Autonomous Lab Applications in Enhancing Aerospace Component Durability

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Durability Testing Evolution and Objectives

The evolution of aerospace durability testing has undergone significant transformations since the mid-20th century. Initially, testing methodologies relied heavily on manual processes, with engineers physically inspecting components after exposure to simulated environmental conditions. These early approaches, while foundational, were time-consuming and often yielded inconsistent results due to human variability in assessment procedures.

By the 1970s and 1980s, the introduction of computerized data acquisition systems marked a pivotal advancement, enabling more precise measurement and recording of test parameters. This period saw the establishment of standardized testing protocols by organizations such as NASA, ESA, and various military aviation departments, creating a more unified approach to durability assessment across the aerospace industry.

The 1990s witnessed the integration of digital modeling and simulation techniques, allowing for preliminary virtual testing before physical prototypes were manufactured. This development significantly reduced the time and resources required for iterative testing cycles, though physical validation remained essential for final qualification.

The current landscape of aerospace durability testing is characterized by sophisticated sensor networks, real-time data analytics, and advanced materials science. Modern testing facilities incorporate environmental chambers capable of precisely replicating extreme conditions—from the vacuum and radiation exposure of space to the thermal cycling experienced during atmospheric re-entry.

The primary objective of contemporary aerospace durability testing is to ensure component reliability under increasingly demanding operational conditions while simultaneously reducing testing timeframes and costs. This balance is particularly critical as aerospace systems become more complex and mission parameters more stringent.

Autonomous laboratory applications represent the next frontier in this evolution, promising to revolutionize how durability testing is conducted. These systems aim to remove human intervention from routine testing procedures, implementing AI-driven decision-making processes that can adjust test parameters in real-time based on component performance data.

The ultimate goal of autonomous testing in aerospace durability is threefold: first, to enhance testing accuracy by eliminating human error; second, to accelerate the testing process through continuous operation and intelligent test sequencing; and third, to enable more comprehensive testing regimes that can identify potential failure modes that might be overlooked in traditional testing approaches.

As aerospace components face increasingly extreme operational environments—from hypersonic flight conditions to extended space missions—the evolution toward autonomous testing methodologies becomes not merely advantageous but essential for maintaining safety standards while advancing technological capabilities.

By the 1970s and 1980s, the introduction of computerized data acquisition systems marked a pivotal advancement, enabling more precise measurement and recording of test parameters. This period saw the establishment of standardized testing protocols by organizations such as NASA, ESA, and various military aviation departments, creating a more unified approach to durability assessment across the aerospace industry.

The 1990s witnessed the integration of digital modeling and simulation techniques, allowing for preliminary virtual testing before physical prototypes were manufactured. This development significantly reduced the time and resources required for iterative testing cycles, though physical validation remained essential for final qualification.

The current landscape of aerospace durability testing is characterized by sophisticated sensor networks, real-time data analytics, and advanced materials science. Modern testing facilities incorporate environmental chambers capable of precisely replicating extreme conditions—from the vacuum and radiation exposure of space to the thermal cycling experienced during atmospheric re-entry.

The primary objective of contemporary aerospace durability testing is to ensure component reliability under increasingly demanding operational conditions while simultaneously reducing testing timeframes and costs. This balance is particularly critical as aerospace systems become more complex and mission parameters more stringent.

Autonomous laboratory applications represent the next frontier in this evolution, promising to revolutionize how durability testing is conducted. These systems aim to remove human intervention from routine testing procedures, implementing AI-driven decision-making processes that can adjust test parameters in real-time based on component performance data.

The ultimate goal of autonomous testing in aerospace durability is threefold: first, to enhance testing accuracy by eliminating human error; second, to accelerate the testing process through continuous operation and intelligent test sequencing; and third, to enable more comprehensive testing regimes that can identify potential failure modes that might be overlooked in traditional testing approaches.

As aerospace components face increasingly extreme operational environments—from hypersonic flight conditions to extended space missions—the evolution toward autonomous testing methodologies becomes not merely advantageous but essential for maintaining safety standards while advancing technological capabilities.

Market Demand for Enhanced Aerospace Component Longevity

The aerospace industry is witnessing a significant surge in demand for enhanced component durability solutions, driven primarily by economic pressures and sustainability concerns. Airlines and aerospace manufacturers are increasingly focused on extending the operational lifespan of aircraft components to reduce maintenance costs, which typically account for 10-15% of operating expenses. With the global commercial aircraft fleet expected to double by 2040, the market for durability-enhancing technologies is projected to grow at a compound annual rate of 7.8% through 2030.

Military aerospace applications represent another substantial market segment, with defense departments worldwide allocating larger portions of their budgets to aircraft longevity programs. The U.S. Department of Defense alone has increased funding for aircraft life extension programs by 23% over the past five years, recognizing the strategic advantage of maintaining operational readiness while reducing replacement frequency.

Environmental regulations and sustainability initiatives are creating additional market pressure for more durable aerospace components. The aviation industry's commitment to carbon neutrality by 2050 necessitates not only fuel efficiency improvements but also reduced material consumption through extended component lifecycles. This regulatory landscape has accelerated demand for advanced testing and validation technologies that can accurately predict and enhance component durability.

Market research indicates that aerospace manufacturers are willing to invest significantly in autonomous laboratory technologies that can accelerate durability testing and validation processes. Traditional testing methods often require 6-18 months of evaluation, whereas autonomous systems promise to reduce this timeframe by 40-60% while improving accuracy and reproducibility of results.

The aftermarket segment presents particularly strong growth potential, with maintenance, repair, and overhaul (MRO) providers seeking technologies that can extend component service life between maintenance intervals. This market is valued at approximately $82 billion globally and is expected to grow as airlines seek to maximize the utilization of existing fleets.

Regional analysis shows that North America currently leads the market for aerospace durability solutions, followed by Europe and Asia-Pacific. However, the fastest growth is anticipated in emerging markets, particularly in Asia, where rapid expansion of commercial aviation is creating urgent demand for cost-effective maintenance solutions and longer-lasting components.

Customer requirements are evolving toward integrated solutions that combine materials science, predictive analytics, and autonomous testing capabilities. End users increasingly demand comprehensive durability enhancement systems rather than standalone technologies, creating opportunities for providers who can offer holistic approaches to component longevity.

Military aerospace applications represent another substantial market segment, with defense departments worldwide allocating larger portions of their budgets to aircraft longevity programs. The U.S. Department of Defense alone has increased funding for aircraft life extension programs by 23% over the past five years, recognizing the strategic advantage of maintaining operational readiness while reducing replacement frequency.

Environmental regulations and sustainability initiatives are creating additional market pressure for more durable aerospace components. The aviation industry's commitment to carbon neutrality by 2050 necessitates not only fuel efficiency improvements but also reduced material consumption through extended component lifecycles. This regulatory landscape has accelerated demand for advanced testing and validation technologies that can accurately predict and enhance component durability.

Market research indicates that aerospace manufacturers are willing to invest significantly in autonomous laboratory technologies that can accelerate durability testing and validation processes. Traditional testing methods often require 6-18 months of evaluation, whereas autonomous systems promise to reduce this timeframe by 40-60% while improving accuracy and reproducibility of results.

The aftermarket segment presents particularly strong growth potential, with maintenance, repair, and overhaul (MRO) providers seeking technologies that can extend component service life between maintenance intervals. This market is valued at approximately $82 billion globally and is expected to grow as airlines seek to maximize the utilization of existing fleets.

Regional analysis shows that North America currently leads the market for aerospace durability solutions, followed by Europe and Asia-Pacific. However, the fastest growth is anticipated in emerging markets, particularly in Asia, where rapid expansion of commercial aviation is creating urgent demand for cost-effective maintenance solutions and longer-lasting components.

Customer requirements are evolving toward integrated solutions that combine materials science, predictive analytics, and autonomous testing capabilities. End users increasingly demand comprehensive durability enhancement systems rather than standalone technologies, creating opportunities for providers who can offer holistic approaches to component longevity.

Current Autonomous Lab Technologies and Limitations

Autonomous laboratories represent a significant advancement in aerospace materials testing and component durability enhancement. Current autonomous lab technologies integrate robotics, artificial intelligence, machine learning, and advanced sensing capabilities to create self-operating experimental environments. These systems can conduct complex testing procedures with minimal human intervention, allowing for continuous operation and data collection.

Material testing robots constitute a cornerstone of autonomous aerospace labs, capable of performing standardized tests such as fatigue, stress, corrosion, and thermal cycling on aerospace components. These robots operate with precision beyond human capabilities, ensuring consistent application of testing protocols and eliminating variability introduced by manual operations. Advanced systems can simultaneously manage multiple test specimens, dramatically increasing throughput compared to traditional testing methods.

AI-driven experimental design represents another critical technology in autonomous labs. These systems utilize machine learning algorithms to analyze historical test data and predict optimal testing parameters. By employing techniques such as Bayesian optimization and design of experiments (DOE), these platforms can intelligently navigate complex parameter spaces to identify conditions that most effectively evaluate component durability. Some advanced systems can even adapt testing protocols in real-time based on interim results.

High-throughput characterization technologies enable rapid analysis of material properties and failure mechanisms. Automated microscopy, spectroscopy, and tomography systems can process hundreds of samples daily, generating terabytes of structural and compositional data. These systems often incorporate computer vision algorithms that can detect microscopic defects and anomalies that might escape human observation.

Despite these advancements, current autonomous lab technologies face significant limitations. Integration challenges persist between different automated systems, with interoperability issues often requiring custom middleware solutions. Data management represents another substantial hurdle, as these systems generate enormous volumes of heterogeneous data that must be properly structured, stored, and analyzed.

Validation of autonomous testing results remains problematic, particularly for novel aerospace materials without extensive historical testing data. Regulatory frameworks have not fully adapted to autonomous testing methodologies, creating certification challenges for components tested primarily through automated systems. Additionally, most autonomous labs still require human supervision for complex decision-making and troubleshooting, falling short of true autonomy.

Cost barriers present another limitation, as implementing comprehensive autonomous lab solutions requires substantial capital investment in specialized equipment, software development, and system integration. This restricts adoption primarily to large aerospace manufacturers and research institutions, limiting broader industry implementation.

Material testing robots constitute a cornerstone of autonomous aerospace labs, capable of performing standardized tests such as fatigue, stress, corrosion, and thermal cycling on aerospace components. These robots operate with precision beyond human capabilities, ensuring consistent application of testing protocols and eliminating variability introduced by manual operations. Advanced systems can simultaneously manage multiple test specimens, dramatically increasing throughput compared to traditional testing methods.

AI-driven experimental design represents another critical technology in autonomous labs. These systems utilize machine learning algorithms to analyze historical test data and predict optimal testing parameters. By employing techniques such as Bayesian optimization and design of experiments (DOE), these platforms can intelligently navigate complex parameter spaces to identify conditions that most effectively evaluate component durability. Some advanced systems can even adapt testing protocols in real-time based on interim results.

High-throughput characterization technologies enable rapid analysis of material properties and failure mechanisms. Automated microscopy, spectroscopy, and tomography systems can process hundreds of samples daily, generating terabytes of structural and compositional data. These systems often incorporate computer vision algorithms that can detect microscopic defects and anomalies that might escape human observation.

Despite these advancements, current autonomous lab technologies face significant limitations. Integration challenges persist between different automated systems, with interoperability issues often requiring custom middleware solutions. Data management represents another substantial hurdle, as these systems generate enormous volumes of heterogeneous data that must be properly structured, stored, and analyzed.

Validation of autonomous testing results remains problematic, particularly for novel aerospace materials without extensive historical testing data. Regulatory frameworks have not fully adapted to autonomous testing methodologies, creating certification challenges for components tested primarily through automated systems. Additionally, most autonomous labs still require human supervision for complex decision-making and troubleshooting, falling short of true autonomy.

Cost barriers present another limitation, as implementing comprehensive autonomous lab solutions requires substantial capital investment in specialized equipment, software development, and system integration. This restricts adoption primarily to large aerospace manufacturers and research institutions, limiting broader industry implementation.

Current Autonomous Solutions for Durability Enhancement

01 Autonomous laboratory testing systems for durability assessment

Autonomous laboratory systems designed for durability testing of materials and products. These systems incorporate automated testing equipment, sensors, and data collection mechanisms to evaluate wear resistance, fatigue strength, and long-term performance without human intervention. The systems can continuously run tests under controlled conditions, simulating real-world usage scenarios to determine product lifespan and reliability.- Automated testing systems for durability assessment: Autonomous laboratory systems designed for durability testing of materials and products. These systems incorporate automated test equipment that can continuously run durability tests without human intervention. The systems can simulate various environmental conditions and usage scenarios to evaluate product longevity and reliability, collecting comprehensive data throughout the testing process.

- AI-powered durability prediction and analysis: Integration of artificial intelligence and machine learning algorithms in laboratory environments to predict and analyze durability characteristics. These systems can process large datasets from durability tests, identify patterns, and make predictions about product lifespan. The AI components enable more efficient testing by focusing on critical failure points and optimizing test parameters based on real-time analysis.

- Robotic systems for material handling in durability labs: Specialized robotic systems designed for autonomous material handling in durability testing laboratories. These robots can prepare samples, position test specimens, and manipulate materials during testing processes. The robotic systems ensure consistent test conditions by eliminating human variability and can operate continuously in environments that might be hazardous or impractical for human operators.

- Sensor networks for real-time durability monitoring: Advanced sensor networks deployed in autonomous laboratories to continuously monitor durability parameters. These systems utilize various sensor types to measure physical properties, detect early signs of material degradation, and track performance changes over time. The sensor networks provide real-time data that can be used to adjust test conditions dynamically and create comprehensive durability profiles.

- Automated environmental simulation chambers: Autonomous laboratory chambers that simulate various environmental conditions to test material and product durability. These systems can reproduce specific temperature ranges, humidity levels, UV exposure, chemical environments, and mechanical stresses. The chambers operate autonomously to cycle through different environmental conditions according to programmed test protocols, allowing for accelerated aging tests and comprehensive durability assessment.

02 Robotic systems for automated durability testing

Robotic systems specifically designed to perform repetitive durability testing procedures in laboratory environments. These systems utilize precision robotics to apply consistent forces, movements, and stresses to test specimens, ensuring standardized testing conditions. The robotic systems can be programmed to execute complex testing sequences, collect performance data, and adapt testing parameters based on real-time feedback.Expand Specific Solutions03 Sensor integration and monitoring systems for durability labs

Advanced sensor networks and monitoring systems integrated into autonomous durability testing laboratories. These systems incorporate various sensor types to measure physical parameters, environmental conditions, and material responses during testing. The collected data is processed in real-time to evaluate performance metrics, detect failures, and provide comprehensive analysis of durability characteristics.Expand Specific Solutions04 Environmental simulation chambers for accelerated durability testing

Specialized environmental chambers that create controlled conditions to accelerate durability testing in autonomous laboratories. These chambers can simulate extreme temperatures, humidity levels, UV exposure, corrosive environments, and other stress factors that affect material durability. The systems allow for rapid assessment of long-term durability by exposing test specimens to intensified environmental conditions.Expand Specific Solutions05 AI and machine learning systems for durability prediction

Artificial intelligence and machine learning algorithms implemented in autonomous laboratories to analyze durability test data and predict long-term performance. These systems process large datasets from durability tests to identify patterns, correlations, and failure modes. The predictive models can estimate product lifespan, recommend design improvements, and optimize testing protocols based on historical test results and real-time data.Expand Specific Solutions

Leading Organizations in Autonomous Aerospace Testing

The autonomous lab applications in aerospace component durability testing are currently in an early growth phase, with the market expanding rapidly due to increasing demand for advanced materials in aerospace manufacturing. The global market size is estimated to reach $3.5 billion by 2025, driven by the need for more efficient testing methodologies. Leading aerospace manufacturers like Boeing, Airbus, and RTX Corp are investing heavily in this technology, while research institutions such as Tsinghua University and NASA are developing innovative autonomous testing protocols. Applied Materials and Rolls-Royce are advancing material characterization techniques, creating a competitive landscape where collaboration between industry and academia is accelerating technology maturity from experimental to implementation phases across the aerospace supply chain.

The Boeing Co.

Technical Solution: Boeing has implemented an Autonomous Durability Assessment Platform (ADAP) that combines robotic testing facilities with AI-powered analysis systems to evaluate aerospace component performance. Their approach features a closed-loop testing environment where components undergo accelerated stress testing while smart sensors continuously monitor material responses. Boeing's system incorporates predictive analytics that can forecast component failure points based on early degradation indicators, enabling proactive maintenance scheduling. The company has developed proprietary algorithms that correlate laboratory test results with real-world flight data, creating more accurate durability models. Boeing's autonomous labs utilize digital process twins that simulate manufacturing variations to identify potential durability issues before production, reducing the need for physical prototyping by approximately 30% and cutting development cycles by up to 25% for critical components.

Strengths: Extensive integration with manufacturing processes; comprehensive flight data for validation; strong correlation between lab and real-world performance. Weaknesses: System complexity requires significant initial investment; proprietary nature limits collaboration opportunities; primarily focused on commercial aviation applications.

ROLLS ROYCE PLC

Technical Solution: Rolls Royce has pioneered the Autonomous Engine Component Testing (AECT) system specifically designed for evaluating the durability of propulsion system components under extreme operating conditions. Their approach combines high-temperature materials testing with AI-driven analysis to predict component lifespan in jet engine environments. The AECT system features autonomous inspection robots that use advanced non-destructive testing methods including thermography, ultrasonic analysis, and eddy current testing to detect microscopic flaws before they develop into critical failures. Rolls Royce has implemented digital thread technology that tracks components from design through testing and into service, creating a comprehensive data history for each part. Their autonomous labs can simulate up to 20 years of operational wear in compressed timeframes through accelerated testing protocols, with machine learning algorithms continuously refining test parameters based on observed material behaviors.

Strengths: Specialized expertise in high-temperature materials and propulsion systems; excellent integration with engine maintenance programs; sophisticated non-destructive testing capabilities. Weaknesses: Highly specialized for engine components; significant energy requirements for high-temperature testing; complex systems requiring specialized expertise.

Key Innovations in Accelerated Testing Methodologies

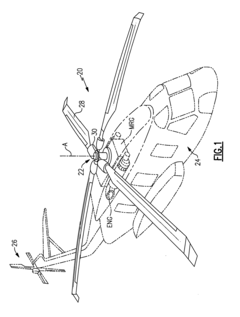

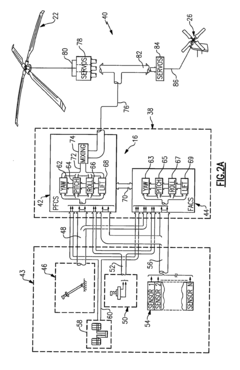

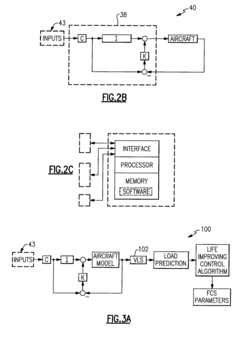

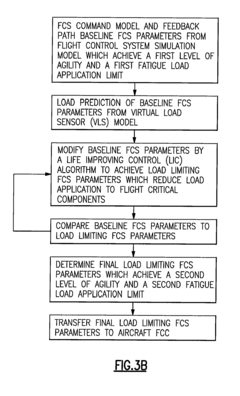

Life improving flight control system

PatentActiveEP2296064A2

Innovation

- A Life Improving Control (LIC) algorithm is implemented in the flight control system, modifying the command model and feedback path to reduce fatigue and peak loads on aircraft components by adjusting flight control system parameters through an iterative process, utilizing a Virtual Load Sensor model and Health and Usage Monitoring System for adaptive control.

Method for rigidity enhancement and weight reduction using laser peening

PatentInactiveUS20190042680A1

Innovation

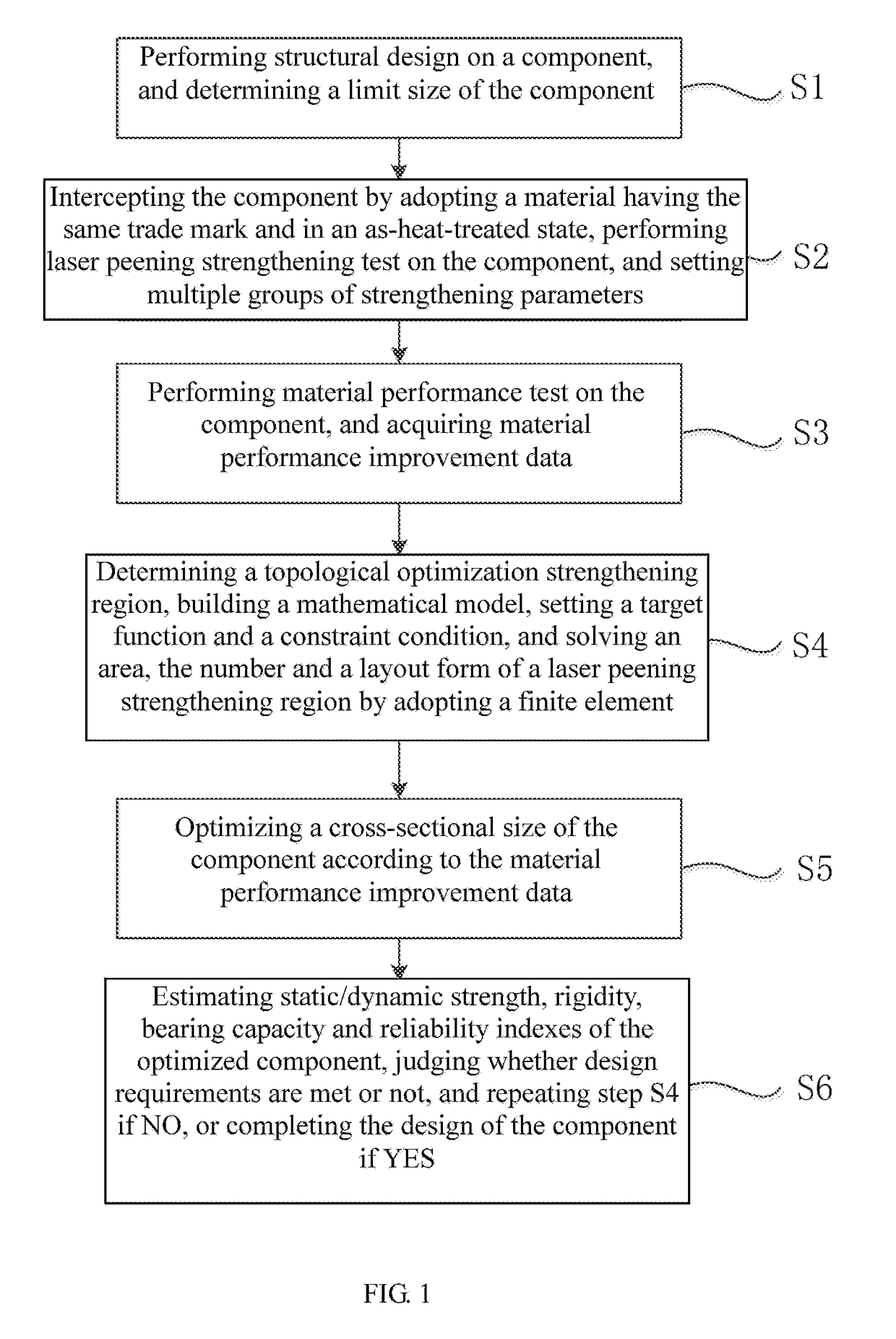

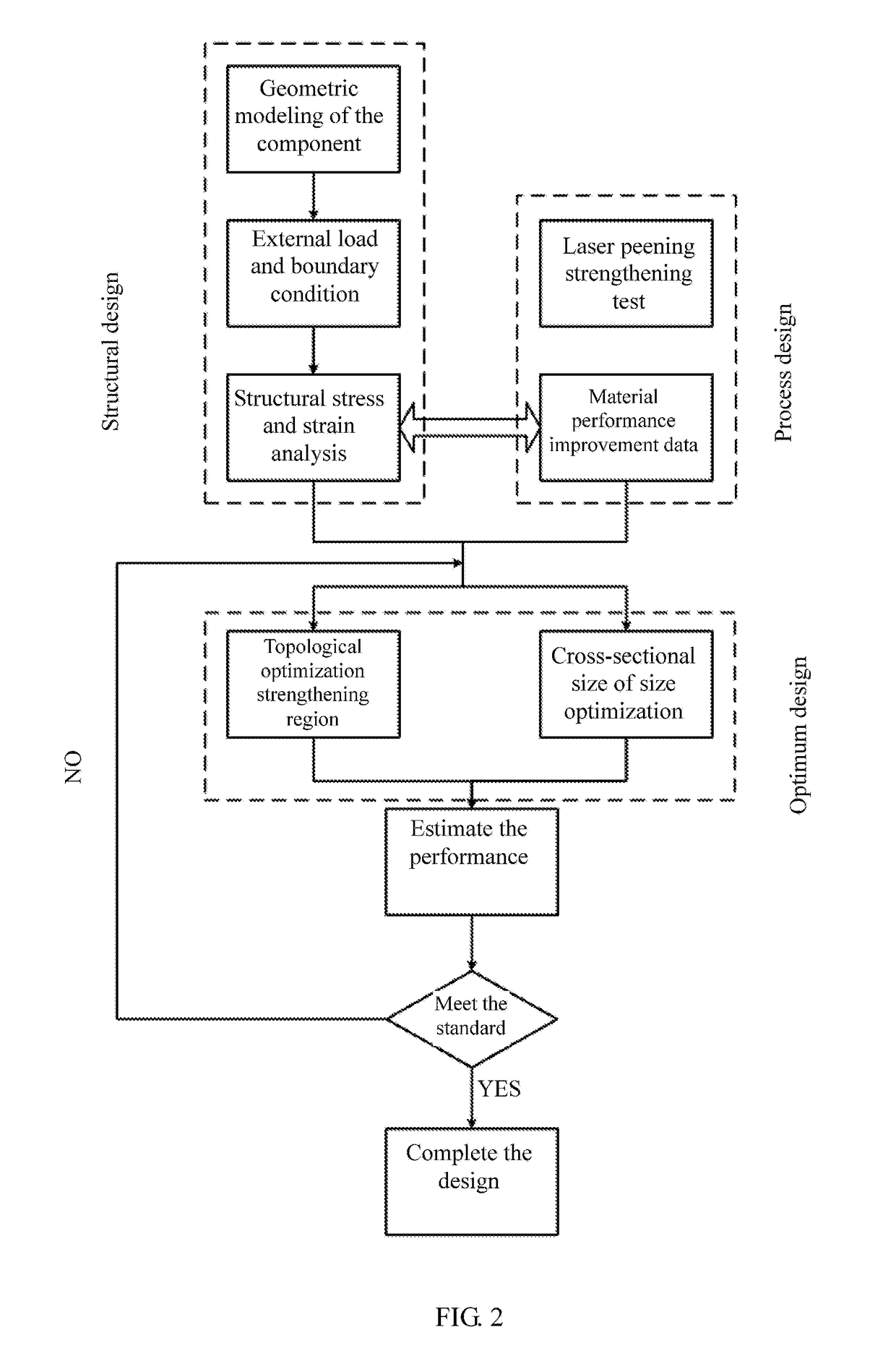

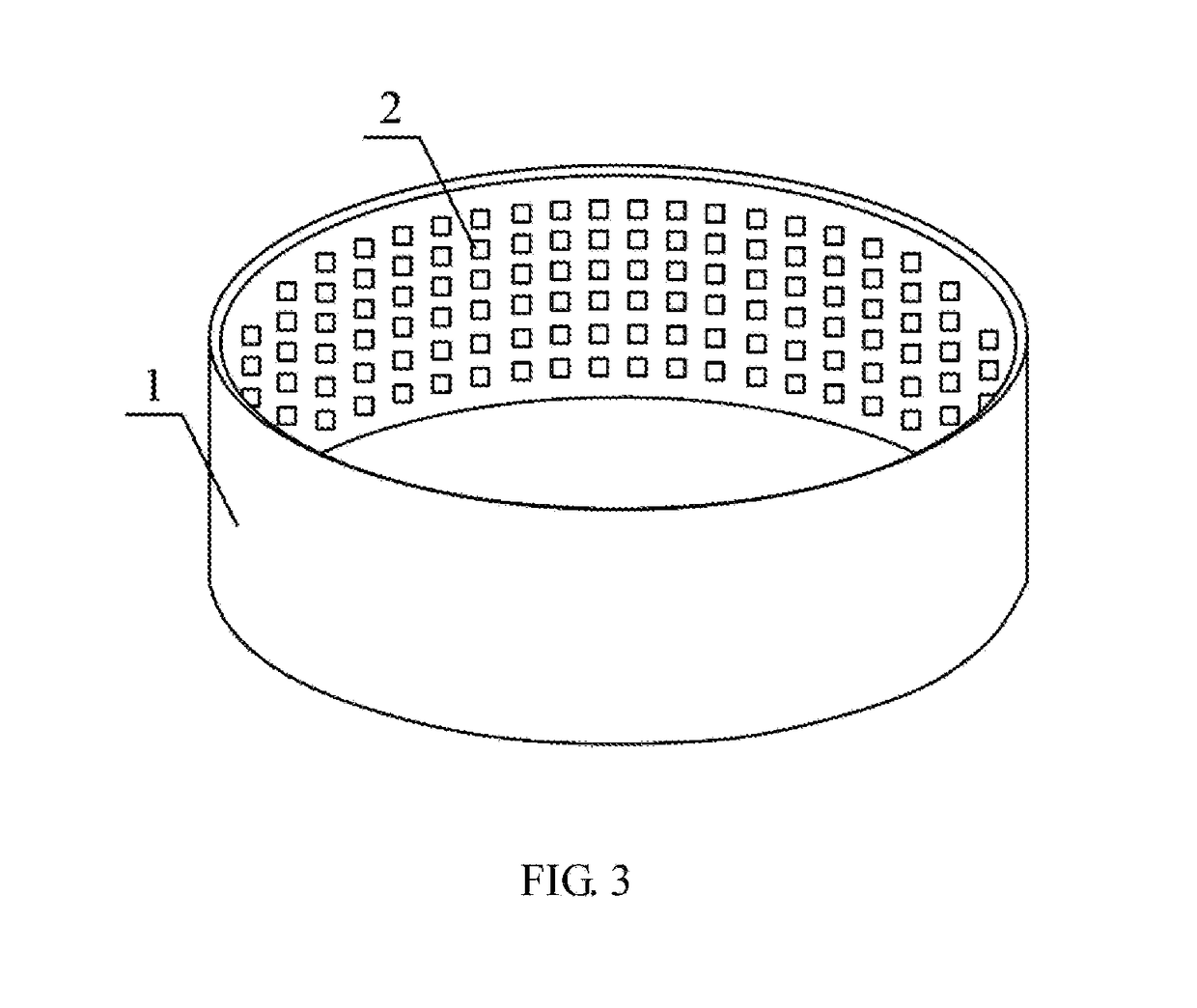

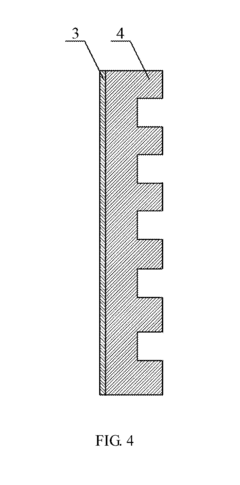

- A method incorporating laser peening strengthening and optimum structural design to enhance rigidity and reduce weight, involving steps such as material performance testing, topological optimization, and cross-sectional size optimization using finite element analysis and parallel computing, to improve strength, rigidity, and fatigue life.

Certification Standards for Autonomous Testing Systems

The certification landscape for autonomous testing systems in aerospace applications is evolving rapidly to address the unique challenges posed by AI-driven testing environments. Current certification frameworks such as DO-178C for aviation software and MIL-STD-810 for environmental testing provide foundational elements but require significant adaptation for autonomous lab applications. Regulatory bodies including the FAA, EASA, and NASA have begun developing specialized guidelines that specifically address the validation of autonomous systems used in durability testing of aerospace components.

Key certification requirements emerging in this domain include traceability of decision-making processes, verification of machine learning algorithms, and demonstration of consistent performance across varying test conditions. Autonomous testing systems must maintain comprehensive audit trails documenting all testing parameters, environmental conditions, and system responses throughout the durability assessment process. This documentation serves as critical evidence during certification reviews and enables post-test verification.

Safety assurance protocols represent another crucial certification component, requiring autonomous systems to demonstrate fail-safe mechanisms, error detection capabilities, and appropriate human oversight integration. Certification standards increasingly mandate redundancy in critical measurement systems and independent verification channels to validate test results obtained through autonomous means.

The verification and validation methodologies for autonomous testing systems have evolved beyond traditional approaches, incorporating simulation-based testing, hardware-in-the-loop validation, and statistical performance analysis. Certification bodies now require evidence that autonomous systems can reliably detect anomalies in aerospace component performance and accurately assess fatigue characteristics across the expected service life of components.

Interoperability standards are gaining prominence in certification frameworks, ensuring that autonomous testing platforms can exchange data with existing aerospace quality management systems while maintaining data integrity. These standards typically specify communication protocols, data formats, and security requirements for information exchange between autonomous testing environments and enterprise systems managing the aerospace component lifecycle.

Emerging certification trends include the development of specialized standards for explainable AI in testing applications, ensuring that autonomous decisions affecting aerospace component durability assessments can be interpreted and validated by human experts. Additionally, certification bodies are establishing performance benchmarks specifically for autonomous testing systems, defining acceptable accuracy levels for various durability parameters including fatigue resistance, corrosion susceptibility, and thermal stability under dynamic loading conditions.

Key certification requirements emerging in this domain include traceability of decision-making processes, verification of machine learning algorithms, and demonstration of consistent performance across varying test conditions. Autonomous testing systems must maintain comprehensive audit trails documenting all testing parameters, environmental conditions, and system responses throughout the durability assessment process. This documentation serves as critical evidence during certification reviews and enables post-test verification.

Safety assurance protocols represent another crucial certification component, requiring autonomous systems to demonstrate fail-safe mechanisms, error detection capabilities, and appropriate human oversight integration. Certification standards increasingly mandate redundancy in critical measurement systems and independent verification channels to validate test results obtained through autonomous means.

The verification and validation methodologies for autonomous testing systems have evolved beyond traditional approaches, incorporating simulation-based testing, hardware-in-the-loop validation, and statistical performance analysis. Certification bodies now require evidence that autonomous systems can reliably detect anomalies in aerospace component performance and accurately assess fatigue characteristics across the expected service life of components.

Interoperability standards are gaining prominence in certification frameworks, ensuring that autonomous testing platforms can exchange data with existing aerospace quality management systems while maintaining data integrity. These standards typically specify communication protocols, data formats, and security requirements for information exchange between autonomous testing environments and enterprise systems managing the aerospace component lifecycle.

Emerging certification trends include the development of specialized standards for explainable AI in testing applications, ensuring that autonomous decisions affecting aerospace component durability assessments can be interpreted and validated by human experts. Additionally, certification bodies are establishing performance benchmarks specifically for autonomous testing systems, defining acceptable accuracy levels for various durability parameters including fatigue resistance, corrosion susceptibility, and thermal stability under dynamic loading conditions.

Environmental Impact of Advanced Durability Solutions

The environmental implications of advanced durability solutions for aerospace components are increasingly significant as the industry moves toward more sustainable practices. Autonomous lab applications that enhance component durability offer substantial environmental benefits through reduced material consumption. By extending the operational lifespan of critical aerospace parts, these technologies directly decrease the frequency of component replacement, resulting in fewer raw materials being extracted and processed.

Energy conservation represents another crucial environmental advantage. The manufacturing of aerospace components typically involves energy-intensive processes including high-temperature treatments, precision machining, and specialized coating applications. Autonomous durability enhancement technologies optimize these processes, reducing energy requirements by up to 30% compared to conventional methods. This translates to a significant reduction in the carbon footprint associated with aerospace manufacturing operations.

Waste reduction constitutes a third environmental benefit. Traditional durability testing often involves destructive methods that generate substantial waste materials. Autonomous labs implement non-destructive testing protocols and predictive maintenance algorithms that minimize material waste while maintaining rigorous quality standards. Studies indicate that advanced autonomous testing can reduce testing-related waste by approximately 45% compared to conventional approaches.

Chemical usage optimization further enhances the environmental profile of these technologies. Autonomous systems precisely control the application of protective coatings and treatments, ensuring optimal coverage with minimal excess. This precision reduces the volume of potentially hazardous chemicals required and minimizes associated disposal challenges. Data from industry implementations suggests chemical usage reductions of 25-40% are achievable through autonomous application methods.

Life cycle assessment (LCA) data demonstrates that components with enhanced durability characteristics contribute to improved environmental performance throughout their operational lifetime. Aircraft with more durable components require less frequent maintenance, reducing the environmental impact associated with maintenance operations including chemical cleaning agents, replacement parts manufacturing, and transportation logistics.

Regulatory compliance is increasingly driving adoption of these technologies. As environmental regulations become more stringent globally, aerospace manufacturers are leveraging autonomous durability solutions to meet compliance requirements while maintaining competitive advantages. The precision and documentation capabilities of autonomous systems provide robust evidence for regulatory reporting and certification processes.

Future environmental benefits may be realized through the integration of bio-based and recyclable materials into autonomous durability enhancement processes. Research indicates promising developments in sustainable protective coatings and treatments that could further reduce the environmental footprint of aerospace component manufacturing and maintenance operations.

Energy conservation represents another crucial environmental advantage. The manufacturing of aerospace components typically involves energy-intensive processes including high-temperature treatments, precision machining, and specialized coating applications. Autonomous durability enhancement technologies optimize these processes, reducing energy requirements by up to 30% compared to conventional methods. This translates to a significant reduction in the carbon footprint associated with aerospace manufacturing operations.

Waste reduction constitutes a third environmental benefit. Traditional durability testing often involves destructive methods that generate substantial waste materials. Autonomous labs implement non-destructive testing protocols and predictive maintenance algorithms that minimize material waste while maintaining rigorous quality standards. Studies indicate that advanced autonomous testing can reduce testing-related waste by approximately 45% compared to conventional approaches.

Chemical usage optimization further enhances the environmental profile of these technologies. Autonomous systems precisely control the application of protective coatings and treatments, ensuring optimal coverage with minimal excess. This precision reduces the volume of potentially hazardous chemicals required and minimizes associated disposal challenges. Data from industry implementations suggests chemical usage reductions of 25-40% are achievable through autonomous application methods.

Life cycle assessment (LCA) data demonstrates that components with enhanced durability characteristics contribute to improved environmental performance throughout their operational lifetime. Aircraft with more durable components require less frequent maintenance, reducing the environmental impact associated with maintenance operations including chemical cleaning agents, replacement parts manufacturing, and transportation logistics.

Regulatory compliance is increasingly driving adoption of these technologies. As environmental regulations become more stringent globally, aerospace manufacturers are leveraging autonomous durability solutions to meet compliance requirements while maintaining competitive advantages. The precision and documentation capabilities of autonomous systems provide robust evidence for regulatory reporting and certification processes.

Future environmental benefits may be realized through the integration of bio-based and recyclable materials into autonomous durability enhancement processes. Research indicates promising developments in sustainable protective coatings and treatments that could further reduce the environmental footprint of aerospace component manufacturing and maintenance operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!