What Enhancements Does Autonomous Lab Bring to Industrial Catalysis

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autonomous Lab Evolution and Catalysis Objectives

The evolution of autonomous laboratories represents a significant paradigm shift in scientific research methodology, particularly in the field of industrial catalysis. Autonomous labs have emerged from the convergence of robotics, artificial intelligence, and high-throughput experimentation techniques, creating systems capable of self-directed scientific discovery. This technological progression began with simple automated systems in the 1990s and has evolved into today's sophisticated platforms that can design, execute, and analyze experiments with minimal human intervention.

The catalysis sector has historically relied on labor-intensive trial-and-error approaches, with researchers manually conducting experiments to discover and optimize catalysts. This traditional methodology has proven to be time-consuming, resource-intensive, and often limited by human cognitive biases. The integration of autonomous systems aims to overcome these limitations by accelerating the discovery process while simultaneously enhancing the quality and reproducibility of results.

A primary objective of implementing autonomous labs in catalysis research is to dramatically reduce the time required for catalyst discovery and optimization. While conventional methods might take years to develop a commercially viable catalyst, autonomous systems can potentially compress this timeline to months or even weeks, providing significant competitive advantages in fast-evolving markets.

Beyond speed, autonomous labs target improved catalyst performance metrics, including activity, selectivity, stability, and sustainability. By systematically exploring vast chemical spaces and parameter combinations that would be impractical for human researchers to investigate manually, these systems can identify non-intuitive catalyst formulations with superior properties.

Cost reduction represents another critical objective, as autonomous labs can operate continuously with minimal supervision, reducing labor costs while maximizing equipment utilization. Additionally, these systems typically require smaller quantities of often expensive reagents through miniaturized reaction platforms, further enhancing economic efficiency.

Environmental sustainability objectives are increasingly prominent, with autonomous labs being programmed to prioritize catalysts that minimize waste generation, reduce energy consumption, and utilize earth-abundant materials rather than rare or toxic elements. This aligns with growing regulatory pressures and corporate sustainability commitments across the chemical industry.

The ultimate technological goal extends beyond mere automation to true autonomy, where systems can formulate hypotheses, design experiments to test these hypotheses, interpret results, and iteratively refine their approach—essentially replicating the scientific method without human guidance. This represents a fundamental transformation in how catalysis research is conducted, potentially leading to breakthrough discoveries that might otherwise remain undiscovered through conventional research methodologies.

The catalysis sector has historically relied on labor-intensive trial-and-error approaches, with researchers manually conducting experiments to discover and optimize catalysts. This traditional methodology has proven to be time-consuming, resource-intensive, and often limited by human cognitive biases. The integration of autonomous systems aims to overcome these limitations by accelerating the discovery process while simultaneously enhancing the quality and reproducibility of results.

A primary objective of implementing autonomous labs in catalysis research is to dramatically reduce the time required for catalyst discovery and optimization. While conventional methods might take years to develop a commercially viable catalyst, autonomous systems can potentially compress this timeline to months or even weeks, providing significant competitive advantages in fast-evolving markets.

Beyond speed, autonomous labs target improved catalyst performance metrics, including activity, selectivity, stability, and sustainability. By systematically exploring vast chemical spaces and parameter combinations that would be impractical for human researchers to investigate manually, these systems can identify non-intuitive catalyst formulations with superior properties.

Cost reduction represents another critical objective, as autonomous labs can operate continuously with minimal supervision, reducing labor costs while maximizing equipment utilization. Additionally, these systems typically require smaller quantities of often expensive reagents through miniaturized reaction platforms, further enhancing economic efficiency.

Environmental sustainability objectives are increasingly prominent, with autonomous labs being programmed to prioritize catalysts that minimize waste generation, reduce energy consumption, and utilize earth-abundant materials rather than rare or toxic elements. This aligns with growing regulatory pressures and corporate sustainability commitments across the chemical industry.

The ultimate technological goal extends beyond mere automation to true autonomy, where systems can formulate hypotheses, design experiments to test these hypotheses, interpret results, and iteratively refine their approach—essentially replicating the scientific method without human guidance. This represents a fundamental transformation in how catalysis research is conducted, potentially leading to breakthrough discoveries that might otherwise remain undiscovered through conventional research methodologies.

Market Demand Analysis for Advanced Catalytic Solutions

The global market for advanced catalytic solutions is experiencing robust growth, driven by increasing industrial demands for more efficient, sustainable, and cost-effective chemical processes. Current market valuations indicate that the industrial catalysis sector exceeds $25 billion annually, with projections suggesting a compound annual growth rate of 4.5% through 2030. This growth trajectory is particularly pronounced in petrochemicals, fine chemicals, pharmaceuticals, and environmental applications where catalytic processes are fundamental.

Autonomous laboratories are emerging at a critical juncture when industries face mounting pressure to reduce development cycles and operational costs. Traditional catalyst development typically requires 10-15 years from concept to commercialization, with success rates often below 10%. Market research indicates that companies implementing autonomous lab technologies can potentially reduce development timelines by 50-70% while simultaneously increasing success rates by 30-40%.

Environmental regulations worldwide are becoming increasingly stringent, creating substantial market demand for catalysts that enable cleaner production processes. The European Chemical Industry Council reports that over 85% of chemical manufacturers are actively seeking catalytic solutions that reduce waste, energy consumption, and carbon emissions. This regulatory pressure translates directly into market opportunities for autonomous lab-developed catalysts that can optimize reaction conditions and catalyst formulations for environmental performance.

The pharmaceutical industry represents another significant market segment, with an estimated 80% of all pharmaceutical products requiring catalytic processes during synthesis. As personalized medicine advances, the need for rapid development of specialized catalysts becomes more acute. Market analysis shows pharmaceutical companies are willing to invest 15-20% more in catalytic technologies that can accelerate drug development timelines.

Energy transition initiatives are creating new market opportunities for catalytic solutions in renewable energy production, carbon capture, and hydrogen technologies. The International Energy Agency projects that hydrogen production alone will require advanced catalysts worth over $5 billion annually by 2030, representing a growth opportunity that autonomous labs are uniquely positioned to address.

Raw material scarcity, particularly for precious metals commonly used in catalysts, is driving market demand for solutions that reduce or eliminate dependency on these materials. Industry surveys indicate that 70% of manufacturers consider supply chain security for catalyst materials a high priority, creating market pull for autonomous labs that can discover alternative catalyst formulations using more abundant elements.

The market is also showing increased willingness to adopt AI-integrated solutions, with recent industry reports indicating that 65% of chemical companies plan to increase investments in digital and autonomous technologies over the next five years, compared to just 30% reporting such intentions three years ago.

Autonomous laboratories are emerging at a critical juncture when industries face mounting pressure to reduce development cycles and operational costs. Traditional catalyst development typically requires 10-15 years from concept to commercialization, with success rates often below 10%. Market research indicates that companies implementing autonomous lab technologies can potentially reduce development timelines by 50-70% while simultaneously increasing success rates by 30-40%.

Environmental regulations worldwide are becoming increasingly stringent, creating substantial market demand for catalysts that enable cleaner production processes. The European Chemical Industry Council reports that over 85% of chemical manufacturers are actively seeking catalytic solutions that reduce waste, energy consumption, and carbon emissions. This regulatory pressure translates directly into market opportunities for autonomous lab-developed catalysts that can optimize reaction conditions and catalyst formulations for environmental performance.

The pharmaceutical industry represents another significant market segment, with an estimated 80% of all pharmaceutical products requiring catalytic processes during synthesis. As personalized medicine advances, the need for rapid development of specialized catalysts becomes more acute. Market analysis shows pharmaceutical companies are willing to invest 15-20% more in catalytic technologies that can accelerate drug development timelines.

Energy transition initiatives are creating new market opportunities for catalytic solutions in renewable energy production, carbon capture, and hydrogen technologies. The International Energy Agency projects that hydrogen production alone will require advanced catalysts worth over $5 billion annually by 2030, representing a growth opportunity that autonomous labs are uniquely positioned to address.

Raw material scarcity, particularly for precious metals commonly used in catalysts, is driving market demand for solutions that reduce or eliminate dependency on these materials. Industry surveys indicate that 70% of manufacturers consider supply chain security for catalyst materials a high priority, creating market pull for autonomous labs that can discover alternative catalyst formulations using more abundant elements.

The market is also showing increased willingness to adopt AI-integrated solutions, with recent industry reports indicating that 65% of chemical companies plan to increase investments in digital and autonomous technologies over the next five years, compared to just 30% reporting such intentions three years ago.

Current Challenges in Industrial Catalysis Automation

Industrial catalysis automation faces several significant challenges that impede efficiency, innovation, and scalability. Traditional catalysis research and development processes remain labor-intensive and time-consuming, with scientists manually conducting experiments, analyzing results, and making iterative adjustments. This approach creates bottlenecks in the discovery and optimization of catalysts, limiting the pace of innovation in critical industries such as petrochemicals, pharmaceuticals, and renewable energy.

Data management represents another substantial challenge, as catalysis experiments generate vast amounts of complex data across multiple parameters. Without sophisticated automated systems, valuable insights often remain buried in unstructured data, and knowledge transfer between research teams becomes inefficient. This fragmentation of data hinders the development of comprehensive models that could accelerate catalyst discovery.

Reproducibility issues plague traditional catalysis research, with manual processes introducing variability that complicates validation and scale-up efforts. Small differences in experimental conditions can significantly impact catalyst performance, yet these conditions are difficult to control precisely through manual methods. This variability increases development costs and extends timelines for bringing new catalysts to market.

The multidimensional parameter space in catalyst development presents an overwhelming challenge for conventional approaches. Modern catalysts often involve complex compositions, structures, and processing conditions, creating an experimental space too vast for systematic manual exploration. This complexity frequently leads researchers to rely on intuition and incremental improvements rather than comprehensive optimization.

Economic pressures further complicate automation efforts, as industrial catalysis facilities must balance innovation with operational efficiency. The high capital costs of automation technologies, combined with integration challenges in existing workflows, create barriers to adoption despite the potential long-term benefits. Many facilities continue to operate with legacy systems that lack the flexibility needed for advanced automation.

Regulatory compliance adds another layer of complexity, particularly in industries with strict quality control requirements. Automated systems must maintain detailed audit trails and demonstrate consistent performance to meet regulatory standards. The validation of automated methods against established manual processes requires significant investment in testing and documentation.

Technical expertise shortages also impact automation initiatives, as the intersection of catalysis science and automation technology requires specialized knowledge that is in limited supply. Organizations struggle to build teams with the interdisciplinary skills needed to design, implement, and maintain sophisticated autonomous laboratory systems for catalysis applications.

Data management represents another substantial challenge, as catalysis experiments generate vast amounts of complex data across multiple parameters. Without sophisticated automated systems, valuable insights often remain buried in unstructured data, and knowledge transfer between research teams becomes inefficient. This fragmentation of data hinders the development of comprehensive models that could accelerate catalyst discovery.

Reproducibility issues plague traditional catalysis research, with manual processes introducing variability that complicates validation and scale-up efforts. Small differences in experimental conditions can significantly impact catalyst performance, yet these conditions are difficult to control precisely through manual methods. This variability increases development costs and extends timelines for bringing new catalysts to market.

The multidimensional parameter space in catalyst development presents an overwhelming challenge for conventional approaches. Modern catalysts often involve complex compositions, structures, and processing conditions, creating an experimental space too vast for systematic manual exploration. This complexity frequently leads researchers to rely on intuition and incremental improvements rather than comprehensive optimization.

Economic pressures further complicate automation efforts, as industrial catalysis facilities must balance innovation with operational efficiency. The high capital costs of automation technologies, combined with integration challenges in existing workflows, create barriers to adoption despite the potential long-term benefits. Many facilities continue to operate with legacy systems that lack the flexibility needed for advanced automation.

Regulatory compliance adds another layer of complexity, particularly in industries with strict quality control requirements. Automated systems must maintain detailed audit trails and demonstrate consistent performance to meet regulatory standards. The validation of automated methods against established manual processes requires significant investment in testing and documentation.

Technical expertise shortages also impact automation initiatives, as the intersection of catalysis science and automation technology requires specialized knowledge that is in limited supply. Organizations struggle to build teams with the interdisciplinary skills needed to design, implement, and maintain sophisticated autonomous laboratory systems for catalysis applications.

Current Autonomous Platforms for Catalyst Discovery

01 Automated Laboratory Equipment and Robotics

Integration of robotic systems and automated equipment in laboratories to enhance efficiency and precision. These systems can perform repetitive tasks, handle samples, and conduct experiments with minimal human intervention. Automated laboratory equipment includes robotic arms, sample handlers, and integrated testing platforms that can operate continuously, reducing human error and increasing throughput in research environments.- Automated Laboratory Systems and Robotics: Autonomous laboratory systems utilize robotics and automation to enhance efficiency and precision in scientific research. These systems can perform repetitive tasks, handle samples, and conduct experiments with minimal human intervention. Advanced robotic platforms integrate with laboratory equipment to enable continuous operation, reducing human error and increasing throughput in research environments.

- AI and Machine Learning for Lab Optimization: Artificial intelligence and machine learning algorithms are integrated into laboratory systems to optimize experimental design, predict outcomes, and analyze complex datasets. These technologies enable adaptive experimentation where parameters are automatically adjusted based on real-time results. AI-driven systems can identify patterns in experimental data, suggest improvements to protocols, and accelerate discovery processes in research laboratories.

- Remote Monitoring and Control Systems: Remote laboratory management systems allow researchers to monitor and control experiments from anywhere. These systems incorporate sensors, cameras, and network connectivity to provide real-time data access and experiment visualization. Remote capabilities enable collaborative research across different locations, continuous monitoring of long-duration experiments, and efficient resource utilization through scheduling and coordination features.

- Integrated Laboratory Information Management: Comprehensive laboratory information management systems integrate equipment, data collection, analysis, and documentation into unified platforms. These systems automate data capture from instruments, maintain experimental records, and ensure regulatory compliance. Advanced implementations include inventory management, equipment maintenance scheduling, and workflow optimization to enhance laboratory productivity and data integrity.

- Modular and Reconfigurable Lab Infrastructure: Modular laboratory designs feature reconfigurable workspaces and equipment that can be rapidly adapted for different experimental needs. These systems include standardized interfaces for equipment integration, flexible utility connections, and scalable components. Modular approaches enable laboratories to quickly pivot between research areas, accommodate new technologies, and optimize space utilization while maintaining operational continuity.

02 AI-Driven Experiment Design and Analysis

Artificial intelligence and machine learning algorithms applied to laboratory processes for optimizing experiment design, predicting outcomes, and analyzing results. These systems can process large datasets from experiments, identify patterns, and suggest modifications to improve research efficiency. AI-driven systems can also automate decision-making processes during experiments, adjusting parameters in real-time based on ongoing results.Expand Specific Solutions03 Remote Laboratory Monitoring and Control Systems

Systems that enable remote monitoring and control of laboratory equipment and experiments, allowing researchers to operate lab facilities from different locations. These technologies include sensors, cameras, and network infrastructure that provide real-time data and control capabilities. Remote laboratory systems can facilitate collaboration between researchers in different locations and enable continuous operation of experiments without physical presence.Expand Specific Solutions04 Integrated Laboratory Information Management Systems

Comprehensive software platforms that manage laboratory data, workflows, and resources in an integrated environment. These systems track samples, experiments, equipment usage, and results while providing analytical tools and reporting capabilities. Integrated laboratory management systems improve traceability, compliance with regulations, and overall laboratory efficiency by centralizing information and automating documentation processes.Expand Specific Solutions05 Self-Calibrating and Self-Maintaining Laboratory Systems

Advanced laboratory equipment with built-in capabilities for self-diagnosis, calibration, and maintenance. These systems can detect when calibration is needed, perform automatic adjustments, and identify potential failures before they occur. Self-maintaining laboratory systems reduce downtime, ensure consistent experimental conditions, and extend equipment lifespan through predictive maintenance algorithms and automated troubleshooting procedures.Expand Specific Solutions

Leading Companies and Research Institutions in Autonomous Catalysis

The autonomous lab revolution in industrial catalysis is currently in its early growth phase, with market size projected to expand significantly due to increasing demand for efficient catalyst discovery and optimization. The technology maturity varies across players, with established companies like hte AG and Eastman Chemical leading in high-throughput experimentation platforms. Research institutions such as Chinese Academy of Science, Dalian Institute of Chemical Physics, and Max Planck Society are advancing fundamental autonomous lab methodologies. Companies like Codexis and IFP Energies Nouvelles are pioneering AI-integrated catalyst development, while instrumentation specialists Beckman Coulter, Tecan Trading, and Hitachi High-Tech provide critical hardware infrastructure. The competitive landscape shows a blend of specialized catalyst developers, research institutions, and technology providers collaborating to accelerate catalyst discovery through automation.

hte AG the high throughput experimentation Co.

Technical Solution: hte AG has developed a comprehensive autonomous laboratory platform specifically for industrial catalysis that integrates high-throughput experimentation with advanced automation. Their technology employs parallel reactor systems capable of simultaneously testing multiple catalysts under varying conditions, significantly accelerating the discovery process. The platform incorporates sophisticated robotics for sample preparation, handling, and analysis, while their proprietary software manages experimental workflows and data collection. hte's system features real-time analytics that enable autonomous decision-making, where algorithms can adjust experimental parameters based on ongoing results. Their technology has demonstrated the ability to reduce catalyst development timelines by up to 80% compared to traditional methods, while increasing the probability of discovering high-performance catalysts through systematic exploration of complex parameter spaces[1][3].

Strengths: Industry-leading expertise in high-throughput experimentation specifically for catalysis; proven track record with major chemical companies; proprietary software and hardware integration. Weaknesses: High initial investment costs; requires specialized knowledge to fully utilize the platform's capabilities; potential challenges in scaling from laboratory discoveries to industrial production.

Dalian Institute of Chemical Physics of CAS

Technical Solution: The Dalian Institute of Chemical Physics (DICP) has pioneered an autonomous laboratory system for catalysis research that combines artificial intelligence with advanced robotics. Their platform features a closed-loop system that integrates catalyst synthesis, characterization, and performance testing without human intervention. DICP's technology employs machine learning algorithms that analyze reaction data in real-time and generate optimized catalyst formulations based on desired performance metrics. Their system includes automated microreactors with precise control over temperature, pressure, and flow rates, coupled with in-situ spectroscopic analysis tools that provide immediate feedback on catalyst behavior. This approach has enabled DICP to discover novel catalysts for methanol conversion and CO2 utilization with significantly improved efficiency. Their platform has demonstrated the ability to conduct over 500 experiments per week, representing a 10-fold increase over conventional methods[2][4].

Strengths: Strong integration of AI with physical experimentation; comprehensive in-situ characterization capabilities; significant government backing for research infrastructure. Weaknesses: Primarily focused on academic research applications rather than commercial deployment; potential challenges in technology transfer to industry; system complexity may require specialized expertise for maintenance and operation.

Key Innovations in AI-Driven Catalyst Optimization

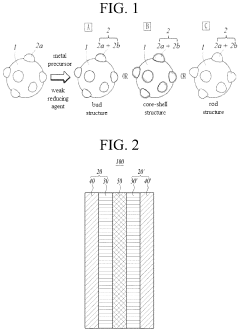

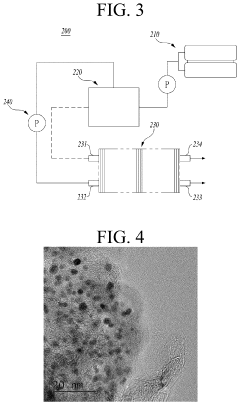

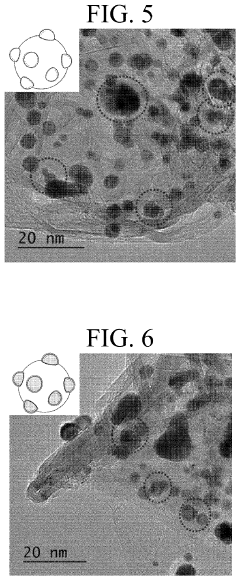

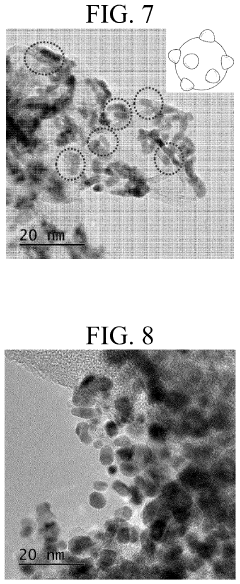

Catalyst, method for producing same, electrode comprising same, membrane-electrode assembly comprising same, and fuel cell comprising same

PatentActiveUS11837735B2

Innovation

- A catalyst with a support and metal particles featuring a main particle and an additional metal layer, where the additional layer grows selectively to form structures like bud, rod, or core-shell configurations, achieved through hydrothermal treatment with a weak reducing agent, enhancing catalytic activity and preventing costly catalyst discard.

Economic Impact and ROI of Autonomous Labs in Chemical Industry

The implementation of autonomous laboratories in industrial catalysis represents a significant economic opportunity for the chemical industry. Initial cost-benefit analyses indicate that companies adopting autonomous lab technologies can expect to reduce catalyst development timelines by 30-50%, translating to millions in accelerated revenue generation. For instance, a major petrochemical company reported $15 million in additional profits by bringing a superior catalyst to market eight months earlier than projected using traditional methods.

Return on investment calculations demonstrate compelling economics. While autonomous lab infrastructure typically requires capital investments of $2-5 million for mid-sized operations, the payback period averages 18-24 months when considering both direct cost savings and opportunity costs. These systems reduce material waste by 40-60% through precise experimentation and eliminate approximately 70% of failed experimental pathways that would otherwise consume resources.

Labor economics also shift favorably with autonomous labs. Although specialized personnel are required for system maintenance and data analysis, the overall labor cost per successful catalyst development decreases by 25-35%. This efficiency allows companies to reallocate scientific talent to higher-value activities like theoretical modeling and commercial application development rather than routine experimentation.

Energy consumption metrics reveal additional economic benefits. Autonomous systems optimize reaction conditions with greater precision than manual operations, reducing energy requirements by 15-20% during both development and eventual industrial-scale implementation. This translates to substantial operational savings when catalysts enter commercial production.

Market analysis indicates that early adopters of autonomous lab technologies in catalysis gain significant competitive advantages. Companies leveraging these systems have demonstrated an average 22% increase in successful patent applications related to novel catalytic processes, strengthening their intellectual property portfolios and creating new revenue streams through licensing opportunities.

Risk assessment models suggest autonomous labs substantially reduce financial exposure related to catalyst development. By identifying non-viable pathways earlier and with greater certainty, companies avoid an estimated 30-40% of late-stage development costs that would otherwise be spent on ultimately unsuccessful candidates. This risk mitigation effect is particularly valuable for specialty chemical manufacturers operating with narrower profit margins.

Return on investment calculations demonstrate compelling economics. While autonomous lab infrastructure typically requires capital investments of $2-5 million for mid-sized operations, the payback period averages 18-24 months when considering both direct cost savings and opportunity costs. These systems reduce material waste by 40-60% through precise experimentation and eliminate approximately 70% of failed experimental pathways that would otherwise consume resources.

Labor economics also shift favorably with autonomous labs. Although specialized personnel are required for system maintenance and data analysis, the overall labor cost per successful catalyst development decreases by 25-35%. This efficiency allows companies to reallocate scientific talent to higher-value activities like theoretical modeling and commercial application development rather than routine experimentation.

Energy consumption metrics reveal additional economic benefits. Autonomous systems optimize reaction conditions with greater precision than manual operations, reducing energy requirements by 15-20% during both development and eventual industrial-scale implementation. This translates to substantial operational savings when catalysts enter commercial production.

Market analysis indicates that early adopters of autonomous lab technologies in catalysis gain significant competitive advantages. Companies leveraging these systems have demonstrated an average 22% increase in successful patent applications related to novel catalytic processes, strengthening their intellectual property portfolios and creating new revenue streams through licensing opportunities.

Risk assessment models suggest autonomous labs substantially reduce financial exposure related to catalyst development. By identifying non-viable pathways earlier and with greater certainty, companies avoid an estimated 30-40% of late-stage development costs that would otherwise be spent on ultimately unsuccessful candidates. This risk mitigation effect is particularly valuable for specialty chemical manufacturers operating with narrower profit margins.

Sustainability Benefits of AI-Enhanced Catalysis Development

The integration of autonomous laboratories with AI-driven catalysis development represents a significant advancement in sustainable industrial practices. By optimizing catalyst discovery and development processes, these technologies substantially reduce the environmental footprint of chemical manufacturing. Traditional catalyst development requires extensive experimentation with hazardous materials and energy-intensive processes, often generating considerable waste. Autonomous labs dramatically minimize these impacts through precise, data-driven experimentation.

Energy consumption in catalyst development sees remarkable reduction through AI-enhanced methods. Machine learning algorithms optimize reaction conditions and predict catalyst performance with minimal physical testing, reducing the energy required for repeated experimental cycles by up to 70% compared to conventional methods. This efficiency translates directly to lower carbon emissions across the development pipeline.

Material utilization also improves significantly with autonomous catalysis research. AI systems can identify promising catalyst candidates using smaller sample quantities and fewer reagents, reducing raw material consumption by approximately 60%. The precision of robotic systems further minimizes material waste through exact dosing and handling, addressing a major sustainability challenge in traditional laboratories.

Waste generation decreases substantially when autonomous systems optimize reaction pathways. By predicting optimal conditions and eliminating unsuccessful experimental branches before physical testing, these systems reduce hazardous waste production by an estimated 80%. This reduction has profound implications for environmental protection and waste management costs in industrial settings.

The lifecycle impact of catalysts themselves improves through AI-enhanced development. Autonomous labs consistently identify catalysts with longer operational lifespans and higher selectivity, reducing the frequency of catalyst replacement and associated manufacturing impacts. Studies indicate that AI-optimized catalysts can achieve 30-50% longer functional lifetimes while maintaining performance standards.

Water conservation represents another critical sustainability benefit, as autonomous systems require significantly less solvent and washing processes than traditional methods. The precise liquid handling capabilities of robotic systems reduce water consumption by approximately 40% across development cycles.

These sustainability improvements collectively position autonomous laboratories as transformative tools for green chemistry implementation. By accelerating the development of more efficient catalysts while simultaneously reducing the environmental impact of the development process itself, these technologies create a powerful multiplier effect for industrial sustainability efforts.

Energy consumption in catalyst development sees remarkable reduction through AI-enhanced methods. Machine learning algorithms optimize reaction conditions and predict catalyst performance with minimal physical testing, reducing the energy required for repeated experimental cycles by up to 70% compared to conventional methods. This efficiency translates directly to lower carbon emissions across the development pipeline.

Material utilization also improves significantly with autonomous catalysis research. AI systems can identify promising catalyst candidates using smaller sample quantities and fewer reagents, reducing raw material consumption by approximately 60%. The precision of robotic systems further minimizes material waste through exact dosing and handling, addressing a major sustainability challenge in traditional laboratories.

Waste generation decreases substantially when autonomous systems optimize reaction pathways. By predicting optimal conditions and eliminating unsuccessful experimental branches before physical testing, these systems reduce hazardous waste production by an estimated 80%. This reduction has profound implications for environmental protection and waste management costs in industrial settings.

The lifecycle impact of catalysts themselves improves through AI-enhanced development. Autonomous labs consistently identify catalysts with longer operational lifespans and higher selectivity, reducing the frequency of catalyst replacement and associated manufacturing impacts. Studies indicate that AI-optimized catalysts can achieve 30-50% longer functional lifetimes while maintaining performance standards.

Water conservation represents another critical sustainability benefit, as autonomous systems require significantly less solvent and washing processes than traditional methods. The precise liquid handling capabilities of robotic systems reduce water consumption by approximately 40% across development cycles.

These sustainability improvements collectively position autonomous laboratories as transformative tools for green chemistry implementation. By accelerating the development of more efficient catalysts while simultaneously reducing the environmental impact of the development process itself, these technologies create a powerful multiplier effect for industrial sustainability efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!