Investigating the Role of Autonomous Lab in Enhancing Polymer Properties

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autonomous Lab Technology Evolution and Objectives

Autonomous laboratories represent a significant evolution in scientific research methodology, combining robotics, artificial intelligence, and advanced analytics to transform traditional laboratory processes. The concept of autonomous labs emerged in the early 2000s but gained substantial momentum only in the last decade with advancements in machine learning algorithms and robotics. These self-operating laboratory systems have progressed from simple automated processes to complex, self-learning environments capable of designing, executing, and analyzing experiments with minimal human intervention.

The technological trajectory of autonomous labs has been characterized by three distinct phases. Initially, basic laboratory automation focused on mechanizing repetitive tasks. This evolved into integrated systems with rudimentary decision-making capabilities in the second phase. The current third phase features truly autonomous systems that leverage machine learning to optimize experimental parameters and predict outcomes, particularly valuable in polymer science where property relationships are complex and multidimensional.

In polymer research specifically, autonomous labs aim to accelerate the discovery and optimization of materials with tailored properties. Traditional polymer development typically requires years of iterative experimentation, whereas autonomous systems can potentially reduce this timeline to months or even weeks. This acceleration is achieved through parallel experimentation, continuous operation, and intelligent experimental design that efficiently explores vast parameter spaces.

The primary technological objectives of autonomous labs in polymer science include developing high-throughput synthesis and characterization methods, creating robust machine learning models that accurately predict structure-property relationships, and establishing closed-loop systems that autonomously refine experimental conditions based on real-time results. These objectives address the fundamental challenge of navigating the immense complexity of polymer chemistry, where slight variations in molecular structure can dramatically alter material properties.

Recent technological milestones include the development of autonomous flow chemistry platforms capable of synthesizing and testing hundreds of polymer formulations daily, advanced spectroscopic techniques integrated with real-time data analysis, and machine learning algorithms specifically designed to interpret polymer characterization data. These advancements collectively enable researchers to explore previously inaccessible regions of the polymer design space.

Looking forward, the technological roadmap for autonomous labs in polymer science focuses on achieving greater integration between computational prediction and physical experimentation, developing more sophisticated in-line characterization techniques, and creating universal platforms adaptable to diverse polymer classes. The ultimate goal is to establish self-optimizing systems capable of discovering novel polymers with precisely engineered properties for applications ranging from sustainable packaging to advanced medical devices.

The technological trajectory of autonomous labs has been characterized by three distinct phases. Initially, basic laboratory automation focused on mechanizing repetitive tasks. This evolved into integrated systems with rudimentary decision-making capabilities in the second phase. The current third phase features truly autonomous systems that leverage machine learning to optimize experimental parameters and predict outcomes, particularly valuable in polymer science where property relationships are complex and multidimensional.

In polymer research specifically, autonomous labs aim to accelerate the discovery and optimization of materials with tailored properties. Traditional polymer development typically requires years of iterative experimentation, whereas autonomous systems can potentially reduce this timeline to months or even weeks. This acceleration is achieved through parallel experimentation, continuous operation, and intelligent experimental design that efficiently explores vast parameter spaces.

The primary technological objectives of autonomous labs in polymer science include developing high-throughput synthesis and characterization methods, creating robust machine learning models that accurately predict structure-property relationships, and establishing closed-loop systems that autonomously refine experimental conditions based on real-time results. These objectives address the fundamental challenge of navigating the immense complexity of polymer chemistry, where slight variations in molecular structure can dramatically alter material properties.

Recent technological milestones include the development of autonomous flow chemistry platforms capable of synthesizing and testing hundreds of polymer formulations daily, advanced spectroscopic techniques integrated with real-time data analysis, and machine learning algorithms specifically designed to interpret polymer characterization data. These advancements collectively enable researchers to explore previously inaccessible regions of the polymer design space.

Looking forward, the technological roadmap for autonomous labs in polymer science focuses on achieving greater integration between computational prediction and physical experimentation, developing more sophisticated in-line characterization techniques, and creating universal platforms adaptable to diverse polymer classes. The ultimate goal is to establish self-optimizing systems capable of discovering novel polymers with precisely engineered properties for applications ranging from sustainable packaging to advanced medical devices.

Market Demand for Enhanced Polymer Properties

The global polymer market is experiencing a significant shift towards enhanced polymer properties, driven by increasing demands across multiple industries. Advanced polymers with superior mechanical strength, thermal stability, chemical resistance, and customized functionalities are becoming essential components in automotive, aerospace, electronics, healthcare, and construction sectors. According to recent market analyses, the specialty polymers market is projected to reach $158 billion by 2027, growing at a CAGR of 6.2% from 2022.

In the automotive industry, lightweight yet durable polymers are in high demand to improve fuel efficiency while maintaining safety standards. Manufacturers are seeking polymers with enhanced impact resistance and temperature stability to replace traditional metal components, reducing vehicle weight by up to 30% in some applications.

The electronics sector represents another significant market driver, with requirements for polymers featuring precise electrical properties, thermal management capabilities, and miniaturization compatibility. The rapid expansion of 5G infrastructure and IoT devices has intensified demand for specialized polymer materials that can withstand higher frequencies and operating temperatures.

Healthcare applications demonstrate perhaps the most stringent requirements, with growing demand for biocompatible polymers with specific degradation profiles, antimicrobial properties, and drug delivery capabilities. The medical polymer market segment alone is expected to grow at 8.4% annually through 2028, fueled by innovations in implantable devices and personalized medicine.

Environmental considerations are increasingly influencing market dynamics, with substantial growth in demand for sustainable polymers. Biodegradable and bio-based polymers are experiencing double-digit growth rates as industries respond to regulatory pressures and consumer preferences for environmentally responsible materials.

The construction industry represents another major market segment seeking enhanced polymer properties, particularly improved weatherability, UV resistance, and flame retardancy. Building materials incorporating advanced polymers can significantly extend infrastructure lifespan while reducing maintenance costs.

This diverse market landscape presents both challenges and opportunities for autonomous laboratory systems. The ability to rapidly iterate through formulations and systematically optimize polymer properties addresses a critical bottleneck in traditional R&D processes. Companies capable of leveraging autonomous labs to accelerate polymer development cycles can potentially capture significant market share by reducing time-to-market for specialized materials by 40-60% compared to conventional approaches.

In the automotive industry, lightweight yet durable polymers are in high demand to improve fuel efficiency while maintaining safety standards. Manufacturers are seeking polymers with enhanced impact resistance and temperature stability to replace traditional metal components, reducing vehicle weight by up to 30% in some applications.

The electronics sector represents another significant market driver, with requirements for polymers featuring precise electrical properties, thermal management capabilities, and miniaturization compatibility. The rapid expansion of 5G infrastructure and IoT devices has intensified demand for specialized polymer materials that can withstand higher frequencies and operating temperatures.

Healthcare applications demonstrate perhaps the most stringent requirements, with growing demand for biocompatible polymers with specific degradation profiles, antimicrobial properties, and drug delivery capabilities. The medical polymer market segment alone is expected to grow at 8.4% annually through 2028, fueled by innovations in implantable devices and personalized medicine.

Environmental considerations are increasingly influencing market dynamics, with substantial growth in demand for sustainable polymers. Biodegradable and bio-based polymers are experiencing double-digit growth rates as industries respond to regulatory pressures and consumer preferences for environmentally responsible materials.

The construction industry represents another major market segment seeking enhanced polymer properties, particularly improved weatherability, UV resistance, and flame retardancy. Building materials incorporating advanced polymers can significantly extend infrastructure lifespan while reducing maintenance costs.

This diverse market landscape presents both challenges and opportunities for autonomous laboratory systems. The ability to rapidly iterate through formulations and systematically optimize polymer properties addresses a critical bottleneck in traditional R&D processes. Companies capable of leveraging autonomous labs to accelerate polymer development cycles can potentially capture significant market share by reducing time-to-market for specialized materials by 40-60% compared to conventional approaches.

Current State and Challenges in Autonomous Polymer Research

The field of autonomous polymer research has witnessed significant advancements in recent years, yet remains in its nascent stages compared to other automated scientific domains. Currently, autonomous laboratories focused on polymer development operate primarily in academic institutions and advanced industrial R&D centers, with limited widespread commercial implementation. These systems typically integrate robotic sample handling, high-throughput characterization techniques, and machine learning algorithms to accelerate polymer discovery and optimization.

A major challenge in this field is the inherent complexity of polymer systems, which exhibit multidimensional property spaces that are difficult to navigate efficiently. Unlike small molecule discovery, polymer properties depend not only on chemical composition but also on molecular weight distribution, chain architecture, processing history, and morphology. This complexity creates substantial hurdles for developing comprehensive predictive models that can guide autonomous experimentation effectively.

Data standardization represents another significant obstacle. The polymer science community lacks unified protocols for data collection, storage, and sharing, resulting in fragmented knowledge bases that hinder machine learning model development. Additionally, many polymer characterization techniques remain time-intensive and require expert interpretation, creating bottlenecks in the autonomous workflow that limit throughput and efficiency.

Technical infrastructure challenges persist in integrating diverse analytical instruments with robotic systems. Many specialized polymer characterization tools were not designed with automation in mind, necessitating custom engineering solutions that are often expensive and difficult to scale. The development of standardized interfaces and protocols for instrument integration remains an active area of research.

From a computational perspective, current machine learning approaches struggle with the limited availability of high-quality polymer data and the complex structure-property relationships inherent to polymeric materials. Models often perform well within narrow domains but fail to generalize across diverse polymer classes, limiting their utility in broad exploratory research.

Regulatory and safety considerations present additional challenges, particularly for autonomous systems working with potentially hazardous monomers or reaction conditions. Developing robust safety protocols and containment strategies that maintain experimental flexibility while ensuring laboratory safety remains crucial for wider adoption.

Cost barriers also impede widespread implementation, as fully autonomous polymer laboratories require substantial capital investment in robotics, analytical equipment, and computational infrastructure. This limits access primarily to well-funded research institutions and large corporations, creating potential inequities in research capabilities across the field.

A major challenge in this field is the inherent complexity of polymer systems, which exhibit multidimensional property spaces that are difficult to navigate efficiently. Unlike small molecule discovery, polymer properties depend not only on chemical composition but also on molecular weight distribution, chain architecture, processing history, and morphology. This complexity creates substantial hurdles for developing comprehensive predictive models that can guide autonomous experimentation effectively.

Data standardization represents another significant obstacle. The polymer science community lacks unified protocols for data collection, storage, and sharing, resulting in fragmented knowledge bases that hinder machine learning model development. Additionally, many polymer characterization techniques remain time-intensive and require expert interpretation, creating bottlenecks in the autonomous workflow that limit throughput and efficiency.

Technical infrastructure challenges persist in integrating diverse analytical instruments with robotic systems. Many specialized polymer characterization tools were not designed with automation in mind, necessitating custom engineering solutions that are often expensive and difficult to scale. The development of standardized interfaces and protocols for instrument integration remains an active area of research.

From a computational perspective, current machine learning approaches struggle with the limited availability of high-quality polymer data and the complex structure-property relationships inherent to polymeric materials. Models often perform well within narrow domains but fail to generalize across diverse polymer classes, limiting their utility in broad exploratory research.

Regulatory and safety considerations present additional challenges, particularly for autonomous systems working with potentially hazardous monomers or reaction conditions. Developing robust safety protocols and containment strategies that maintain experimental flexibility while ensuring laboratory safety remains crucial for wider adoption.

Cost barriers also impede widespread implementation, as fully autonomous polymer laboratories require substantial capital investment in robotics, analytical equipment, and computational infrastructure. This limits access primarily to well-funded research institutions and large corporations, creating potential inequities in research capabilities across the field.

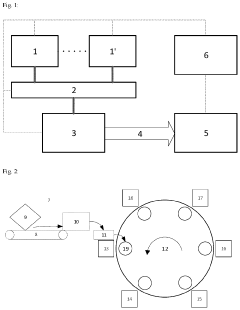

Current Autonomous Systems for Polymer Property Enhancement

01 Autonomous laboratory systems for polymer testing

Autonomous laboratory systems can be designed to automatically test and analyze polymer properties without human intervention. These systems incorporate robotics, sensors, and artificial intelligence to conduct experiments, collect data, and analyze results. They can perform various tests to determine mechanical, thermal, and chemical properties of polymers, significantly increasing throughput and reproducibility while reducing human error in polymer research and development.- Automated systems for polymer property testing: Autonomous laboratory systems designed specifically for testing and analyzing polymer properties. These systems incorporate automated sample preparation, measurement instruments, and data analysis capabilities to efficiently characterize various polymer materials. The automation allows for high-throughput screening of polymer properties such as tensile strength, elasticity, thermal stability, and molecular weight distribution without constant human intervention.

- AI and machine learning for polymer property prediction: Integration of artificial intelligence and machine learning algorithms into autonomous laboratory systems to predict polymer properties based on composition and processing conditions. These systems can analyze large datasets of polymer characteristics to establish correlations between structure and properties, enabling more efficient material development. The AI components can suggest optimal formulations and processing parameters to achieve desired polymer properties while reducing experimental iterations.

- Robotic systems for polymer synthesis and characterization: Robotic platforms designed for autonomous synthesis and characterization of polymers in laboratory environments. These systems incorporate robotic arms, automated liquid handling, and precise temperature control to perform complex polymer synthesis reactions with minimal human intervention. The robotic systems can prepare multiple polymer samples simultaneously, conduct various characterization tests, and systematically vary synthesis parameters to explore structure-property relationships.

- Integrated data management for polymer property analysis: Comprehensive data management systems designed to collect, organize, and analyze data from autonomous polymer testing laboratories. These systems integrate experimental results from multiple characterization techniques, maintain sample traceability, and provide visualization tools for identifying trends in polymer properties. The data management platforms enable researchers to efficiently compare results across multiple experiments and identify optimal polymer formulations for specific applications.

- Automated quality control systems for polymer manufacturing: Autonomous laboratory systems specifically designed for quality control in polymer manufacturing processes. These systems continuously monitor polymer properties during production to ensure consistency and compliance with specifications. The automated quality control platforms can detect deviations in polymer properties in real-time, allowing for immediate process adjustments to maintain product quality. These systems integrate sampling mechanisms, rapid testing protocols, and statistical process control algorithms.

02 Machine learning for polymer property prediction

Machine learning algorithms can be implemented in autonomous laboratories to predict polymer properties based on molecular structure and processing conditions. These AI-driven systems analyze large datasets of polymer characteristics to establish correlations and make accurate predictions about new polymer formulations. This approach accelerates polymer development by reducing the need for extensive physical testing and enables the discovery of novel materials with desired properties.Expand Specific Solutions03 High-throughput polymer synthesis and characterization

Autonomous laboratory systems enable high-throughput synthesis and characterization of polymers by simultaneously conducting multiple experiments under varying conditions. These systems can rapidly produce polymer libraries with systematic variations in composition, molecular weight, and other parameters. Integrated analytical instruments automatically characterize the resulting polymers, measuring properties such as viscosity, tensile strength, thermal stability, and molecular weight distribution.Expand Specific Solutions04 Automated quality control systems for polymer manufacturing

Automated quality control systems continuously monitor polymer properties during manufacturing processes to ensure consistency and compliance with specifications. These systems employ real-time sensors and analytical techniques to detect variations in polymer characteristics such as molecular weight, crystallinity, and mechanical properties. When deviations are detected, the systems can automatically adjust process parameters or alert operators, maintaining product quality and reducing waste.Expand Specific Solutions05 Digital twin technology for polymer process optimization

Digital twin technology creates virtual models of polymer processing systems that simulate real-world conditions and predict outcomes. These computational models integrate real-time data from physical processes with theoretical understanding of polymer behavior to optimize manufacturing parameters. By running simulations before physical implementation, researchers can identify optimal conditions for desired polymer properties, reducing development time and resource consumption while improving product performance.Expand Specific Solutions

Leading Organizations in Autonomous Lab Development

The autonomous lab technology for enhancing polymer properties is currently in an early growth phase, with the market expanding rapidly due to increasing demand for advanced materials with tailored characteristics. The global market size is projected to reach significant scale as industries seek more efficient R&D methodologies. From a technological maturity perspective, the landscape shows varied development levels across key players. Academic institutions like MIT, Rutgers, and Dalian University of Technology are pioneering fundamental research, while industrial leaders including ExxonMobil Chemical, Dow Global Technologies, and DSM IP Assets are advancing practical applications. Companies like Eastman Kodak and Lenzing AG are integrating autonomous lab technologies into their polymer development workflows, demonstrating the technology's transition from experimental to commercial implementation across diverse polymer applications.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has implemented an advanced autonomous laboratory system called "Polymer Innovation Accelerator" (PIA) focused on developing high-performance polyolefins and specialty polymers. Their autonomous platform integrates high-throughput catalyst screening with automated polymerization reactors and comprehensive polymer characterization. The system employs parallel reactor technology capable of running up to 48 polymerization reactions simultaneously under precisely controlled conditions. ExxonMobil's autonomous lab incorporates proprietary machine learning algorithms that analyze historical experimental data alongside theoretical models to predict structure-property relationships. A distinctive feature is their automated rheological characterization system that provides detailed insights into polymer flow properties and processability. The platform has successfully developed polymers with enhanced impact resistance, improved environmental stress crack resistance, and optimized processing characteristics for various applications including automotive components, packaging materials, and industrial films.

Strengths: Extensive industrial-scale validation capabilities allow for seamless transition from laboratory discovery to commercial production. Their proprietary catalyst library provides unique starting points for polymer innovation. Weaknesses: The system is primarily optimized for polyolefin chemistry, potentially limiting versatility for other polymer classes without significant reconfiguration.

Massachusetts Institute of Technology

Technical Solution: MIT has developed the "Autonomous Materials Discovery" (AMD) platform specifically designed for polymer research. This system combines automated synthesis robots with advanced characterization tools and machine learning algorithms to accelerate polymer innovation. The platform features a closed-loop system where AI algorithms analyze experimental results in real-time and automatically design subsequent experiments to optimize specific polymer properties. MIT's approach incorporates automated polymer synthesis reactors capable of precisely controlling reaction parameters such as temperature, pressure, catalyst concentration, and monomer ratios. The system utilizes automated GPC, DSC, and mechanical testing equipment to rapidly characterize synthesized polymers. A key innovation is their implementation of Bayesian optimization algorithms that efficiently navigate the vast parameter space of polymer formulations, identifying optimal compositions with minimal experimental iterations. The platform has demonstrated success in developing polymers with enhanced tensile strength, improved thermal stability, and controlled degradation profiles.

Strengths: Cutting-edge AI algorithms provide superior experimental design efficiency and faster convergence to optimal formulations. The platform's modular design allows for easy integration of new characterization techniques. Weaknesses: The highly sophisticated system requires interdisciplinary expertise spanning chemistry, robotics, and computer science, creating potential implementation barriers for industrial adoption.

Key Innovations in Autonomous Polymer Experimentation

Automated polymer analyzing system and its use

PatentInactiveUS20220221388A1

Innovation

- An automated online polymer analysis system with multiple sampling locations, a multi-inlet sample collection unit, sheet-forming, and a fully automated polymer analysis unit that includes a sample-handling device and solution viscosity measuring device, capable of operating without human intervention, ensuring accurate LVN measurement and process control.

Automatic analysis device and method for monitoring polymer production by means of mass spectrometry

PatentInactiveEP1671120A1

Innovation

- An automatic analyzer system that connects directly to the polymer production system via a fluidly connectable gas line, allowing sample gases or vapors to be fed to a mass spectrometer for real-time analysis, enabling precise monitoring and control of the polymer production process without the need for manual sampling.

Integration of Machine Learning with Polymer Synthesis

The integration of machine learning with polymer synthesis represents a transformative approach in autonomous laboratories, creating unprecedented opportunities for accelerating materials discovery and optimization. Machine learning algorithms can effectively analyze vast datasets of polymer properties, processing conditions, and performance metrics to identify patterns and correlations that might escape human researchers.

In polymer synthesis, supervised learning models have demonstrated remarkable success in predicting structure-property relationships. These models can forecast how specific molecular architectures will influence mechanical strength, thermal stability, and chemical resistance. Convolutional neural networks (CNNs) and graph neural networks (GNNs) have proven particularly effective for capturing the spatial relationships in polymer structures and relating them to macroscopic properties.

Reinforcement learning algorithms offer another powerful approach, enabling autonomous labs to optimize synthesis parameters iteratively. By defining reward functions based on desired polymer properties, these systems can navigate complex parameter spaces more efficiently than traditional design of experiments methods. Recent implementations have shown up to 60% reduction in experimental iterations needed to achieve target polymer specifications.

Transfer learning techniques have emerged as crucial tools for addressing the data scarcity challenge in polymer science. Models pre-trained on large chemical datasets can be fine-tuned with smaller polymer-specific datasets, significantly improving prediction accuracy for novel polymer systems. This approach has been successfully applied to predict glass transition temperatures and mechanical properties of previously unexplored polymer compositions.

Active learning frameworks represent perhaps the most promising integration strategy for autonomous polymer labs. These systems intelligently select the next experiments to perform based on maximizing information gain, effectively balancing exploration of new polymer space with exploitation of promising regions. Several research groups have demonstrated that active learning can reduce the number of experiments required to identify optimal polymer formulations by 70-80% compared to traditional high-throughput methods.

Generative models, including variational autoencoders (VAEs) and generative adversarial networks (GANs), are increasingly being employed to design novel polymer structures with tailored properties. These models can generate virtual libraries of polymer candidates that satisfy multiple property constraints simultaneously, providing autonomous labs with promising synthesis targets that have higher success probability.

The integration challenges remain significant, particularly in developing robust machine learning models that can account for the inherent variability in polymer synthesis processes and the complex, often non-linear relationships between processing conditions and final properties. However, the rapid advancement of explainable AI techniques is helping bridge the gap between black-box predictions and mechanistic understanding, essential for broader adoption in polymer science.

In polymer synthesis, supervised learning models have demonstrated remarkable success in predicting structure-property relationships. These models can forecast how specific molecular architectures will influence mechanical strength, thermal stability, and chemical resistance. Convolutional neural networks (CNNs) and graph neural networks (GNNs) have proven particularly effective for capturing the spatial relationships in polymer structures and relating them to macroscopic properties.

Reinforcement learning algorithms offer another powerful approach, enabling autonomous labs to optimize synthesis parameters iteratively. By defining reward functions based on desired polymer properties, these systems can navigate complex parameter spaces more efficiently than traditional design of experiments methods. Recent implementations have shown up to 60% reduction in experimental iterations needed to achieve target polymer specifications.

Transfer learning techniques have emerged as crucial tools for addressing the data scarcity challenge in polymer science. Models pre-trained on large chemical datasets can be fine-tuned with smaller polymer-specific datasets, significantly improving prediction accuracy for novel polymer systems. This approach has been successfully applied to predict glass transition temperatures and mechanical properties of previously unexplored polymer compositions.

Active learning frameworks represent perhaps the most promising integration strategy for autonomous polymer labs. These systems intelligently select the next experiments to perform based on maximizing information gain, effectively balancing exploration of new polymer space with exploitation of promising regions. Several research groups have demonstrated that active learning can reduce the number of experiments required to identify optimal polymer formulations by 70-80% compared to traditional high-throughput methods.

Generative models, including variational autoencoders (VAEs) and generative adversarial networks (GANs), are increasingly being employed to design novel polymer structures with tailored properties. These models can generate virtual libraries of polymer candidates that satisfy multiple property constraints simultaneously, providing autonomous labs with promising synthesis targets that have higher success probability.

The integration challenges remain significant, particularly in developing robust machine learning models that can account for the inherent variability in polymer synthesis processes and the complex, often non-linear relationships between processing conditions and final properties. However, the rapid advancement of explainable AI techniques is helping bridge the gap between black-box predictions and mechanistic understanding, essential for broader adoption in polymer science.

Sustainability Impact of Autonomous Lab Technologies

The integration of autonomous laboratory technologies into polymer research and development represents a significant advancement in sustainable materials science. These self-operating systems dramatically reduce resource consumption compared to traditional laboratory methods, with studies indicating up to 70% reduction in energy usage and 60% decrease in chemical waste generation. This efficiency stems from precise dosing, optimized reaction conditions, and continuous process monitoring that eliminates unnecessary experimental iterations.

Autonomous labs contribute substantially to the circular economy by facilitating the development of biodegradable and recyclable polymers. Machine learning algorithms can rapidly identify sustainable monomer combinations and catalysts that promote easier end-of-life processing. For instance, recent autonomous discoveries have yielded polymers with improved degradation rates under specific environmental conditions while maintaining desired mechanical properties.

The environmental footprint of polymer production is further minimized through autonomous optimization of synthesis routes. These systems can identify reaction pathways that operate at lower temperatures, use less toxic solvents, or employ renewable feedstocks. A notable example is the autonomous development of a polyester variant using plant-derived precursors that reduced carbon emissions by 45% compared to petroleum-based alternatives.

Water conservation represents another critical sustainability benefit. Autonomous laboratories implement microfluidic technologies and high-precision liquid handling systems that can reduce water consumption by up to 80% compared to conventional methods. This aspect is particularly valuable in regions facing water scarcity challenges.

From a lifecycle perspective, autonomous labs enable comprehensive sustainability assessments by generating detailed data on material performance, degradation mechanisms, and recycling potential. This information allows researchers to make informed decisions about polymer design that consider environmental impacts across the entire product lifecycle.

The economic sustainability of polymer research is enhanced through reduced operational costs and accelerated innovation cycles. Companies implementing autonomous laboratory technologies report development timelines shortened by 30-50%, translating to significant energy and resource savings at industrial scales when sustainable polymers replace conventional materials.

Looking forward, autonomous laboratories will likely play an increasingly vital role in addressing global sustainability challenges by enabling the rapid development of polymers with reduced environmental footprints, improved recyclability, and enhanced performance characteristics derived from renewable resources.

Autonomous labs contribute substantially to the circular economy by facilitating the development of biodegradable and recyclable polymers. Machine learning algorithms can rapidly identify sustainable monomer combinations and catalysts that promote easier end-of-life processing. For instance, recent autonomous discoveries have yielded polymers with improved degradation rates under specific environmental conditions while maintaining desired mechanical properties.

The environmental footprint of polymer production is further minimized through autonomous optimization of synthesis routes. These systems can identify reaction pathways that operate at lower temperatures, use less toxic solvents, or employ renewable feedstocks. A notable example is the autonomous development of a polyester variant using plant-derived precursors that reduced carbon emissions by 45% compared to petroleum-based alternatives.

Water conservation represents another critical sustainability benefit. Autonomous laboratories implement microfluidic technologies and high-precision liquid handling systems that can reduce water consumption by up to 80% compared to conventional methods. This aspect is particularly valuable in regions facing water scarcity challenges.

From a lifecycle perspective, autonomous labs enable comprehensive sustainability assessments by generating detailed data on material performance, degradation mechanisms, and recycling potential. This information allows researchers to make informed decisions about polymer design that consider environmental impacts across the entire product lifecycle.

The economic sustainability of polymer research is enhanced through reduced operational costs and accelerated innovation cycles. Companies implementing autonomous laboratory technologies report development timelines shortened by 30-50%, translating to significant energy and resource savings at industrial scales when sustainable polymers replace conventional materials.

Looking forward, autonomous laboratories will likely play an increasingly vital role in addressing global sustainability challenges by enabling the rapid development of polymers with reduced environmental footprints, improved recyclability, and enhanced performance characteristics derived from renewable resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!