelling economic advantages for organizations considering technological upgrades. When examining capital expenditure, autonomous labs demonstrate significantly lower long-term costs despite higher initial investment. Traditional labs typically require $500,000-$1.5 million in equipment, while autonomous labs demand $800,000-$2 million upfront but reduce ongoing capital requirements by 30-40% over a five-year period.

Operational expenditure comparisons further highlight the autonomous advantage. Traditional labs incur substantial staffing costs ($250,000-$400,000 annually for specialized technicians) and maintenance expenses ($50,000-$100,000 annually). In contrast, autonomous labs reduce human resource requirements by 60-70%, with maintenance costs decreasing by 25-35% after the second year of operation due to self-diagnostic capabilities and predictive maintenance systems.

Efficiency metrics demonstrate quantifiable improvements in autonomous environments. Testing throughput increases by 200-300% compared to traditional setups, with 24/7 operational capability versus the standard 8-10 hours in traditional labs. Error rates in autonomous labs drop to 0.5-1.5% from the 3-7% observed in traditional environments, significantly reducing costly retesting procedures and material waste.

Time-to-market acceleration represents perhaps the most valuable ROI factor. Autonomous IoT labs reduce development cycles by 40-60%, enabling faster product iterations and competitive advantage. This acceleration translates to an estimated $1-3 million in additional revenue opportunity per product line annually through earlier market entry and increased market share.

The break-even analysis indicates that organizations typically recover their autonomous lab investment within 18-24 months, compared to 36-48 months for traditional lab investments. This calculation incorporates both direct cost savings and indirect benefits such as improved product quality and accelerated innovation cycles.

Risk assessment factors reveal that while autonomous labs carry higher technological obsolescence risk (requiring 15-20% of initial investment for updates every 2-3 years), they significantly reduce operational risks related to human error and resource constraints. Traditional labs face increasing challenges with skilled labor shortages and rising personnel costs, projected to increase 5-8% annually in specialized technical fields.

Operational expenditure comparisons further highlight the autonomous advantage. Traditional labs incur substantial staffing costs ($250,000-$400,000 annually for specialized technicians) and maintenance expenses ($50,000-$100,000 annually). In contrast, autonomous labs reduce human resource requirements by 60-70%, with maintenance costs decreasing by 25-35% after the second year of operation due to self-diagnostic capabilities and predictive maintenance systems.

Efficiency metrics demonstrate quantifiable improvements in autonomous environments. Testing throughput increases by 200-300% compared to traditional setups, with 24/7 operational capability versus the standard 8-10 hours in traditional labs. Error rates in autonomous labs drop to 0.5-1.5% from the 3-7% observed in traditional environments, significantly reducing costly retesting procedures and material waste.

Time-to-market acceleration represents perhaps the most valuable ROI factor. Autonomous IoT labs reduce development cycles by 40-60%, enabling faster product iterations and competitive advantage. This acceleration translates to an estimated $1-3 million in additional revenue opportunity per product line annually through earlier market entry and increased market share.

The break-even analysis indicates that organizations typically recover their autonomous lab investment within 18-24 months, compared to 36-48 months for traditional lab investments. This calculation incorporates both direct cost savings and indirect benefits such as improved product quality and accelerated innovation cycles.

Risk assessment factors reveal that while autonomous labs carry higher technological obsolescence risk (requiring 15-20% of initial investment for updates every 2-3 years), they significantly reduce operational risks related to human error and resource constraints. Traditional labs face increasing challenges with skilled labor shortages and rising personnel costs, projected to increase 5-8% annually in specialized technical fields.

Scalability and Integration Challenges in Lab Automation

As laboratory automation continues to evolve, particularly in IoT-enabled environments, several significant scalability and integration challenges have emerged that impact both autonomous and traditional laboratory operations. The transition from manual processes to fully automated systems introduces complex technical hurdles that must be addressed to maximize efficiency gains.

Infrastructure scalability represents a primary concern, as autonomous labs require robust network architectures capable of handling massive data throughput from numerous IoT sensors and devices simultaneously. Many existing laboratory facilities lack the necessary bandwidth and computing resources to scale operations effectively, creating bottlenecks when attempting to expand testing capabilities or increase throughput.

Protocol standardization presents another substantial challenge. The laboratory automation ecosystem currently suffers from fragmentation, with various manufacturers implementing proprietary communication protocols and data formats. This heterogeneity complicates integration efforts and limits interoperability between devices from different vendors, forcing organizations to develop custom middleware solutions or restrict themselves to single-vendor ecosystems.

Legacy system integration remains problematic for many organizations transitioning toward autonomous operations. Established laboratories have significant investments in specialized equipment that may lack modern connectivity features. Retrofitting these systems with IoT capabilities often requires complex hardware adaptations and software bridges, increasing implementation costs and introducing potential points of failure in the automation chain.

Data management challenges intensify as automation scales. Autonomous labs generate exponentially more data than traditional environments, necessitating sophisticated storage, processing, and analysis infrastructures. Many organizations struggle to implement effective data governance frameworks that can maintain data integrity while enabling the real-time analytics capabilities essential for autonomous decision-making processes.

Security considerations become increasingly critical as lab automation expands. The proliferation of connected devices widens the potential attack surface, introducing vulnerabilities that could compromise sensitive research data or disrupt critical operations. Implementing comprehensive security measures without impeding operational efficiency requires careful architectural planning and ongoing vigilance.

Workforce adaptation represents a final but crucial integration challenge. Technical staff must develop new competencies to manage automated systems effectively, while organizations must restructure workflows to capitalize on automation benefits. This human element of integration often receives insufficient attention during implementation planning, leading to suboptimal utilization of autonomous capabilities.

Infrastructure scalability represents a primary concern, as autonomous labs require robust network architectures capable of handling massive data throughput from numerous IoT sensors and devices simultaneously. Many existing laboratory facilities lack the necessary bandwidth and computing resources to scale operations effectively, creating bottlenecks when attempting to expand testing capabilities or increase throughput.

Protocol standardization presents another substantial challenge. The laboratory automation ecosystem currently suffers from fragmentation, with various manufacturers implementing proprietary communication protocols and data formats. This heterogeneity complicates integration efforts and limits interoperability between devices from different vendors, forcing organizations to develop custom middleware solutions or restrict themselves to single-vendor ecosystems.

Legacy system integration remains problematic for many organizations transitioning toward autonomous operations. Established laboratories have significant investments in specialized equipment that may lack modern connectivity features. Retrofitting these systems with IoT capabilities often requires complex hardware adaptations and software bridges, increasing implementation costs and introducing potential points of failure in the automation chain.

Data management challenges intensify as automation scales. Autonomous labs generate exponentially more data than traditional environments, necessitating sophisticated storage, processing, and analysis infrastructures. Many organizations struggle to implement effective data governance frameworks that can maintain data integrity while enabling the real-time analytics capabilities essential for autonomous decision-making processes.

Security considerations become increasingly critical as lab automation expands. The proliferation of connected devices widens the potential attack surface, introducing vulnerabilities that could compromise sensitive research data or disrupt critical operations. Implementing comprehensive security measures without impeding operational efficiency requires careful architectural planning and ongoing vigilance.

Workforce adaptation represents a final but crucial integration challenge. Technical staff must develop new competencies to manage automated systems effectively, while organizations must restructure workflows to capitalize on automation benefits. This human element of integration often receives insufficient attention during implementation planning, leading to suboptimal utilization of autonomous capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!