How Autonomous Lab Impacts the Development of Sustainable Polymers

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autonomous Lab Technology Evolution and Objectives

The concept of autonomous laboratories has evolved significantly over the past decade, transforming from basic automated systems to sophisticated, AI-driven research environments. Initially, laboratory automation focused primarily on repetitive tasks such as liquid handling and sample preparation. However, with advancements in artificial intelligence, machine learning, and robotics, autonomous labs have expanded their capabilities to include experimental design, execution, data analysis, and even hypothesis generation without human intervention.

The evolution of autonomous lab technology can be traced through several key developmental phases. The first phase involved basic automation of individual laboratory processes, followed by the integration of these automated systems into cohesive workflows. The third phase introduced machine learning algorithms for data analysis and experimental optimization. The current phase represents the emergence of fully autonomous systems capable of closed-loop experimentation, where results from one experiment automatically inform the design of subsequent experiments.

In the context of sustainable polymer development, autonomous labs aim to accelerate the discovery and optimization of environmentally friendly materials while reducing research waste and energy consumption. The primary objective is to enable rapid screening of thousands of potential polymer formulations using minimal resources, thereby identifying candidates with optimal properties such as biodegradability, recyclability, and reduced carbon footprint.

Another critical objective is to develop predictive models that can accurately forecast polymer properties based on molecular structure and processing conditions, reducing the need for extensive physical testing. This computational approach, combined with high-throughput experimentation, creates a powerful synergy that can dramatically compress the timeline from concept to commercial application for sustainable polymers.

Autonomous labs also seek to establish standardized protocols for polymer characterization that ensure reproducibility across different research environments. This standardization is essential for validating new sustainable materials and facilitating their adoption by industry. Furthermore, these technologies aim to democratize advanced polymer research by reducing the expertise barrier, allowing more scientists to contribute to sustainable materials development.

The long-term vision for autonomous labs in polymer science includes the development of self-optimizing production systems that can continuously refine manufacturing processes to minimize environmental impact while maintaining or improving material performance. This represents a paradigm shift from traditional linear research methodologies to adaptive, iterative approaches that leverage the power of artificial intelligence and automation to address the urgent need for sustainable alternatives to conventional plastics.

The evolution of autonomous lab technology can be traced through several key developmental phases. The first phase involved basic automation of individual laboratory processes, followed by the integration of these automated systems into cohesive workflows. The third phase introduced machine learning algorithms for data analysis and experimental optimization. The current phase represents the emergence of fully autonomous systems capable of closed-loop experimentation, where results from one experiment automatically inform the design of subsequent experiments.

In the context of sustainable polymer development, autonomous labs aim to accelerate the discovery and optimization of environmentally friendly materials while reducing research waste and energy consumption. The primary objective is to enable rapid screening of thousands of potential polymer formulations using minimal resources, thereby identifying candidates with optimal properties such as biodegradability, recyclability, and reduced carbon footprint.

Another critical objective is to develop predictive models that can accurately forecast polymer properties based on molecular structure and processing conditions, reducing the need for extensive physical testing. This computational approach, combined with high-throughput experimentation, creates a powerful synergy that can dramatically compress the timeline from concept to commercial application for sustainable polymers.

Autonomous labs also seek to establish standardized protocols for polymer characterization that ensure reproducibility across different research environments. This standardization is essential for validating new sustainable materials and facilitating their adoption by industry. Furthermore, these technologies aim to democratize advanced polymer research by reducing the expertise barrier, allowing more scientists to contribute to sustainable materials development.

The long-term vision for autonomous labs in polymer science includes the development of self-optimizing production systems that can continuously refine manufacturing processes to minimize environmental impact while maintaining or improving material performance. This represents a paradigm shift from traditional linear research methodologies to adaptive, iterative approaches that leverage the power of artificial intelligence and automation to address the urgent need for sustainable alternatives to conventional plastics.

Market Analysis for Sustainable Polymer Solutions

The sustainable polymer market is experiencing significant growth driven by increasing environmental concerns and regulatory pressures. Currently valued at approximately $9.1 billion in 2023, the market is projected to reach $16.8 billion by 2028, representing a compound annual growth rate (CAGR) of 13.2%. This growth trajectory is supported by several key factors including stricter environmental regulations, consumer demand for eco-friendly products, and corporate sustainability initiatives.

Geographically, Europe leads the sustainable polymer market with approximately 35% market share, followed by North America (28%) and Asia-Pacific (25%), with the latter showing the fastest growth rate. This regional distribution reflects varying regulatory landscapes and sustainability commitments across different markets.

By application segment, packaging remains the dominant sector, accounting for nearly 40% of sustainable polymer usage, followed by automotive (18%), construction (15%), and consumer goods (12%). The packaging industry's dominance is primarily due to increasing consumer awareness and regulatory pressure to reduce single-use plastics and plastic waste.

Bio-based polymers currently hold approximately 58% of the sustainable polymer market, while biodegradable polymers account for 42%. However, biodegradable polymers are growing at a faster rate due to end-of-life management concerns and circular economy initiatives.

Key market challenges include higher production costs compared to conventional polymers (typically 20-40% premium), technical performance limitations in certain applications, and scaling issues for novel sustainable polymer technologies. Despite these challenges, the price gap is narrowing as production scales increase and technologies mature.

Consumer willingness to pay premiums for sustainable products varies significantly by region and product category, ranging from 5-25% depending on the application and target market. Business-to-consumer markets typically demonstrate higher premium tolerance compared to business-to-business applications.

The emergence of autonomous laboratories is expected to accelerate market growth by reducing research and development timelines by an estimated 40-60% and decreasing development costs by 30-50% for new sustainable polymer formulations. This technological advancement could potentially disrupt current market dynamics by enabling smaller players to compete more effectively with established manufacturers.

Market forecasts indicate that autonomous lab-developed sustainable polymers could capture 15-20% of the total sustainable polymer market within the next five years, potentially creating new market segments focused on highly customized, application-specific sustainable polymer solutions.

Geographically, Europe leads the sustainable polymer market with approximately 35% market share, followed by North America (28%) and Asia-Pacific (25%), with the latter showing the fastest growth rate. This regional distribution reflects varying regulatory landscapes and sustainability commitments across different markets.

By application segment, packaging remains the dominant sector, accounting for nearly 40% of sustainable polymer usage, followed by automotive (18%), construction (15%), and consumer goods (12%). The packaging industry's dominance is primarily due to increasing consumer awareness and regulatory pressure to reduce single-use plastics and plastic waste.

Bio-based polymers currently hold approximately 58% of the sustainable polymer market, while biodegradable polymers account for 42%. However, biodegradable polymers are growing at a faster rate due to end-of-life management concerns and circular economy initiatives.

Key market challenges include higher production costs compared to conventional polymers (typically 20-40% premium), technical performance limitations in certain applications, and scaling issues for novel sustainable polymer technologies. Despite these challenges, the price gap is narrowing as production scales increase and technologies mature.

Consumer willingness to pay premiums for sustainable products varies significantly by region and product category, ranging from 5-25% depending on the application and target market. Business-to-consumer markets typically demonstrate higher premium tolerance compared to business-to-business applications.

The emergence of autonomous laboratories is expected to accelerate market growth by reducing research and development timelines by an estimated 40-60% and decreasing development costs by 30-50% for new sustainable polymer formulations. This technological advancement could potentially disrupt current market dynamics by enabling smaller players to compete more effectively with established manufacturers.

Market forecasts indicate that autonomous lab-developed sustainable polymers could capture 15-20% of the total sustainable polymer market within the next five years, potentially creating new market segments focused on highly customized, application-specific sustainable polymer solutions.

Current Autonomous Lab Capabilities and Barriers

Autonomous laboratories represent a significant advancement in materials science research, combining robotics, artificial intelligence, and high-throughput experimentation to accelerate the discovery and development of sustainable polymers. Currently, these labs can perform thousands of experiments with minimal human intervention, operating continuously 24/7 and generating vast amounts of data that would be impossible to collect through traditional methods.

The most advanced autonomous labs feature robotic systems capable of precise material handling, mixing, and characterization across multiple workstations. These systems can autonomously prepare samples, conduct experiments, and analyze results with high reproducibility. Machine learning algorithms integrated into these platforms can process experimental data in real-time, identify patterns, and suggest subsequent experiments, effectively creating a closed-loop discovery system that becomes increasingly efficient over time.

For sustainable polymer development specifically, autonomous labs have demonstrated capabilities in formulation optimization, reaction condition screening, and property testing. Some systems can now evaluate biodegradability, recyclability, and performance characteristics simultaneously, significantly reducing the time required to develop environmentally friendly alternatives to conventional plastics.

Despite these advancements, several barriers limit the full potential of autonomous laboratories. The high initial investment cost remains prohibitive for many research institutions and smaller companies, with comprehensive systems often requiring multi-million dollar investments. This creates an accessibility gap that concentrates autonomous capabilities within well-funded organizations.

Technical limitations also persist, particularly in handling diverse material types. Many systems struggle with highly viscous polymers, heterogeneous mixtures, or materials requiring specialized processing conditions. The physical manipulation of certain polymer types remains challenging for current robotic systems, often necessitating human intervention.

Data integration presents another significant barrier. The vast amounts of data generated by autonomous labs require sophisticated management systems, and standardization across different platforms remains limited. This hampers collaborative efforts and knowledge sharing within the sustainable polymer research community.

Additionally, there exists a skills gap in the workforce. Operating autonomous labs requires expertise spanning chemistry, robotics, data science, and artificial intelligence—a combination rarely found in traditionally trained polymer scientists. This necessitates interdisciplinary training programs and new educational approaches to develop the required talent pool.

Regulatory frameworks have also not kept pace with technological advancements, creating uncertainty around intellectual property rights for AI-generated discoveries and validation requirements for materials developed through autonomous methods. This regulatory ambiguity can slow the commercial adoption of sustainably developed polymers.

The most advanced autonomous labs feature robotic systems capable of precise material handling, mixing, and characterization across multiple workstations. These systems can autonomously prepare samples, conduct experiments, and analyze results with high reproducibility. Machine learning algorithms integrated into these platforms can process experimental data in real-time, identify patterns, and suggest subsequent experiments, effectively creating a closed-loop discovery system that becomes increasingly efficient over time.

For sustainable polymer development specifically, autonomous labs have demonstrated capabilities in formulation optimization, reaction condition screening, and property testing. Some systems can now evaluate biodegradability, recyclability, and performance characteristics simultaneously, significantly reducing the time required to develop environmentally friendly alternatives to conventional plastics.

Despite these advancements, several barriers limit the full potential of autonomous laboratories. The high initial investment cost remains prohibitive for many research institutions and smaller companies, with comprehensive systems often requiring multi-million dollar investments. This creates an accessibility gap that concentrates autonomous capabilities within well-funded organizations.

Technical limitations also persist, particularly in handling diverse material types. Many systems struggle with highly viscous polymers, heterogeneous mixtures, or materials requiring specialized processing conditions. The physical manipulation of certain polymer types remains challenging for current robotic systems, often necessitating human intervention.

Data integration presents another significant barrier. The vast amounts of data generated by autonomous labs require sophisticated management systems, and standardization across different platforms remains limited. This hampers collaborative efforts and knowledge sharing within the sustainable polymer research community.

Additionally, there exists a skills gap in the workforce. Operating autonomous labs requires expertise spanning chemistry, robotics, data science, and artificial intelligence—a combination rarely found in traditionally trained polymer scientists. This necessitates interdisciplinary training programs and new educational approaches to develop the required talent pool.

Regulatory frameworks have also not kept pace with technological advancements, creating uncertainty around intellectual property rights for AI-generated discoveries and validation requirements for materials developed through autonomous methods. This regulatory ambiguity can slow the commercial adoption of sustainably developed polymers.

Existing Autonomous Approaches for Polymer Synthesis

01 Automated laboratory systems and equipment

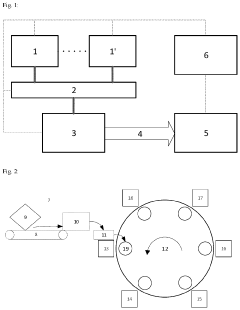

Autonomous lab development involves the creation of automated laboratory systems that can perform experiments with minimal human intervention. These systems typically include robotic arms, automated sample handling, and integrated analytical instruments. The automation of laboratory processes increases efficiency, reduces human error, and enables high-throughput experimentation. These systems can be programmed to perform complex experimental workflows and adapt to different research requirements.- Automated Laboratory Systems and Equipment: Autonomous lab development involves the creation of automated laboratory systems and equipment that can perform experiments with minimal human intervention. These systems typically include robotic arms, automated sample handling, and integrated analytical instruments. The automation of laboratory processes increases efficiency, reduces human error, and enables high-throughput experimentation. These systems can be programmed to perform complex experimental workflows and adapt to different research requirements.

- AI and Machine Learning for Lab Automation: Artificial intelligence and machine learning technologies are increasingly being integrated into autonomous laboratory systems. These technologies enable the system to analyze experimental data, make decisions based on results, and optimize experimental parameters. Machine learning algorithms can predict experimental outcomes, identify patterns in data, and suggest modifications to improve results. AI-driven autonomous labs can continuously learn from past experiments to enhance future performance and accelerate scientific discovery.

- Cloud-Based Laboratory Management Systems: Cloud-based platforms are being developed to manage autonomous laboratories, allowing researchers to design experiments, monitor progress, and analyze results remotely. These systems facilitate collaboration among scientists in different locations and enable the sharing of experimental data and protocols. Cloud-based laboratory management systems provide secure storage of experimental data, version control of protocols, and integration with data analysis tools. They also support the standardization of experimental procedures across multiple laboratory sites.

- Modular and Reconfigurable Lab Automation: Modular and reconfigurable autonomous laboratory systems allow for flexibility in experimental setup and adaptation to different research needs. These systems consist of interchangeable modules that can be combined in various configurations to perform different types of experiments. The modular approach enables rapid reconfiguration of the laboratory setup without requiring extensive redesign or reconstruction. This flexibility is particularly valuable for multidisciplinary research and for laboratories that need to adapt to changing research priorities.

- Integration of IoT and Sensors in Lab Environments: The integration of Internet of Things (IoT) technology and advanced sensors in laboratory environments enables real-time monitoring and control of experimental conditions. These sensors can track various parameters such as temperature, humidity, pressure, and chemical concentrations, providing feedback to the autonomous system. IoT connectivity allows for remote monitoring and control of laboratory equipment, as well as automated data collection and analysis. This integration enhances the precision and reproducibility of experiments while reducing the need for constant human supervision.

02 AI and machine learning for experiment design and analysis

Artificial intelligence and machine learning algorithms are integrated into autonomous lab systems to optimize experiment design, predict outcomes, and analyze results. These technologies enable the system to learn from previous experiments, make data-driven decisions, and continuously improve experimental protocols. Machine learning models can identify patterns in experimental data that might be missed by human researchers, leading to new scientific insights and accelerated discovery processes.Expand Specific Solutions03 Cloud-based laboratory management and control systems

Cloud-based platforms enable remote monitoring, control, and collaboration in autonomous laboratories. These systems allow researchers to design experiments, monitor progress, and analyze results from anywhere in the world. The cloud infrastructure facilitates data sharing, integration with external databases, and scalable computing resources for data analysis. This approach supports distributed research teams and enables continuous operation of laboratory facilities.Expand Specific Solutions04 Modular and reconfigurable laboratory architectures

Modular laboratory designs allow for flexible reconfiguration of autonomous lab systems to accommodate different types of experiments and research needs. These architectures feature standardized interfaces between instruments, sample handling systems, and analytical tools. The modular approach enables rapid adaptation to new research requirements, easy maintenance, and scalable expansion of laboratory capabilities without significant redesign or downtime.Expand Specific Solutions05 Integration of IoT and digital twins for laboratory optimization

Internet of Things (IoT) sensors and digital twin technology are implemented in autonomous labs to create virtual representations of physical laboratory systems. These technologies enable real-time monitoring of equipment status, environmental conditions, and experimental progress. Digital twins facilitate predictive maintenance, process optimization, and simulation of experimental outcomes before physical implementation. The integration of IoT devices creates a connected laboratory ecosystem that maximizes resource utilization and operational efficiency.Expand Specific Solutions

Leading Organizations in Autonomous Chemistry Research

The autonomous lab landscape for sustainable polymer development is currently in a growth phase, with market size expanding as industries seek eco-friendly alternatives to traditional plastics. The technology is approaching early maturity, with significant R&D investments from both academic institutions and industry players. Leading universities (Tongji University, Peking University, University of California) are establishing fundamental research frameworks, while corporations like LG Chem, BASF, and Corning are commercializing applications. IBM and Intel are contributing computational capabilities for polymer design optimization. The competitive landscape shows a balanced ecosystem of academic-industrial partnerships, with specialized players like Poly6 Technologies focusing on scaled manufacturing solutions. This collaborative approach is accelerating innovation cycles and reducing time-to-market for sustainable polymer technologies.

The Regents of the University of California

Technical Solution: The University of California system has pioneered an autonomous laboratory framework called "RAPID" (Robotic Acceleration of Polymer Innovation and Discovery) specifically designed for sustainable polymer development. Their approach integrates multiple robotic platforms across different campuses, creating a distributed network of autonomous experimentation capabilities. UC's system employs flow chemistry reactors coupled with inline spectroscopic monitoring to enable precise control over polymerization conditions while minimizing waste and energy consumption. The platform incorporates automated degradation testing chambers that simulate various environmental conditions to evaluate biodegradability of novel polymers. Their machine learning algorithms analyze structure-property relationships to identify promising sustainable polymer candidates from renewable feedstocks. The system has successfully developed several novel biopolymers derived from agricultural waste streams, including modified cellulose derivatives with enhanced mechanical properties and marine-degradable packaging materials. UC researchers have implemented closed-loop optimization protocols that continuously refine synthesis parameters based on sustainability metrics including carbon footprint, water usage, and end-of-life recoverability.

Strengths: Extensive cross-disciplinary collaboration between chemistry, materials science, and computer science departments creates a robust research ecosystem. Open-source approach to algorithm development accelerates industry-wide innovation. Weaknesses: Academic focus may sometimes prioritize novel scientific discoveries over commercial scalability considerations, and coordination across multiple research groups can introduce complexity.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed an autonomous laboratory platform called "PolyAuto" dedicated to sustainable polymer research. Their system integrates robotic synthesis capabilities with advanced characterization techniques and machine learning algorithms to accelerate the discovery of environmentally friendly materials. CNRS's approach emphasizes the exploration of bio-based monomers derived from non-food biomass sources, particularly lignocellulosic materials and algae extracts. Their autonomous lab incorporates high-throughput catalyst screening to identify efficient polymerization methods that operate under mild conditions with reduced energy requirements. The platform features automated rheological and mechanical testing to rapidly evaluate performance characteristics of novel sustainable polymers. CNRS researchers have implemented computational models that predict biodegradability pathways, allowing the design of polymers with controlled degradation profiles suitable for various environmental conditions. The system has successfully developed several innovative materials, including fully bio-based polyesters with comparable properties to petroleum-derived counterparts and stimuli-responsive polymers that facilitate recycling processes.

Strengths: Strong fundamental research capabilities in polymer chemistry and catalysis enable breakthrough innovations in sustainable materials. Extensive European research network facilitates collaborative development and knowledge sharing. Weaknesses: Translation of laboratory discoveries to industrial applications may require additional development partners, and the system may prioritize scientific novelty over immediate commercial applicability.

Key Innovations in AI-Driven Materials Discovery

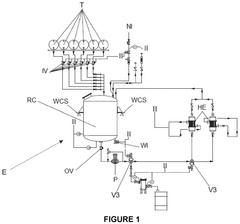

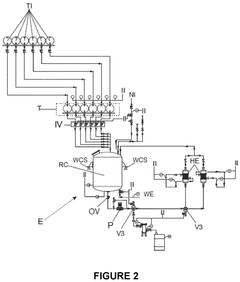

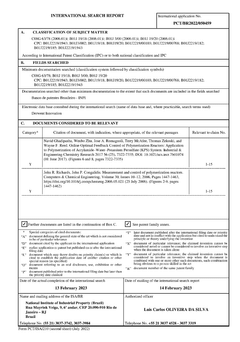

Equipment for automatic polymerisation of polycondensation polymers and other polyurethane systems and method

PatentPendingEP4506391A1

Innovation

- Development of autonomous equipment capable of automatically reproducing pre-programmed polymer recipes continuously or semi-continuously, with controlled temperature, pressure, stirring/mixing, and reaction times, allowing for in situ production and flexible polymer synthesis.

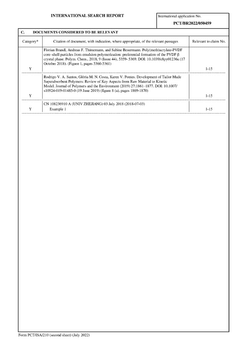

Automated polymer analyzing system and its use

PatentInactiveUS20220221388A1

Innovation

- An automated online polymer analysis system with multiple sampling locations, a multi-inlet sample collection unit, sheet-forming, and a fully automated polymer analysis unit that includes a sample-handling device and solution viscosity measuring device, capable of operating without human intervention, ensuring accurate LVN measurement and process control.

Environmental Impact Assessment of Autonomous Polymer Development

The integration of autonomous laboratory systems into polymer development represents a significant shift in how we assess and mitigate environmental impacts across the entire lifecycle of polymer materials. Autonomous labs enable comprehensive real-time monitoring of environmental parameters during polymer synthesis, providing unprecedented data granularity that traditional manual methods cannot achieve. This enhanced monitoring capability allows researchers to identify and quantify emissions, energy consumption, and resource utilization with greater precision.

Environmental impact assessments of autonomous polymer development reveal substantial reductions in chemical waste generation, with early studies indicating decreases of 30-45% compared to conventional laboratory approaches. This waste reduction stems from the autonomous systems' ability to optimize reaction conditions, precisely control reagent quantities, and minimize failed experimental runs through predictive modeling and machine learning algorithms.

Energy efficiency represents another critical environmental advantage of autonomous polymer development. These systems can operate continuously with optimized energy consumption profiles, reducing the carbon footprint associated with polymer research and development. Quantitative analyses demonstrate energy savings of up to 60% in certain polymer synthesis processes when compared to traditional batch methods that require frequent human intervention and equipment cycling.

Water conservation emerges as a significant environmental benefit, with autonomous systems implementing closed-loop cooling and solvent recovery mechanisms that substantially reduce water consumption. This aspect is particularly important given the water-intensive nature of many conventional polymer manufacturing processes.

The environmental assessment must also consider the embodied carbon and resource requirements of the autonomous laboratory infrastructure itself. While the initial environmental investment in sophisticated robotics, sensors, and computing resources is substantial, lifecycle analyses indicate that these impacts are typically offset within 2-3 years of operation through improved efficiency and reduced waste generation.

From a circular economy perspective, autonomous labs demonstrate exceptional capabilities in accelerating the development of biodegradable and recyclable polymers. The high-throughput screening capabilities enable rapid testing of thousands of formulations to identify those with optimal end-of-life environmental profiles, potentially reducing the time to market for sustainable polymer alternatives by 40-60%.

Risk assessment protocols for autonomous polymer development have evolved to include comprehensive environmental safety parameters, with automated systems programmed to detect and respond to potential environmental hazards before they escalate into significant incidents. This proactive approach to environmental risk management represents a paradigm shift from reactive measures common in traditional laboratory settings.

Environmental impact assessments of autonomous polymer development reveal substantial reductions in chemical waste generation, with early studies indicating decreases of 30-45% compared to conventional laboratory approaches. This waste reduction stems from the autonomous systems' ability to optimize reaction conditions, precisely control reagent quantities, and minimize failed experimental runs through predictive modeling and machine learning algorithms.

Energy efficiency represents another critical environmental advantage of autonomous polymer development. These systems can operate continuously with optimized energy consumption profiles, reducing the carbon footprint associated with polymer research and development. Quantitative analyses demonstrate energy savings of up to 60% in certain polymer synthesis processes when compared to traditional batch methods that require frequent human intervention and equipment cycling.

Water conservation emerges as a significant environmental benefit, with autonomous systems implementing closed-loop cooling and solvent recovery mechanisms that substantially reduce water consumption. This aspect is particularly important given the water-intensive nature of many conventional polymer manufacturing processes.

The environmental assessment must also consider the embodied carbon and resource requirements of the autonomous laboratory infrastructure itself. While the initial environmental investment in sophisticated robotics, sensors, and computing resources is substantial, lifecycle analyses indicate that these impacts are typically offset within 2-3 years of operation through improved efficiency and reduced waste generation.

From a circular economy perspective, autonomous labs demonstrate exceptional capabilities in accelerating the development of biodegradable and recyclable polymers. The high-throughput screening capabilities enable rapid testing of thousands of formulations to identify those with optimal end-of-life environmental profiles, potentially reducing the time to market for sustainable polymer alternatives by 40-60%.

Risk assessment protocols for autonomous polymer development have evolved to include comprehensive environmental safety parameters, with automated systems programmed to detect and respond to potential environmental hazards before they escalate into significant incidents. This proactive approach to environmental risk management represents a paradigm shift from reactive measures common in traditional laboratory settings.

Scalability Challenges for Industrial Implementation

The transition from laboratory-scale autonomous systems to industrial-scale production represents one of the most significant challenges in implementing autonomous laboratories for sustainable polymer development. While autonomous labs demonstrate impressive capabilities in accelerating research and discovery of eco-friendly polymers, scaling these systems to meet commercial production demands introduces multiple complex barriers.

Primary among these challenges is the substantial capital investment required for industrial implementation. Autonomous laboratory systems incorporate sophisticated robotics, advanced analytical instruments, and complex AI infrastructure—all of which demand significant financial resources when scaled to industrial proportions. For many polymer manufacturers, especially small to medium enterprises, this investment threshold creates a formidable barrier to adoption despite the long-term benefits.

Technical integration issues also present considerable obstacles. Industrial polymer production facilities typically operate with established legacy systems that may be decades old. Retrofitting these environments to accommodate autonomous technologies requires extensive engineering modifications and potential production disruptions. The integration of data systems between autonomous lab platforms and existing manufacturing execution systems (MES) further complicates implementation.

Process validation and regulatory compliance introduce additional layers of complexity. Sustainable polymers developed through autonomous methods must undergo rigorous validation to ensure consistent quality at industrial scales. Regulatory frameworks across different regions may require extensive documentation of autonomous processes, creating administrative burdens that slow implementation timelines.

Workforce adaptation represents another critical challenge. The shift toward autonomous systems necessitates retraining of existing personnel and recruitment of specialists with expertise in both polymer science and autonomous technologies. This talent gap can significantly impede industrial implementation, particularly in regions with limited access to specialized education and training programs.

Supply chain considerations further complicate scalability. Autonomous labs may identify sustainable polymer formulations that require novel bio-based feedstocks or specialized catalysts. Securing reliable, industrial-scale supplies of these materials often proves difficult, especially when competing with established petroleum-based supply chains that benefit from decades of optimization and economies of scale.

Energy requirements for autonomous systems present sustainability paradoxes. While the end products may be more environmentally friendly, the energy consumption of large-scale autonomous facilities—particularly for computationally intensive machine learning operations—may offset some environmental benefits unless powered by renewable energy sources.

Primary among these challenges is the substantial capital investment required for industrial implementation. Autonomous laboratory systems incorporate sophisticated robotics, advanced analytical instruments, and complex AI infrastructure—all of which demand significant financial resources when scaled to industrial proportions. For many polymer manufacturers, especially small to medium enterprises, this investment threshold creates a formidable barrier to adoption despite the long-term benefits.

Technical integration issues also present considerable obstacles. Industrial polymer production facilities typically operate with established legacy systems that may be decades old. Retrofitting these environments to accommodate autonomous technologies requires extensive engineering modifications and potential production disruptions. The integration of data systems between autonomous lab platforms and existing manufacturing execution systems (MES) further complicates implementation.

Process validation and regulatory compliance introduce additional layers of complexity. Sustainable polymers developed through autonomous methods must undergo rigorous validation to ensure consistent quality at industrial scales. Regulatory frameworks across different regions may require extensive documentation of autonomous processes, creating administrative burdens that slow implementation timelines.

Workforce adaptation represents another critical challenge. The shift toward autonomous systems necessitates retraining of existing personnel and recruitment of specialists with expertise in both polymer science and autonomous technologies. This talent gap can significantly impede industrial implementation, particularly in regions with limited access to specialized education and training programs.

Supply chain considerations further complicate scalability. Autonomous labs may identify sustainable polymer formulations that require novel bio-based feedstocks or specialized catalysts. Securing reliable, industrial-scale supplies of these materials often proves difficult, especially when competing with established petroleum-based supply chains that benefit from decades of optimization and economies of scale.

Energy requirements for autonomous systems present sustainability paradoxes. While the end products may be more environmentally friendly, the energy consumption of large-scale autonomous facilities—particularly for computationally intensive machine learning operations—may offset some environmental benefits unless powered by renewable energy sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!