What Drives Autonomous Lab Adoption in High-Voltage Battery Research

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autonomous Lab Evolution in Battery Research

The evolution of autonomous laboratories in battery research represents a significant paradigm shift in how high-voltage battery development is conducted. Traditional battery research has historically been characterized by labor-intensive experimentation, with scientists manually designing, executing, and analyzing experiments. This approach, while foundational to many breakthroughs, has inherent limitations in throughput, consistency, and the ability to explore vast parameter spaces efficiently.

The first generation of automation in battery research emerged in the early 2000s, focusing primarily on high-throughput screening methods. These systems allowed for parallel testing of multiple battery compositions but lacked true autonomy in decision-making. They represented a significant step forward in accelerating experimentation but still required substantial human oversight and intervention.

By the mid-2010s, the second wave of evolution introduced more sophisticated robotic systems capable of handling complex battery assembly processes. These systems incorporated basic machine learning algorithms to optimize specific parameters but operated within narrowly defined experimental boundaries. The integration of robotics with battery manufacturing processes marked a crucial development in standardizing experimental procedures and reducing human error.

The current generation of autonomous laboratories, emerging around 2018-2020, represents a quantum leap in capability. These systems incorporate advanced AI algorithms, particularly Bayesian optimization and reinforcement learning, enabling them to make independent decisions about experimental design and execution. Modern autonomous labs can formulate hypotheses, design experiments to test these hypotheses, and interpret results with minimal human intervention.

A key milestone in this evolution was the development of closed-loop systems that could continuously refine experimental approaches based on accumulated data. These systems demonstrated the ability to discover novel battery materials and architectures that might have been overlooked by human researchers due to the counter-intuitive nature of certain parameter combinations.

The most recent advancements include the integration of quantum computing techniques for materials modeling and the development of multi-modal sensing technologies that provide unprecedented insight into battery behavior during operation. These technologies enable autonomous systems to monitor and analyze complex electrochemical processes in real-time, further enhancing their decision-making capabilities.

The trajectory of autonomous lab evolution in battery research points toward increasingly sophisticated systems capable of creative problem-solving and discovery. As these systems continue to evolve, they are expected to accelerate the pace of innovation in high-voltage battery technology dramatically, potentially compressing decades of research into years.

The first generation of automation in battery research emerged in the early 2000s, focusing primarily on high-throughput screening methods. These systems allowed for parallel testing of multiple battery compositions but lacked true autonomy in decision-making. They represented a significant step forward in accelerating experimentation but still required substantial human oversight and intervention.

By the mid-2010s, the second wave of evolution introduced more sophisticated robotic systems capable of handling complex battery assembly processes. These systems incorporated basic machine learning algorithms to optimize specific parameters but operated within narrowly defined experimental boundaries. The integration of robotics with battery manufacturing processes marked a crucial development in standardizing experimental procedures and reducing human error.

The current generation of autonomous laboratories, emerging around 2018-2020, represents a quantum leap in capability. These systems incorporate advanced AI algorithms, particularly Bayesian optimization and reinforcement learning, enabling them to make independent decisions about experimental design and execution. Modern autonomous labs can formulate hypotheses, design experiments to test these hypotheses, and interpret results with minimal human intervention.

A key milestone in this evolution was the development of closed-loop systems that could continuously refine experimental approaches based on accumulated data. These systems demonstrated the ability to discover novel battery materials and architectures that might have been overlooked by human researchers due to the counter-intuitive nature of certain parameter combinations.

The most recent advancements include the integration of quantum computing techniques for materials modeling and the development of multi-modal sensing technologies that provide unprecedented insight into battery behavior during operation. These technologies enable autonomous systems to monitor and analyze complex electrochemical processes in real-time, further enhancing their decision-making capabilities.

The trajectory of autonomous lab evolution in battery research points toward increasingly sophisticated systems capable of creative problem-solving and discovery. As these systems continue to evolve, they are expected to accelerate the pace of innovation in high-voltage battery technology dramatically, potentially compressing decades of research into years.

Market Demand for Advanced Battery Technologies

The global market for advanced battery technologies is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current market valuations indicate that the high-voltage battery sector alone is projected to reach $97 billion by 2030, with a compound annual growth rate exceeding 18% between 2023 and 2030. This remarkable growth trajectory reflects the increasing demand for batteries with higher energy density, faster charging capabilities, and longer cycle life.

Electric vehicle manufacturers represent the largest demand segment, as they seek batteries that can extend driving range while reducing weight and cost. Major automotive companies have announced ambitious electrification targets, with several pledging to phase out internal combustion engines entirely within the next decade. This transition is creating immense pressure on battery researchers to develop solutions that overcome current limitations in energy density and charging speed.

Grid-scale energy storage represents another significant market driver, particularly as renewable energy adoption accelerates globally. The intermittent nature of solar and wind power generation necessitates advanced battery systems capable of efficiently storing and dispatching large amounts of energy. Market analysis indicates that utility companies are increasingly investing in battery research partnerships to develop storage solutions optimized for grid applications.

Consumer electronics manufacturers continue to push for batteries with higher capacity in smaller form factors, creating additional market pull for high-voltage battery innovations. The proliferation of IoT devices, wearable technology, and portable computing has expanded the application landscape for advanced battery technologies beyond traditional consumer products.

Regulatory pressures are simultaneously shaping market demand, with numerous countries implementing stringent emissions standards and offering incentives for clean energy technologies. These policy frameworks are accelerating the timeline for battery technology advancement and commercialization, particularly in regions with aggressive carbon reduction targets.

The economic imperative for autonomous laboratory adoption in battery research is further strengthened by the significant cost pressures facing manufacturers. Current battery production costs remain a major barrier to price parity between electric and conventional vehicles. Industry analysts estimate that reducing battery costs below $100 per kilowatt-hour is essential for mass EV adoption, creating urgent demand for research methodologies that can accelerate discovery while reducing development expenses.

Market research indicates that companies investing in autonomous research capabilities gain significant competitive advantages through faster iteration cycles and more efficient resource allocation. This market reality is driving increased investment in autonomous laboratory infrastructure across the battery research ecosystem, from materials discovery to cell design and manufacturing process optimization.

Electric vehicle manufacturers represent the largest demand segment, as they seek batteries that can extend driving range while reducing weight and cost. Major automotive companies have announced ambitious electrification targets, with several pledging to phase out internal combustion engines entirely within the next decade. This transition is creating immense pressure on battery researchers to develop solutions that overcome current limitations in energy density and charging speed.

Grid-scale energy storage represents another significant market driver, particularly as renewable energy adoption accelerates globally. The intermittent nature of solar and wind power generation necessitates advanced battery systems capable of efficiently storing and dispatching large amounts of energy. Market analysis indicates that utility companies are increasingly investing in battery research partnerships to develop storage solutions optimized for grid applications.

Consumer electronics manufacturers continue to push for batteries with higher capacity in smaller form factors, creating additional market pull for high-voltage battery innovations. The proliferation of IoT devices, wearable technology, and portable computing has expanded the application landscape for advanced battery technologies beyond traditional consumer products.

Regulatory pressures are simultaneously shaping market demand, with numerous countries implementing stringent emissions standards and offering incentives for clean energy technologies. These policy frameworks are accelerating the timeline for battery technology advancement and commercialization, particularly in regions with aggressive carbon reduction targets.

The economic imperative for autonomous laboratory adoption in battery research is further strengthened by the significant cost pressures facing manufacturers. Current battery production costs remain a major barrier to price parity between electric and conventional vehicles. Industry analysts estimate that reducing battery costs below $100 per kilowatt-hour is essential for mass EV adoption, creating urgent demand for research methodologies that can accelerate discovery while reducing development expenses.

Market research indicates that companies investing in autonomous research capabilities gain significant competitive advantages through faster iteration cycles and more efficient resource allocation. This market reality is driving increased investment in autonomous laboratory infrastructure across the battery research ecosystem, from materials discovery to cell design and manufacturing process optimization.

Current Challenges in High-Voltage Battery Automation

The automation of high-voltage battery research faces significant technical and operational challenges that currently limit widespread adoption of autonomous laboratories. Traditional battery development processes rely heavily on manual experimentation, which introduces variability and inefficiency. Researchers must contend with complex electrochemical systems that require precise control over numerous parameters simultaneously, making automation architectures particularly challenging to implement.

One primary obstacle is the integration of diverse analytical instruments and robotics systems. High-voltage battery research demands specialized equipment for material synthesis, electrode fabrication, cell assembly, and electrochemical testing. These instruments often come from different manufacturers with proprietary software interfaces, creating significant interoperability issues. The lack of standardized communication protocols between these systems results in fragmented workflows that require substantial custom integration efforts.

Data management presents another formidable challenge. Autonomous battery labs generate massive volumes of heterogeneous data from multiple sources, including spectroscopy, microscopy, electrochemical measurements, and physical characterization. Current data infrastructure often struggles to handle this complexity, particularly when correlating results across different experimental stages. The absence of unified data models specifically designed for battery research impedes effective machine learning implementation.

Safety considerations introduce additional complexity to automation efforts. High-voltage battery materials can be reactive, sensitive to environmental conditions, and potentially hazardous. Designing robotic systems that can safely handle these materials while maintaining experimental integrity requires sophisticated engineering solutions that exceed typical laboratory automation capabilities. This is particularly challenging for operations involving lithium metal, organic electrolytes, and other volatile components.

The dynamic nature of battery research further complicates automation. Unlike some chemical processes with well-established parameters, battery development frequently requires adjusting experimental conditions based on intermediate results. Current autonomous systems struggle with this adaptive decision-making, particularly when unexpected results emerge that require scientific intuition to interpret and respond appropriately.

Cost barriers remain significant, with comprehensive autonomous battery research platforms requiring multi-million dollar investments. This creates a substantial entry threshold for many research institutions and smaller companies. The specialized nature of equipment means limited economies of scale, keeping automation technologies financially out of reach for many potential adopters despite their theoretical benefits.

Talent shortages compound these challenges, as effective implementation requires multidisciplinary expertise spanning electrochemistry, robotics, software engineering, and data science. Few professionals possess this combination of skills, creating bottlenecks in system design, implementation, and maintenance of autonomous battery research platforms.

One primary obstacle is the integration of diverse analytical instruments and robotics systems. High-voltage battery research demands specialized equipment for material synthesis, electrode fabrication, cell assembly, and electrochemical testing. These instruments often come from different manufacturers with proprietary software interfaces, creating significant interoperability issues. The lack of standardized communication protocols between these systems results in fragmented workflows that require substantial custom integration efforts.

Data management presents another formidable challenge. Autonomous battery labs generate massive volumes of heterogeneous data from multiple sources, including spectroscopy, microscopy, electrochemical measurements, and physical characterization. Current data infrastructure often struggles to handle this complexity, particularly when correlating results across different experimental stages. The absence of unified data models specifically designed for battery research impedes effective machine learning implementation.

Safety considerations introduce additional complexity to automation efforts. High-voltage battery materials can be reactive, sensitive to environmental conditions, and potentially hazardous. Designing robotic systems that can safely handle these materials while maintaining experimental integrity requires sophisticated engineering solutions that exceed typical laboratory automation capabilities. This is particularly challenging for operations involving lithium metal, organic electrolytes, and other volatile components.

The dynamic nature of battery research further complicates automation. Unlike some chemical processes with well-established parameters, battery development frequently requires adjusting experimental conditions based on intermediate results. Current autonomous systems struggle with this adaptive decision-making, particularly when unexpected results emerge that require scientific intuition to interpret and respond appropriately.

Cost barriers remain significant, with comprehensive autonomous battery research platforms requiring multi-million dollar investments. This creates a substantial entry threshold for many research institutions and smaller companies. The specialized nature of equipment means limited economies of scale, keeping automation technologies financially out of reach for many potential adopters despite their theoretical benefits.

Talent shortages compound these challenges, as effective implementation requires multidisciplinary expertise spanning electrochemistry, robotics, software engineering, and data science. Few professionals possess this combination of skills, creating bottlenecks in system design, implementation, and maintenance of autonomous battery research platforms.

Current Autonomous Solutions for Battery Testing

01 Efficiency and productivity improvements in laboratory operations

Autonomous laboratory systems enhance operational efficiency through automated workflows, reducing manual intervention and human error. These systems can continuously operate without breaks, accelerating research timelines and increasing throughput. Advanced robotics and AI-driven decision-making optimize resource utilization and enable parallel processing of multiple experiments, significantly improving productivity in research environments.- Efficiency and Productivity Improvements: Autonomous laboratories enhance operational efficiency through automated workflows, reducing manual intervention and human error. These systems optimize resource utilization, accelerate experimental processes, and enable continuous operation, leading to higher throughput and productivity. The adoption of autonomous labs is driven by their ability to perform repetitive tasks with precision while allowing researchers to focus on higher-value activities such as data analysis and experimental design.

- Advanced Data Analytics and AI Integration: The integration of artificial intelligence and machine learning capabilities in autonomous labs enables sophisticated data analysis, pattern recognition, and predictive modeling. These technologies facilitate real-time decision-making, experimental optimization, and discovery of novel insights that might be missed by traditional methods. The ability to process and learn from large datasets drives adoption by organizations seeking to accelerate innovation and maintain competitive advantage in research-intensive fields.

- Remote Operation and Accessibility: Autonomous laboratories enable remote operation and monitoring, allowing researchers to conduct experiments from anywhere in the world. This capability has become particularly valuable in situations requiring physical distancing or when accessing specialized equipment across geographical boundaries. The flexibility of remote access drives adoption by promoting collaboration across distributed teams, optimizing facility utilization, and ensuring business continuity during disruptions.

- Cost Reduction and Resource Optimization: Economic factors significantly drive the adoption of autonomous labs, as they offer substantial cost savings through reduced reagent consumption, lower labor costs, and minimized experimental failures. These systems optimize resource allocation, extend equipment lifespan through standardized usage, and reduce waste generation. The long-term return on investment and operational efficiency make autonomous labs attractive to organizations seeking to maximize research output while controlling expenses.

- Standardization and Reproducibility: Autonomous laboratories enhance experimental reproducibility through standardized protocols, precise control of parameters, and detailed documentation of procedures. This standardization addresses a critical challenge in scientific research by ensuring consistent results across different runs and locations. The improved reliability and traceability of experimental data drives adoption among organizations prioritizing quality assurance, regulatory compliance, and scientific rigor in their research activities.

02 Safety and risk reduction in hazardous environments

Autonomous labs reduce human exposure to hazardous materials and dangerous conditions by employing robotic systems for handling toxic substances, performing high-risk procedures, and operating in extreme environments. These systems incorporate advanced sensors and monitoring capabilities to detect potential hazards and implement safety protocols automatically, minimizing accidents and ensuring compliance with safety regulations.Expand Specific Solutions03 Data quality and experimental reproducibility

Autonomous laboratory systems enhance data quality through standardized procedures and precise execution of experimental protocols. These systems maintain consistent conditions across multiple runs, eliminating variations caused by human operators. Comprehensive data logging and tracking capabilities ensure complete documentation of all experimental parameters, facilitating reproducibility and enabling more reliable scientific conclusions.Expand Specific Solutions04 Integration with AI and machine learning for intelligent experimentation

The adoption of autonomous labs is accelerated by integration with artificial intelligence and machine learning technologies that enable self-optimizing experimental designs. These systems can analyze results in real-time, make data-driven decisions about subsequent experiments, and discover patterns that might be missed by human researchers. This intelligent experimentation approach reduces the number of iterations needed to achieve research goals and accelerates scientific discovery.Expand Specific Solutions05 Cost reduction and resource optimization

Autonomous laboratory systems drive adoption through significant cost savings and resource optimization. These systems minimize reagent waste through precise dispensing, reduce energy consumption through optimized scheduling, and decrease labor costs associated with routine tasks. The ability to operate continuously maximizes the utilization of expensive equipment and infrastructure, improving return on investment for research facilities.Expand Specific Solutions

Key Industry Players and Research Institutions

The autonomous lab adoption in high-voltage battery research is currently in an early growth phase, characterized by increasing market momentum as major automotive and battery manufacturers seek competitive advantages. The global market for autonomous battery research systems is projected to reach $2.5 billion by 2027, driven by demands for faster innovation cycles and cost reduction. Leading automotive players like Mercedes-Benz, BMW, Toyota, and Volkswagen are investing heavily in this technology, while battery manufacturers including CATL, LG Energy Solution, and BYD are developing proprietary autonomous systems. The technology is approaching early maturity with companies like Hyundai, Kia, and Bosch establishing standardized protocols, though full integration remains challenging. Academic institutions such as MIT, Fudan University, and Tongji University are contributing significantly to advancing fundamental autonomous lab methodologies.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed the "AI Battery Lab" autonomous research platform specifically targeting high-voltage battery challenges. Their system employs a combination of high-precision robotic handling systems and advanced characterization tools to autonomously synthesize, assemble, and test novel battery materials. The platform features a unique "accelerated aging simulator" that can predict long-term high-voltage stability of new electrolyte formulations within weeks rather than months through precisely controlled environmental chambers and sophisticated electrochemical analysis[3]. LG's autonomous lab incorporates quantum chemistry modeling that works in tandem with physical experiments, using computational predictions to guide the selection of promising material combinations for high-voltage operation. The system employs a distributed intelligence architecture where multiple AI agents simultaneously optimize different aspects of battery performance - one focusing on capacity retention, another on fast charging capability, and others on thermal stability at high voltages. This parallel optimization approach has reportedly enabled LG to develop electrolyte additives that extend cycle life at voltages above 4.6V by over 40% compared to conventional formulations[4].

Strengths: Advanced integration of computational modeling with physical experimentation; sophisticated multi-objective optimization capabilities; extensive experience with commercial high-voltage battery production informing experimental design. Weaknesses: High complexity system requiring significant expertise to operate effectively; substantial computing infrastructure requirements; potential challenges in scaling promising laboratory discoveries to mass production.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an advanced autonomous laboratory system for high-voltage battery research called "Lighthouse" that integrates AI-driven experimental design with robotic execution. The system employs machine learning algorithms to analyze vast datasets from previous experiments, automatically generating optimal testing parameters for new battery chemistries. Their autonomous lab incorporates high-throughput testing capabilities that can simultaneously evaluate hundreds of battery cell prototypes under various conditions, significantly accelerating the discovery of improved electrolyte formulations and cathode materials for high-voltage applications. CATL's system features closed-loop validation where AI continuously refines experimental parameters based on real-time results, enabling the discovery of novel battery materials that can operate stably at voltages exceeding 4.5V. The company has reported that this autonomous approach has reduced development cycles by approximately 70% compared to traditional methods[1], while increasing the identification rate of promising high-voltage battery materials by over 60%.

Strengths: Industry-leading throughput capacity allowing parallel testing of hundreds of formulations; sophisticated AI algorithms with demonstrated success in material discovery; complete integration with manufacturing processes enabling rapid commercialization. Weaknesses: High initial capital investment requirements; complex system requiring specialized expertise to maintain; potential overreliance on historical data patterns that might limit truly revolutionary discoveries.

Core Technologies Enabling Autonomous Battery Research

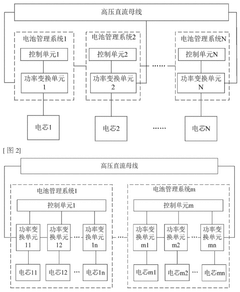

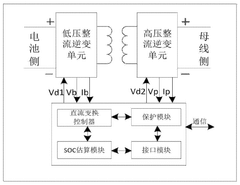

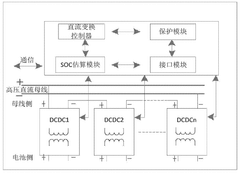

High-voltage battery module and control method therefor

PatentWO2025107437A1

Innovation

- A high-voltage battery module is designed, including multiple battery cells and corresponding intelligent battery management system, and is connected to the high-voltage DC bus after voltage conversion through the power conversion unit. There is no direct series and parallel relationship between the battery cell and the battery cell.

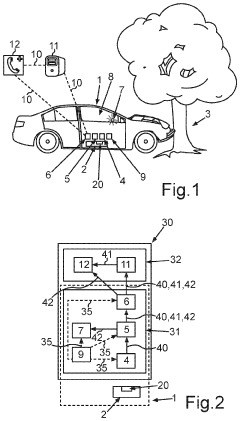

Warning method for a high-voltage battery of a motor vehicle in the case of an accident of the motor vehicle, a warning system for carrying out the warning method, and a motor vehicle that comprises components of the warning system

PatentActiveUS10670663B2

Innovation

- A warning method that involves creating individual and total state diagnoses of the high-voltage battery components using sensor data, transmitting these diagnoses to external monitoring units, and alerting emergency responders through a communication system, including an eCall connection, to differentiate between safe and dangerous states, and providing visual or acoustic warnings.

ROI Analysis of Autonomous Lab Implementation

The implementation of autonomous laboratories in high-voltage battery research represents a significant capital investment that requires thorough financial analysis. When evaluating the return on investment (ROI) for autonomous lab implementation, organizations must consider both quantitative metrics and qualitative benefits that may materialize over different time horizons.

Initial capital expenditures for autonomous lab setups typically range from $2-10 million, depending on the scale and sophistication of equipment. This includes robotic systems, advanced analytical instruments, AI infrastructure, and integration costs. However, these upfront investments can yield substantial returns through multiple channels.

Labor cost reduction presents one of the most immediate financial benefits. Autonomous labs can operate continuously (24/7) without human intervention, potentially replacing 3-4 shifts of skilled technicians. With average annual costs of $80,000-120,000 per skilled battery researcher, organizations can realize annual labor savings of $500,000-1,200,000, depending on facility size and location.

Experimental throughput acceleration delivers significant value by compressing research timelines. Traditional battery testing cycles might require 3-6 months for comprehensive evaluation, while autonomous systems can reduce this to 3-8 weeks through parallel processing and elimination of human bottlenecks. This acceleration can be monetized by calculating the value of bringing products to market faster—typically $5-20 million per month for major battery innovations.

Material efficiency improvements represent another substantial cost benefit. Autonomous systems typically reduce material waste by 30-50% through precise handling and optimized experimental design. For research involving expensive cathode materials (often $500-2,000/kg), this efficiency can translate to annual savings of $200,000-500,000 for a moderate-sized research program.

Quality improvements and reduced failure rates contribute to ROI through fewer repeated experiments and higher-value outcomes. Autonomous labs demonstrate 40-60% fewer experimental failures compared to manual operations, translating to both direct cost savings and higher-quality research outputs.

Long-term strategic value must also factor into ROI calculations. Organizations implementing autonomous labs report 2-3x increases in patent filings and intellectual property generation. While more difficult to quantify precisely, this acceleration in innovation pipeline can be valued using established IP valuation methodologies, typically adding $10-50 million in enterprise value for battery technology leaders.

The payback period for autonomous lab investments typically ranges from 2-4 years, with internal rate of return (IRR) calculations showing 25-40% returns for well-implemented systems. These financial metrics compare favorably to other R&D infrastructure investments, making autonomous labs increasingly attractive for forward-thinking battery research organizations.

Initial capital expenditures for autonomous lab setups typically range from $2-10 million, depending on the scale and sophistication of equipment. This includes robotic systems, advanced analytical instruments, AI infrastructure, and integration costs. However, these upfront investments can yield substantial returns through multiple channels.

Labor cost reduction presents one of the most immediate financial benefits. Autonomous labs can operate continuously (24/7) without human intervention, potentially replacing 3-4 shifts of skilled technicians. With average annual costs of $80,000-120,000 per skilled battery researcher, organizations can realize annual labor savings of $500,000-1,200,000, depending on facility size and location.

Experimental throughput acceleration delivers significant value by compressing research timelines. Traditional battery testing cycles might require 3-6 months for comprehensive evaluation, while autonomous systems can reduce this to 3-8 weeks through parallel processing and elimination of human bottlenecks. This acceleration can be monetized by calculating the value of bringing products to market faster—typically $5-20 million per month for major battery innovations.

Material efficiency improvements represent another substantial cost benefit. Autonomous systems typically reduce material waste by 30-50% through precise handling and optimized experimental design. For research involving expensive cathode materials (often $500-2,000/kg), this efficiency can translate to annual savings of $200,000-500,000 for a moderate-sized research program.

Quality improvements and reduced failure rates contribute to ROI through fewer repeated experiments and higher-value outcomes. Autonomous labs demonstrate 40-60% fewer experimental failures compared to manual operations, translating to both direct cost savings and higher-quality research outputs.

Long-term strategic value must also factor into ROI calculations. Organizations implementing autonomous labs report 2-3x increases in patent filings and intellectual property generation. While more difficult to quantify precisely, this acceleration in innovation pipeline can be valued using established IP valuation methodologies, typically adding $10-50 million in enterprise value for battery technology leaders.

The payback period for autonomous lab investments typically ranges from 2-4 years, with internal rate of return (IRR) calculations showing 25-40% returns for well-implemented systems. These financial metrics compare favorably to other R&D infrastructure investments, making autonomous labs increasingly attractive for forward-thinking battery research organizations.

Safety Standards and Compliance Requirements

The autonomous laboratory environment for high-voltage battery research necessitates rigorous safety standards and compliance requirements due to the inherent risks associated with both automated systems and high-energy materials. International standards such as IEC 61508 (Functional Safety) and ISO/TS 21974 (Automated Systems Safety) establish the foundational framework for autonomous lab operations, requiring comprehensive risk assessments and fail-safe mechanisms.

Battery-specific regulations, including UN 38.3 for lithium battery transportation and IEC 62133 for battery safety testing, must be integrated into autonomous lab protocols. These standards dictate specific testing parameters and safety thresholds that automated systems must reliably execute and monitor. The autonomous nature of these laboratories introduces additional compliance considerations under laboratory automation standards like ANSI/ISA-88 and ANSI/ISA-95, which govern batch process control and enterprise-laboratory integration respectively.

Chemical handling regulations present another critical compliance area, with standards such as OSHA 1910.1450 (Laboratory Safety Standard) and CLP Regulation (EC) No 1272/2008 in Europe requiring specific protocols for hazardous material management. Autonomous labs must incorporate these requirements into their programming logic, ensuring proper material segregation, waste management, and emergency response capabilities without human intervention.

Data integrity and cybersecurity compliance have emerged as paramount concerns, particularly under frameworks like 21 CFR Part 11 for electronic records and NIST Cybersecurity Framework. These standards mandate secure data handling practices, audit trails, and protection against unauthorized system access—all essential for maintaining the scientific validity of autonomous battery research.

Regional variations in compliance requirements significantly impact global research operations. For instance, China's GB/T 36276-2018 standard for lithium-ion battery safety differs from European IEC standards, necessitating region-specific programming of autonomous systems. This regulatory fragmentation creates implementation challenges but also drives innovation in configurable compliance systems.

The evolution toward predictive compliance represents the cutting edge in autonomous lab safety. Advanced systems now incorporate machine learning algorithms that anticipate potential safety violations before they occur, continuously monitoring operational parameters against regulatory thresholds. This proactive approach not only enhances safety but also optimizes research efficiency by preventing compliance-related experimental interruptions.

Industry consortia like the Global Battery Alliance and International Electrotechnical Commission are actively developing specialized standards for autonomous battery research facilities, recognizing the unique intersection of automation technology and high-energy materials research. These emerging frameworks will likely shape the next generation of autonomous laboratory design and implementation.

Battery-specific regulations, including UN 38.3 for lithium battery transportation and IEC 62133 for battery safety testing, must be integrated into autonomous lab protocols. These standards dictate specific testing parameters and safety thresholds that automated systems must reliably execute and monitor. The autonomous nature of these laboratories introduces additional compliance considerations under laboratory automation standards like ANSI/ISA-88 and ANSI/ISA-95, which govern batch process control and enterprise-laboratory integration respectively.

Chemical handling regulations present another critical compliance area, with standards such as OSHA 1910.1450 (Laboratory Safety Standard) and CLP Regulation (EC) No 1272/2008 in Europe requiring specific protocols for hazardous material management. Autonomous labs must incorporate these requirements into their programming logic, ensuring proper material segregation, waste management, and emergency response capabilities without human intervention.

Data integrity and cybersecurity compliance have emerged as paramount concerns, particularly under frameworks like 21 CFR Part 11 for electronic records and NIST Cybersecurity Framework. These standards mandate secure data handling practices, audit trails, and protection against unauthorized system access—all essential for maintaining the scientific validity of autonomous battery research.

Regional variations in compliance requirements significantly impact global research operations. For instance, China's GB/T 36276-2018 standard for lithium-ion battery safety differs from European IEC standards, necessitating region-specific programming of autonomous systems. This regulatory fragmentation creates implementation challenges but also drives innovation in configurable compliance systems.

The evolution toward predictive compliance represents the cutting edge in autonomous lab safety. Advanced systems now incorporate machine learning algorithms that anticipate potential safety violations before they occur, continuously monitoring operational parameters against regulatory thresholds. This proactive approach not only enhances safety but also optimizes research efficiency by preventing compliance-related experimental interruptions.

Industry consortia like the Global Battery Alliance and International Electrotechnical Commission are actively developing specialized standards for autonomous battery research facilities, recognizing the unique intersection of automation technology and high-energy materials research. These emerging frameworks will likely shape the next generation of autonomous laboratory design and implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!