Autonomous Lab Impact on Electrode Dynamics in Advanced Battery Systems

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Electrode Technology Background and Objectives

Battery electrode technology has evolved significantly over the past several decades, transitioning from simple metal-based systems to complex composite structures with engineered properties. The journey began with lead-acid batteries in the 19th century, progressing through nickel-cadmium and nickel-metal hydride systems, before reaching the lithium-ion revolution in the 1990s. Today's advanced battery systems incorporate sophisticated electrode designs that balance multiple competing factors including energy density, power capability, cycle life, and safety.

The emergence of autonomous laboratory systems represents a paradigm shift in battery electrode research and development. These AI-driven platforms can systematically explore vast parameter spaces, conduct experiments with precision beyond human capabilities, and generate insights through advanced data analytics. The integration of robotics, machine learning, and high-throughput characterization techniques enables unprecedented acceleration in the discovery and optimization of electrode materials and architectures.

Current electrode technology faces several critical challenges that autonomous labs are uniquely positioned to address. These include understanding complex degradation mechanisms, optimizing electrode microstructure for fast charging without compromising longevity, and developing sustainable alternatives to critical materials. The dynamic nature of electrodes during cycling—involving phase transformations, interfacial reactions, and mechanical deformations—creates a multidimensional problem space that traditional experimental approaches struggle to fully characterize.

The primary objective of autonomous lab implementation in electrode research is to establish predictive frameworks that connect synthesis parameters, processing conditions, and resulting electrode properties to battery performance metrics. This requires developing closed-loop systems capable of designing experiments, executing them with precision, analyzing results, and generating new hypotheses without human intervention. The ultimate goal is to compress development timelines from years to months or even weeks.

Another key objective is to elucidate the fundamental relationships between electrode dynamics and battery performance across multiple time and length scales. This includes understanding how nanoscale phenomena propagate to macroscale behavior, how transient processes influence long-term stability, and how stochastic variations affect reproducibility. Autonomous labs offer the throughput and consistency needed to build statistically robust models of these complex relationships.

Looking forward, the technology trajectory aims to develop "self-optimizing" manufacturing processes informed by autonomous lab discoveries. This involves creating digital twins of electrode manufacturing that can predict how variations in raw materials and processing conditions will affect final product performance, enabling real-time adjustments to maintain optimal quality. The convergence of autonomous labs with advanced manufacturing represents the next frontier in battery technology evolution.

The emergence of autonomous laboratory systems represents a paradigm shift in battery electrode research and development. These AI-driven platforms can systematically explore vast parameter spaces, conduct experiments with precision beyond human capabilities, and generate insights through advanced data analytics. The integration of robotics, machine learning, and high-throughput characterization techniques enables unprecedented acceleration in the discovery and optimization of electrode materials and architectures.

Current electrode technology faces several critical challenges that autonomous labs are uniquely positioned to address. These include understanding complex degradation mechanisms, optimizing electrode microstructure for fast charging without compromising longevity, and developing sustainable alternatives to critical materials. The dynamic nature of electrodes during cycling—involving phase transformations, interfacial reactions, and mechanical deformations—creates a multidimensional problem space that traditional experimental approaches struggle to fully characterize.

The primary objective of autonomous lab implementation in electrode research is to establish predictive frameworks that connect synthesis parameters, processing conditions, and resulting electrode properties to battery performance metrics. This requires developing closed-loop systems capable of designing experiments, executing them with precision, analyzing results, and generating new hypotheses without human intervention. The ultimate goal is to compress development timelines from years to months or even weeks.

Another key objective is to elucidate the fundamental relationships between electrode dynamics and battery performance across multiple time and length scales. This includes understanding how nanoscale phenomena propagate to macroscale behavior, how transient processes influence long-term stability, and how stochastic variations affect reproducibility. Autonomous labs offer the throughput and consistency needed to build statistically robust models of these complex relationships.

Looking forward, the technology trajectory aims to develop "self-optimizing" manufacturing processes informed by autonomous lab discoveries. This involves creating digital twins of electrode manufacturing that can predict how variations in raw materials and processing conditions will affect final product performance, enabling real-time adjustments to maintain optimal quality. The convergence of autonomous labs with advanced manufacturing represents the next frontier in battery technology evolution.

Market Analysis for Advanced Battery Systems

The global advanced battery market is experiencing unprecedented growth, driven by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current market valuations place the advanced battery sector at approximately $112 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 18.7% through 2030, potentially reaching $380 billion by decade's end. This remarkable trajectory is primarily fueled by governmental policies promoting clean energy adoption, substantial reductions in battery production costs, and increasing consumer demand for sustainable technology solutions.

Within this expanding landscape, the electrode dynamics segment represents a critical component, accounting for roughly 35% of research and development investments in advanced battery systems. The optimization of electrode performance directly impacts energy density, charging speeds, cycle life, and overall battery efficiency—all key factors in consumer adoption and commercial viability.

Market demand is increasingly focused on batteries that deliver higher energy density while maintaining safety standards. Industry surveys indicate that automotive manufacturers are specifically seeking batteries with energy densities exceeding 350 Wh/kg, representing a 40% improvement over current commercial standards. This demand is driving significant investment in electrode material research and manufacturing process optimization.

The integration of autonomous laboratory systems into battery research represents an emerging market segment with substantial growth potential. Early adopters of autonomous lab technologies for electrode development report accelerated discovery timelines by factors of 5-10x compared to traditional research methodologies. This acceleration directly translates to competitive advantages in bringing next-generation battery technologies to market.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity, with China, South Korea, and Japan collectively controlling 78% of global advanced battery production. However, significant shifts are occurring as both North America and Europe invest heavily in domestic battery supply chains, with announced investments exceeding $50 billion across these regions in the past two years alone.

Consumer preferences are evolving toward batteries with faster charging capabilities, with market research indicating 80% of potential EV buyers consider charging time a critical purchase factor. This demand directly influences electrode development priorities, as electrode dynamics fundamentally determine charging performance limitations.

The autonomous lab segment specifically addressing electrode dynamics is projected to grow at 25.3% CAGR through 2028, outpacing the broader battery market. This accelerated growth reflects the industry recognition that electrode optimization represents one of the most promising pathways to achieving next-generation battery performance metrics required by emerging applications in aviation, grid storage, and advanced mobility solutions.

Within this expanding landscape, the electrode dynamics segment represents a critical component, accounting for roughly 35% of research and development investments in advanced battery systems. The optimization of electrode performance directly impacts energy density, charging speeds, cycle life, and overall battery efficiency—all key factors in consumer adoption and commercial viability.

Market demand is increasingly focused on batteries that deliver higher energy density while maintaining safety standards. Industry surveys indicate that automotive manufacturers are specifically seeking batteries with energy densities exceeding 350 Wh/kg, representing a 40% improvement over current commercial standards. This demand is driving significant investment in electrode material research and manufacturing process optimization.

The integration of autonomous laboratory systems into battery research represents an emerging market segment with substantial growth potential. Early adopters of autonomous lab technologies for electrode development report accelerated discovery timelines by factors of 5-10x compared to traditional research methodologies. This acceleration directly translates to competitive advantages in bringing next-generation battery technologies to market.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity, with China, South Korea, and Japan collectively controlling 78% of global advanced battery production. However, significant shifts are occurring as both North America and Europe invest heavily in domestic battery supply chains, with announced investments exceeding $50 billion across these regions in the past two years alone.

Consumer preferences are evolving toward batteries with faster charging capabilities, with market research indicating 80% of potential EV buyers consider charging time a critical purchase factor. This demand directly influences electrode development priorities, as electrode dynamics fundamentally determine charging performance limitations.

The autonomous lab segment specifically addressing electrode dynamics is projected to grow at 25.3% CAGR through 2028, outpacing the broader battery market. This accelerated growth reflects the industry recognition that electrode optimization represents one of the most promising pathways to achieving next-generation battery performance metrics required by emerging applications in aviation, grid storage, and advanced mobility solutions.

Current Challenges in Electrode Dynamics Research

Despite significant advancements in battery technology, electrode dynamics research faces several persistent challenges that impede further progress in developing high-performance advanced battery systems. One primary obstacle is the complexity of multi-scale phenomena occurring simultaneously within electrodes. Researchers struggle to accurately model and predict interactions spanning from atomic-level processes to macroscopic behaviors, particularly during fast charging and extreme operating conditions.

The limited temporal and spatial resolution of current characterization techniques presents another significant barrier. While techniques like X-ray diffraction and electron microscopy provide valuable insights, they often cannot capture real-time electrode dynamics at the necessary resolution to fully understand degradation mechanisms and performance limitations. This creates a substantial gap between theoretical models and experimental validation.

Data management and integration challenges further complicate electrode dynamics research. The vast amounts of heterogeneous data generated from multiple characterization techniques and computational models are difficult to harmonize into cohesive insights. Traditional manual analysis methods cannot efficiently process this data volume, leading to potential missed correlations and incomplete understanding of electrode behavior.

Material interface complexities represent another frontier challenge. The solid-electrolyte interphase (SEI) formation and evolution critically impact battery performance and longevity, yet remain poorly understood due to their dynamic nature and sensitivity to environmental conditions. Researchers struggle to develop standardized protocols for studying these interfaces across different battery chemistries and operating conditions.

Manufacturing variability introduces additional complexity to electrode dynamics research. Small variations in electrode fabrication processes can significantly impact performance characteristics, making it difficult to isolate intrinsic material properties from manufacturing artifacts. This variability complicates efforts to translate laboratory findings to industrial-scale production.

The lack of standardized testing protocols and metrics for electrode dynamics evaluation hinders comparative analysis across research groups. Different testing conditions and reporting methods make it challenging to benchmark new materials and designs against existing technologies, slowing the pace of innovation and technology transfer.

Finally, the interdisciplinary nature of electrode dynamics research requires expertise spanning electrochemistry, materials science, physics, and data science. The shortage of researchers with cross-disciplinary training creates bottlenecks in addressing complex electrode dynamics challenges, particularly as battery systems become increasingly sophisticated and application-specific.

The limited temporal and spatial resolution of current characterization techniques presents another significant barrier. While techniques like X-ray diffraction and electron microscopy provide valuable insights, they often cannot capture real-time electrode dynamics at the necessary resolution to fully understand degradation mechanisms and performance limitations. This creates a substantial gap between theoretical models and experimental validation.

Data management and integration challenges further complicate electrode dynamics research. The vast amounts of heterogeneous data generated from multiple characterization techniques and computational models are difficult to harmonize into cohesive insights. Traditional manual analysis methods cannot efficiently process this data volume, leading to potential missed correlations and incomplete understanding of electrode behavior.

Material interface complexities represent another frontier challenge. The solid-electrolyte interphase (SEI) formation and evolution critically impact battery performance and longevity, yet remain poorly understood due to their dynamic nature and sensitivity to environmental conditions. Researchers struggle to develop standardized protocols for studying these interfaces across different battery chemistries and operating conditions.

Manufacturing variability introduces additional complexity to electrode dynamics research. Small variations in electrode fabrication processes can significantly impact performance characteristics, making it difficult to isolate intrinsic material properties from manufacturing artifacts. This variability complicates efforts to translate laboratory findings to industrial-scale production.

The lack of standardized testing protocols and metrics for electrode dynamics evaluation hinders comparative analysis across research groups. Different testing conditions and reporting methods make it challenging to benchmark new materials and designs against existing technologies, slowing the pace of innovation and technology transfer.

Finally, the interdisciplinary nature of electrode dynamics research requires expertise spanning electrochemistry, materials science, physics, and data science. The shortage of researchers with cross-disciplinary training creates bottlenecks in addressing complex electrode dynamics challenges, particularly as battery systems become increasingly sophisticated and application-specific.

Autonomous Lab Solutions for Electrode Analysis

01 Electrode material innovations for enhanced battery performance

Advanced electrode materials are being developed to improve battery performance characteristics such as energy density, power output, and cycle life. These innovations include novel composite materials, nanostructured electrodes, and specialized coatings that enhance electron transfer and ion diffusion within the electrode structure. These materials are designed to address limitations in conventional battery systems by optimizing the electrochemical reactions at the electrode-electrolyte interface.- Electrode material innovations for enhanced battery performance: Advanced electrode materials are being developed to improve battery performance characteristics such as energy density, power output, and cycle life. These innovations include novel composite structures, nanomaterials, and specialized coatings that optimize electron transfer and ion diffusion within the electrode matrix. By engineering electrode materials at the nano and micro scales, researchers can achieve better electrochemical dynamics and overall battery efficiency.

- Electrode-electrolyte interface optimization: The interface between electrodes and electrolytes plays a crucial role in battery performance and longevity. Research focuses on understanding and controlling the solid-electrolyte interphase (SEI) formation, reducing interfacial resistance, and preventing unwanted side reactions. Advanced techniques for surface modification and protective layers help stabilize this critical interface, leading to improved ion transport dynamics and extended battery lifespan.

- Dynamic modeling and simulation of electrode processes: Computational modeling and simulation techniques are being employed to understand the complex electrochemical processes occurring within battery electrodes. These models capture the dynamics of ion diffusion, electron transfer, and structural changes during charge-discharge cycles. Advanced algorithms and multi-scale modeling approaches enable researchers to predict battery behavior under various operating conditions, optimize electrode designs, and accelerate the development of next-generation battery systems.

- Fast-charging electrode architectures: Novel electrode architectures are being designed specifically to enable fast-charging capabilities while maintaining battery life and safety. These designs focus on optimizing ion transport pathways, reducing diffusion limitations, and managing heat generation during rapid charging. Structured electrodes with controlled porosity, gradient compositions, and specialized conductive networks allow for improved charge transfer dynamics and reduced degradation under high current conditions.

- In-situ monitoring and adaptive control of electrode dynamics: Advanced sensing and control systems are being integrated into battery systems to monitor electrode dynamics in real-time. These technologies enable the detection of degradation mechanisms, state-of-charge estimation, and adaptive management of charging protocols. By continuously monitoring electrochemical parameters and implementing feedback control strategies, these systems can optimize performance, prevent damage, and extend the operational lifetime of battery electrodes under varying usage conditions.

02 Electrode dynamics monitoring and control systems

Advanced monitoring and control systems are being developed to track electrode dynamics in real-time during battery operation. These systems utilize sensors and analytical algorithms to measure parameters such as temperature, current distribution, and electrochemical impedance. By continuously monitoring electrode behavior, these systems can optimize charging protocols, predict failure modes, and extend battery lifespan through adaptive management strategies.Expand Specific Solutions03 Three-dimensional electrode architectures

Three-dimensional electrode designs are being implemented to increase the active surface area available for electrochemical reactions while maintaining efficient electron and ion transport pathways. These architectures include porous structures, interdigitated designs, and hierarchical frameworks that maximize energy and power density. The 3D configurations help overcome limitations of traditional planar electrodes by providing shorter diffusion distances for ions and more efficient utilization of active materials.Expand Specific Solutions04 Interface engineering for improved electrode-electrolyte interactions

Interface engineering focuses on optimizing the critical boundary between electrodes and electrolytes to enhance electrochemical performance. This includes developing specialized coatings, functional interlayers, and surface modifications that stabilize the solid-electrolyte interphase, reduce unwanted side reactions, and improve ion transport across interfaces. These innovations help minimize capacity fade, enhance rate capability, and improve the overall stability of battery systems during cycling.Expand Specific Solutions05 Computational modeling of electrode dynamics

Advanced computational methods are being employed to model and predict electrode behavior under various operating conditions. These include multi-scale simulations that capture phenomena from atomic interactions to macroscopic performance characteristics. By modeling electrochemical reactions, ion transport mechanisms, and degradation processes, researchers can design more efficient electrode structures and optimize battery operation parameters without extensive physical testing.Expand Specific Solutions

Leading Organizations in Battery Automation

The autonomous laboratory landscape for electrode dynamics in advanced battery systems is evolving rapidly, currently in a growth phase with increasing market adoption. The global market is expanding significantly as battery technology becomes critical for electric vehicles and renewable energy storage. Technologically, the field shows varying maturity levels across players. Industry leaders like BYD, LG Energy Solution, and Samsung Electronics have established robust autonomous lab capabilities, while research institutions such as University of Houston and Xi'an Jiaotong University are driving fundamental innovations. Companies like PolyPlus Battery and Sion Power are advancing specialized technologies in lithium electrodes. Automotive manufacturers including BMW, Renault, and Toyota Industries are integrating these advancements into their battery development processes, creating a competitive ecosystem balancing academic research with industrial applications.

BYD Co., Ltd.

Technical Solution: BYD has developed an autonomous laboratory system for electrode dynamics research called "Battery Cloud Lab" that integrates AI-driven experimentation with high-throughput testing capabilities. Their approach combines robotic sample preparation, automated cell assembly, and in-situ characterization tools to rapidly iterate through electrode formulations. The system employs machine learning algorithms to analyze electrode-electrolyte interactions during cycling, with particular focus on their proprietary Blade Battery technology. BYD's autonomous lab can simultaneously test hundreds of electrode variations under different conditions, collecting real-time data on lithium-ion transport, interfacial resistance changes, and degradation mechanisms. This has enabled them to optimize their LFP cathode microstructures for improved fast-charging capabilities while maintaining structural stability.

Strengths: Vertical integration allows direct implementation of research findings into production; extensive dataset from millions of vehicles in operation provides valuable real-world validation. Weaknesses: System primarily optimized for LFP chemistry, potentially limiting applicability to other advanced battery chemistries; relatively closed ecosystem with limited academic collaboration compared to competitors.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has implemented an advanced autonomous laboratory system called "AI Battery Lab" that focuses specifically on electrode dynamics optimization. Their approach integrates high-precision robotics for electrode preparation with AI-driven experimental design to accelerate battery development cycles. The system features multi-scale characterization capabilities that simultaneously monitor electrode behavior at nano, micro and macro levels during operation. A key innovation is their "Digital Twin" technology that creates virtual models of electrode structures to predict long-term performance based on short-term test data. The autonomous lab employs over 200 parallel testing channels with in-situ differential electrochemical mass spectrometry to detect gas evolution during cycling, allowing real-time identification of unwanted side reactions at electrode surfaces. This has enabled LG to develop new nickel-rich cathode formulations with significantly improved cycle life and reduced cobalt content.

Strengths: Sophisticated AI algorithms that continuously improve through accumulated test data; seamless integration with manufacturing processes allows rapid commercialization of research findings. Weaknesses: High capital investment requirements; system complexity requires specialized expertise for maintenance and operation; primarily focused on high-energy density applications rather than broader battery technologies.

Key Innovations in Electrode Dynamics Monitoring

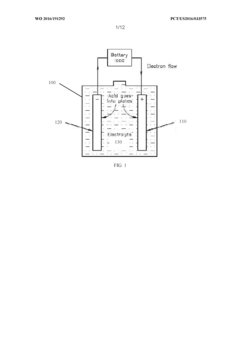

Lead-acid batteries with fast charge acceptance

PatentWO2016191292A2

Innovation

- The development of lead-organic batteries that incorporate organic materials with cyclic substructures and carbonyl groups as electrodes, reducing lead usage by 50% and enhancing charge acceptance through reversible electrochemical reactions, allowing for higher charge rates and improved capacity retention.

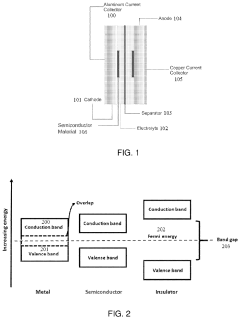

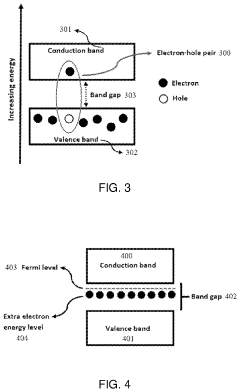

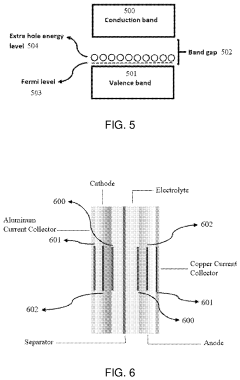

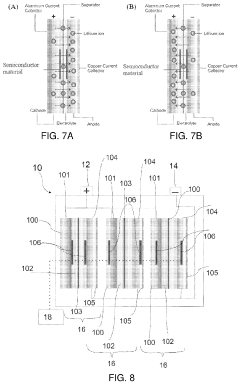

Semiconductor Based Material for Battery Health and Performance Assessment and Monitoring in the Sub-Cell Level

PatentPendingUS20230216156A1

Innovation

- The integration of semiconductor materials, such as silicon-based, gallium-based, and germanium-based semiconductors, directly onto or between the electrodes of lithium-ion batteries for precise monitoring of State-of-Health (SOH) and State-of-Charge (SOC) through methods like electrochemical deposition, 3D printing, or chemical vapor deposition, allowing for real-time monitoring of ion changes during charge and discharge cycles.

Environmental Impact of Advanced Battery Technologies

The environmental implications of advanced battery technologies extend far beyond their operational efficiency, encompassing their entire lifecycle from raw material extraction to disposal. As battery technologies evolve to meet growing energy storage demands, their environmental footprint becomes increasingly significant. Advanced battery systems, particularly those utilizing autonomous laboratory techniques for electrode dynamics optimization, present both challenges and opportunities for environmental sustainability.

The extraction of critical materials for advanced batteries, including lithium, cobalt, nickel, and rare earth elements, has substantial environmental consequences. Mining operations often result in habitat destruction, soil erosion, and water contamination. Autonomous laboratory approaches can mitigate these impacts by identifying alternative material compositions that reduce dependence on environmentally problematic elements while maintaining or enhancing performance characteristics.

Manufacturing processes for advanced batteries typically consume significant energy and water resources while generating hazardous waste streams. The integration of autonomous laboratory systems enables more precise control over electrode formation and chemistry, potentially reducing resource consumption and waste generation through optimized production parameters. These systems can rapidly iterate through thousands of potential formulations to identify those with minimal environmental impact.

During operational lifespans, advanced batteries developed through autonomous laboratory techniques demonstrate improved efficiency and longevity. Enhanced electrode dynamics result in reduced energy losses during charge-discharge cycles, decreasing the overall carbon footprint associated with battery operation. Furthermore, extended cycle life reduces replacement frequency, thereby lowering cumulative environmental impacts from manufacturing and disposal.

End-of-life management represents a critical environmental challenge for battery technologies. Current recycling processes often recover only a fraction of valuable materials while consuming substantial energy and potentially releasing toxins. Autonomous laboratory approaches are pioneering electrode designs specifically optimized for recyclability, incorporating phase-change materials and self-disassembly mechanisms that facilitate more efficient material recovery.

Carbon emissions associated with advanced battery technologies vary significantly across their lifecycle. While manufacturing processes contribute substantially to emissions profiles, the net environmental impact depends largely on the energy sources powering both production facilities and the electrical grid where batteries operate. Autonomous laboratory innovations in electrode dynamics can reduce embedded carbon through more efficient manufacturing and extended operational lifespans.

Water resource impacts from advanced battery technologies include both consumption during manufacturing and potential contamination from improper disposal. Autonomous laboratory techniques are enabling the development of water-based electrode processing methods that significantly reduce solvent use and associated environmental hazards, representing a promising direction for sustainable battery production.

The extraction of critical materials for advanced batteries, including lithium, cobalt, nickel, and rare earth elements, has substantial environmental consequences. Mining operations often result in habitat destruction, soil erosion, and water contamination. Autonomous laboratory approaches can mitigate these impacts by identifying alternative material compositions that reduce dependence on environmentally problematic elements while maintaining or enhancing performance characteristics.

Manufacturing processes for advanced batteries typically consume significant energy and water resources while generating hazardous waste streams. The integration of autonomous laboratory systems enables more precise control over electrode formation and chemistry, potentially reducing resource consumption and waste generation through optimized production parameters. These systems can rapidly iterate through thousands of potential formulations to identify those with minimal environmental impact.

During operational lifespans, advanced batteries developed through autonomous laboratory techniques demonstrate improved efficiency and longevity. Enhanced electrode dynamics result in reduced energy losses during charge-discharge cycles, decreasing the overall carbon footprint associated with battery operation. Furthermore, extended cycle life reduces replacement frequency, thereby lowering cumulative environmental impacts from manufacturing and disposal.

End-of-life management represents a critical environmental challenge for battery technologies. Current recycling processes often recover only a fraction of valuable materials while consuming substantial energy and potentially releasing toxins. Autonomous laboratory approaches are pioneering electrode designs specifically optimized for recyclability, incorporating phase-change materials and self-disassembly mechanisms that facilitate more efficient material recovery.

Carbon emissions associated with advanced battery technologies vary significantly across their lifecycle. While manufacturing processes contribute substantially to emissions profiles, the net environmental impact depends largely on the energy sources powering both production facilities and the electrical grid where batteries operate. Autonomous laboratory innovations in electrode dynamics can reduce embedded carbon through more efficient manufacturing and extended operational lifespans.

Water resource impacts from advanced battery technologies include both consumption during manufacturing and potential contamination from improper disposal. Autonomous laboratory techniques are enabling the development of water-based electrode processing methods that significantly reduce solvent use and associated environmental hazards, representing a promising direction for sustainable battery production.

Data Management in Autonomous Battery Testing

The autonomous laboratory revolution has fundamentally transformed data management practices in battery testing environments. Traditional battery testing generated limited datasets that could be manually processed and analyzed. However, autonomous battery testing systems now produce massive volumes of high-dimensional data across multiple parameters simultaneously, creating unprecedented data management challenges. These systems continuously monitor voltage, current, temperature, pressure, and impedance measurements across thousands of test cells, generating terabytes of data that require sophisticated storage architectures.

Cloud-based data management solutions have emerged as the primary infrastructure for autonomous battery testing facilities. These platforms implement distributed storage systems with redundancy protocols to ensure data integrity while maintaining accessibility for real-time analysis. Leading battery manufacturers have developed proprietary data lakes specifically designed to handle the unique characteristics of battery testing data, including specialized metadata tagging systems that facilitate rapid retrieval of experimental conditions and results.

Machine learning algorithms now play a critical role in autonomous battery testing data pipelines. These systems automatically identify anomalous data points, correct for sensor drift, and normalize measurements across different testing equipment. Advanced feature extraction techniques identify subtle patterns in electrode behavior that human analysts might overlook, particularly in long-duration cycling tests where degradation mechanisms evolve gradually over thousands of cycles.

Data visualization tools have evolved to address the complexity of battery testing data. Interactive dashboards now enable researchers to simultaneously visualize multiple dimensions of battery performance, with particular emphasis on electrode-electrolyte interface dynamics. These visualization systems incorporate statistical analysis tools that automatically highlight significant correlations between testing parameters and performance outcomes, dramatically accelerating the hypothesis generation process.

Standardization efforts within the industry have produced several competing data exchange formats specifically for battery testing. The Battery Data Markup Language (BDML) and Electrochemical Data Interface (EDI) protocols have gained significant adoption, though fragmentation remains a challenge. These standards incorporate detailed metadata schemas that capture experimental conditions, cell construction details, and material specifications, enabling more effective knowledge sharing across research institutions.

Security considerations have become increasingly important as autonomous battery testing generates potentially valuable intellectual property. Encryption protocols for data in transit and at rest are now standard practice, with sophisticated access control systems that maintain detailed audit trails of data access and modification. These security measures must balance protection of proprietary information with the collaborative requirements of research teams often distributed across multiple global locations.

Cloud-based data management solutions have emerged as the primary infrastructure for autonomous battery testing facilities. These platforms implement distributed storage systems with redundancy protocols to ensure data integrity while maintaining accessibility for real-time analysis. Leading battery manufacturers have developed proprietary data lakes specifically designed to handle the unique characteristics of battery testing data, including specialized metadata tagging systems that facilitate rapid retrieval of experimental conditions and results.

Machine learning algorithms now play a critical role in autonomous battery testing data pipelines. These systems automatically identify anomalous data points, correct for sensor drift, and normalize measurements across different testing equipment. Advanced feature extraction techniques identify subtle patterns in electrode behavior that human analysts might overlook, particularly in long-duration cycling tests where degradation mechanisms evolve gradually over thousands of cycles.

Data visualization tools have evolved to address the complexity of battery testing data. Interactive dashboards now enable researchers to simultaneously visualize multiple dimensions of battery performance, with particular emphasis on electrode-electrolyte interface dynamics. These visualization systems incorporate statistical analysis tools that automatically highlight significant correlations between testing parameters and performance outcomes, dramatically accelerating the hypothesis generation process.

Standardization efforts within the industry have produced several competing data exchange formats specifically for battery testing. The Battery Data Markup Language (BDML) and Electrochemical Data Interface (EDI) protocols have gained significant adoption, though fragmentation remains a challenge. These standards incorporate detailed metadata schemas that capture experimental conditions, cell construction details, and material specifications, enabling more effective knowledge sharing across research institutions.

Security considerations have become increasingly important as autonomous battery testing generates potentially valuable intellectual property. Encryption protocols for data in transit and at rest are now standard practice, with sophisticated access control systems that maintain detailed audit trails of data access and modification. These security measures must balance protection of proprietary information with the collaborative requirements of research teams often distributed across multiple global locations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!