Why Autonomous Labs Improve Aerodynamics Testing in Aerospace Engineering

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autonomous Aerodynamics Testing Background and Objectives

Aerodynamic testing has been a cornerstone of aerospace engineering since the Wright brothers conducted rudimentary wind tunnel experiments in the early 1900s. The evolution of this field has been marked by increasingly sophisticated methodologies, from basic wind tunnels to complex computational fluid dynamics (CFD) simulations. Traditional aerodynamic testing involves extensive manual intervention, requiring engineers to physically adjust models, record data, and analyze results—a process that is both time-consuming and prone to human error.

The aerospace industry faces mounting pressure to accelerate development cycles while improving fuel efficiency, reducing emissions, and enhancing safety. These challenges necessitate more efficient and accurate testing methodologies. Autonomous laboratories represent a paradigm shift in this domain, offering unprecedented capabilities for high-throughput experimentation and data-driven discovery.

The primary objective of autonomous aerodynamics testing is to create self-operating laboratory environments that can conduct experiments, collect data, analyze results, and make intelligent decisions about subsequent tests without human intervention. This approach aims to dramatically increase the speed and efficiency of aerodynamic testing while simultaneously improving the quality and reliability of results through the elimination of human bias and error.

Recent technological advancements in robotics, artificial intelligence, machine learning, and sensor technology have converged to make autonomous labs increasingly viable. These systems can now perform complex tasks such as automated model positioning, real-time data acquisition, and adaptive experimental design based on ongoing results. The integration of these technologies enables continuous operation, allowing for round-the-clock testing that significantly accelerates the research and development process.

Beyond efficiency gains, autonomous labs aim to expand the exploration of design spaces that would be impractical to investigate using conventional methods. By leveraging machine learning algorithms, these systems can identify optimal designs through intelligent sampling of vast parameter spaces, potentially uncovering aerodynamic configurations that human engineers might overlook.

The ultimate goal of autonomous aerodynamics testing is to establish a new paradigm where physical testing and computational methods work in harmony, with autonomous systems bridging the gap between simulation and reality. This synergy promises to revolutionize aerospace design by enabling rapid iteration, validation, and refinement of concepts, thereby accelerating innovation while reducing development costs and environmental impact.

As we look toward the future of aerospace engineering, autonomous labs represent not merely an incremental improvement but a fundamental transformation in how aerodynamic testing is conducted, with far-reaching implications for aircraft design, performance, and sustainability.

The aerospace industry faces mounting pressure to accelerate development cycles while improving fuel efficiency, reducing emissions, and enhancing safety. These challenges necessitate more efficient and accurate testing methodologies. Autonomous laboratories represent a paradigm shift in this domain, offering unprecedented capabilities for high-throughput experimentation and data-driven discovery.

The primary objective of autonomous aerodynamics testing is to create self-operating laboratory environments that can conduct experiments, collect data, analyze results, and make intelligent decisions about subsequent tests without human intervention. This approach aims to dramatically increase the speed and efficiency of aerodynamic testing while simultaneously improving the quality and reliability of results through the elimination of human bias and error.

Recent technological advancements in robotics, artificial intelligence, machine learning, and sensor technology have converged to make autonomous labs increasingly viable. These systems can now perform complex tasks such as automated model positioning, real-time data acquisition, and adaptive experimental design based on ongoing results. The integration of these technologies enables continuous operation, allowing for round-the-clock testing that significantly accelerates the research and development process.

Beyond efficiency gains, autonomous labs aim to expand the exploration of design spaces that would be impractical to investigate using conventional methods. By leveraging machine learning algorithms, these systems can identify optimal designs through intelligent sampling of vast parameter spaces, potentially uncovering aerodynamic configurations that human engineers might overlook.

The ultimate goal of autonomous aerodynamics testing is to establish a new paradigm where physical testing and computational methods work in harmony, with autonomous systems bridging the gap between simulation and reality. This synergy promises to revolutionize aerospace design by enabling rapid iteration, validation, and refinement of concepts, thereby accelerating innovation while reducing development costs and environmental impact.

As we look toward the future of aerospace engineering, autonomous labs represent not merely an incremental improvement but a fundamental transformation in how aerodynamic testing is conducted, with far-reaching implications for aircraft design, performance, and sustainability.

Market Demand Analysis for Advanced Aerospace Testing Solutions

The aerospace testing market is experiencing significant growth, driven by increasing demand for more efficient, safer, and environmentally friendly aircraft. Current market projections indicate that the global aerospace testing market will reach approximately $7.3 billion by 2025, with a compound annual growth rate of 3.5% from 2020. This growth is primarily fueled by the rising production of commercial aircraft, military modernization programs, and the emergence of urban air mobility concepts.

Autonomous laboratories represent a revolutionary approach to aerodynamics testing, addressing several critical market needs. Airlines and aircraft manufacturers face intense pressure to reduce fuel consumption, with fuel costs accounting for nearly 25% of airline operating expenses. This economic imperative drives demand for advanced testing solutions that can optimize aerodynamic performance and reduce drag, potentially saving millions in operational costs over an aircraft's lifetime.

Environmental regulations are becoming increasingly stringent worldwide, with the International Civil Aviation Organization (ICAO) setting ambitious targets to reduce aviation's carbon footprint by 50% by 2050 compared to 2005 levels. This regulatory landscape creates substantial demand for testing technologies that can help develop more fuel-efficient aircraft designs with lower emissions profiles.

The complexity of modern aircraft design has increased exponentially, with manufacturers incorporating composite materials, adaptive structures, and complex control systems. Traditional testing methodologies struggle to efficiently evaluate these multifaceted designs, creating market demand for autonomous labs that can perform comprehensive, multi-parameter testing with minimal human intervention.

Time-to-market pressures represent another significant market driver. Aircraft development cycles traditionally span 5-7 years, but competitive pressures are pushing manufacturers to reduce this timeframe. Autonomous testing facilities can operate continuously and process results faster than conventional approaches, potentially reducing development timelines by 15-30%.

Defense applications constitute a substantial segment of the market, with military organizations seeking advanced testing capabilities for next-generation fighter aircraft, unmanned aerial vehicles, and hypersonic platforms. These applications often require testing under extreme conditions that autonomous labs can simulate more safely and consistently than traditional methods.

Emerging markets in Asia-Pacific, particularly China and India, are investing heavily in aerospace infrastructure and indigenous aircraft development programs. These regions represent high-growth opportunities for advanced testing solutions, with annual investment in aerospace R&D facilities growing at approximately 8-10% in these regions.

Autonomous laboratories represent a revolutionary approach to aerodynamics testing, addressing several critical market needs. Airlines and aircraft manufacturers face intense pressure to reduce fuel consumption, with fuel costs accounting for nearly 25% of airline operating expenses. This economic imperative drives demand for advanced testing solutions that can optimize aerodynamic performance and reduce drag, potentially saving millions in operational costs over an aircraft's lifetime.

Environmental regulations are becoming increasingly stringent worldwide, with the International Civil Aviation Organization (ICAO) setting ambitious targets to reduce aviation's carbon footprint by 50% by 2050 compared to 2005 levels. This regulatory landscape creates substantial demand for testing technologies that can help develop more fuel-efficient aircraft designs with lower emissions profiles.

The complexity of modern aircraft design has increased exponentially, with manufacturers incorporating composite materials, adaptive structures, and complex control systems. Traditional testing methodologies struggle to efficiently evaluate these multifaceted designs, creating market demand for autonomous labs that can perform comprehensive, multi-parameter testing with minimal human intervention.

Time-to-market pressures represent another significant market driver. Aircraft development cycles traditionally span 5-7 years, but competitive pressures are pushing manufacturers to reduce this timeframe. Autonomous testing facilities can operate continuously and process results faster than conventional approaches, potentially reducing development timelines by 15-30%.

Defense applications constitute a substantial segment of the market, with military organizations seeking advanced testing capabilities for next-generation fighter aircraft, unmanned aerial vehicles, and hypersonic platforms. These applications often require testing under extreme conditions that autonomous labs can simulate more safely and consistently than traditional methods.

Emerging markets in Asia-Pacific, particularly China and India, are investing heavily in aerospace infrastructure and indigenous aircraft development programs. These regions represent high-growth opportunities for advanced testing solutions, with annual investment in aerospace R&D facilities growing at approximately 8-10% in these regions.

Current State and Challenges in Aerodynamics Testing Technology

Aerodynamic testing in aerospace engineering has evolved significantly over the past decades, yet continues to face substantial challenges. Traditional wind tunnel testing, while foundational to the field, presents limitations in terms of cost, time efficiency, and data comprehensiveness. A single wind tunnel test campaign for a commercial aircraft can cost millions of dollars and require months of preparation, creating significant financial and scheduling pressures for aerospace companies.

Current aerodynamic testing methodologies primarily rely on a combination of physical wind tunnel testing and computational fluid dynamics (CFD) simulations. Wind tunnels remain the gold standard for validation but suffer from scaling issues, as most tests use scaled-down models that cannot perfectly replicate real-world conditions. Additionally, traditional wind tunnels have limited measurement capabilities, often capturing data at discrete points rather than providing comprehensive flow field information.

CFD simulations have advanced considerably but still struggle with accurately modeling complex turbulent flows, boundary layer transitions, and separated flows that are critical in aerospace applications. The computational resources required for high-fidelity simulations remain substantial, with some detailed analyses requiring supercomputing capabilities and weeks of processing time.

The aerospace industry also faces challenges related to test repeatability and environmental control. Variations in atmospheric conditions can significantly impact test results, making perfect replication of test conditions difficult. This introduces uncertainty in the validation process and complicates the comparison between different design iterations.

Data integration represents another significant hurdle. Information from physical tests and computational simulations often exists in different formats and resolutions, making direct comparisons challenging. Engineers frequently spend considerable time reconciling these disparate data sources rather than focusing on design improvements.

Globally, aerodynamic testing capabilities are unevenly distributed, with advanced facilities concentrated in a few countries including the United States, Germany, France, Russia, and China. This geographic concentration creates access barriers for emerging aerospace companies and developing nations.

The increasing complexity of modern aircraft designs, including unconventional configurations like blended wing bodies and distributed propulsion systems, further strains existing testing methodologies. These innovative designs often exhibit aerodynamic behaviors that fall outside the validated range of current predictive tools, necessitating more extensive and costly testing campaigns.

Labor requirements present another challenge, with traditional testing approaches requiring teams of specialized technicians and engineers to configure equipment, monitor tests, and process results. This human-intensive process introduces potential for error and inconsistency while limiting the pace of innovation.

Current aerodynamic testing methodologies primarily rely on a combination of physical wind tunnel testing and computational fluid dynamics (CFD) simulations. Wind tunnels remain the gold standard for validation but suffer from scaling issues, as most tests use scaled-down models that cannot perfectly replicate real-world conditions. Additionally, traditional wind tunnels have limited measurement capabilities, often capturing data at discrete points rather than providing comprehensive flow field information.

CFD simulations have advanced considerably but still struggle with accurately modeling complex turbulent flows, boundary layer transitions, and separated flows that are critical in aerospace applications. The computational resources required for high-fidelity simulations remain substantial, with some detailed analyses requiring supercomputing capabilities and weeks of processing time.

The aerospace industry also faces challenges related to test repeatability and environmental control. Variations in atmospheric conditions can significantly impact test results, making perfect replication of test conditions difficult. This introduces uncertainty in the validation process and complicates the comparison between different design iterations.

Data integration represents another significant hurdle. Information from physical tests and computational simulations often exists in different formats and resolutions, making direct comparisons challenging. Engineers frequently spend considerable time reconciling these disparate data sources rather than focusing on design improvements.

Globally, aerodynamic testing capabilities are unevenly distributed, with advanced facilities concentrated in a few countries including the United States, Germany, France, Russia, and China. This geographic concentration creates access barriers for emerging aerospace companies and developing nations.

The increasing complexity of modern aircraft designs, including unconventional configurations like blended wing bodies and distributed propulsion systems, further strains existing testing methodologies. These innovative designs often exhibit aerodynamic behaviors that fall outside the validated range of current predictive tools, necessitating more extensive and costly testing campaigns.

Labor requirements present another challenge, with traditional testing approaches requiring teams of specialized technicians and engineers to configure equipment, monitor tests, and process results. This human-intensive process introduces potential for error and inconsistency while limiting the pace of innovation.

Current Autonomous Lab Solutions for Aerodynamics Testing

01 Automated aerodynamic testing systems

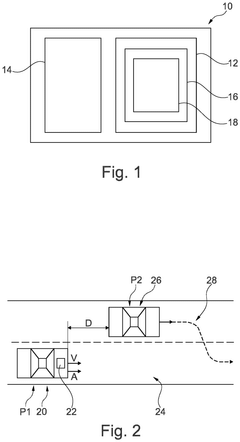

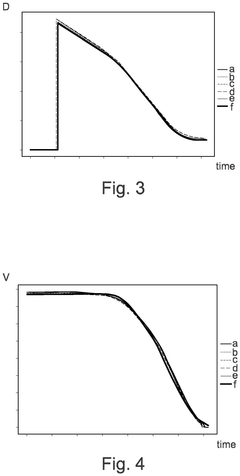

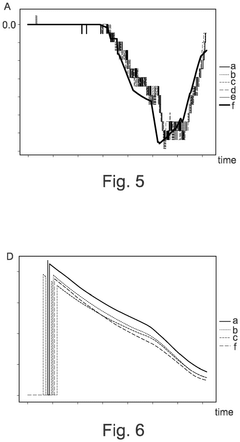

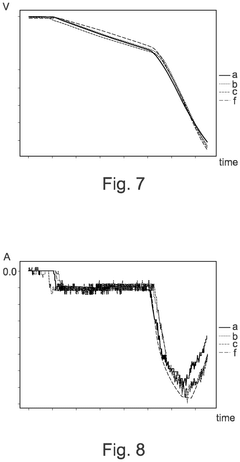

Autonomous laboratory systems designed for aerodynamic testing utilize advanced robotics and sensors to conduct tests without human intervention. These systems can automatically configure test parameters, position models in wind tunnels, collect data, and adjust testing conditions in real-time based on feedback. This automation increases testing efficiency, reduces human error, and allows for continuous operation, significantly accelerating the development cycle for aerodynamic designs.- Automated aerodynamic testing systems: Advanced systems for autonomous aerodynamic testing that incorporate automated data collection, analysis, and validation processes. These systems utilize sensors, cameras, and computational tools to measure airflow patterns, pressure distributions, and other aerodynamic parameters without human intervention. The automation enables more efficient testing cycles, reduces human error, and allows for continuous operation in laboratory environments.

- Machine learning for aerodynamic data analysis: Implementation of machine learning algorithms and artificial intelligence to analyze complex aerodynamic testing data. These technologies enable pattern recognition, anomaly detection, and predictive modeling based on large datasets collected during wind tunnel and flight tests. The autonomous systems can identify correlations between design parameters and aerodynamic performance, optimize testing protocols, and suggest design improvements without human guidance.

- Virtual simulation environments for aerodynamic testing: Development of sophisticated virtual environments that simulate real-world aerodynamic conditions for testing purposes. These digital twins and computational fluid dynamics (CFD) platforms allow for preliminary testing before physical prototypes are built. The autonomous labs can run multiple simulations simultaneously, compare results with physical tests, and automatically refine models based on discrepancies between virtual and physical testing data.

- Robotic systems for physical model manipulation: Integration of robotic systems in aerodynamic testing facilities to autonomously handle, position, and modify test models. These robotic assistants can adjust model configurations, change testing parameters, and reposition sensors without human intervention. The systems enable continuous testing operations with precise, repeatable movements and can adapt to different model types and testing requirements through advanced control algorithms.

- Networked testing facilities with real-time data exchange: Creation of interconnected aerodynamic testing facilities that share data and resources in real-time. These networked autonomous labs can coordinate testing activities across multiple locations, compare results from different facilities, and optimize resource allocation. The systems utilize secure cloud infrastructure, standardized data formats, and automated synchronization protocols to ensure consistent testing methodologies and comparable results across distributed testing environments.

02 AI-powered aerodynamic analysis and simulation

Artificial intelligence and machine learning algorithms are integrated into autonomous aerodynamic testing labs to enhance data analysis and simulation capabilities. These systems can predict aerodynamic performance, identify optimal design parameters, and generate virtual models that simulate real-world conditions. The AI components learn from historical test data to improve prediction accuracy and can suggest design modifications to enhance aerodynamic efficiency without requiring physical prototyping for every iteration.Expand Specific Solutions03 Sensor integration and data acquisition systems

Advanced sensor networks are crucial components in autonomous aerodynamics labs, providing comprehensive data collection during testing. These systems incorporate pressure sensors, thermal imaging, flow visualization tools, and high-speed cameras that work in concert to capture detailed aerodynamic phenomena. The integrated data acquisition systems synchronize multiple data streams, filter noise, and process raw measurements into usable information for analysis, enabling researchers to understand complex aerodynamic interactions.Expand Specific Solutions04 Digital twin technology for aerodynamic testing

Digital twin technology creates virtual replicas of physical aerodynamic test environments, allowing for parallel physical and virtual testing. These systems maintain a bidirectional data flow between the physical test setup and its digital counterpart, enabling real-time validation of computational models against experimental data. The digital twin approach facilitates predictive analysis, remote monitoring of tests, and virtual experimentation that can reduce the number of physical tests required while improving the understanding of aerodynamic performance.Expand Specific Solutions05 Modular and reconfigurable testing platforms

Autonomous aerodynamic testing laboratories utilize modular and reconfigurable hardware platforms that can be rapidly adapted for different test scenarios. These systems feature interchangeable components, adjustable test sections, and programmable mounting systems that allow for testing various vehicle shapes, sizes, and configurations without extensive manual setup. The flexibility of these platforms enables efficient testing across multiple industries including automotive, aerospace, and renewable energy, maximizing the utility of testing facilities.Expand Specific Solutions

Key Industry Players in Autonomous Aerospace Testing

The autonomous labs market in aerodynamics testing for aerospace engineering is currently in a growth phase, characterized by increasing adoption of automated testing environments that enhance efficiency and accuracy. The global market size is expanding rapidly, driven by demands for fuel-efficient aircraft designs and reduced development cycles. Technologically, the field shows varying maturity levels, with established players like China Academy of Space Technology and Commercial Aircraft Corporation of China leading in comprehensive testing capabilities, while innovative companies such as DJI Technology are advancing drone-based testing methodologies. Universities including Beihang University and Zhejiang University contribute significantly through research partnerships with industry. The competitive landscape features both traditional aerospace corporations and emerging technology firms developing specialized autonomous testing solutions for this high-precision field.

Beihang University

Technical Solution: Beihang University has developed a cutting-edge autonomous aerodynamics testing laboratory system specifically designed for aerospace engineering applications. Their solution combines advanced robotics with sophisticated sensor networks to create a fully automated testing environment. The system features AI-driven test planning that optimizes test sequences based on specific research objectives, significantly reducing testing time and resource consumption. Beihang's autonomous lab incorporates multi-spectral imaging systems that can simultaneously capture surface pressure distributions, boundary layer transitions, and flow separation phenomena without human intervention. The university has pioneered a novel approach to autonomous model fabrication and modification within the testing environment, allowing for rapid prototyping and iterative design improvements during testing cycles. Their system also includes automated data validation protocols that can identify measurement anomalies and automatically recalibrate sensors or repeat tests when necessary.

Strengths: Exceptional integration of research-oriented flexibility with industrial testing rigor; superior iterative testing capabilities through in-lab prototyping; advanced AI-driven test optimization. Weaknesses: Higher complexity in operation compared to traditional methods; requires significant technical expertise to fully utilize capabilities; relatively high maintenance requirements.

China Academy of Space Technology

Technical Solution: China Academy of Space Technology (CAST) has developed an advanced autonomous aerodynamics testing laboratory system that integrates AI-driven test automation with high-precision measurement capabilities. Their solution employs a network of intelligent sensors that continuously monitor airflow patterns, pressure distributions, and thermal characteristics during wind tunnel testing. The system utilizes machine learning algorithms to adaptively adjust test parameters in real-time, optimizing test conditions without human intervention. CAST's autonomous labs feature digital twin technology that creates virtual replicas of physical test environments, enabling simultaneous physical and virtual testing to validate results. Their system incorporates automated model positioning systems with six degrees of freedom that can make micro-adjustments to test models based on real-time data feedback, significantly reducing the need for manual reconfiguration between test runs.

Strengths: Exceptional integration of AI with traditional aerospace testing methodologies; superior data collection efficiency through autonomous operation; reduced human error in testing procedures. Weaknesses: High implementation costs; requires significant expertise to maintain and operate; potential cybersecurity vulnerabilities in the autonomous systems.

Critical Technologies Enabling Autonomous Aerodynamics Labs

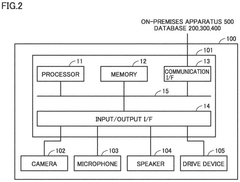

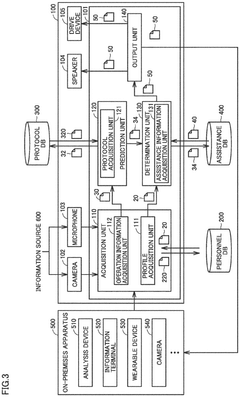

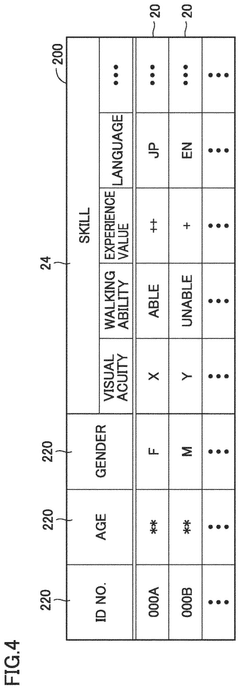

Assistive apparatus

PatentPendingEP4442405A1

Innovation

- An assistive apparatus comprising a first acquisition unit for operator profile information, a second acquisition unit for operation information, a prediction unit to forecast upcoming operations, a determination unit to decide assistive actions based on predicted operations and profile information, and an output unit to execute these actions, which can include tasks like sample transportation or issuing notifications, tailored to individual operator skills and needs.

Method for enabling validation of testing environments for testing a control system of an autonomous vehicle, data processing apparatus, computer program, and computerreadable storage medium

PatentPendingEP4538895A1

Innovation

- A method is developed to validate a first testing environment against a second testing environment by receiving and coordinating data from both environments, determining a correlation between the data elements, and comparing it to a correlation threshold to ensure that both environments adequately replicate the real-world scenario.

Cost-Benefit Analysis of Autonomous Labs Implementation

The implementation of autonomous laboratories in aerospace engineering represents a significant capital investment that must be carefully evaluated against potential returns. Initial setup costs for autonomous aerodynamics testing facilities typically range from $5-15 million, depending on the sophistication of robotics, AI systems, and sensor arrays deployed. However, these upfront expenditures must be weighed against substantial operational savings over time.

Labor cost reduction presents one of the most compelling financial benefits, with autonomous labs reducing staffing requirements by 40-60% compared to traditional testing facilities. A mid-sized aerospace testing facility can potentially save $1.2-2.5 million annually in personnel costs alone, achieving return on investment within 3-7 years depending on utilization rates.

Energy efficiency improvements further enhance the economic case, as autonomous systems optimize resource usage through intelligent scheduling and precise environmental control. Studies indicate energy consumption reductions of 25-35% compared to conventional laboratories, translating to approximately $300,000-500,000 in annual utility savings for larger facilities.

The acceleration of testing cycles delivers perhaps the most significant economic impact. Autonomous labs operate continuously without human fatigue factors, increasing testing throughput by 200-300%. This dramatic reduction in development timelines can advance product launches by 6-18 months, potentially worth tens of millions in competitive advantage and market positioning for aerospace manufacturers.

Risk mitigation represents another quantifiable benefit. Autonomous systems reduce human error rates by an estimated 70-85%, minimizing costly testing failures and material waste. For complex aerospace components, preventing even a single major testing failure can save $500,000-1.5 million in materials and retesting costs.

Maintenance considerations must be factored into the long-term cost structure. While autonomous systems require specialized maintenance, predictive analytics capabilities typically reduce unexpected downtime by 60-75%, with annual maintenance costs averaging 4-7% of initial capital investment—comparable to traditional laboratories despite greater technological complexity.

Scalability provides additional economic advantages, as autonomous labs can be reconfigured for different testing protocols at approximately 40% the cost of establishing separate dedicated facilities. This flexibility enables aerospace companies to pursue diverse research directions without proportional infrastructure investments.

Labor cost reduction presents one of the most compelling financial benefits, with autonomous labs reducing staffing requirements by 40-60% compared to traditional testing facilities. A mid-sized aerospace testing facility can potentially save $1.2-2.5 million annually in personnel costs alone, achieving return on investment within 3-7 years depending on utilization rates.

Energy efficiency improvements further enhance the economic case, as autonomous systems optimize resource usage through intelligent scheduling and precise environmental control. Studies indicate energy consumption reductions of 25-35% compared to conventional laboratories, translating to approximately $300,000-500,000 in annual utility savings for larger facilities.

The acceleration of testing cycles delivers perhaps the most significant economic impact. Autonomous labs operate continuously without human fatigue factors, increasing testing throughput by 200-300%. This dramatic reduction in development timelines can advance product launches by 6-18 months, potentially worth tens of millions in competitive advantage and market positioning for aerospace manufacturers.

Risk mitigation represents another quantifiable benefit. Autonomous systems reduce human error rates by an estimated 70-85%, minimizing costly testing failures and material waste. For complex aerospace components, preventing even a single major testing failure can save $500,000-1.5 million in materials and retesting costs.

Maintenance considerations must be factored into the long-term cost structure. While autonomous systems require specialized maintenance, predictive analytics capabilities typically reduce unexpected downtime by 60-75%, with annual maintenance costs averaging 4-7% of initial capital investment—comparable to traditional laboratories despite greater technological complexity.

Scalability provides additional economic advantages, as autonomous labs can be reconfigured for different testing protocols at approximately 40% the cost of establishing separate dedicated facilities. This flexibility enables aerospace companies to pursue diverse research directions without proportional infrastructure investments.

Data Management and AI Integration in Aerodynamics Testing

The integration of advanced data management systems and artificial intelligence has revolutionized aerodynamics testing in autonomous laboratories. These technologies enable unprecedented capabilities in data collection, processing, and analysis, creating a seamless workflow that significantly enhances testing efficiency and accuracy.

Modern autonomous aerodynamics labs generate massive volumes of data from various sensors, high-speed cameras, pressure transducers, and computational fluid dynamics simulations. Traditional data management approaches struggle with this scale and complexity. Advanced data management systems now implement hierarchical storage architectures that automatically categorize and store data based on importance, frequency of access, and computational requirements.

Real-time data processing has become essential in autonomous testing environments. Edge computing solutions deployed directly within testing facilities process critical data on-site, reducing latency and enabling immediate decision-making during experiments. This capability is particularly valuable when testing critical flight conditions where rapid adjustments may be necessary.

Artificial intelligence algorithms, particularly machine learning models, have transformed how aerodynamic data is analyzed. These systems can identify patterns and correlations that would be impossible for human engineers to detect manually. Deep learning networks trained on historical test data can predict aerodynamic performance with remarkable accuracy, reducing the number of physical tests required and accelerating the development cycle.

Digital twin technology represents another significant advancement in this domain. By creating high-fidelity virtual replicas of physical testing environments, engineers can conduct preliminary tests in the digital realm before committing to physical prototypes. These digital twins continuously improve through AI-driven learning from real-world test data, creating a positive feedback loop that enhances both virtual and physical testing accuracy.

Cloud-based collaborative platforms enable geographically dispersed engineering teams to access and analyze test data simultaneously. This democratization of data access accelerates innovation by allowing specialists from different disciplines to contribute insights based on the same dataset. Furthermore, these platforms implement sophisticated version control systems that track changes and maintain data provenance throughout the testing lifecycle.

Predictive maintenance algorithms monitor testing equipment in autonomous labs, identifying potential failures before they occur. This proactive approach minimizes downtime and ensures consistent test conditions, which is crucial for obtaining reliable aerodynamic data. The integration of these AI-driven maintenance systems with laboratory management software creates a holistic operational environment that maximizes testing throughput.

Modern autonomous aerodynamics labs generate massive volumes of data from various sensors, high-speed cameras, pressure transducers, and computational fluid dynamics simulations. Traditional data management approaches struggle with this scale and complexity. Advanced data management systems now implement hierarchical storage architectures that automatically categorize and store data based on importance, frequency of access, and computational requirements.

Real-time data processing has become essential in autonomous testing environments. Edge computing solutions deployed directly within testing facilities process critical data on-site, reducing latency and enabling immediate decision-making during experiments. This capability is particularly valuable when testing critical flight conditions where rapid adjustments may be necessary.

Artificial intelligence algorithms, particularly machine learning models, have transformed how aerodynamic data is analyzed. These systems can identify patterns and correlations that would be impossible for human engineers to detect manually. Deep learning networks trained on historical test data can predict aerodynamic performance with remarkable accuracy, reducing the number of physical tests required and accelerating the development cycle.

Digital twin technology represents another significant advancement in this domain. By creating high-fidelity virtual replicas of physical testing environments, engineers can conduct preliminary tests in the digital realm before committing to physical prototypes. These digital twins continuously improve through AI-driven learning from real-world test data, creating a positive feedback loop that enhances both virtual and physical testing accuracy.

Cloud-based collaborative platforms enable geographically dispersed engineering teams to access and analyze test data simultaneously. This democratization of data access accelerates innovation by allowing specialists from different disciplines to contribute insights based on the same dataset. Furthermore, these platforms implement sophisticated version control systems that track changes and maintain data provenance throughout the testing lifecycle.

Predictive maintenance algorithms monitor testing equipment in autonomous labs, identifying potential failures before they occur. This proactive approach minimizes downtime and ensures consistent test conditions, which is crucial for obtaining reliable aerodynamic data. The integration of these AI-driven maintenance systems with laboratory management software creates a holistic operational environment that maximizes testing throughput.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!